Cracking ignition device for pulverized coal fired boiler

An ignition device, pulverized coal boiler technology, applied in the direction of combustion ignition, incandescent ignition, combustion method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

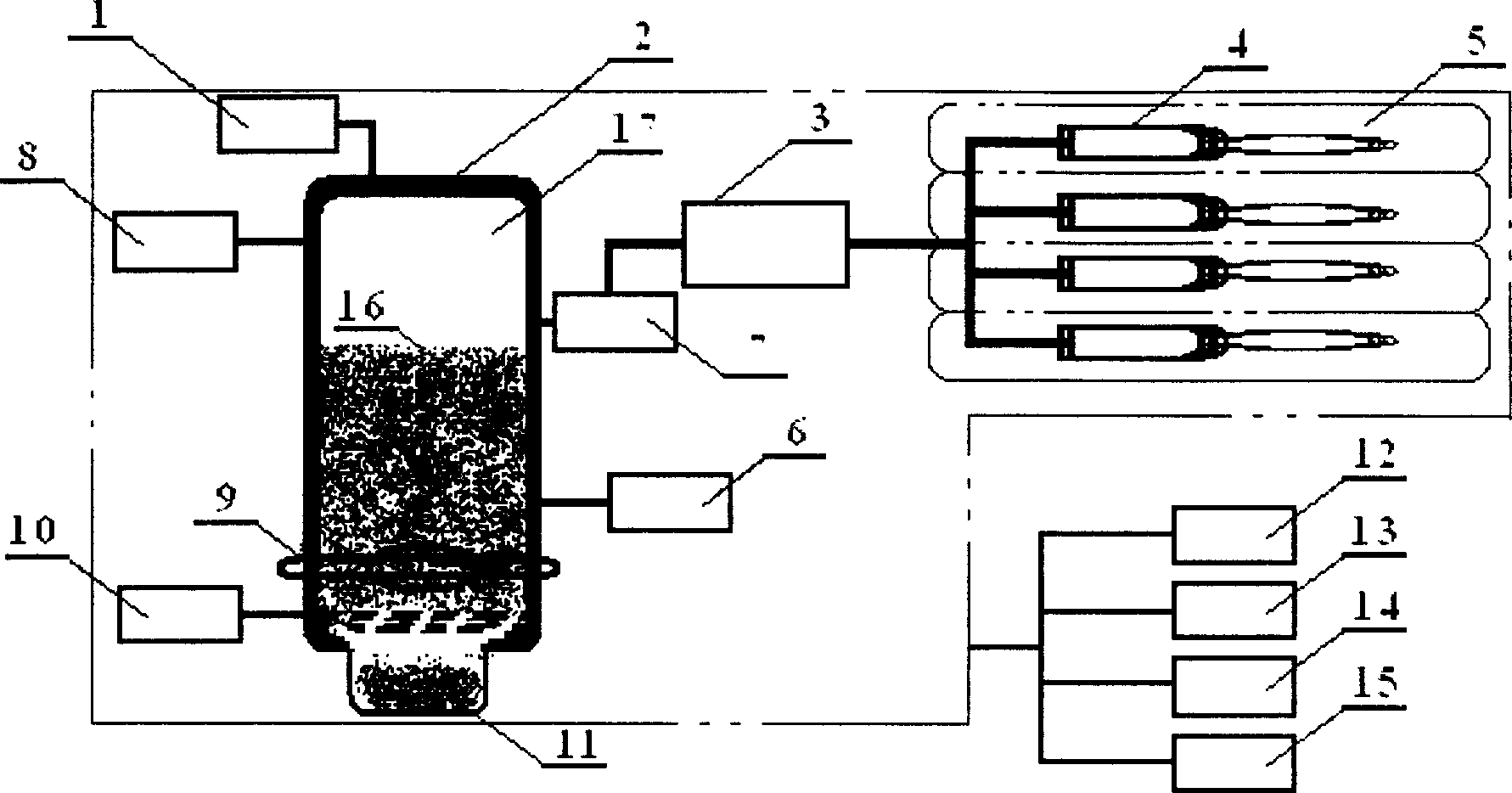

[0011] Referring to accompanying drawing 1, a kind of cracking ignition device that is used for pulverized coal boiler comprises a cracking furnace 2, and cracking furnace 2 upper ends are provided with safety valve 1 and feeding system 8, and feeding system 8 can adopt screw conveyor, conveyer belt or Chain bucket conveyor. A slagging system 11 is provided at the bottom of the cracking furnace 2, a heating device 9 is provided near the bottom of the furnace cavity, and a cracking medium supply system 10 is installed below the heating device 9. The heating device 9 can use the plasma generator as a heat source in an oxygen-free environment, and use plasma heating to promote coal cracking; it can also use local combustion heating or electric heating of part of the coal, and use the combustion of part of the coal in the furnace to cause local high temperature to promote coal cracking. The cracking method, adopting this method needs to carry out the cracking medium in the crackin...

Embodiment 2

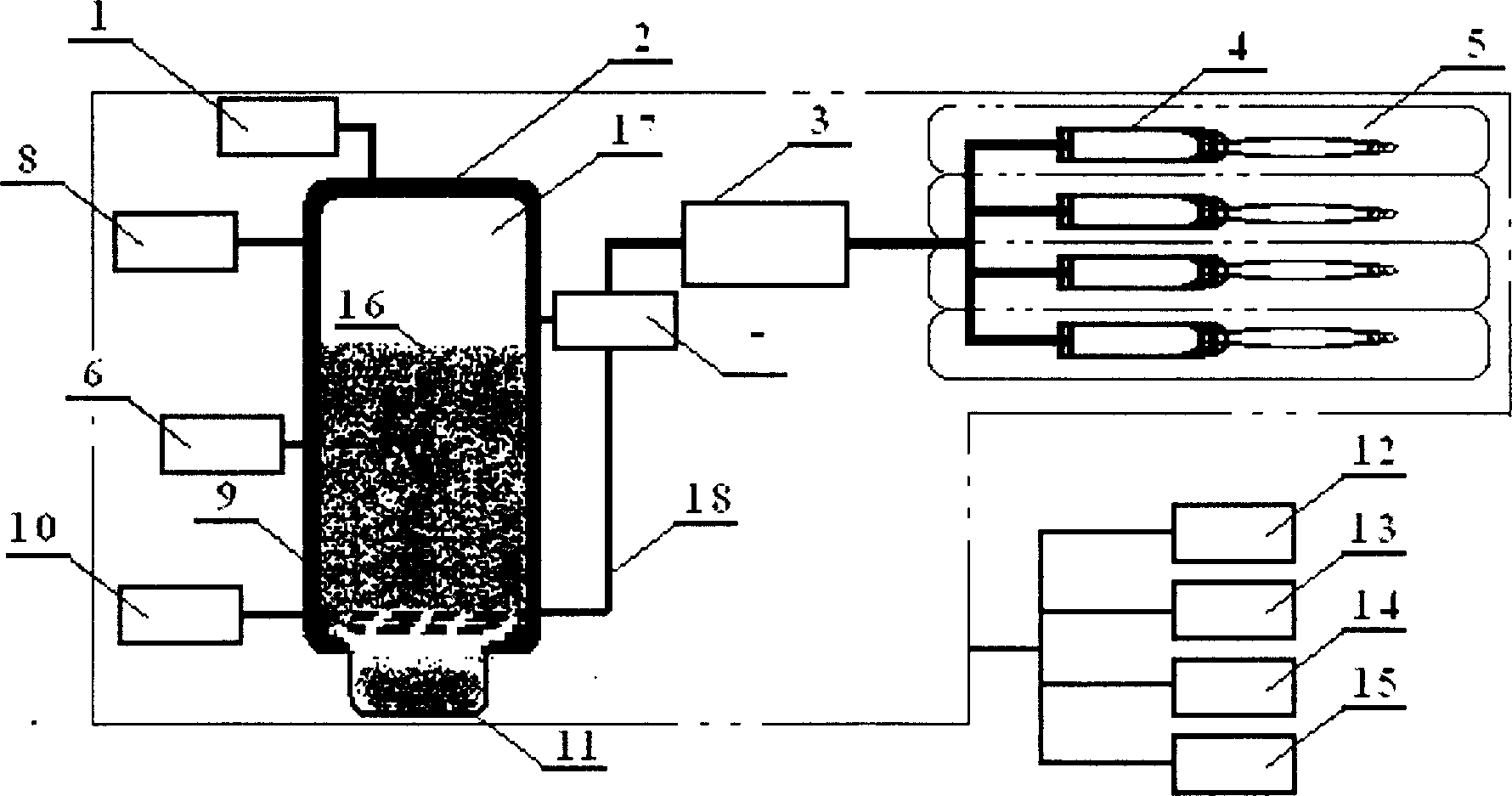

[0014] Referring to accompanying drawing 2, a kind of pyrolysis ignition device that is used for pulverized coal boiler, this ignition device is not provided with heating device 9, but installs combustible gas feedback heating system 18 on the gas output pipe, the other end of combustible gas feedback heating system 18 It communicates with the bottom of the cracking furnace 2, and uses the combustible gas fed back to heat the coal 16 in the furnace to crack in an oxygen-free or low-oxygen environment. The rest are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com