Device for quickly lifting and clearing crucible of vacuum furnace

A technology for cleaning devices and vacuum furnaces, which is applied to crucible furnaces, descaling devices, furnaces, etc., can solve the problems of low efficiency of crucibles, and achieve the effects of fast cleaning speed, economical and environmentally friendly use, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in further detail below in conjunction with the examples, but the present invention is not limited only to the following examples.

[0019] After the alloy smelting is completed, the crucible can be accurately and quickly lifted by a hoist and put into the crucible cleaning device. The residual heat of the crucible can be used to quickly clean up the alloy adhered to the crucible wall, and the dust removal device can be used to purify the waste gas generated during the crucible cleaning process. , high efficiency, fast removal speed, energy saving, economical and environmental protection.

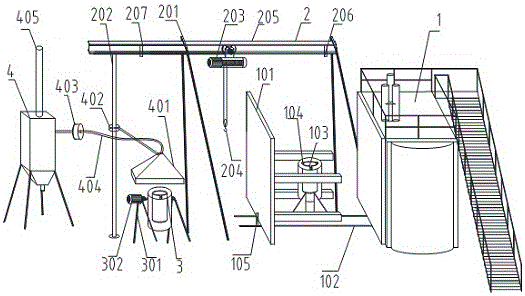

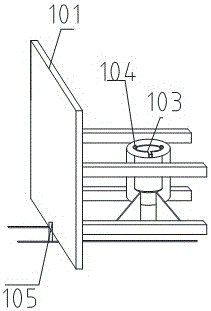

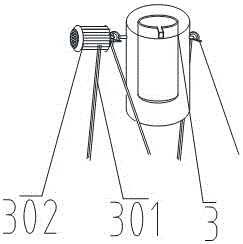

[0020] Such as figure 1 , figure 2 As shown, a vacuum furnace crucible fast hoisting and cleaning device includes a furnace body 1, which also includes a furnace door 101, a crucible 103 on the right side of the furnace door is connected with the furnace door, and the crucible can be placed on the furnace door along with the furnace door. Move ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com