Method for growing boron nitride membrane on graphite substrate

A technology of graphite substrate and boron nitride film, which is applied in metal material coating process, vacuum evaporation coating, coating and other directions, can solve problems such as not yet, and achieve the requirements of reducing process requirements, low stress and reducing energy loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The film deposition in the present invention is accomplished on a radio frequency magnetron sputtering system.

[0038] 1) Substrate pretreatment: Graphite substrate adopts 1×1cm 2, Thickness of about 2mm is mainly c-axis oriented flake graphite, after the growth surface is mechanically polished, rinsed with deionized water, then immersed in acetone and ethanol solutions for ultrasonic cleaning for 10 to 20 minutes, and then ultrasonically cleaned with deionized water Wash for 15-20 minutes, repeat the above-mentioned cleaning 2-3 times until the surface is very clean, take out the graphite sheet and dry it.

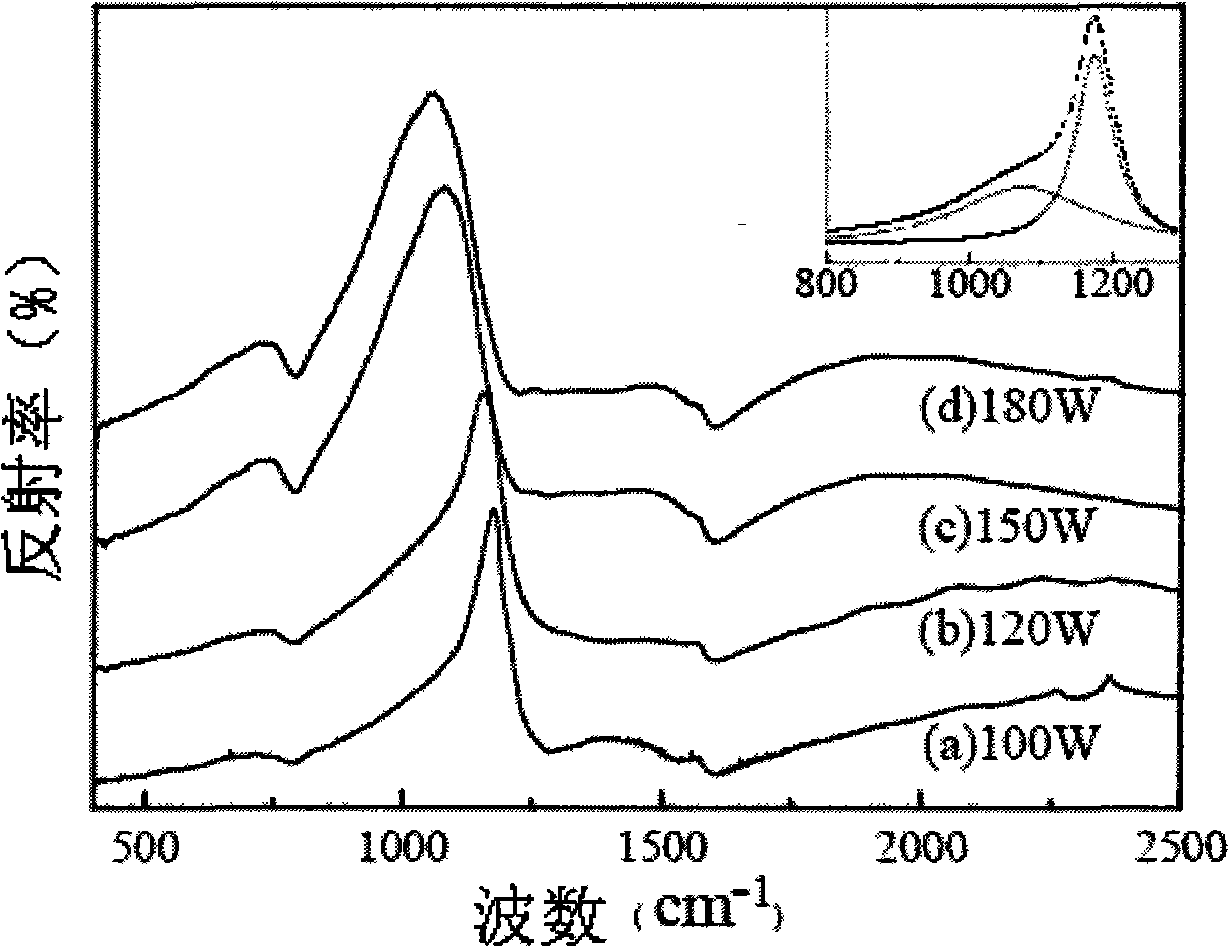

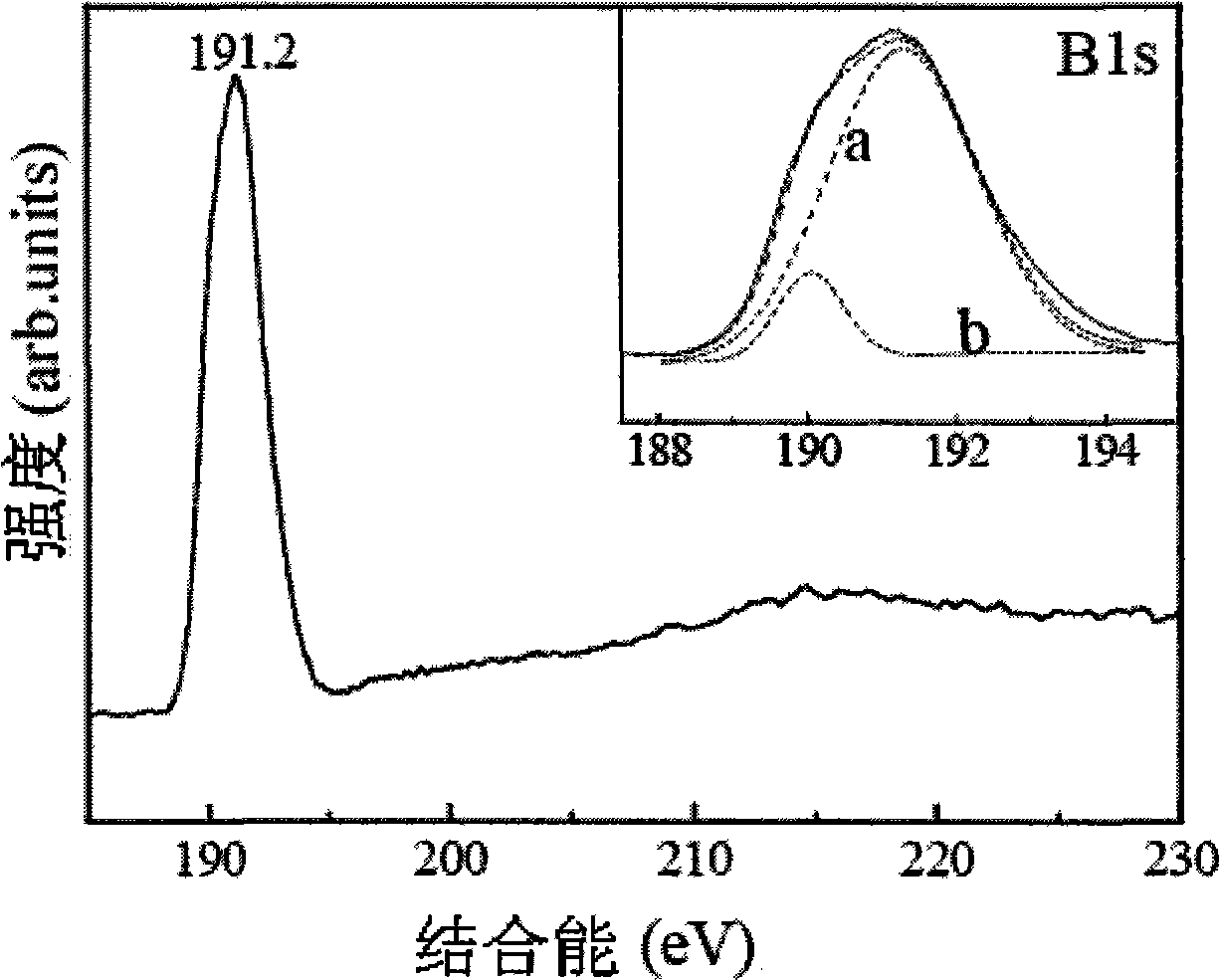

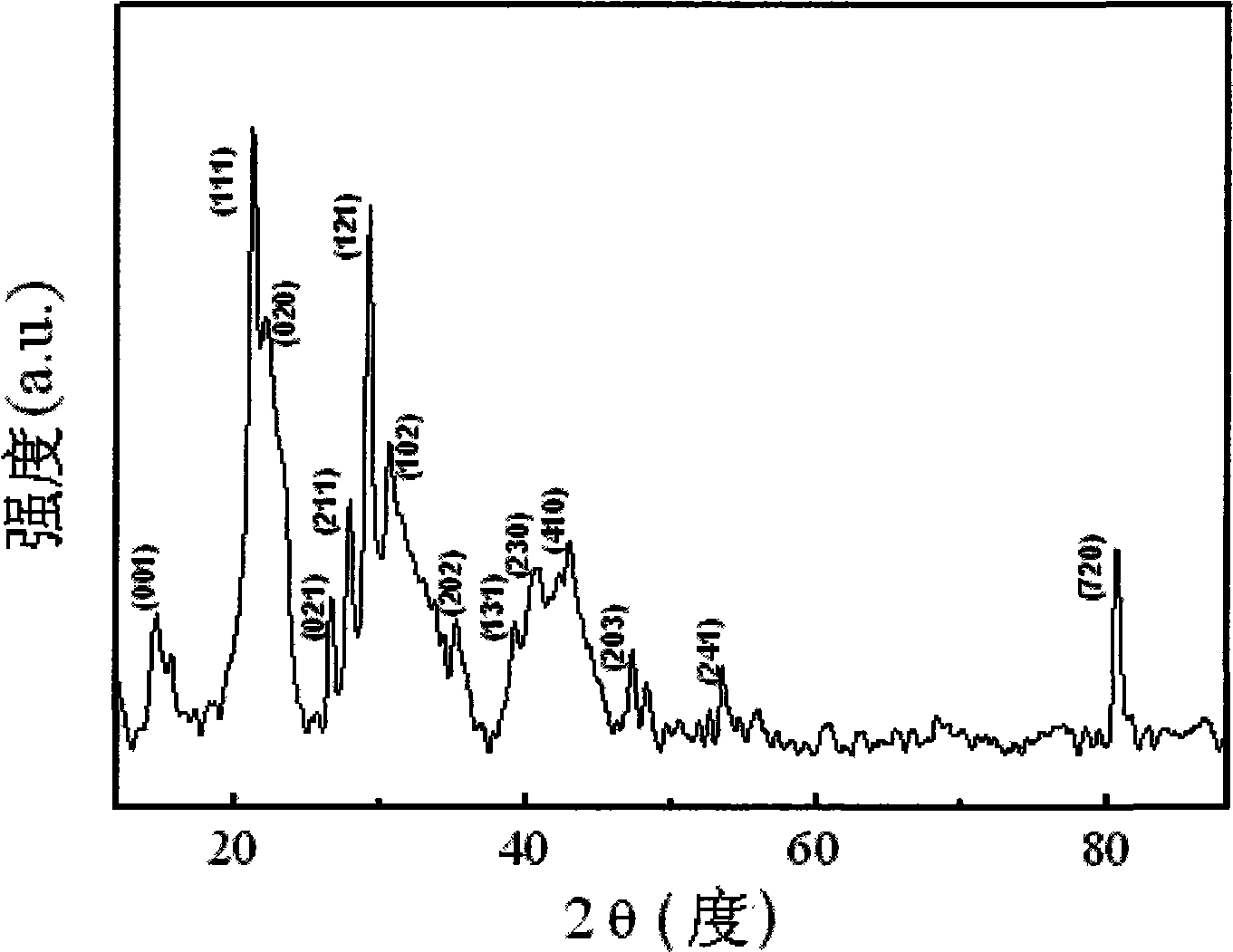

[0039] 2) Magnetron sputtering deposition process: use a radio frequency magnetron sputtering device, adopt the process of radio frequency magnetron sputtering, do not use temperature and bias substrate assistance; place the growth surface of the graphite substrate upward on the radio frequency magnetron On the substrate table of the sputtering deposition equipme...

Embodiment 2

[0042] 1) Substrate pretreatment: Same as in Example 1.

[0043] 2) Magnetron sputtering deposition process: use a radio frequency magnetron sputtering device, adopt the process of radio frequency magnetron sputtering, do not use temperature and bias substrate assistance; place the growth surface of the graphite substrate upward on the radio frequency magnetron The substrate table of the sputtering deposition equipment is used as the substrate; a hexagonal boron nitride sheet with a diameter of 50mm and a purity of 99.8% is used as the sputtering target, and the vacuum chamber is evacuated with a mechanical pump. When the pressure drops to 10Pa Turn on the molecular pump until the vacuum reaches 2×10 -3 Pa; into Ar (99.999%) and N 2 (99.999%) mixed gas, adjust the mass flowmeter to the ratio of nitrogen and argon to 1:6, keep the vacuum chamber pressure at 2Pa, radio frequency sputtering power at 150W, deposition time for 120 minutes, and finally prepare the cBN film.

[004...

Embodiment 3

[0046] 1) Substrate pretreatment: Same as in Example 1.

[0047] 2) Magnetron sputtering deposition process: use a radio frequency magnetron sputtering device, adopt the process of radio frequency magnetron sputtering, do not use temperature and bias substrate assistance; place the growth surface of the graphite substrate upward on the radio frequency magnetron The substrate table of the sputtering deposition equipment is used as the substrate; a hexagonal boron nitride sheet with a diameter of 50mm and a purity of 99.8% is used as the sputtering target, and the vacuum chamber is evacuated with a mechanical pump. When the pressure drops to 10Pa Turn on the molecular pump until the vacuum reaches 2×10 -3 Pa; into Ar (99.999%) and N 2 (99.999%) mixed gas, adjust the mass flowmeter to the ratio of nitrogen and argon to 1:6, keep the vacuum chamber pressure at 2Pa, radio frequency sputtering power at 120W, deposition time for 45 minutes, and finally prepare the eBN film.

[0048...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com