A fully automatic dismantling device and method for waste power batteries

A power battery, fully automatic technology, used in battery recycling, solid waste removal, waste collector recycling, etc., can solve the problems of non-continuous production process, contact with battery waste liquid, and explosion of used batteries, and improve equipment handling. Efficiency, reduced cutting losses and, the effect of reducing equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

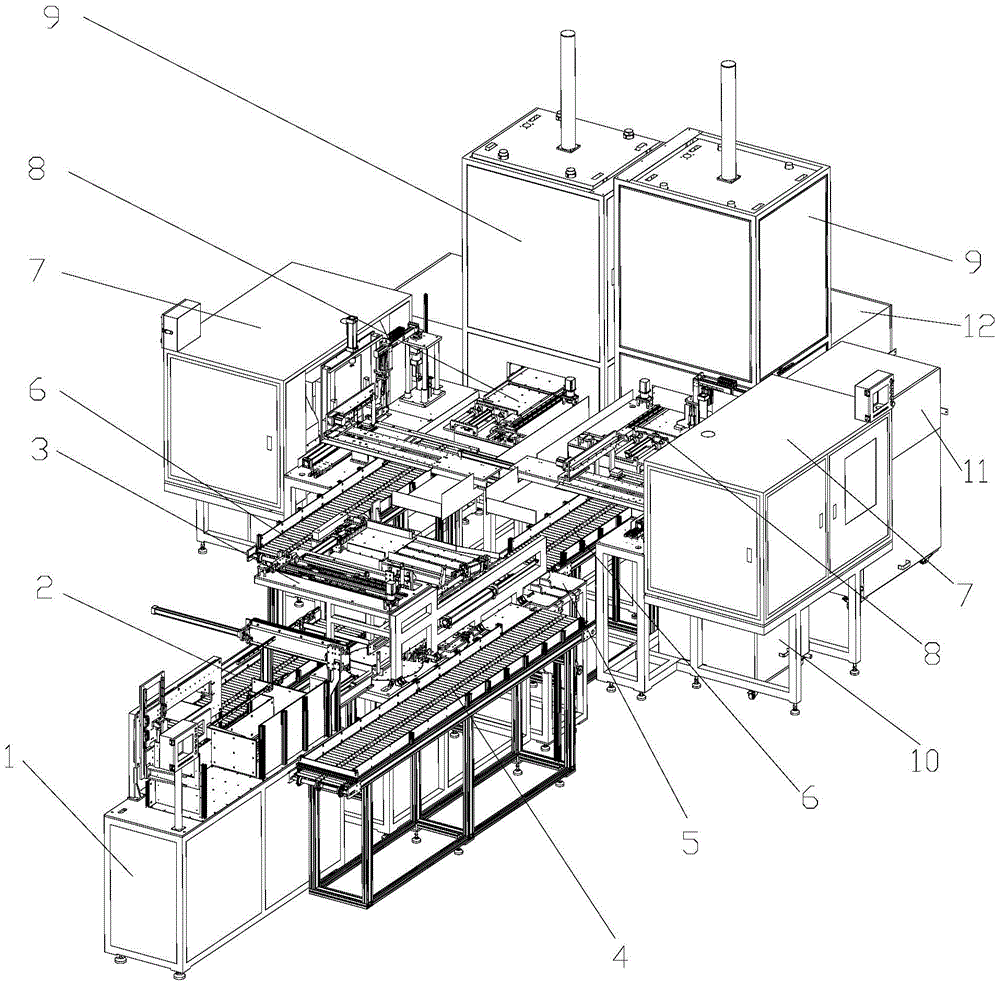

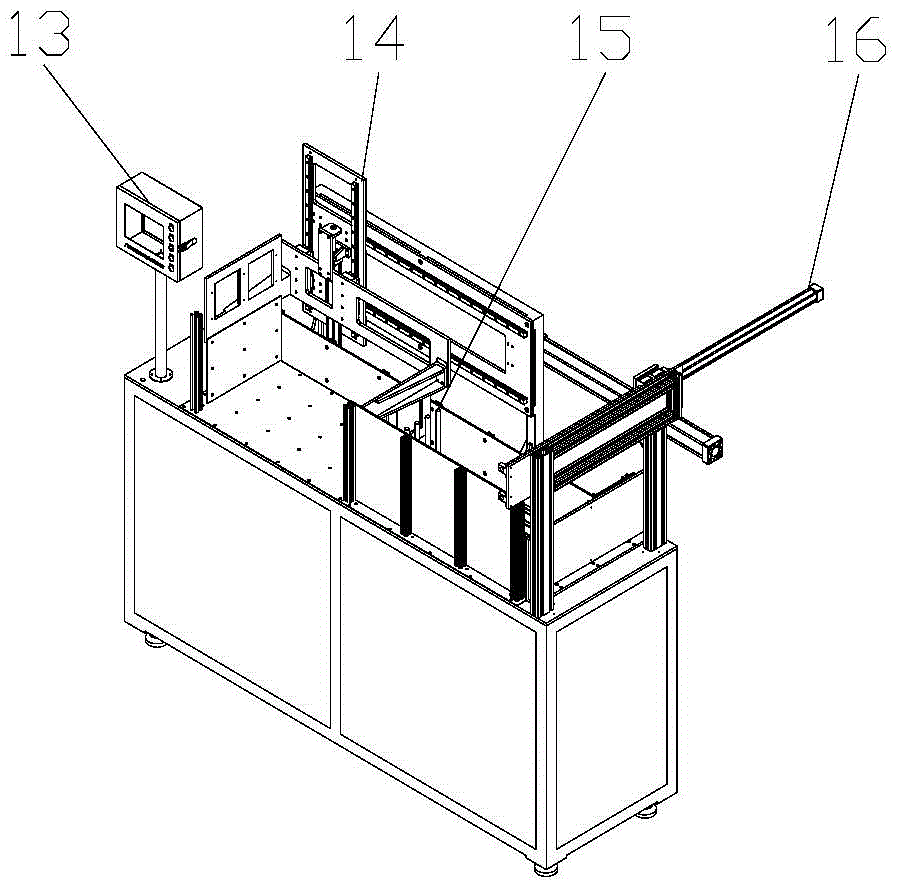

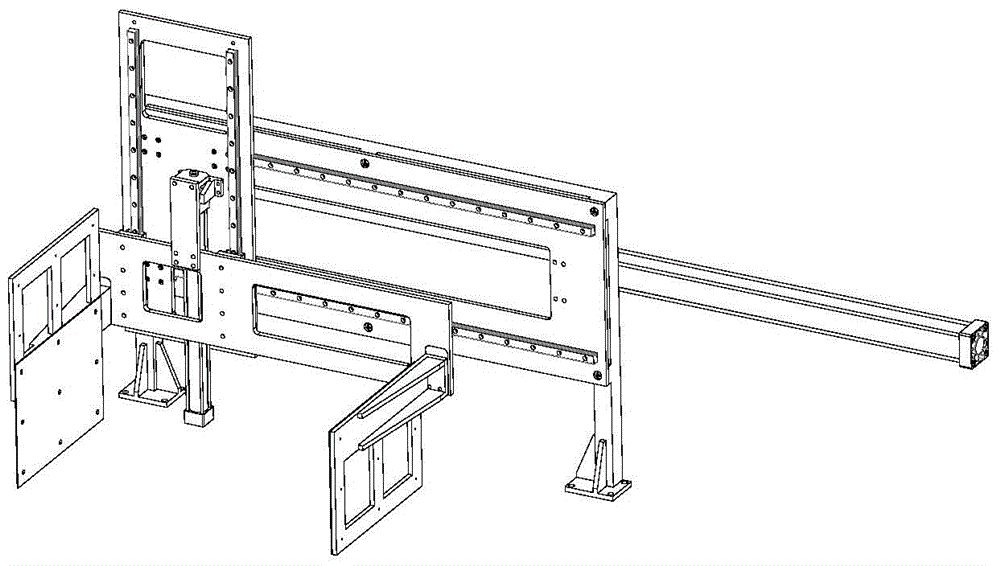

[0059] like figure 1 , a fully automatic dismantling equipment for waste power batteries, including: a feeding mechanism, a feeding conveyor, a four-station shifting mechanism, a return conveyor, a material distribution mechanism, two distribution conveyors, and two cutting mechanisms , Two separate feeding mechanisms, two separators, two waste storage boxes, two shell storage boxes, and two battery storage boxes. The feeding mechanism, the feeding conveyor, and the four-station shifting mechanism are connected in sequence, and the return conveyor is connected to the third discharge port of the four-station shifting mechanism. A sorting conveyor, a cutting mechanism, a separating feeding mechanism, and a separating machine are connected in sequence, and are equipped with a waste storage box, a shell output box and a battery storage box to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com