Iron-based amorphous nanocrystalline laser cladding composite coating, preparation method and test method

An amorphous nanocrystalline and composite coating technology, used in laser welding equipment, coatings, nanotechnology and other directions, can solve the problem of reducing the volume content and performance of amorphous cladding coatings, increasing the process flow and preparation cost, and being easy to oxidize. Burning and other problems of elemental elements, to achieve the effects of excellent mechanical properties, increased hardness and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

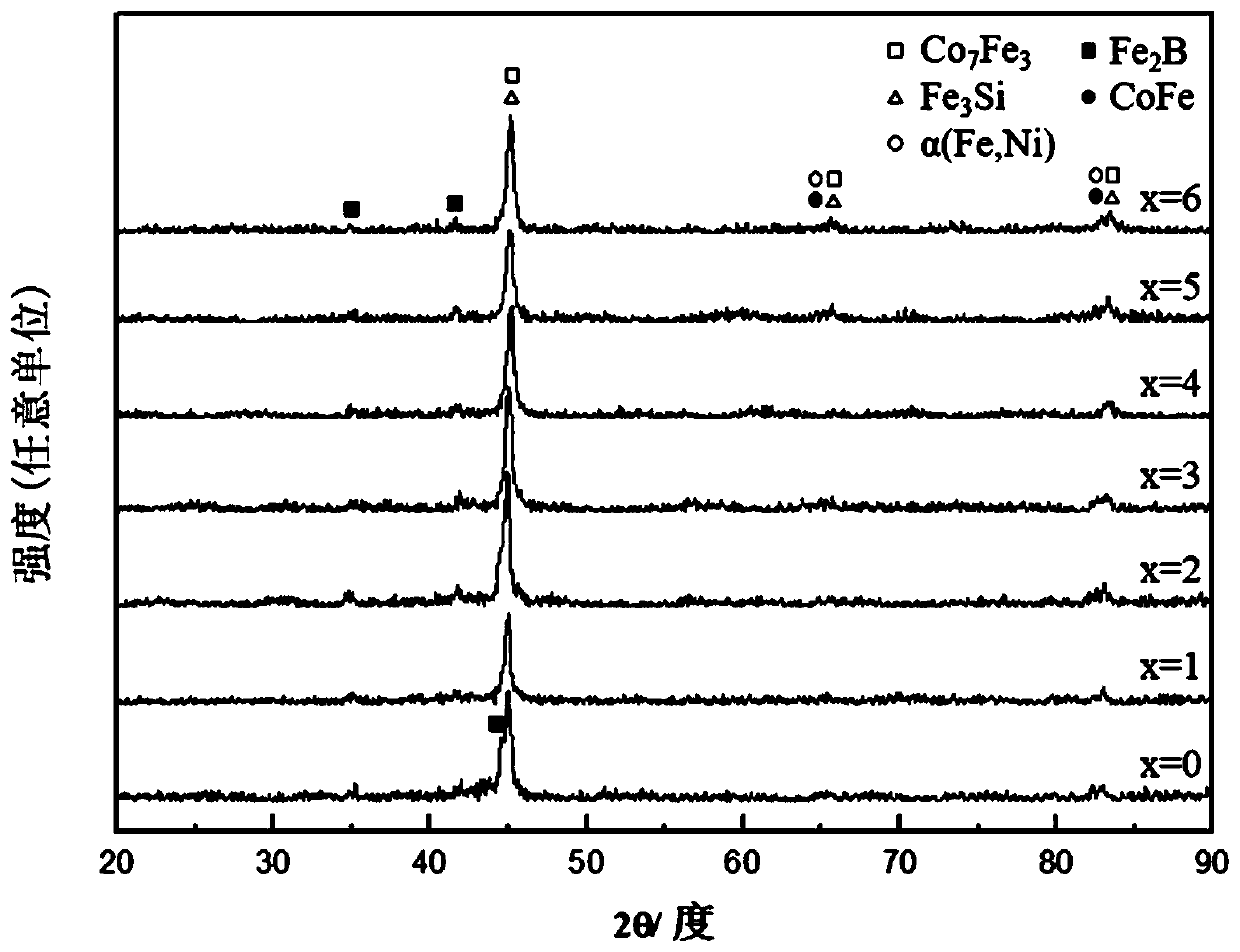

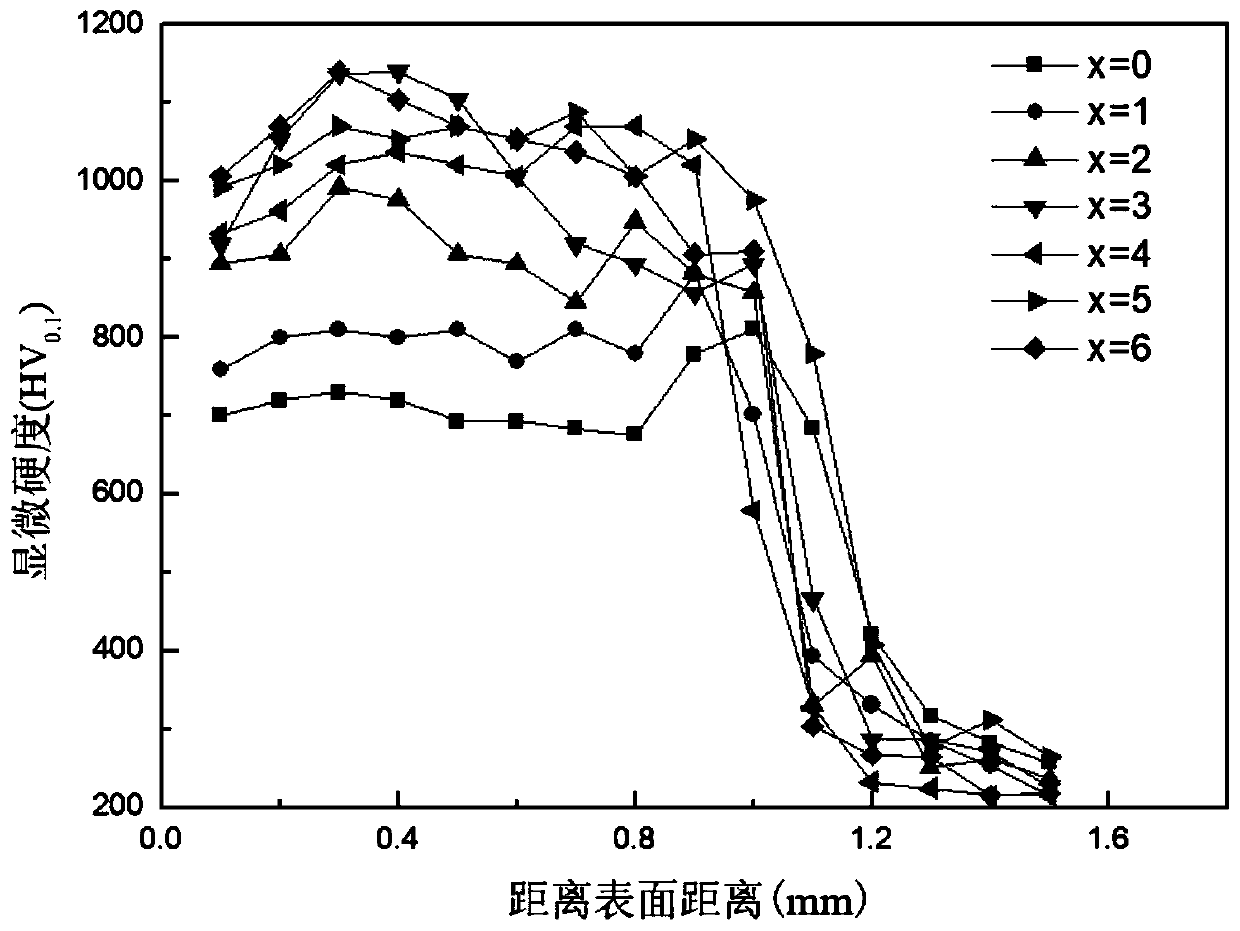

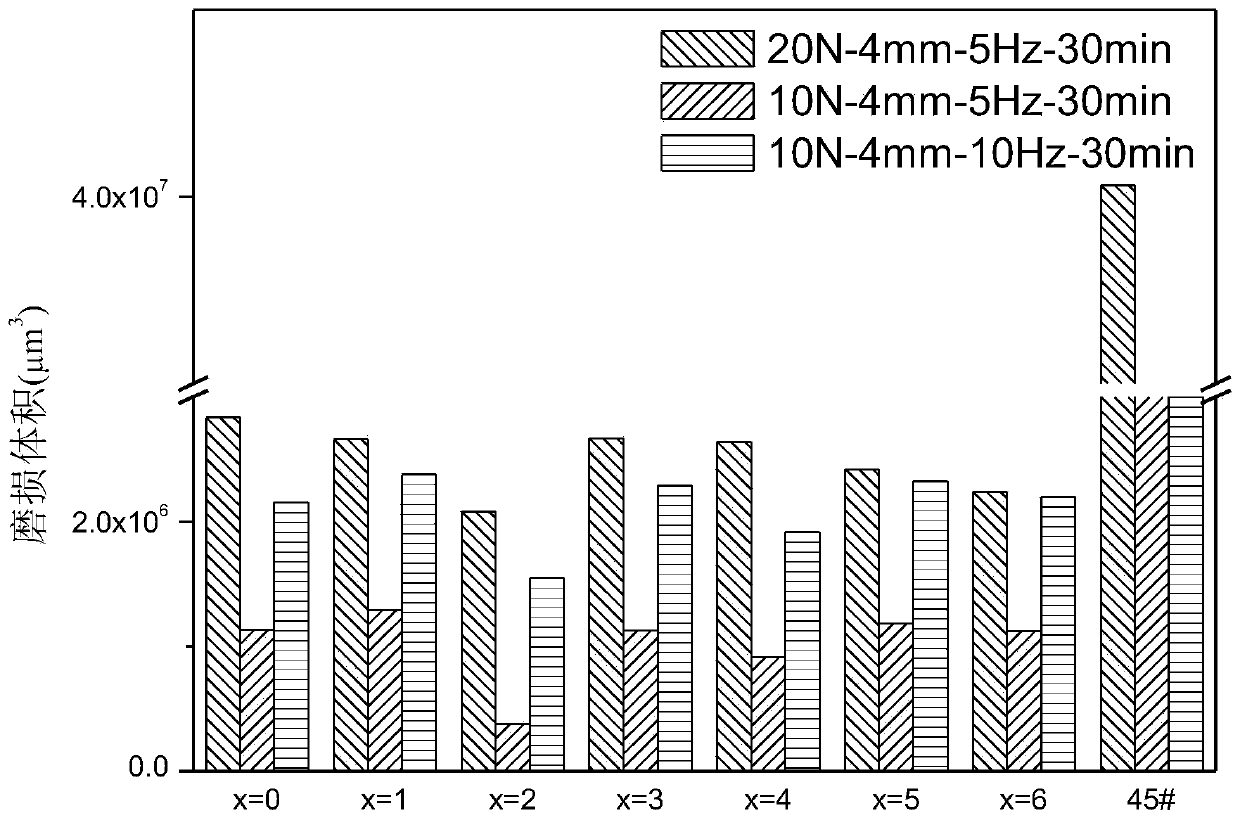

[0046] An iron-based amorphous nanocrystalline laser cladding composite coating, the composition of the cladding composite coating satisfies the molecular formula [(Fe 0.6 co 0.2 Ni 0.2 ) 0.75 B 0.2 Si 0.05 ] 96 Nb 4 , which has high strength and high wear resistance, the structure is an amorphous nanocrystalline composite structure, the integral fraction of amorphous is 21.4%, the nanocrystalline particle size is 17nm, and the micro Vickers hardness is 720HV 0.1 , the wear resistance is 11 times that of traditional 45# steel, and the breaking strength is 2160MPa.

[0047] A method for preparing an iron-based amorphous nanocrystalline laser cladding composite coating, comprising the following steps:

[0048] 1. According to the molecular formula [(Fe 0.6 co 0.2 Ni 0.2 ) 0.75 B 0.2 Si 0.05 ] 96 Nb 4 The atomic percentage in Weigh raw materials: pure iron powder (Fe>99.9wt%), cobalt-iron powder (Co>99.9wt%), nickel-iron powder (Ni>99.9wt%), boron-iron powder (B 19...

Embodiment 2

[0058] An iron-based amorphous nanocrystalline laser cladding composite coating, the composition of the cladding composite coating satisfies the molecular formula [(Fe 0.6 co 0.2 Ni 0.2 ) 0.72 B 0.2 Si 0.08 ] 96 Nb 4 , which has high strength and high wear resistance, the structure is an amorphous nanocrystalline composite structure, the integral fraction of amorphous is 25.5%, the nanocrystalline particle size is 20nm, and the micro Vickers hardness is 791HV 0.1 , the wear resistance is 15 times that of traditional 45# steel, and the breaking strength is 2428MPa.

[0059] A method for preparing an iron-based amorphous nanocrystalline laser cladding composite coating, comprising the following steps:

[0060] 1. According to the molecular formula [(Fe 0.6 co 0.2 Ni 0.2 ) 0.72 B 0.2 Si 0.08 ] 96 Nb 4 The atomic percentage in Weigh raw materials: pure iron powder (Fe>99.9wt%), cobalt-iron powder (Co>99.9wt%), nickel-iron powder (Ni>99.9wt%), boron-iron powder (B 19...

Embodiment 3

[0070] An iron-based amorphous nanocrystalline laser cladding composite coating, the composition of the cladding composite coating satisfies the molecular formula [(Fe 0.6 co 0.2 Ni 0.2 ) 0.69 B 0.2 Si 0.11 ] 96 Nb 4 , which has high strength and high wear resistance, the structure is an amorphous nanocrystalline composite structure, the integral fraction of amorphous is 41.9%, the nanocrystalline particle size is 17nm, and the micro Vickers hardness is 918HV 0.1 , the wear resistance is 19 times that of traditional 45# steel, and the breaking strength is 2880MPa.

[0071] A method for preparing an iron-based amorphous nanocrystalline laser cladding composite coating, comprising the following steps:

[0072] 1. According to the molecular formula [(Fe 0.6 co 0.2 Ni 0.2 ) 0.69 B 0.2 Si 0.11 ] 96 Nb 4 The atomic percentage in Weigh raw materials: pure iron powder (Fe>99.9wt%), cobalt-iron powder (Co>99.9wt%), nickel-iron powder (Ni>99.9wt%), boron-iron powder (B 19.4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com