Fuel supply part structure of vehicle

A supply part and fuel technology, applied to the arrangement combined with the internal combustion engine fuel supply, vehicle components, power devices, etc., can solve the problems of increasing the cost of clips, rust, and long tethers, etc., to improve operability and reduce Cost, the effect of avoiding rust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Embodiments of the present invention will now be described with reference to the accompanying drawings.

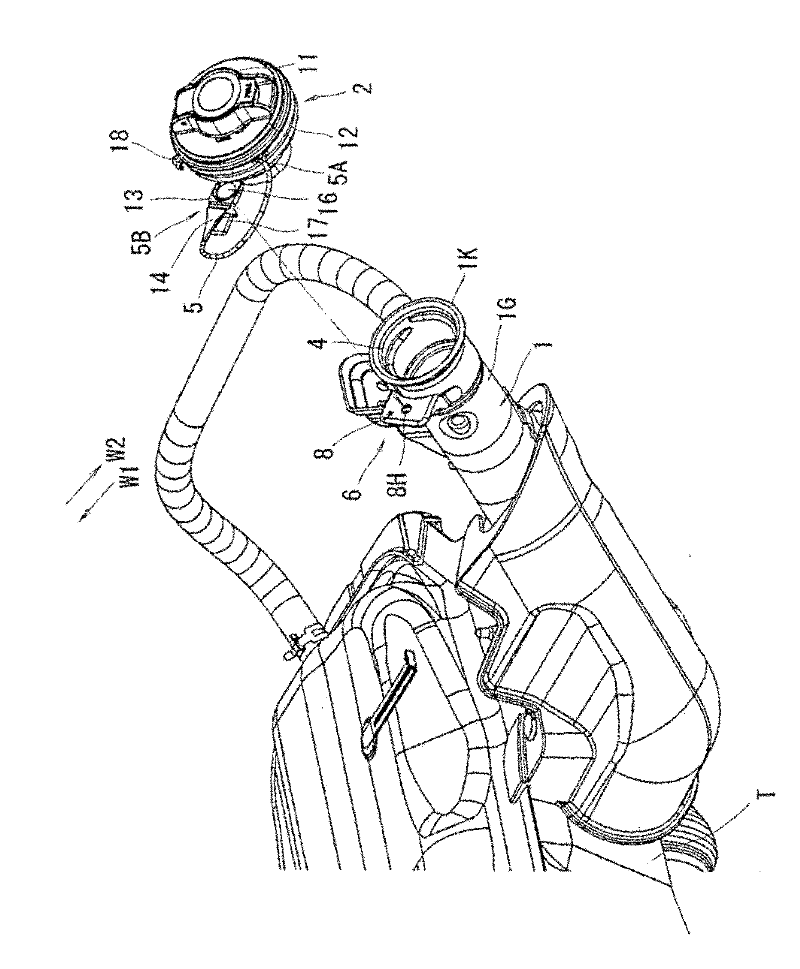

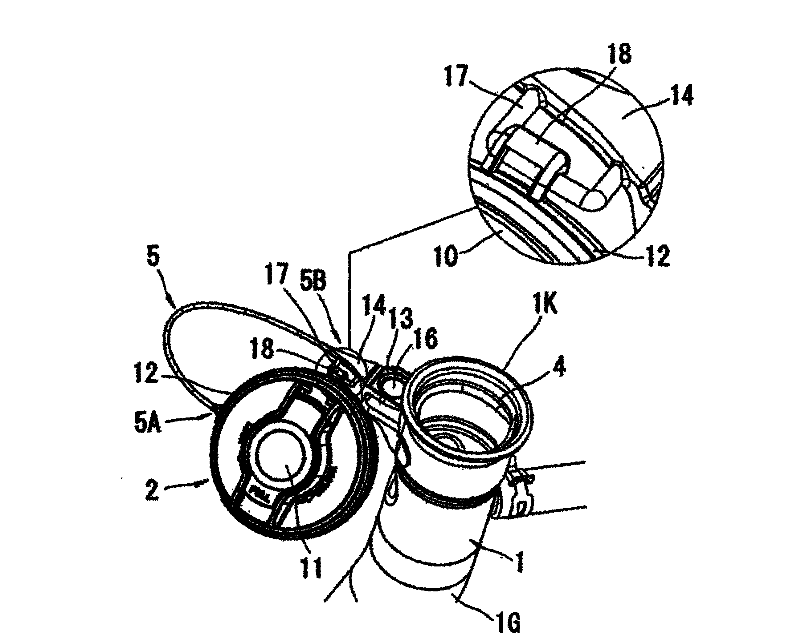

[0041] figure 1 A fuel supply portion structure of a truck-type motor vehicle (corresponding to a vehicle) provided with a fuel filler neck 1 and a resin-made fuel filler cap 2 is shown. The fuel filler neck 1 is connected to the fuel tank T, and is attached to the vehicle body in a state where a portion near the filler hole 1K is exposed. A fuel filler cap 2 is mounted to a filler hole 1K of a fuel filler neck 1 .

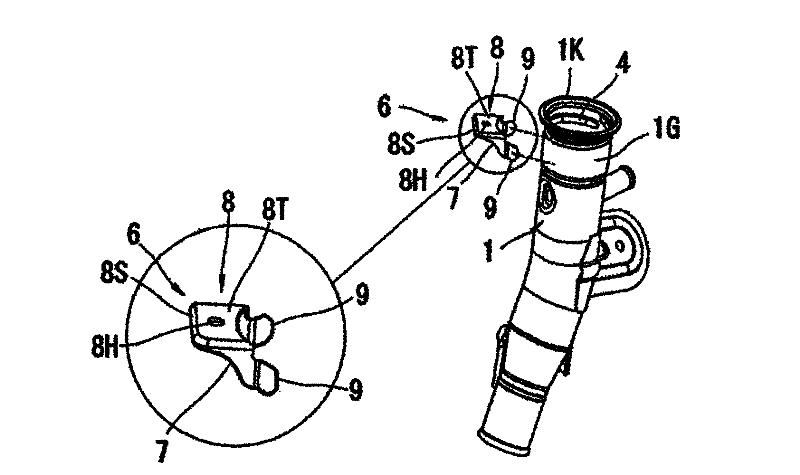

[0042] The fuel filler neck 1 extends obliquely upward laterally from the fuel tank T side, and the filler hole 1K of the fuel filler neck 1 is inclined in a state of being located on the upper side as it goes toward the inner side W1 in the vehicle width direction. The hole end of the fuel filler neck 1 is formed with an internal threaded portion 4, which is threadedly engaged with the external threaded portion 3 of the fuel filler cap 2 (refer to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com