Forming method of balancing weight of solid ballast

A technology of solid ballasting and forming methods, applied in the direction of balance weight, load hanging components, auxiliary devices, etc., can solve problems such as difficult assembly, heavy assembly or welding workload, etc., and achieve the goal of reducing labor intensity and improving work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

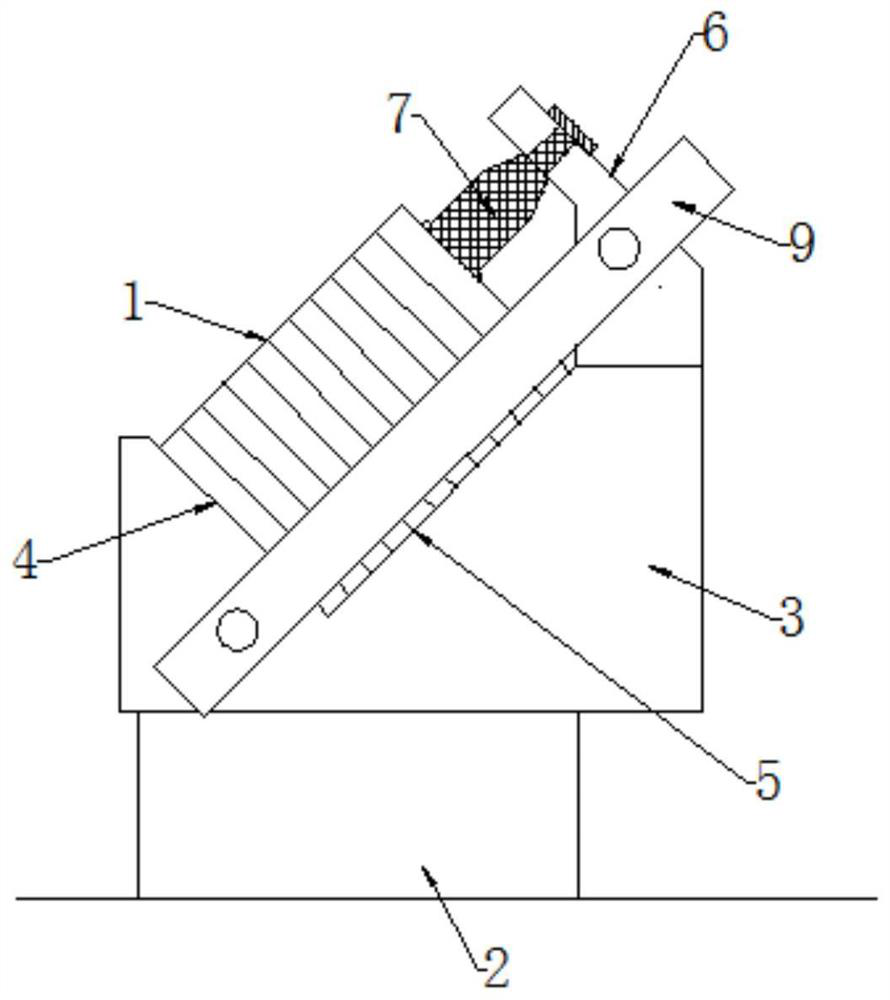

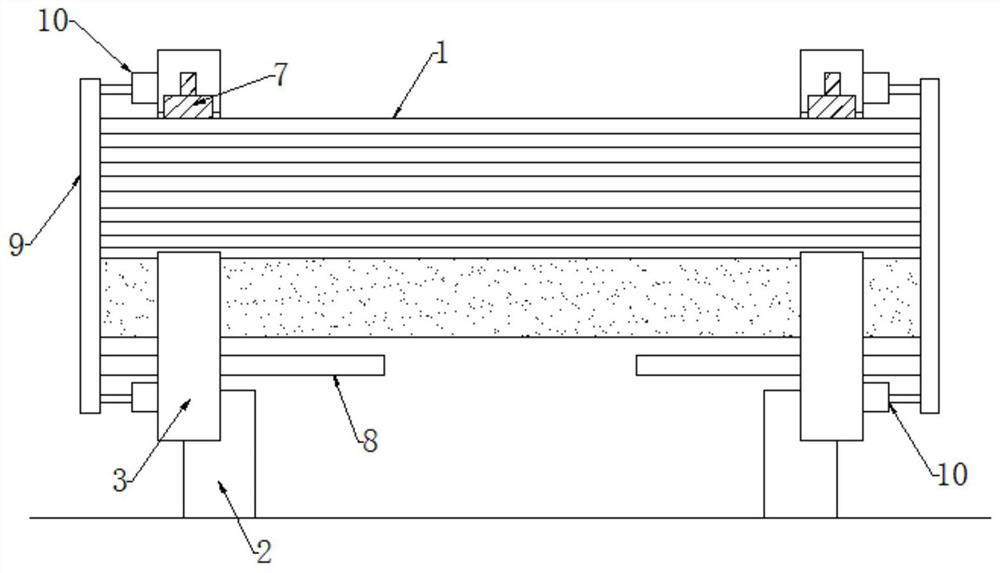

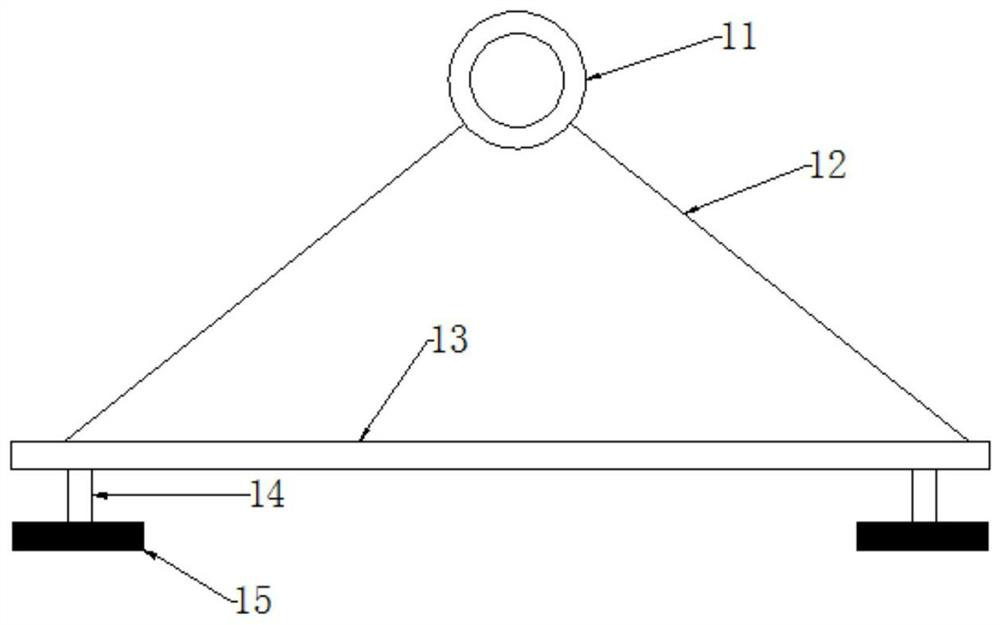

[0018] like Figure 1 to Figure 3 Shown, the present invention is a kind of forming method of the counterweight block of solid ballast, comprises the following steps:

[0019] S1: Prepare materials. According to the weight and size of the solid ballast, cut the steel plate raw material into slats 1 of the same specification and size. The length, width and thickness of the slats are 3000*350*25mm, and the number of the slats is 5000 blocks, every 18 slats form a counterweight;

[0020] S2: Hoist the slats and weld them into shape, hoist the slats of a counterweight to the forming tool one by one, align the hoisted slats one by one, and then weld the four s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com