Quick installation method for fully-mechanized coal mining equipment of fully-mechanized coal mining face

A fully mechanized mining equipment and installation method technology, which is applied in mining equipment, earth drilling, transportation, packaging, etc., can solve the problems of personal injury, pulley block, and hydraulic support that are prone to broken ropes, etc., and achieve fast construction and save construction labor Cost and equipment loss costs, the effect of reducing the use of dedicated lifting points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

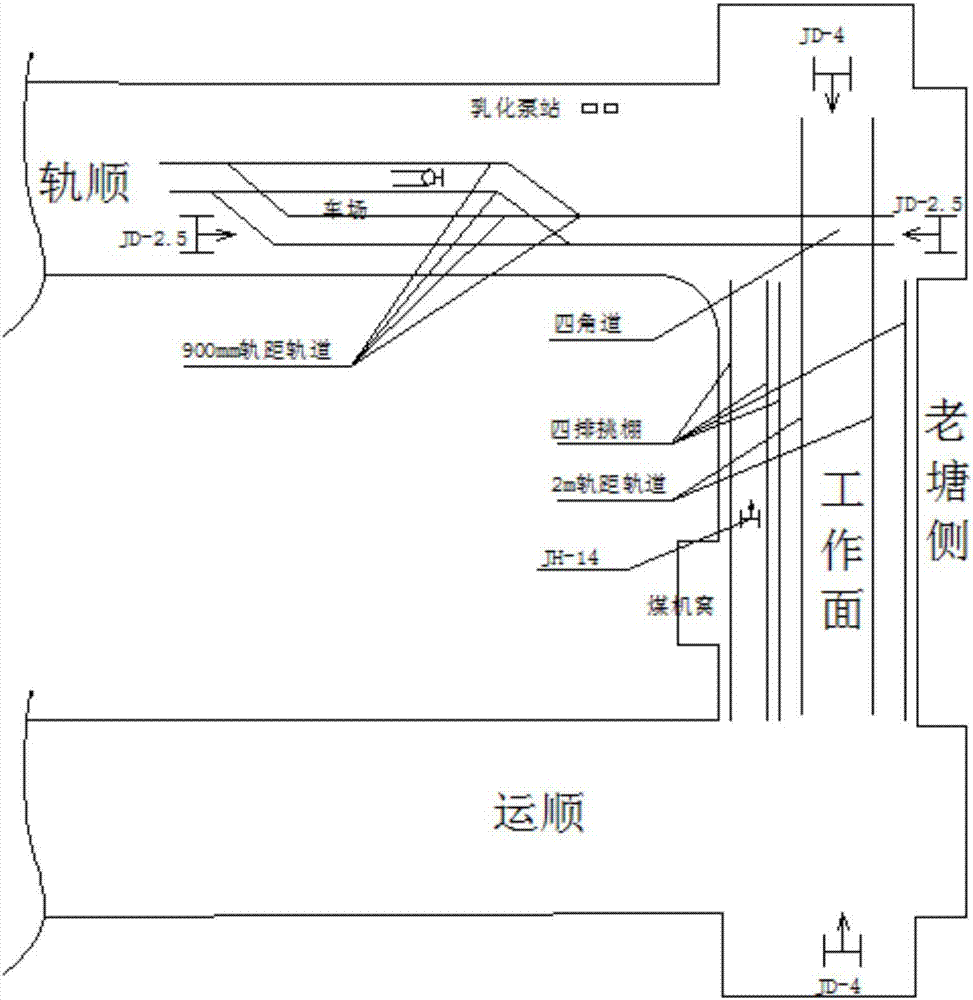

[0029] Such as figure 1 As shown, a quick installation method for fully mechanized mining face equipment has the following steps:

[0030] 1. Preparation of equipment and tools

[0031] 1) The auxiliary equipment, materials and tools required for the installation of the working face must be prepared in place, and the equipment list is shown in Table 1

[0032] Table 1 Detailed list of auxiliary equipment installed on the working face

[0033] device name

model

Number of Units

Remark

Scheduling winch

JD-2.5

2 units

Used for the transportation of equipment from the Likou parking lot to the working surface

Scheduling winch

JD-4

2 units

for eye cutting equipment transport

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com