Device for early removal and quick removal of building formwork

A technology of building formwork and matching device, which is applied to the preparation of building components on site, construction, building structure, etc., can solve the problem of not being able to disassemble the crossbar, so as to facilitate civilized construction and reduce the impact of human and material quality. , the effect of a clear force state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

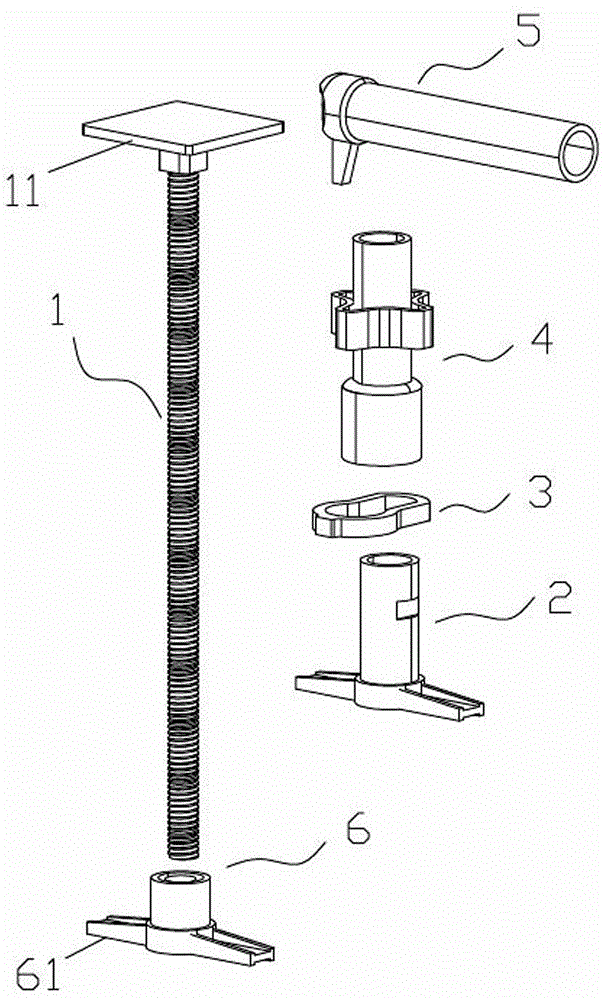

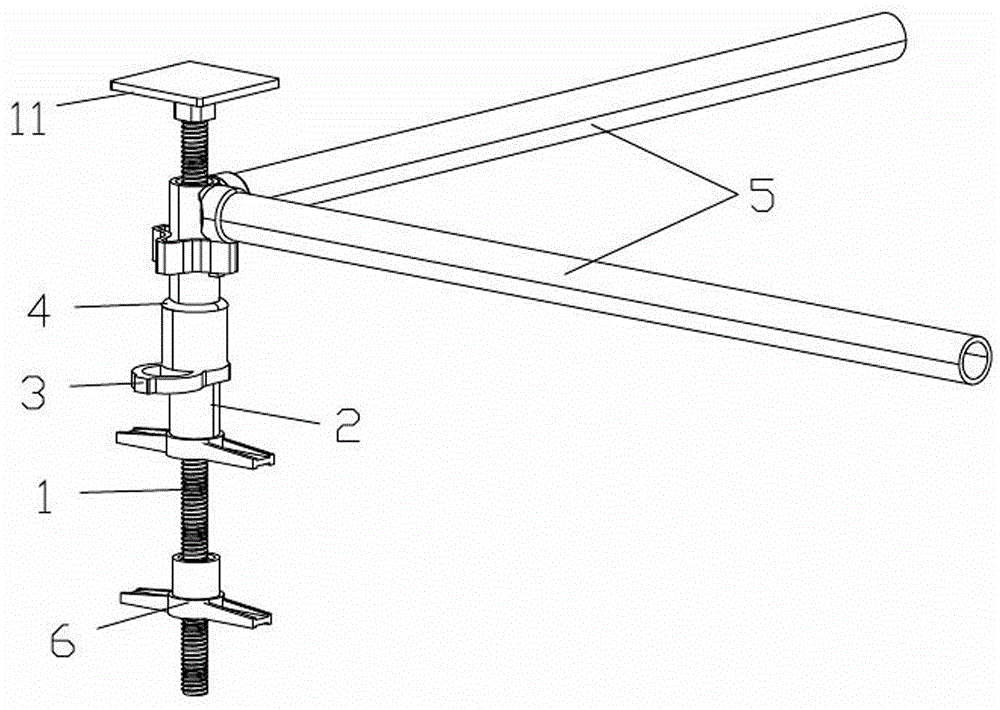

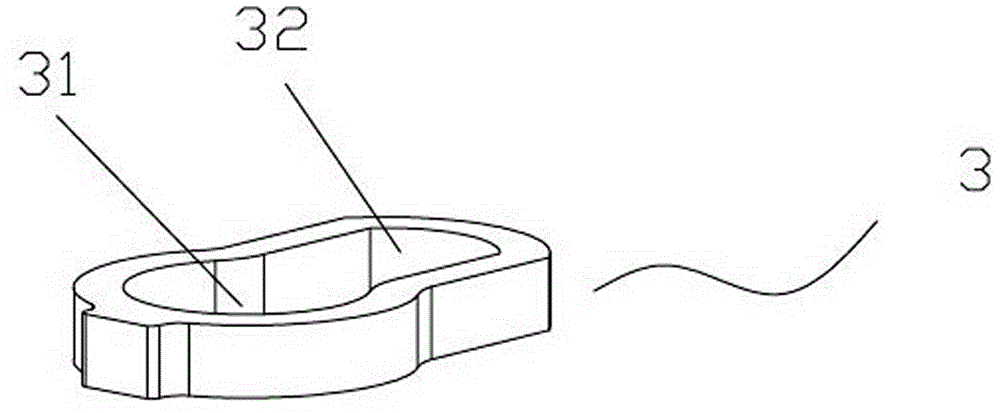

[0035] Such as Figure 1 to Figure 6 As shown, a device for realizing early dismantling and quick dismantling of building templates, including a vertical rod 1 with external threads, a support cylinder 2 with internal threads for supporting and height adjustment, and a supporting and sliding The elongated ring 3 of the function, the supporting cylinder 2 is screwed with the vertical rod 1, and the supporting cylinder 2 can be raised and lowered along the vertical rod 1; a pair of positioning grooves 21 are formed on the outer wall of the supporting cylinder 2, and the pair of positioning grooves 21 The central axis of the support cylinder 2 is arranged symmetrically to the axis of symmetry; the elongated ring 3 has a sliding hole 31 pierced up and down that mainly plays a sliding role and a positioning hole 32 pierced up and down that pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com