Kitchen waste treatment device and method with improved dry-type anaerobic fermentation effect

A dry-type anaerobic fermentation and kitchen waste technology, applied in the direction of biomass post-treatment, biomass pre-treatment, biochemical cleaning equipment, etc., can solve the problems of high labor costs, irregular design, waste of materials, etc., and achieve good results Magnetic conductivity and heat transfer performance, convenient recycling and reuse, and the effect of a good fermentation environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solutions and beneficial effects of the present invention will be described in detail below in conjunction with the accompanying drawings.

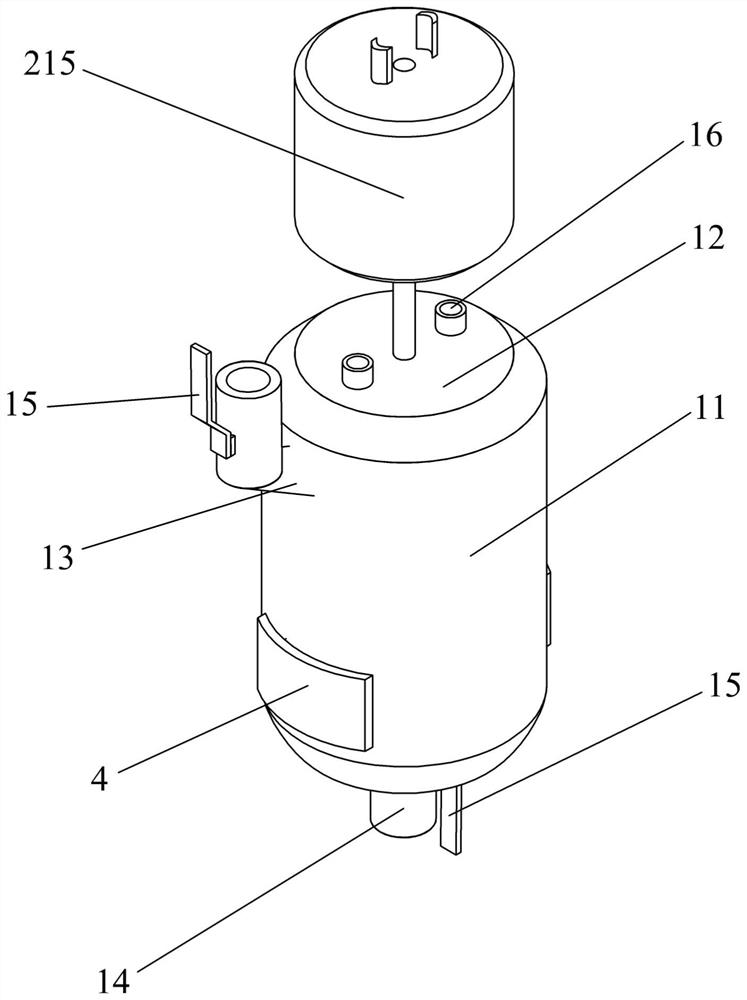

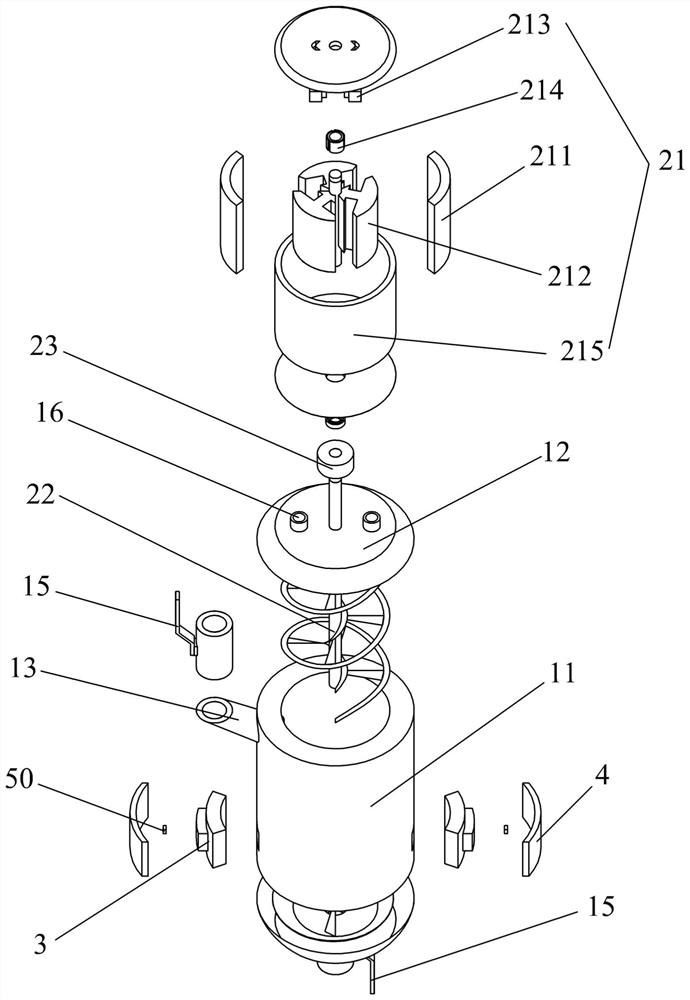

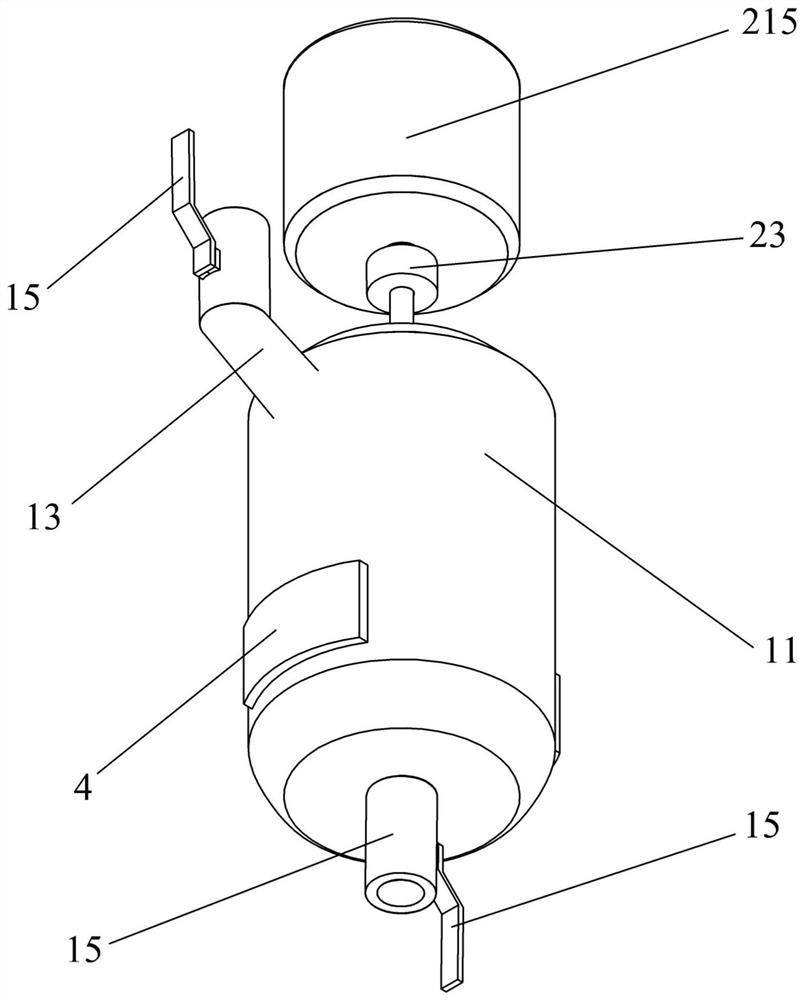

[0038] Such as Figure 1 to Figure 5 As shown, the present invention provides a food waste treatment device for improving the effect of dry anaerobic fermentation, including a fermenter, a stirring component, a sensing component, a control component, a heating component and an adsorption component, which will be introduced separately below.

[0039]The fermenter includes a tank body 11 and a tank cover 12 fastened on the top of the tank body 11. There is an accommodating space in the tank body 11, and the tank body 11 and the tank cover 12 are locked together to provide a fermentation space for accommodating the Treated kitchen waste, and iron ferric oxide (iron powder) used for mixing during the stirring process; a feed inlet 13 is opened on the upper side of the tank body 11, and a feed port 13 is opened at the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com