Semi-solidified grinding disk for semiconductor substrate grinding, and preparation method and application thereof

A technology of grinding discs and semiconductors, which is applied in the direction of grinding tools, grinding/polishing equipment, grinding devices, etc., can solve the problems of difficulty in ensuring the surface shape accuracy of substrates, deformation of grinding discs, etc., and achieve improved surface shape accuracy, rigidity, The effect of good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

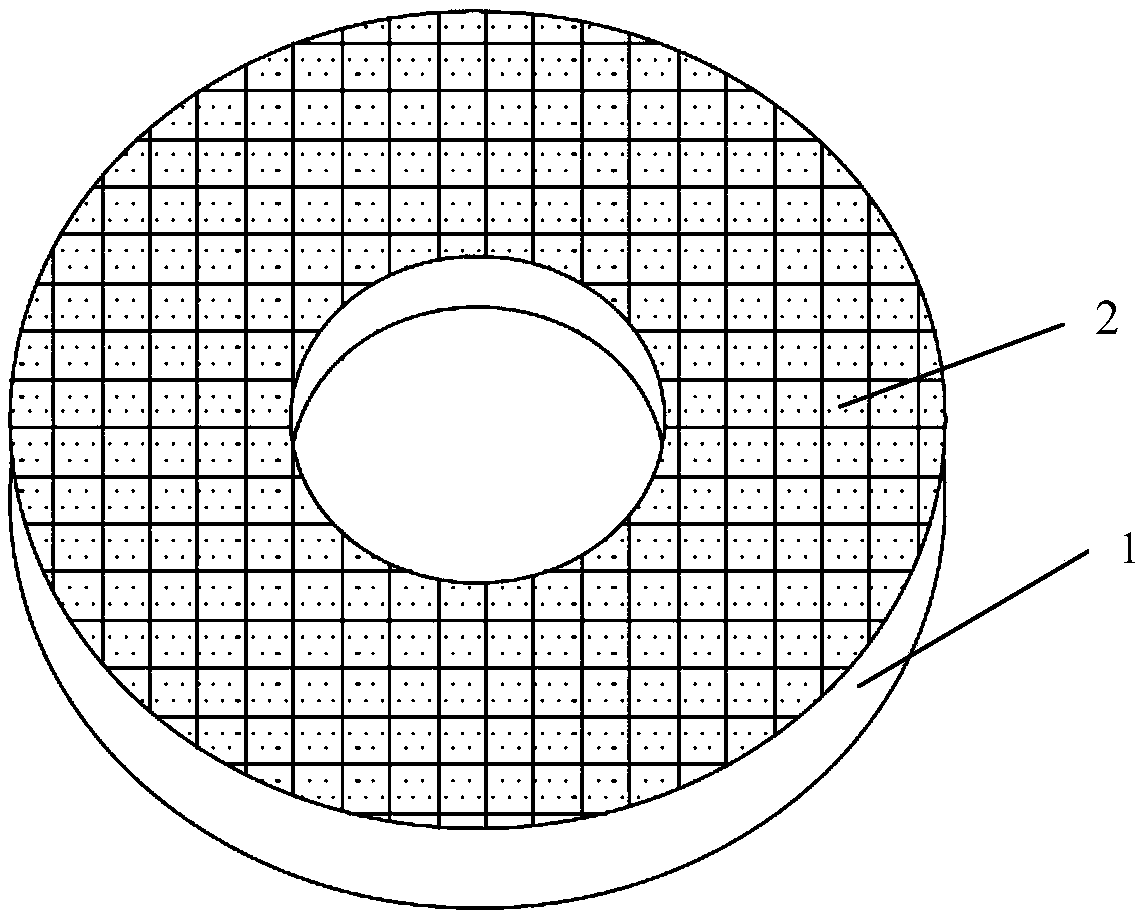

[0040] Please check figure 1 , which is a semi-consolidated grinding disc for semiconductor substrate grinding in this embodiment, including a base disc 1 and a number of grinding discs 2 evenly arranged on the base disc;

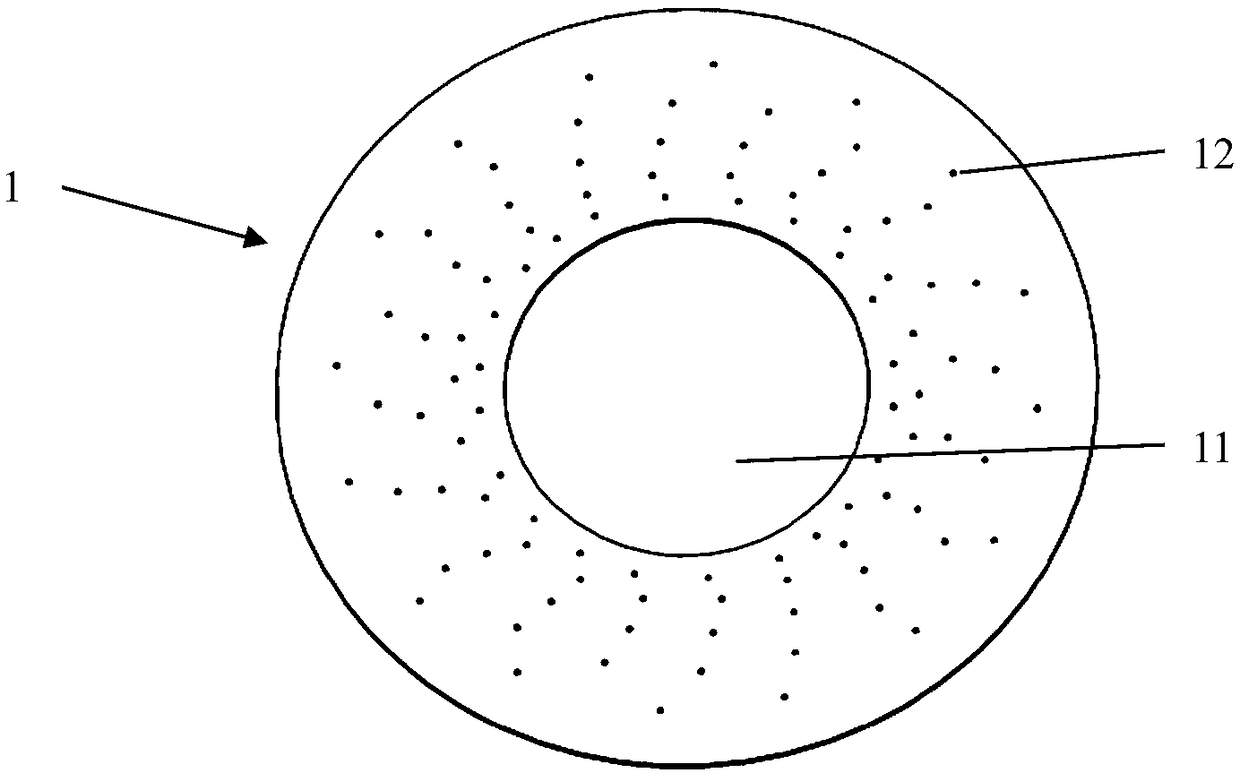

[0041] Please refer to figure 2 , the base plate 1 is circular, with a circular mounting hole 11 in the center, which is convenient to connect with the processing machine tool; the base plate 1 is also provided with a number of uniformly distributed grinding fluid holes 12 with a diameter of about 8mm, which are used to introduce grinding liquid. A plurality of grinding discs 2 are regularly arranged on the surface of the base plate 1 in a lattice shape, and the upper surfaces of the grinding discs 2 jointly form a grinding working surface, and there is a gap with a width of 2 mm between adjacent grinding discs 2 to form a flow channel 23, such as Figure 4 shown.

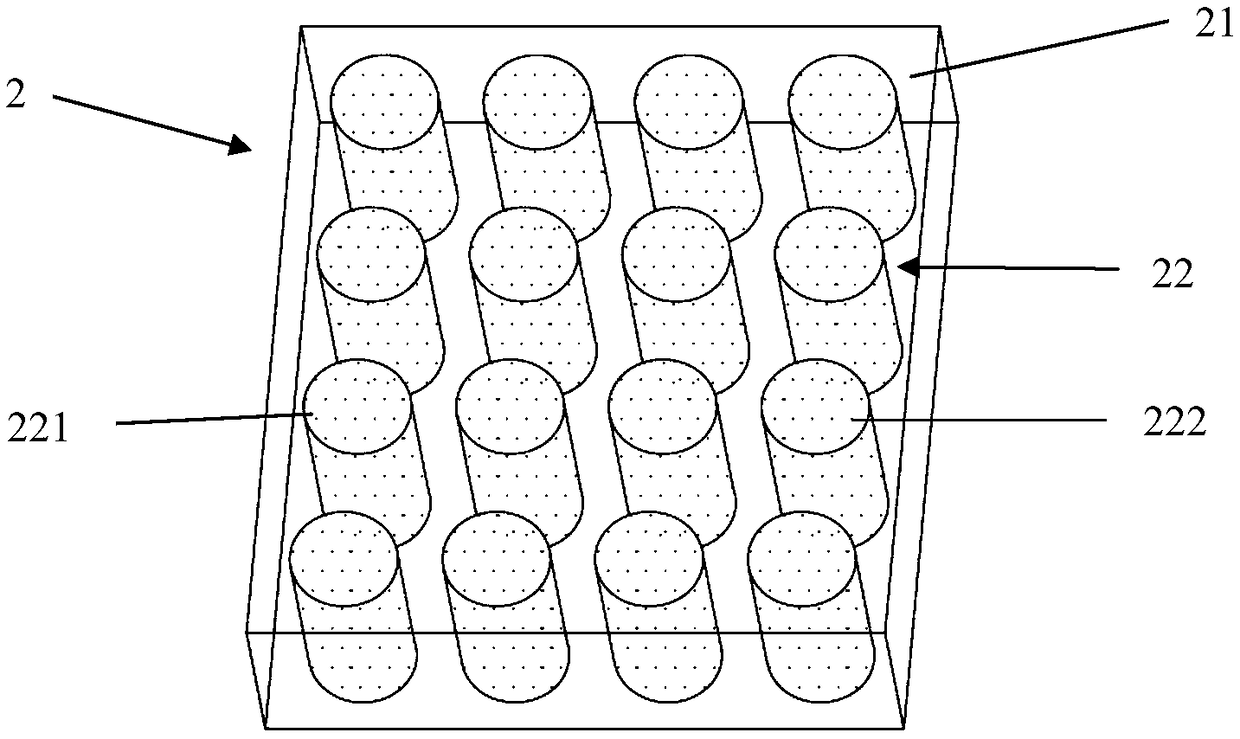

[0042] Please refer to image 3 , the grinding plate 2 is in the shape of a square sheet...

Embodiment 2

[0058] The semi-consolidated grinding disc used for grinding semiconductor substrates in this embodiment includes a base disc and several grinding discs evenly arranged on the base disc;

[0059] The base plate is circular, with a circular mounting hole in the center, which is convenient for connection with the processing machine tool; there are also a number of grinding liquid holes with a diameter of about 8mm on the base plate, which are used to introduce the grinding liquid. A number of grinding discs are regularly arranged on the surface of the base plate in a grid pattern, and the upper surfaces of the grinding discs jointly form a grinding working surface, and there is a gap with a width of 2 mm between adjacent grinding discs to form a flow channel.

[0060] The grinding disc is in the shape of a square sheet, including a skeleton and a semi-consolidated grinding medium containing abrasive grains; the skeleton is made of a hard epoxy resin material, and a number of circ...

Embodiment 3

[0068] The semi-consolidated grinding disc used for grinding semiconductor substrates in this embodiment includes a base disc and several grinding discs evenly arranged on the base disc;

[0069] The base plate is circular, with a circular mounting hole in the center, which is convenient for connection with the processing machine tool; there are also a number of grinding liquid holes with a diameter of about 8mm on the base plate, which are used to introduce the grinding liquid. A number of grinding discs are regularly arranged on the surface of the base plate in a grid pattern, and the upper surfaces of the grinding discs jointly form a grinding working surface, and there is a gap with a width of 2 mm between adjacent grinding discs to form a flow channel.

[0070] The grinding disc is in the shape of a square sheet, including a skeleton and a semi-consolidated grinding medium containing abrasive grains; the skeleton is made of a hard epoxy resin material, and a number of circ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com