Multi-purpose slightly-ground oat kernels and production method thereof

A kind of oat kernel, multi-purpose technology, applied in the direction of application, grain milling, food extrusion, etc., can solve the problems of short shelf life, short processing time, long cooking time, etc., achieve passivation of lipase activity, and low equipment investment cost , Improve the effect of food safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

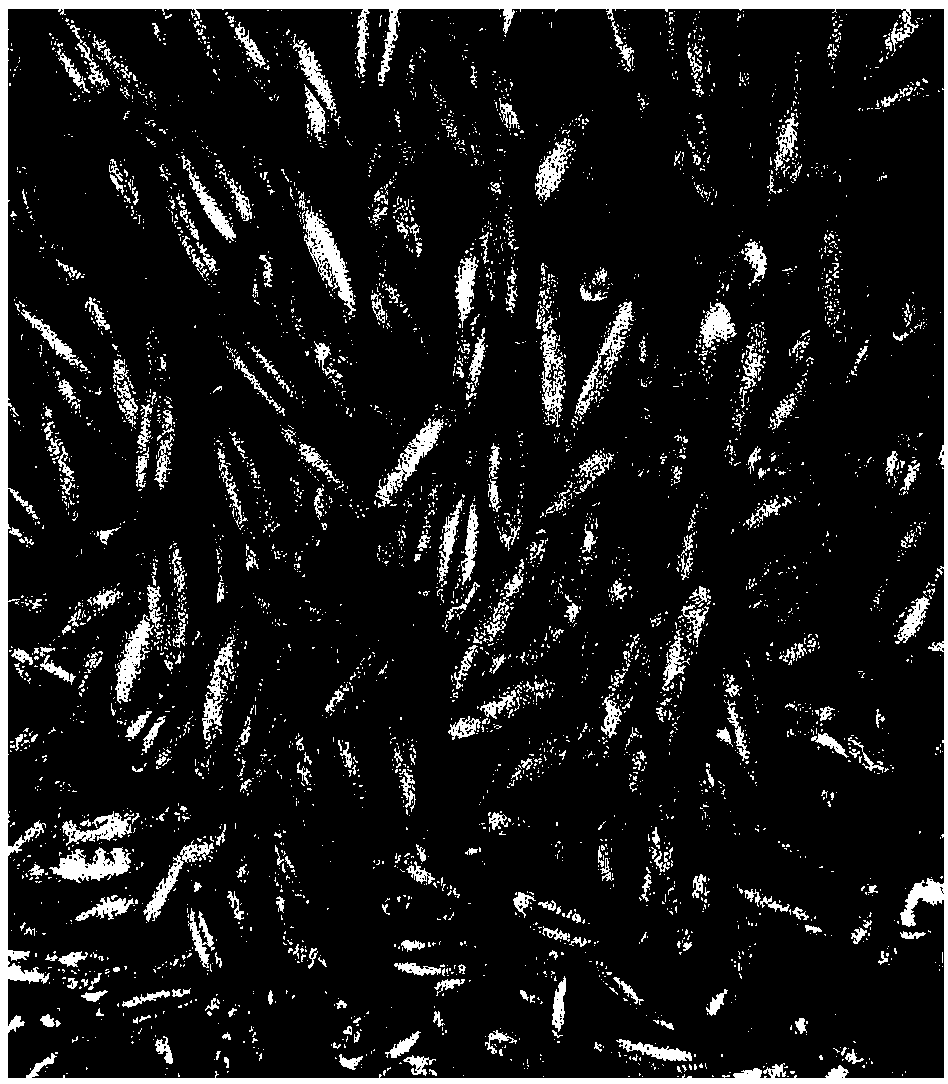

Image

Examples

Embodiment 1

[0048] Embodiment 1, the preparation of multi-purpose micro-rolled oatmeal

[0049] The specific operation steps of multi-purpose micro-rolled oat kernels are as follows:

[0050] (1) Cleaning: remove wheat straw and other light impurities and remove stones, use the difference in particle size between grain and impurities, remove straw and other light impurities through a vertical suction separator, and use the difference in gravity between grain and stones to remove small stones;

[0051] (2) Wheat cleaning: Use surface cleaning equipment such as wheat threshing machine and wheat cleaning machine to strike, rub and clean the surface of oats, remove the fluff of oats, clean the abdominal groove of oats, and make the raw grain cleaner;

[0052] (3) Polishing: use a polishing machine to roughly polish the oats to remove the dirt and dust on the surface of the oats, so that the surface of the oats is clean and smooth, and the quality of the oatmeal is improved;

[0053] (4) Colo...

Embodiment 2

[0064] Embodiment 2, the preparation of multi-purpose micro-rolled oatmeal

[0065] The specific operation steps of multi-purpose micro-rolled oat kernels are as follows:

[0066] (1) Cleaning: air sieve machines, stone removers, gravity screen machines, etc. remove straw, stones, soil clods and other sundries in the raw grain;

[0067] (2) Wheat cleaning: Use surface cleaning equipment such as wheat threshing machine and wheat cleaning machine to strike, rub and clean the surface of oats, remove the fluff of oats, clean the abdominal groove of oats, and make the raw grain cleaner;

[0068] (3) Polishing: use a polishing machine to roughly polish the oats to remove the dirt and dust on the surface of the oats, so that the surface of the oats is clean and smooth, and the quality of the oatmeal is improved;

[0069] (4) Color sorting: Use the photoelectric color sorter to sort out incomplete grains, mildewed grains, and heterogeneous grains from oat raw materials according to c...

Embodiment 3

[0081] Embodiment 3, the preparation of multi-purpose micro-rolled oatmeal

[0082] The specific operation steps of multi-purpose micro-rolled oat kernels are as follows:

[0083] (1) Cleaning: air sieve machines, stone removers, gravity screen machines, etc. remove straw, stones, soil clods and other sundries in the raw grain;

[0084] (2) Wheat cleaning: use surface cleaning equipment such as wheat threshing machine and wheat cleaning machine to strike, rub and clean the surface of oats, remove the fluff of oats, clean the abdominal groove of oats, and make the raw grain cleaner;

[0085] (3) Polishing: use a polishing machine to roughly polish the oats to remove the dirt and dust on the surface of the oats, so that the surface of the oats is clean and smooth, and the quality of the oatmeal is improved;

[0086] (4) Color sorting: use the photoelectric color sorter to sort out incomplete grains, mildewed grains, and heterogeneous grains from oat raw materials according to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com