Pre-supporting and post-mounting shaping early-dismantling form system and construction method thereof

A technology for early dismantling of formwork and systems, applied in the fields of formwork/formwork/work frame, on-site preparation of building components, construction, etc., can solve the problems of poor dimensional adaptability, high cost, heavy weight, etc., and reduce strength and rigidity. requirements, improved adaptability, the effect of a large application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

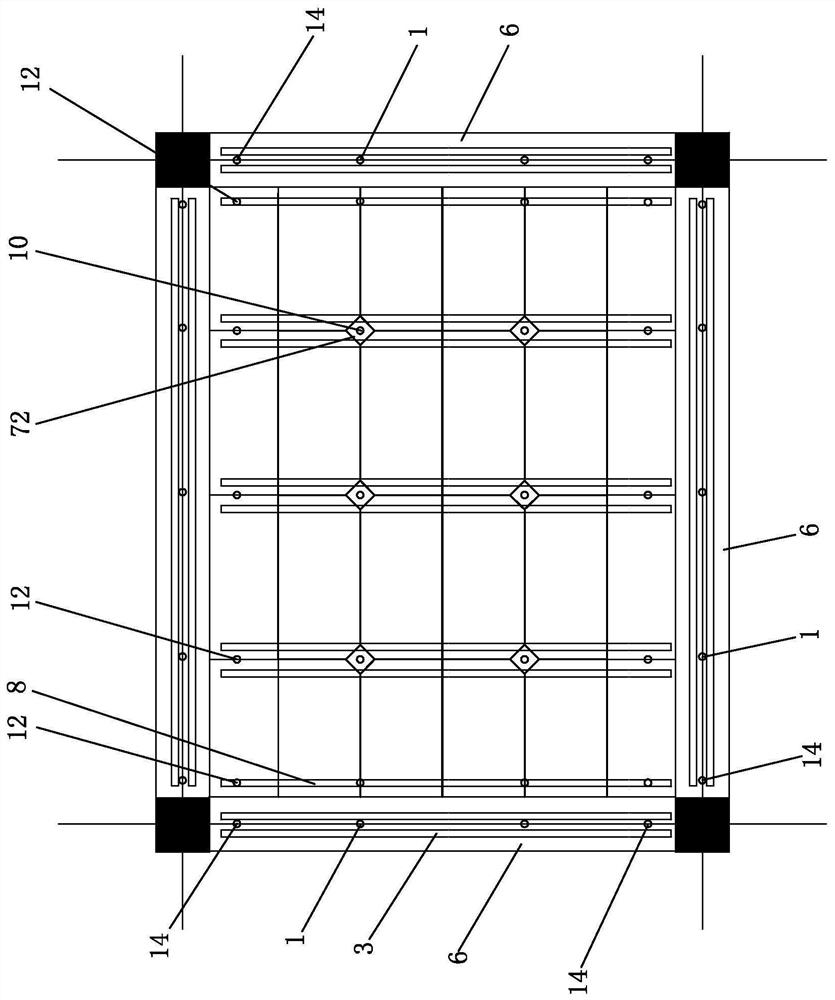

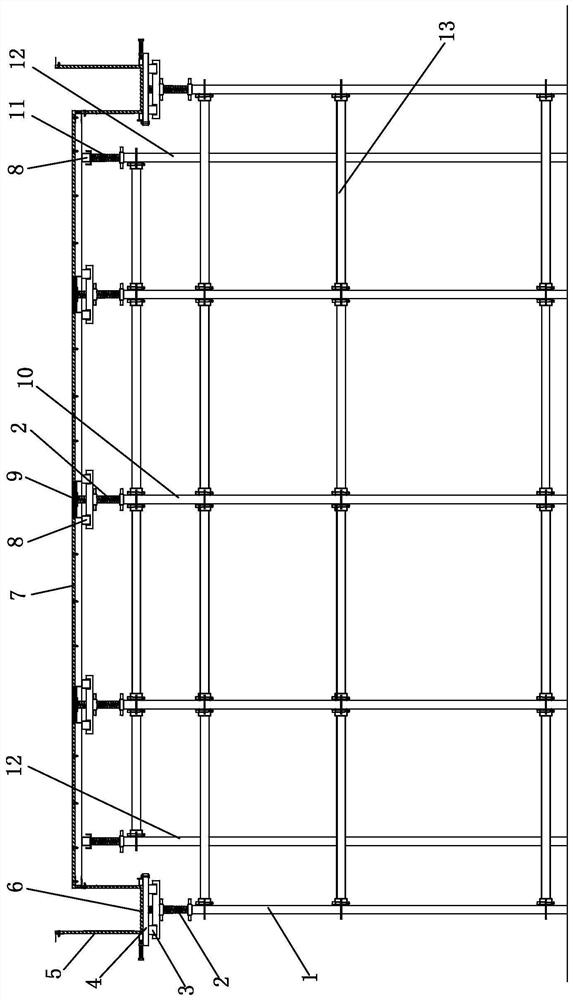

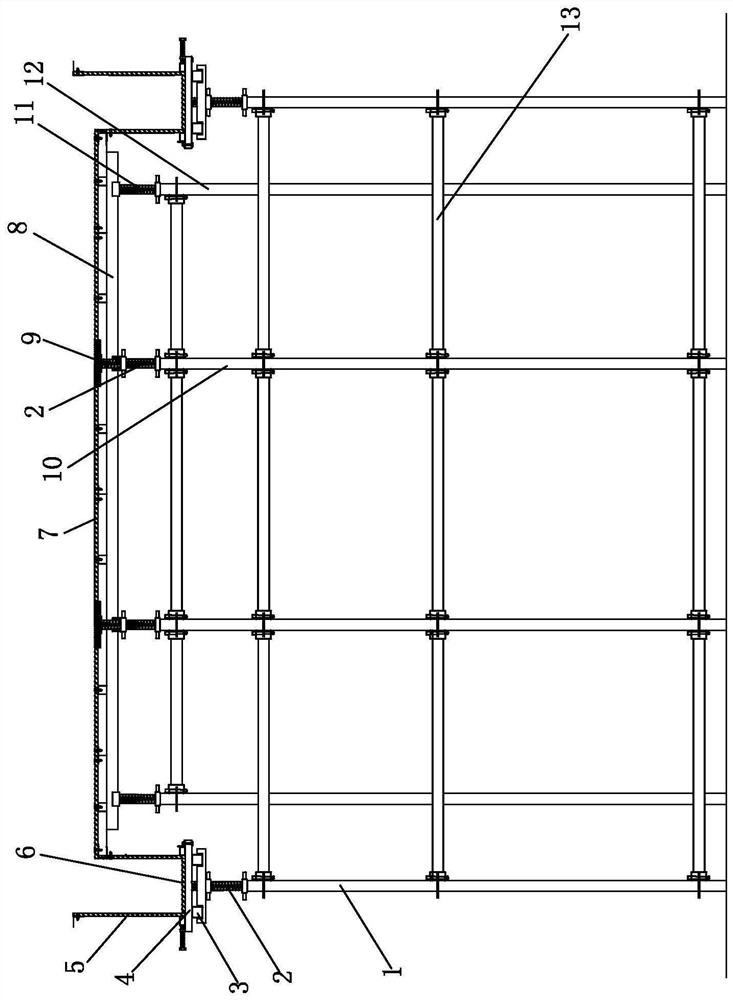

[0050] Such as Figure 1 to Figure 16 As shown, the present invention is a formwork system that is supported first, then installed, fixed, and early dismantled, including a support system and a formwork system.

[0051] The support system of the present invention includes a support frame body, a jacking, a support beam and a support device 4 at the bottom of the beam; An integral support erected by scaffolding steel pipes of this type not only has the capacity to carry formwork, concrete and construction loads, but also has the stability to ensure the stability of the entire formwork system. In this embodiment, the support frame body includes plate The support pole 10 is removed at the bottom, the support pole 12 is removed early at the bottom of the board, the support pole 1 is removed at the bottom of the beam, the support pole 14 is removed early at the bottom of the beam, and the connecting cross bar 13; and the common jacking bracket 11, the early demolition jacking brac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com