Self-adaptive adjustable early-dismantling jack for supporting building formworks

A building formwork and self-adaptive technology, which is applied in the on-site preparation of building components, construction, building construction, etc., can solve problems such as non-adjustment, and achieve the effect of strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

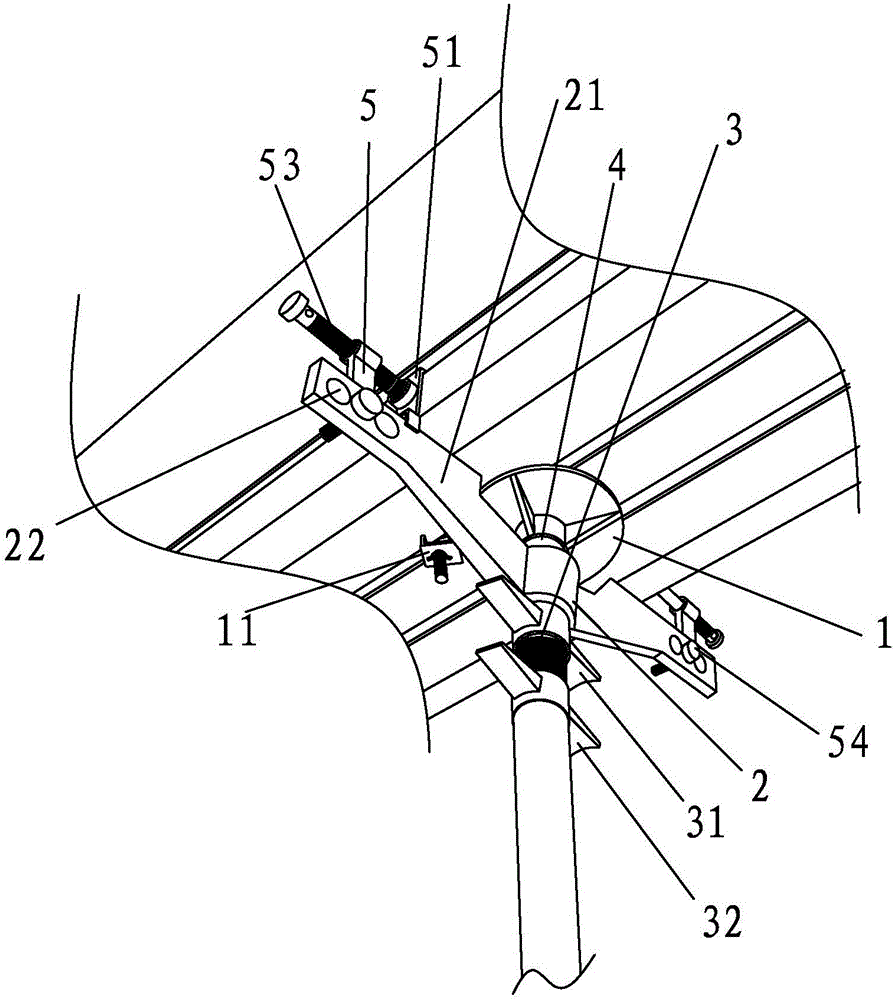

[0061] Such as Figure 1-4 As shown, the present invention is an self-adaptive adjustable early demolition jack bracket for building formwork support, which has a support plate 1, a bracket 2 and a support column 3. The support plate 1 and the support column 3 are connected together by a hinge structure 4 .

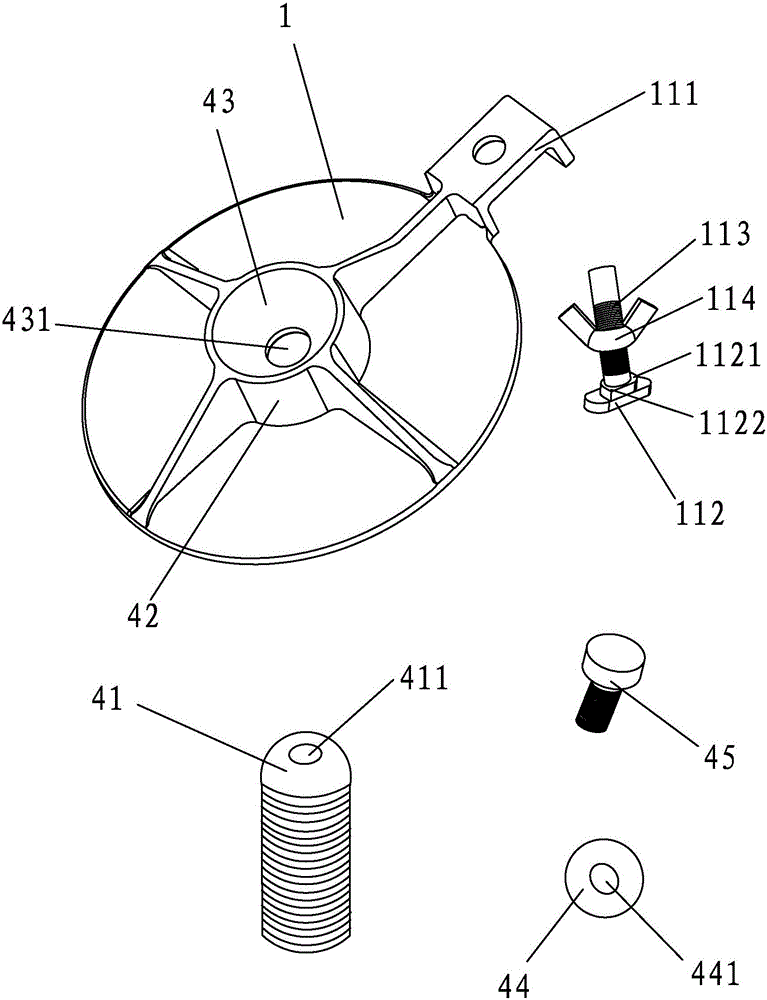

[0062]The upper end of the support column 3 is processed into a protruding head 41, the protruding head 41 is in the shape of a spherical surface, the central position of the protruding head 41 is provided with a through hole 411 along the axial direction, and the inner surface of the through hole 1 411 is provided with an internal thread. A boss 42 is connected to the bottom of the support plate 1 , and the boss 42 is hollow cylindrical. An axial through hole (not shown) corresponding to the boss 42 is formed at the center of the support plate 1 . In this embodiment, the support plate 1 and the boss 42 are integrally formed. The inner cavity of the boss 42 is provided ...

Embodiment 2

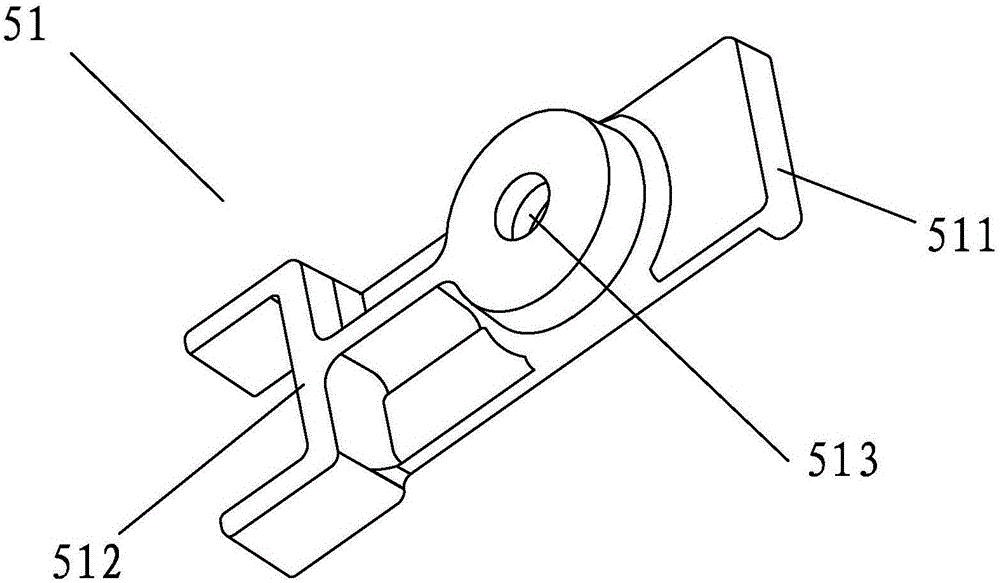

[0068] Such as Figure 5-8 As shown, the difference between the second embodiment of the present invention and the first embodiment lies in the structure of the tightening step by step and the structure of the supporting arm. The second step is tightened 6 in the present embodiment. The bracket 2 has a bracket arm 23 and a bracket arm 24 . Both the bracket arm 23 and the bracket arm 24 are in the shape of a T-shaped strip, and the two are symmetrically distributed on both sides of the support plate of the jacking bracket. The upper sides of the bracket arm 23 and the bracket arm 24 are on the same level as the upper surface of the support plate. The upper side of the bracket arm 23 is provided with convex strips 231 along the length direction of the bracket arm, and the upper side of the bracket arm 24 is densely covered with protruding teeth 241 along the length direction of the bracket arm.

[0069] The bracket arm 23 is connected with a limiting plate 61 , the upper end ...

Embodiment 3

[0076] The difference between the third embodiment of the present invention and the second embodiment lies in the structure of the slider, such as Figure 9 As shown, compared with the slider 63, the slider 66 has less convex strips 6311. During installation, the slide block 66 is directly connected with the bayonet pin 64; or, a locking member such as a screw is penetrated from the side of the groove of the slide block 66, and the bayonet pin 64 and the slide block 66 are more tightly connected by the screw. together.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com