Washing machine

A washing machine and clothing technology, which is applied to other washing machines, control devices of washing machines, washing devices, etc., can solve the problems of limited spraying direction, clothing cannot be evenly wetted, fluid cannot be sprayed evenly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 approach

[0806] Figure 63 is a view for explaining a control method of a washing machine according to another embodiment of the present invention.

[0807] refer to Figure 63 The controller may control the washing motor such that the laundry in the drum 32 rises by a first angle along the rotation direction of the drum 32 while being in contact with the side surface portion 321 of the drum 32 .

[0808] The first angle may be an angle less than 90 degrees. The controller may perform a rolling action to rotate the drum 32 in one direction so that the laundry on the side surface portion 321 of the drum 32 falls from a position corresponding to a position where the rotation angle of the drum 32 is less than about 90 degrees.

[0809] Alternatively, the first angle may be an angle between 90 degrees and 130 degrees. The controller may perform a tumbling action to rotate the drum 32 in one direction so that the laundry on the side surface portion 321 of the drum 32 falls from a positio...

no. 3 approach

[0853] Figure 64 is a view for explaining a control method of a washing machine according to another embodiment of the present invention.

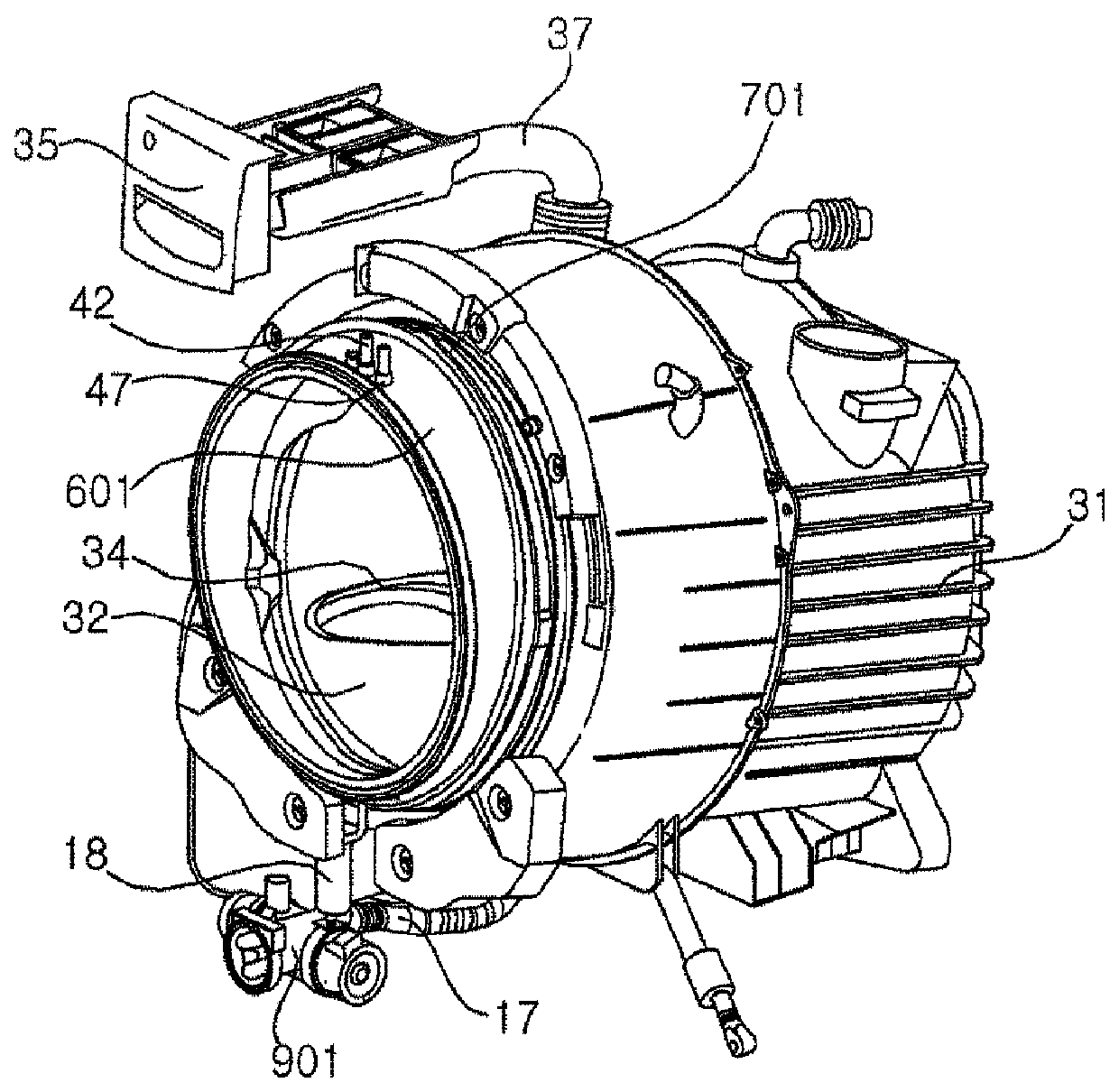

[0854] According to the third embodiment, the nozzles may include a pair of middle nozzles 610b and 610e and a pair of lower nozzles 610c and 610d. The nozzles may include a pair of middle nozzles 610b and 610e, a pair of lower nozzles 610c and 610d, and an upper nozzle 610a.

[0855] The upper nozzle 610a may be a nozzle for supplying circulating water or a direct water nozzle for supplying water not mixed with detergent introduced through the water supply valve. Alternatively, the upper nozzle 610a may be a nozzle for supplying water mixed with the fabric softener while passing through the detergent container containing the fabric softener.

[0856] Hereinafter, nozzles will be described based on the case of an upper nozzle 610a, a pair of middle nozzles 610b and 610e, and a pair of lower nozzles 610c and 610d.

[0857] refer to Fi...

no. 4 approach

[0941] Figure 66 is a flowchart illustrating a method of controlling a washing machine according to another embodiment of the present invention. Figure 67 is showing Figure 66 A flowchart of an embodiment of the water supply step S10 is shown. Figure 68 A main part of a washing machine according to another embodiment of the present invention is schematically shown, and more specifically, an example of a flow caused in the detergent dissolving step S20 is shown. Figure 69 A main part of a washing machine according to another embodiment of the present invention is schematically shown, and more specifically, an example of a flow induced in the washing step S30 is shown. Figure 70 A main part of a washing machine according to another embodiment of the present invention is schematically shown, and more specifically, an example of a flow caused in the detergent dissolving step S20 is shown. Figure 71 Shown is a speed change (a) of an inner tank in a method of controlling a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com