Patents

Literature

133results about How to "Play the role of guide limit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

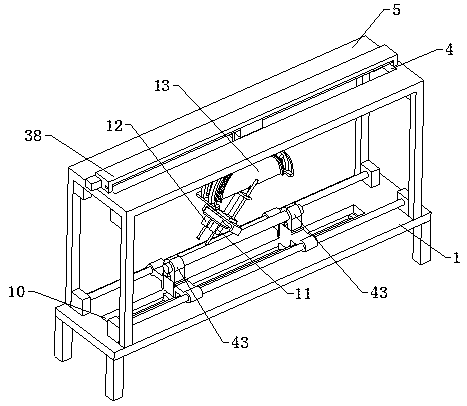

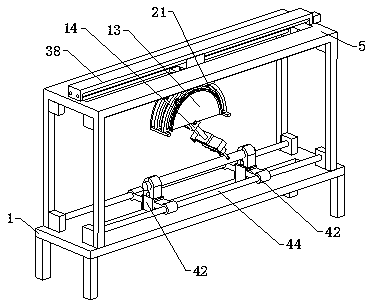

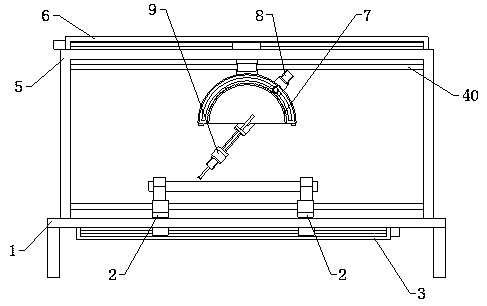

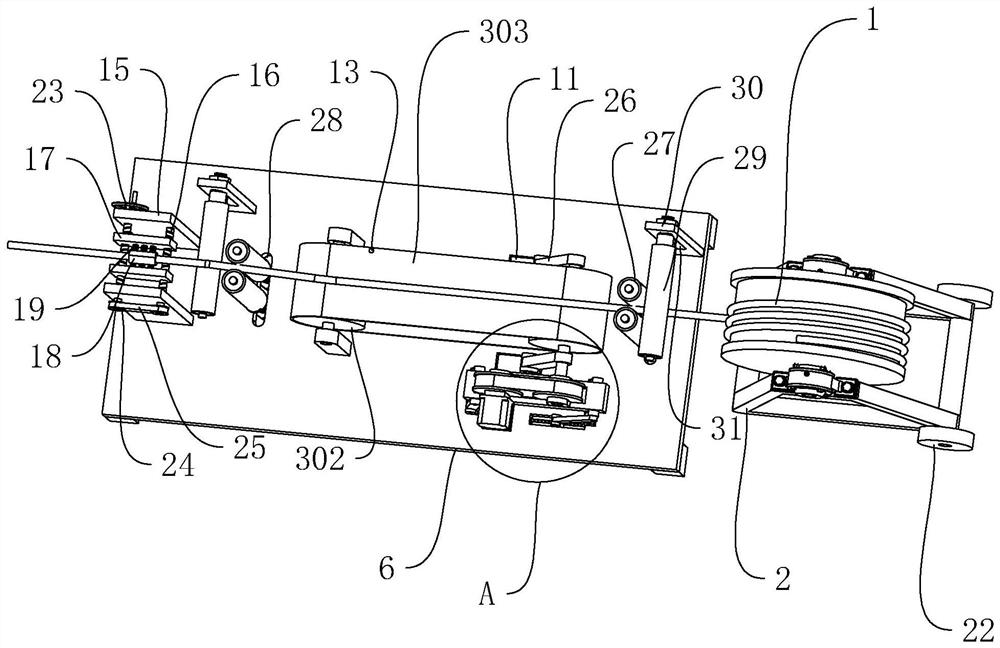

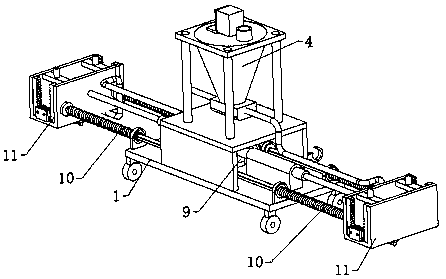

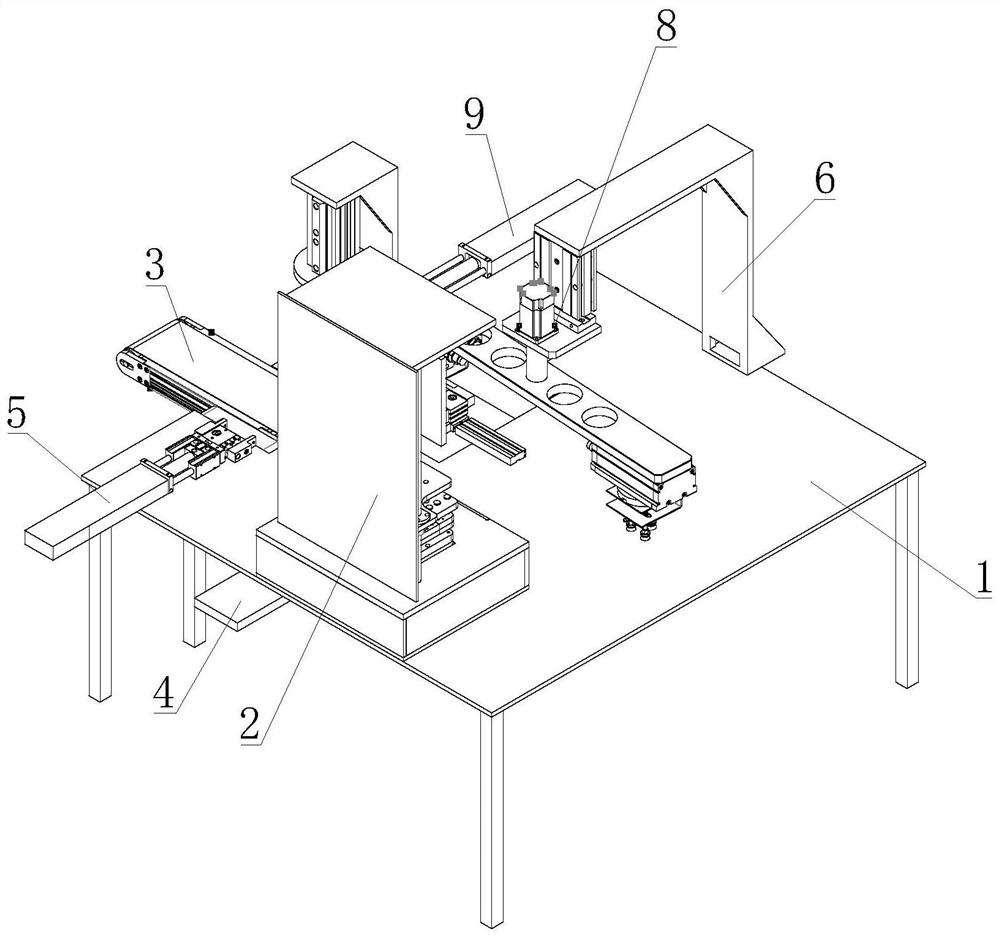

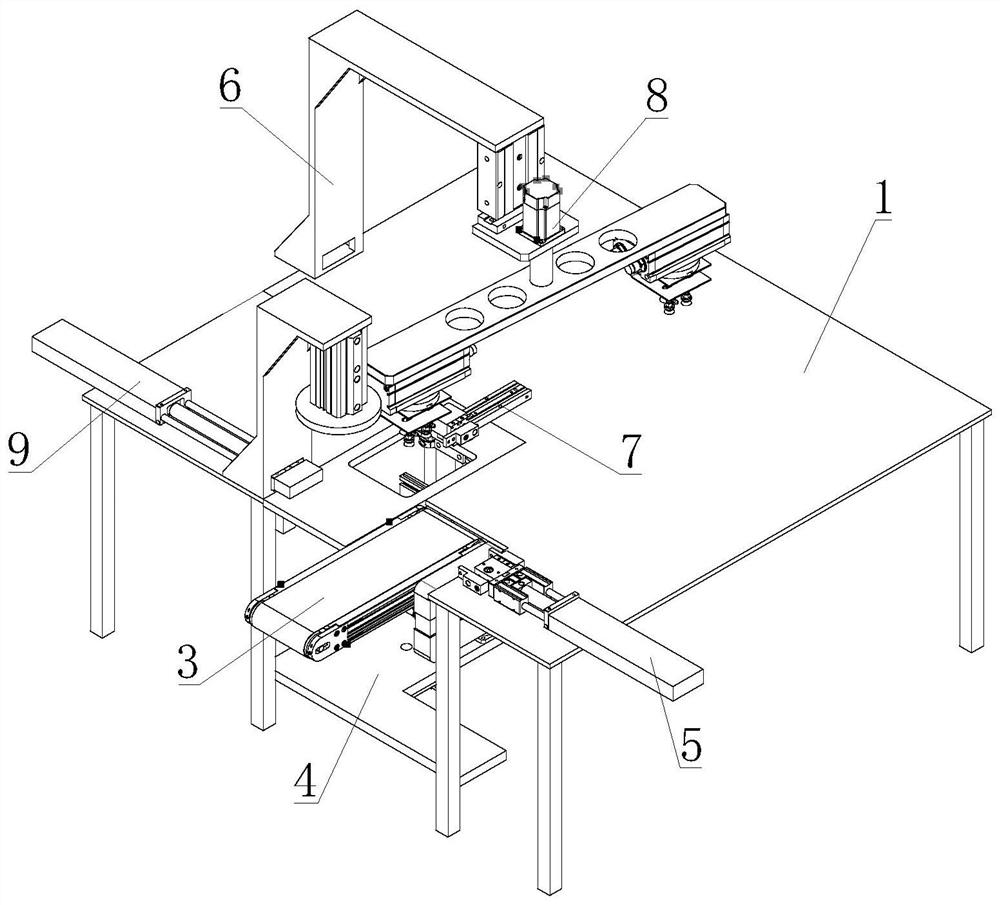

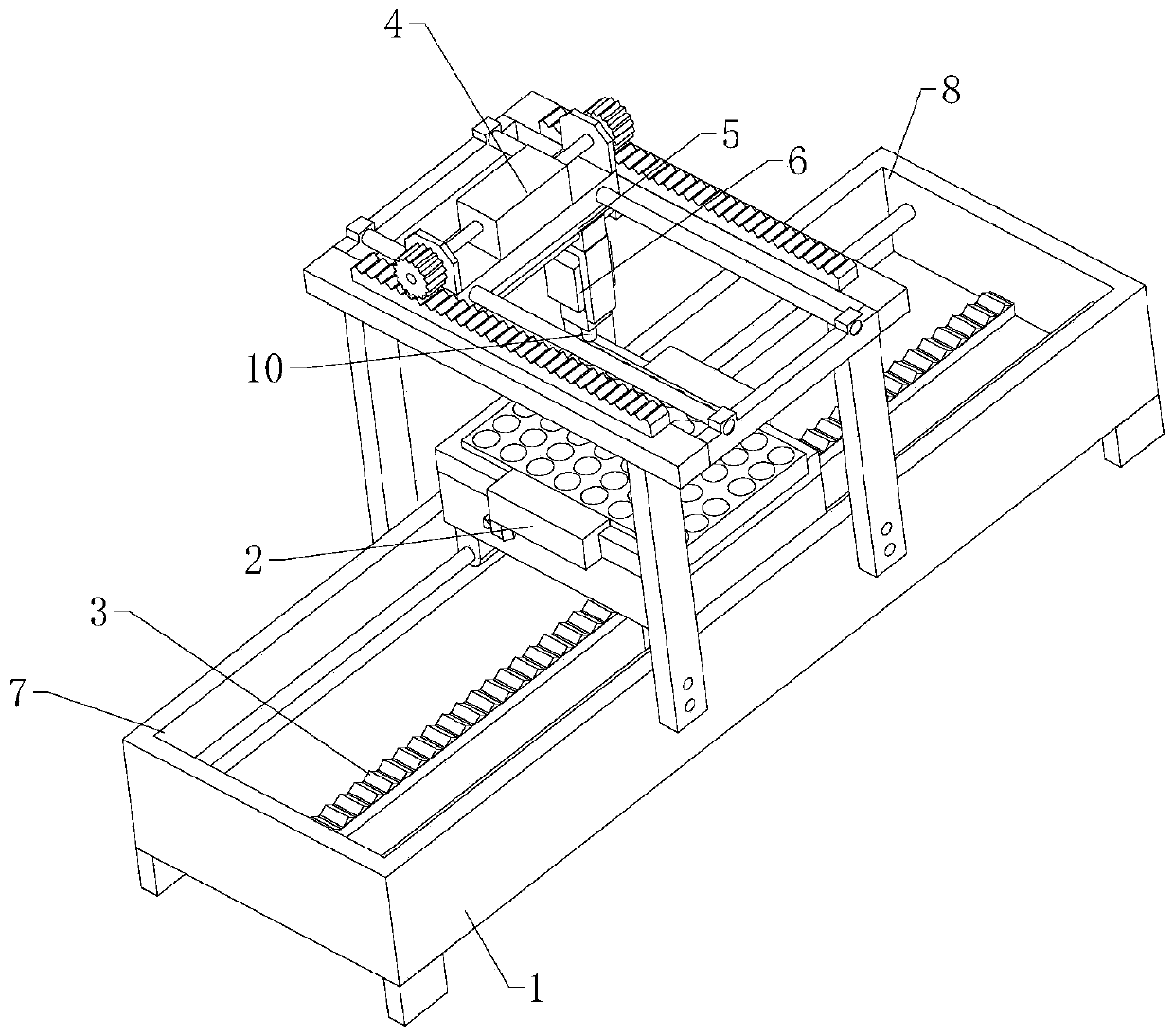

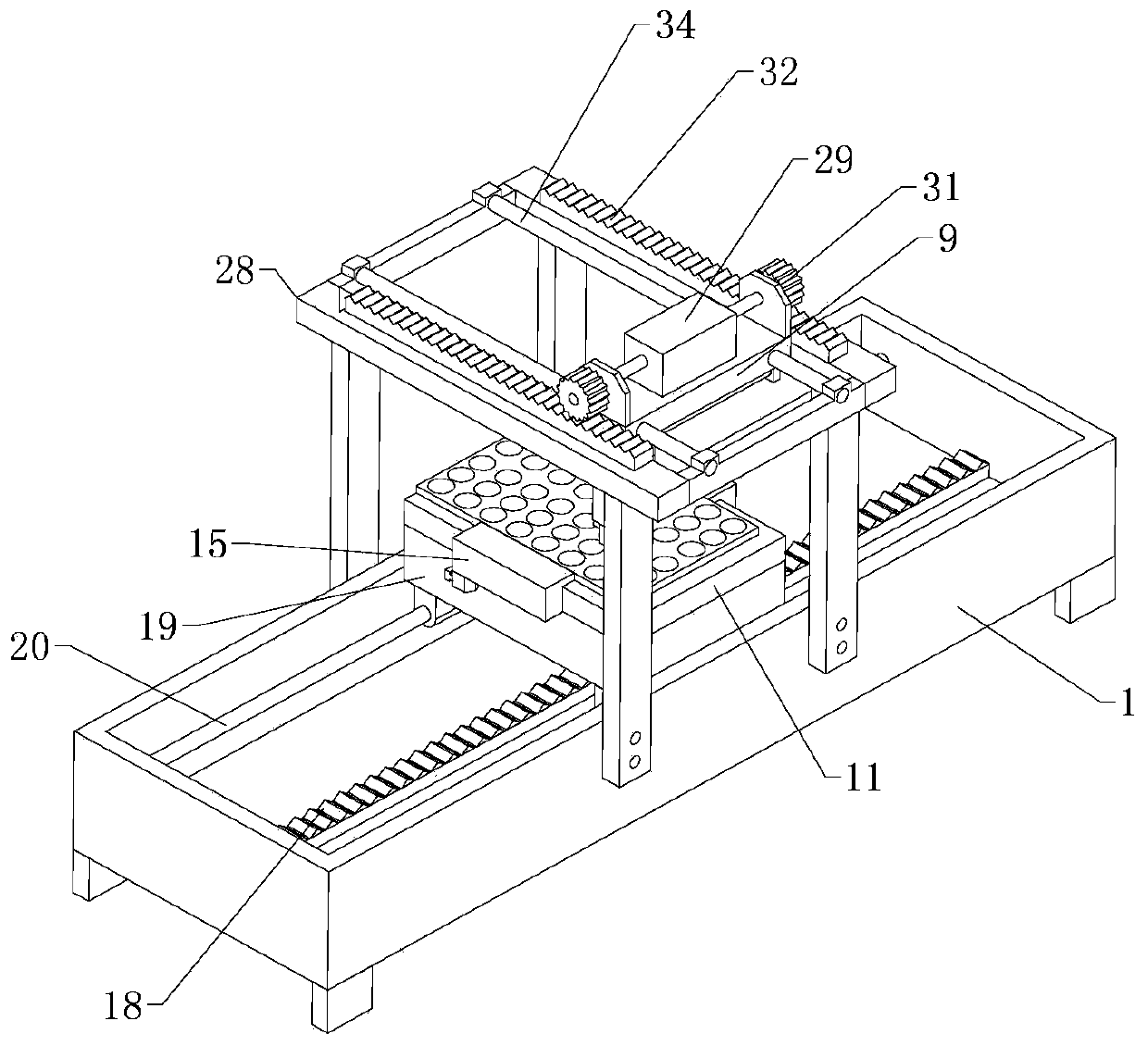

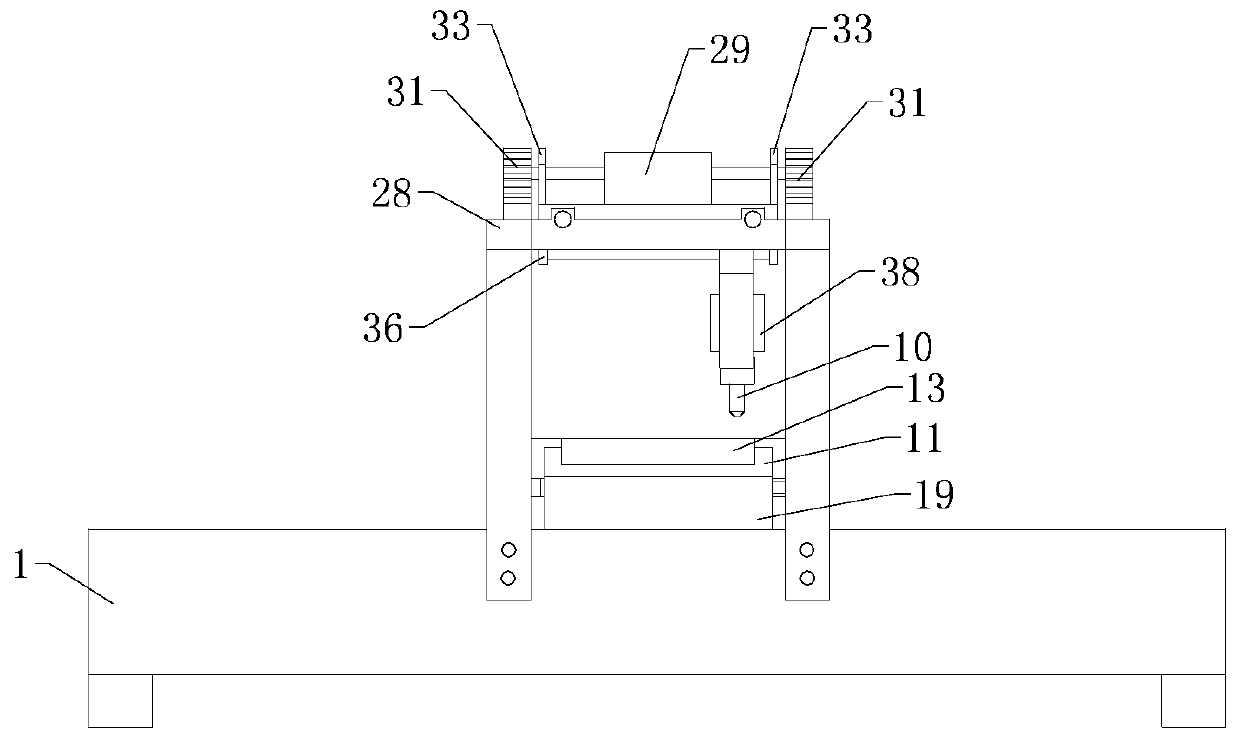

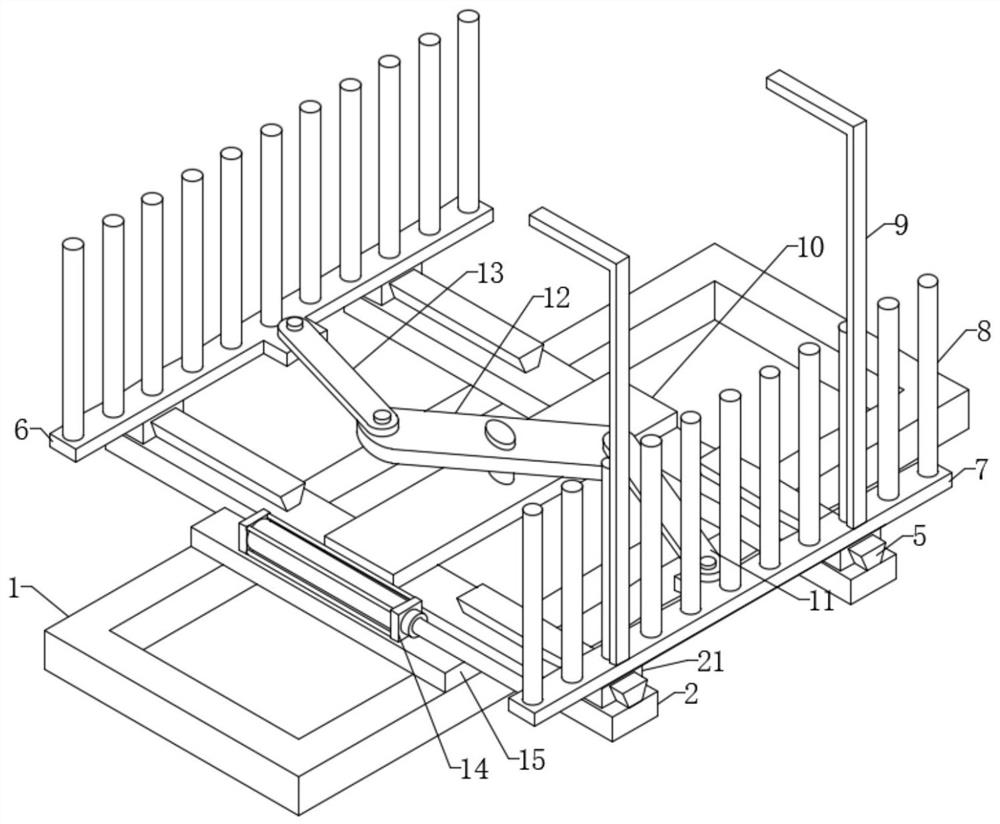

Shaft workpiece automatic inclined hole drilling device

InactiveCN110385456APlay the role of guide limitWork clamping meansLarge fixed membersEngineeringMachining

The invention relates to the field of shaft workpiece machining, in particular to a shaft workpiece automatic inclined hole drilling device. The shaft workpiece automatic inclined hole drilling devicecomprises a workbench, and further comprises a discharge locating mechanism, a horizontal moving mechanism and an adjusting mechanism. The discharge locating mechanism comprises two clamping assemblies and a face-to-face adjusting assembly. The workbench is provided with a rectangular avoidance port. The horizontal moving mechanism comprises a horizontal support and a horizontal moving assembly.The adjusting mechanism comprises an angular adjusting assembly, a push assembly and a horizontal driving assembly. The horizontal support is provided with an avoidance penetration port used for avoiding the angular adjusting assembly during moving. The working end of a longitudinal driving assembly comprises a main drilling motor and an auxiliary drilling motor. The main drilling motor and the auxiliary drilling motor are symmetrically arranged at the working end of the longitudinal driving assembly in a spaced mode. The shaft workpiece automatic inclined hole drilling device can conduct inclined hole drilling by adjusting the angle at random and can improve the hole precision and the machining efficiency.

Owner:云和县凯毅德电子设备厂

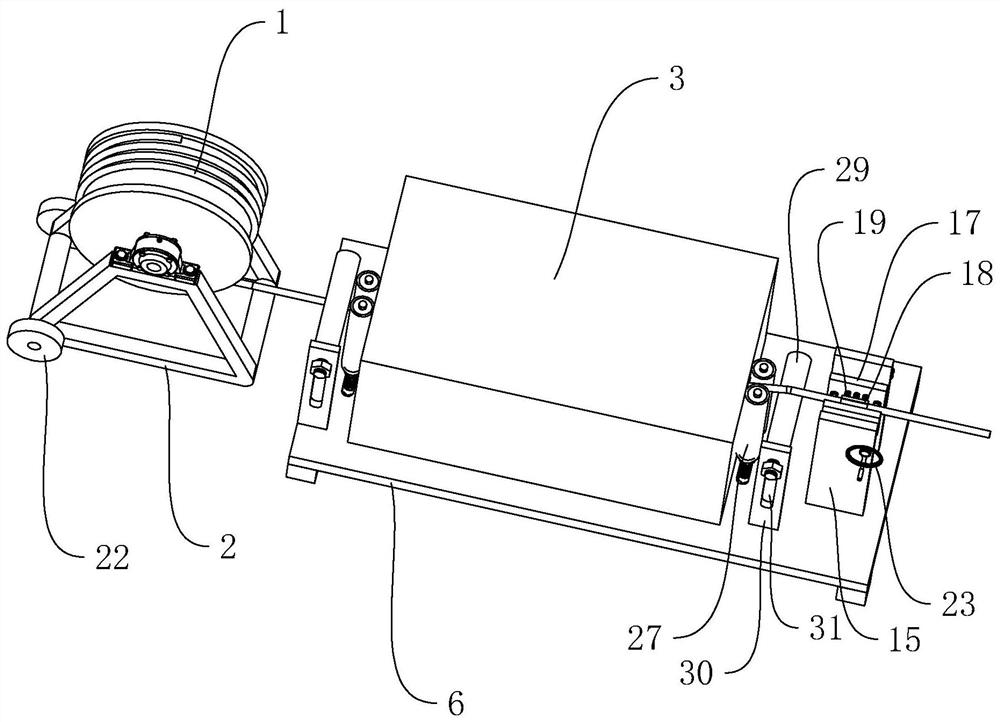

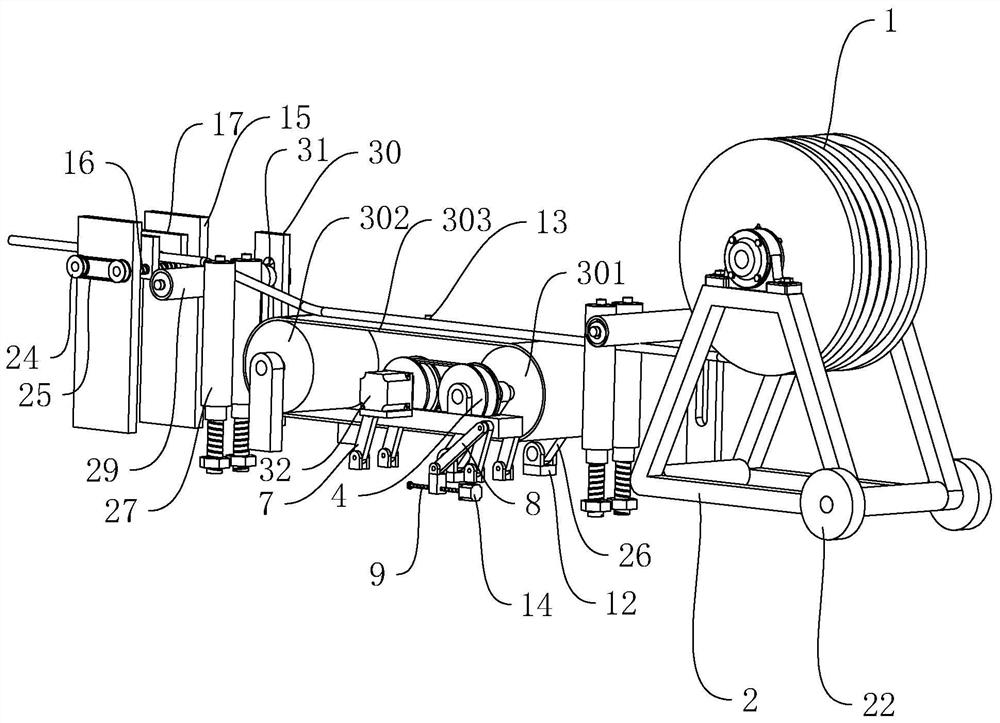

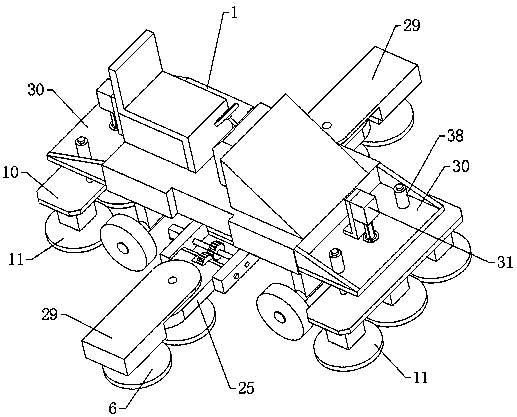

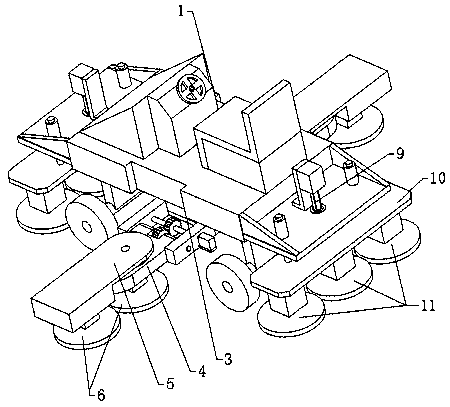

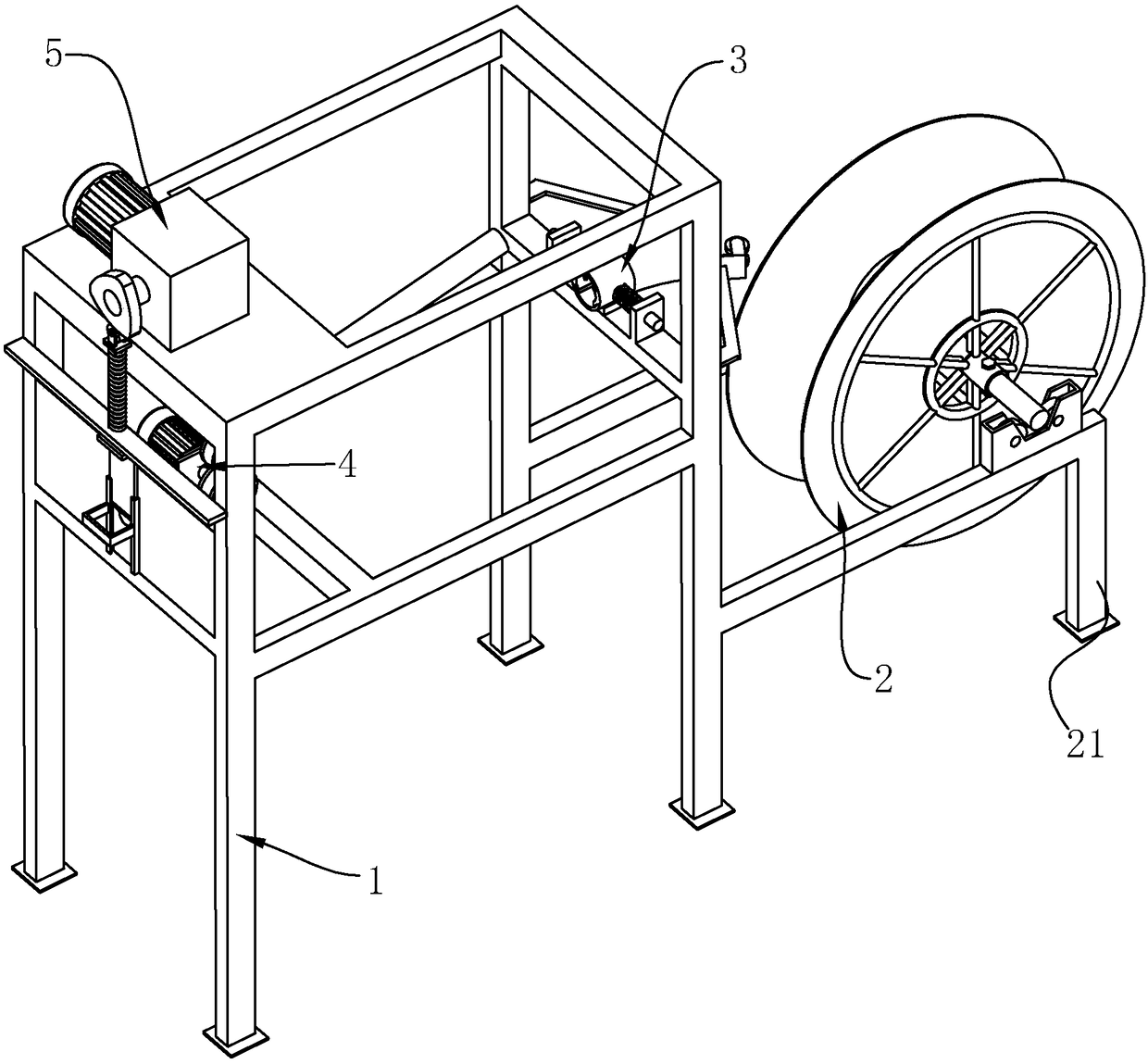

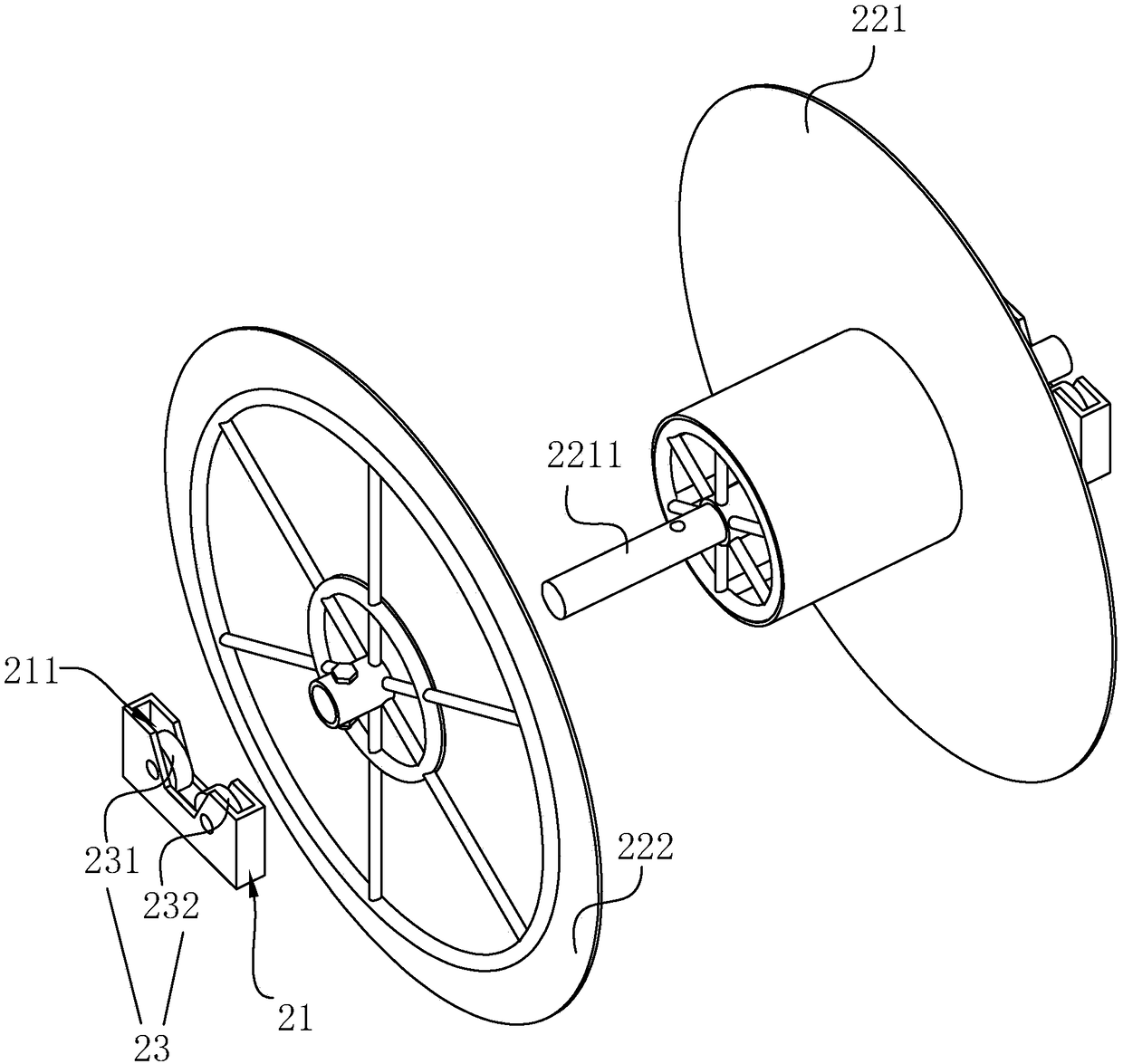

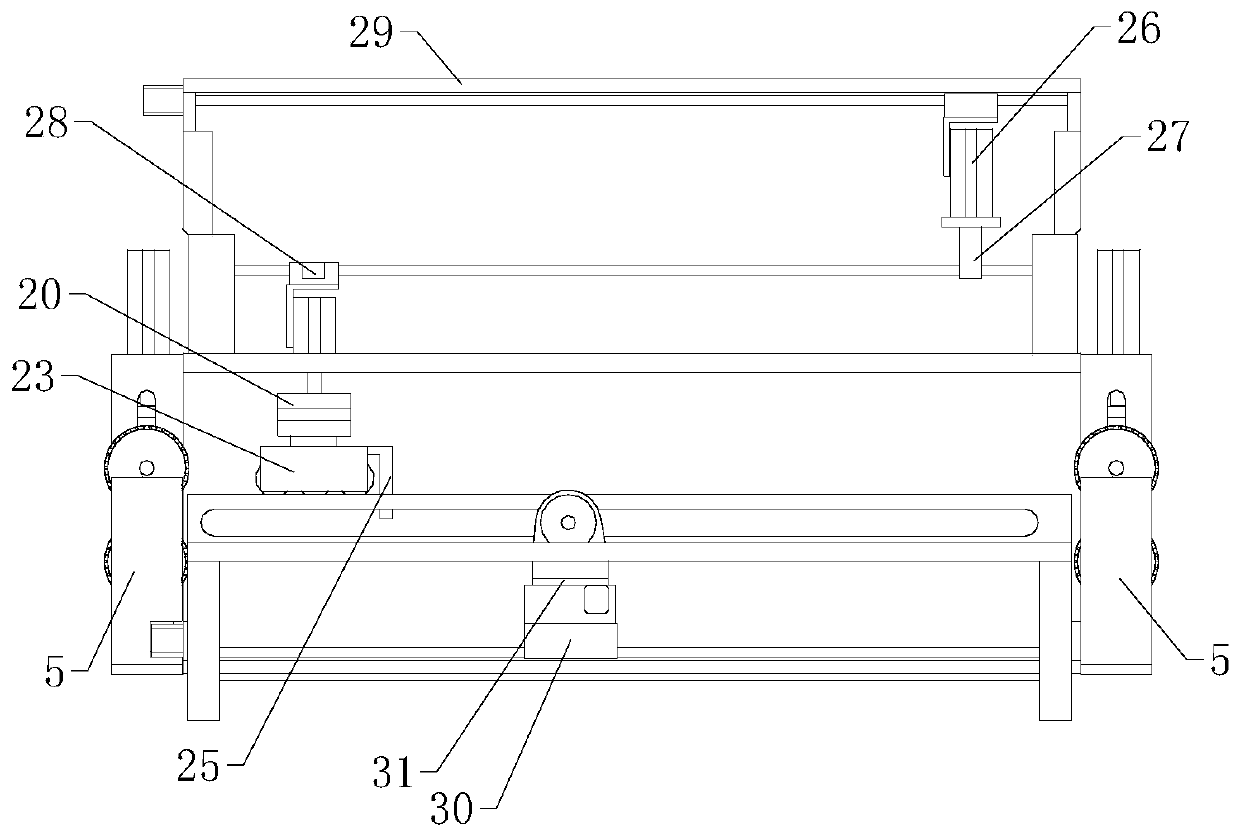

Cable laying device for electric power engineering construction and use method thereof

The invention aims to provide a cable laying device for electric power engineering construction and a use method thereof. The cable laying device comprises a cable rack and a tractor; the tractor comprises a driving wheel and a driven wheel, a belt is wound between the driving wheel and the driven wheel, a gear is fixed in the axis direction of the driving wheel, an adjusting base is fixed at thebottom of the gear, a mounting base is arranged below the adjusting base, at least four retractable rods are hinged between the adjusting base and the mounting base, an adjusting rod is hinged to oneretractable rod, a horizontally-arranged screw rod is rotationally connected into the mounting base, the end, away from the retracting rods, of the adjusting rod is in threaded connection with the screw rod, a driving mechanism for automatically driving the screw rod to rotate is fixedly mounted at the end part of the screw rod, and the driving wheel is slidably connected to the mounting base. According to the cable laying device for electric power engineering construction and the use method thereof, the problem that when cables are laid in a pipeline, due to improper traction control, the belt is prone to looseness is solved. The device has the effects of automatically adjusting the belt when the belt is loosened, reducing the conditions of belt deviation and failure and improving the construction efficiency.

Owner:广州恒泰电力工程有限公司

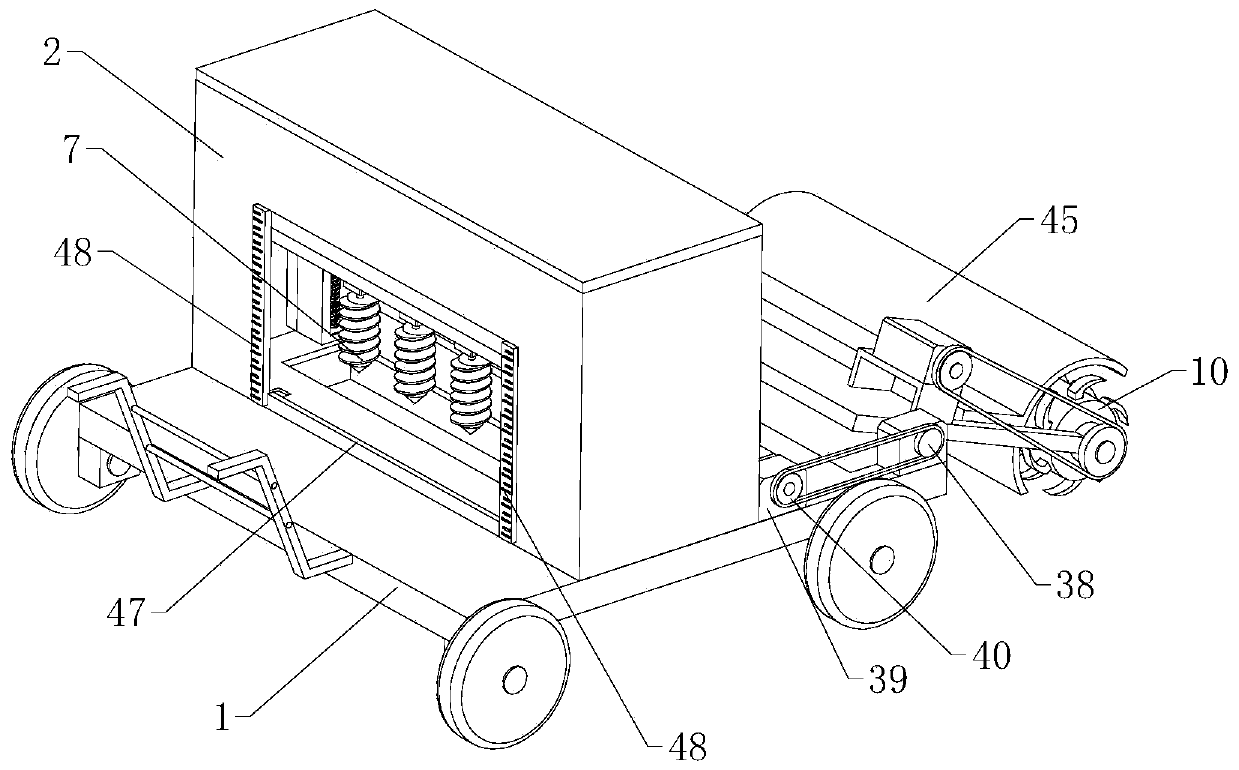

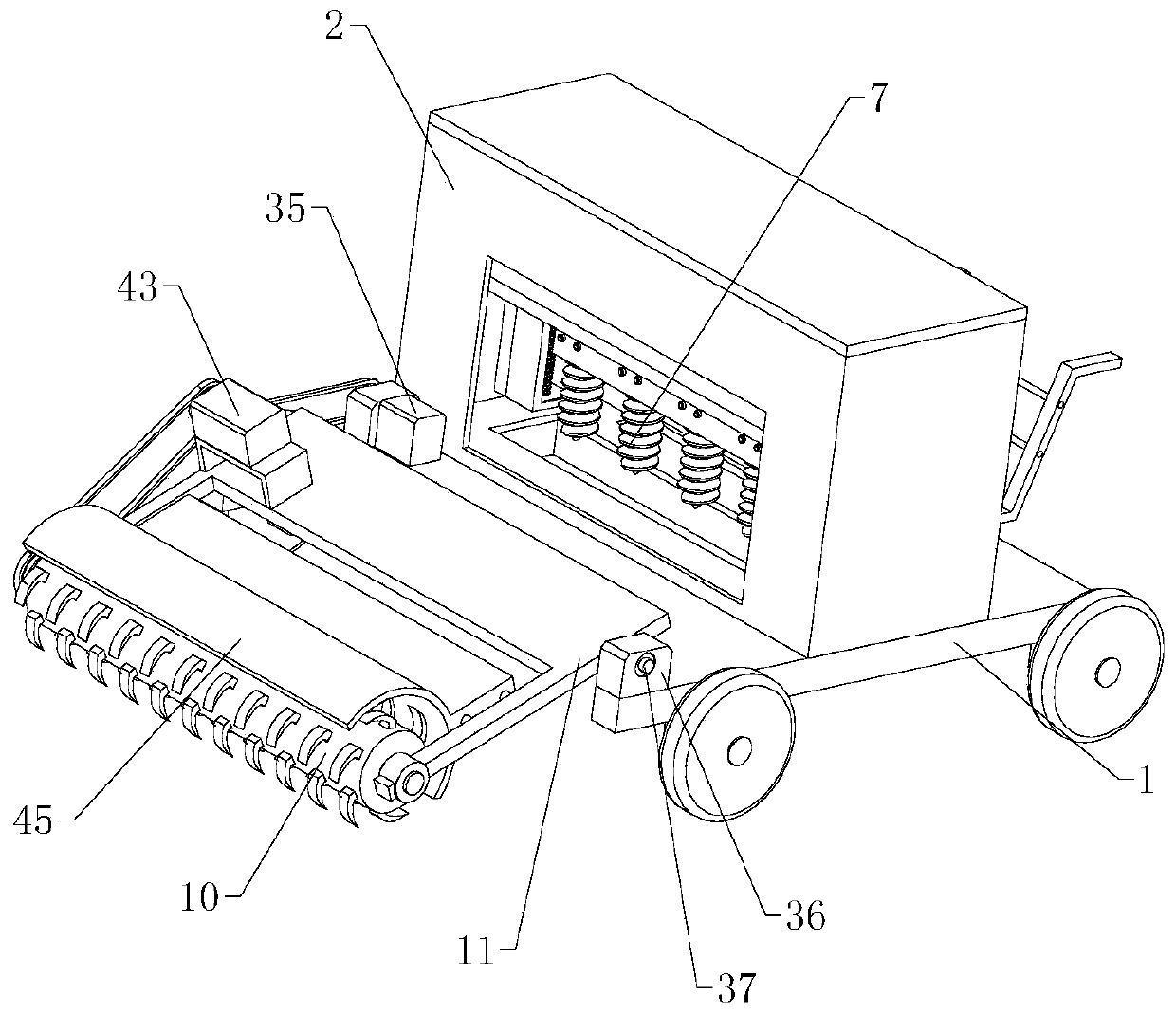

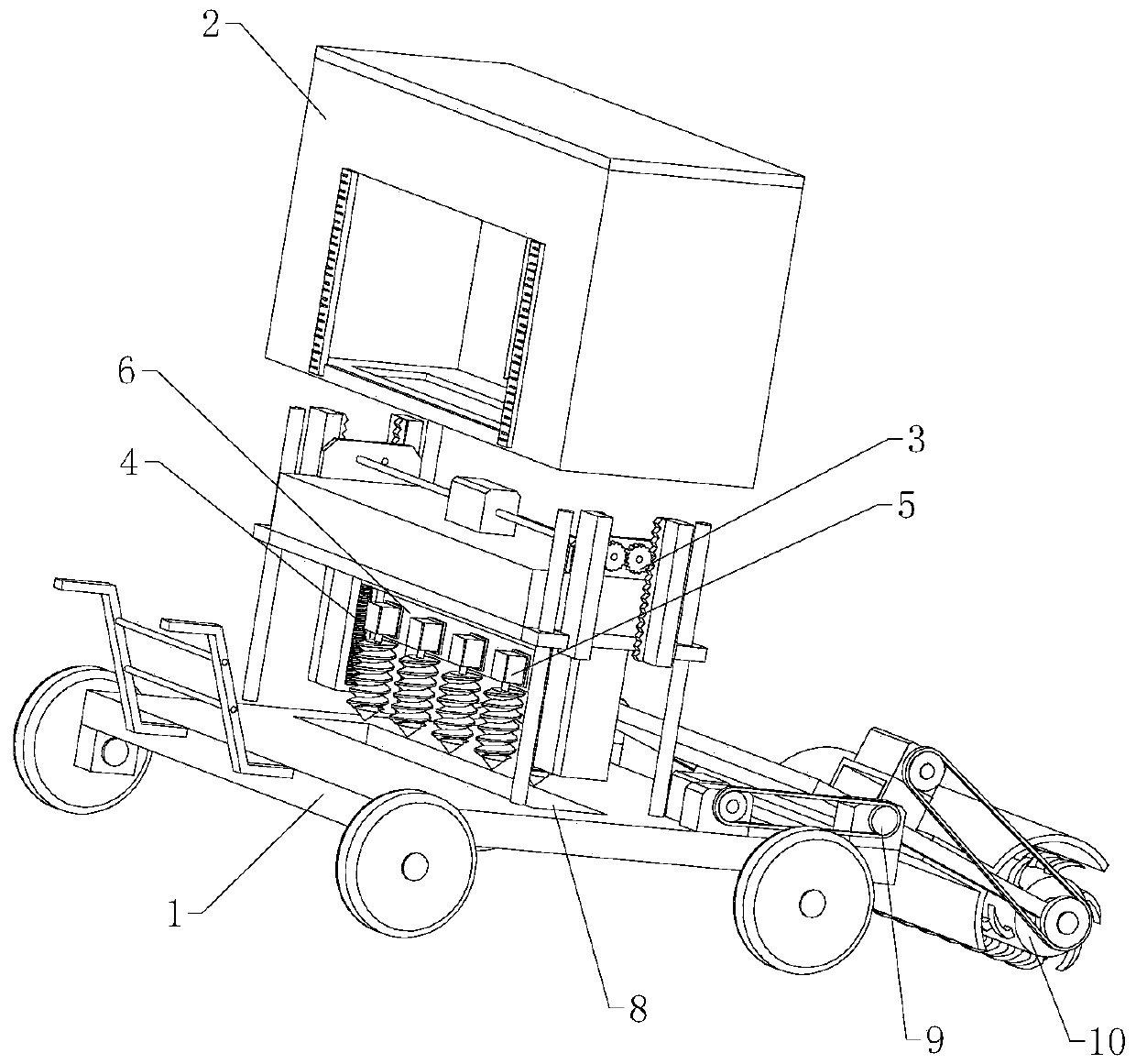

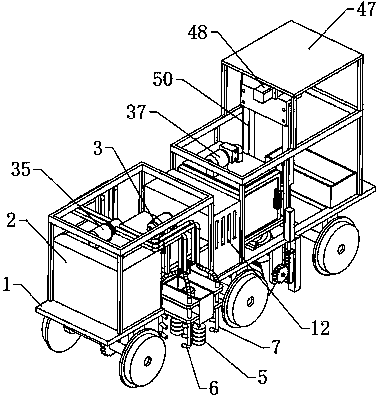

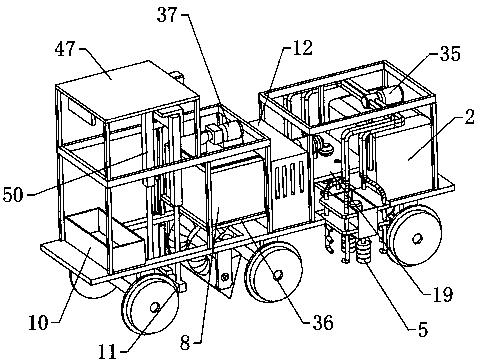

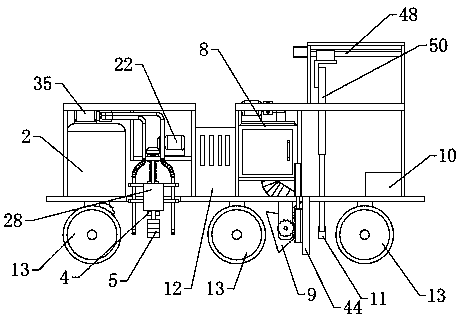

Agricultural pit digging device capable of loosening soil

InactiveCN110447328APlay the role of guide limitPrevent splashSpadesPlantingAgricultural engineeringAgricultural machinery

The invention relates to the technical field of agricultural machinery, in particular to an agricultural pit digging device capable of loosening soil. The agricultural pit digging device comprises a movable vehicle body and also comprises a soil loosening mechanism and a pit digging mechanism, wherein the pit digging mechanism comprises a pit digging box, a height adjusting assembly, a lifting assembly and a plurality of digging assemblies, the lifting assembly comprises a long lifting installation plate capable of lifting, each of the digging assemblies comprises a spiral digging shovel, andthe pit digging box and the movable vehicle body are respectively provided with a rectangular through hole for the corresponding spiral digging shovel to move, the soil loosening mechanism comprises aturnover adjusting assembly and a soil loosening roller shaft, the turnover adjusting assembly comprises a turnover support, and the turnover support is horizontal and can be arranged at one end of the movable vehicle body in a turnable mode. The agricultural pit digging device can be matched with a plurality of spiral digging shovels to dig pits according to the number of pits required, the planting efficiency is improved, soil can be loosened at the positions of the pits needing to be dug before the pits are dug, and the survival rate of crops is improved.

Owner:丽水市智汇佳科技有限公司

Marking device for road paving

The invention relates to the field of road engineering, in particular to a marking device for road paving. The marking device comprises a mobile bottom plate and also comprises a stirring mechanism and a double-side marking mechanism. The bottom of the mobile bottom plate is provided with four swivel wheels; the stirring mechanism comprises a supporting platform and a stirring tank; the stirring tank is fixedly connected to the top of the supporting platform through a second support frame; the top of the stirring tank is provided with a feeding pipe; the bottom of the stirring tank is providedwith a material guiding pipe; the double-side marking mechanism comprises a synchronous driving assembly, two telescopic assemblies and two lifting and marking assemblies; each of the lifting assemblies comprises a spraying pipe capable of lifting and lowering; working ends of the spraying pipes are arranged downwards; and the inner ends of the spraying pipes are separately and fixedly connectedto the material guiding pipe through guiding hoses. The marking device for road paving can simultaneously perform marking on two sides of a road, and perform adjustment according to the width of the road. Through the cooperation with stirring, the marking device can prevent powder from knotting and improve the clarity of markings.

Owner:倪晋挺

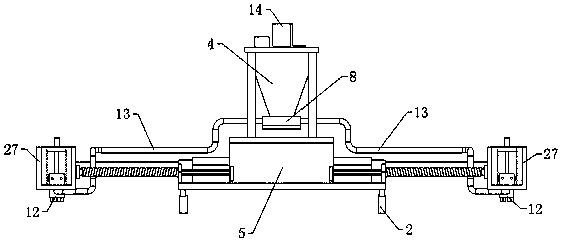

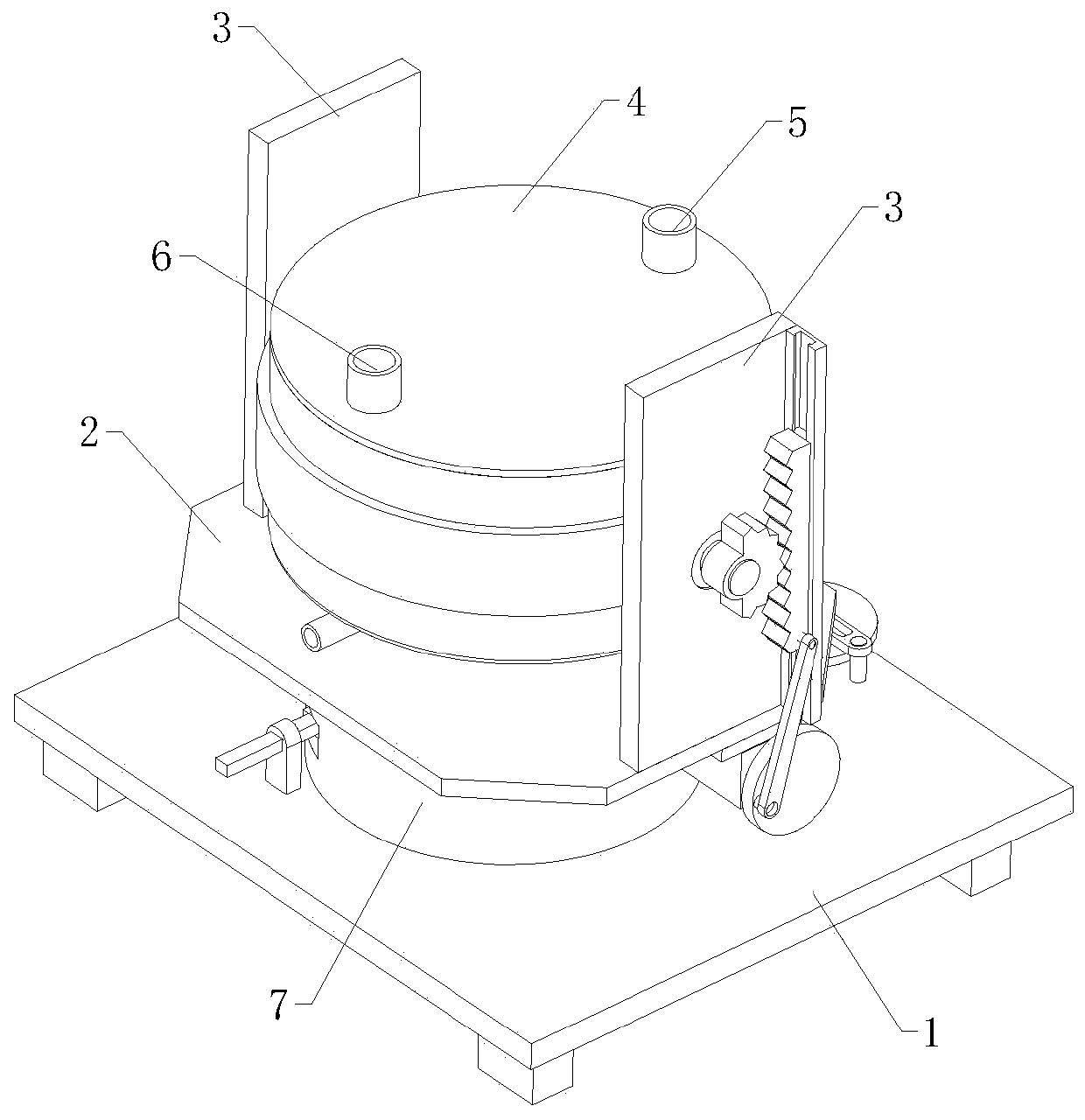

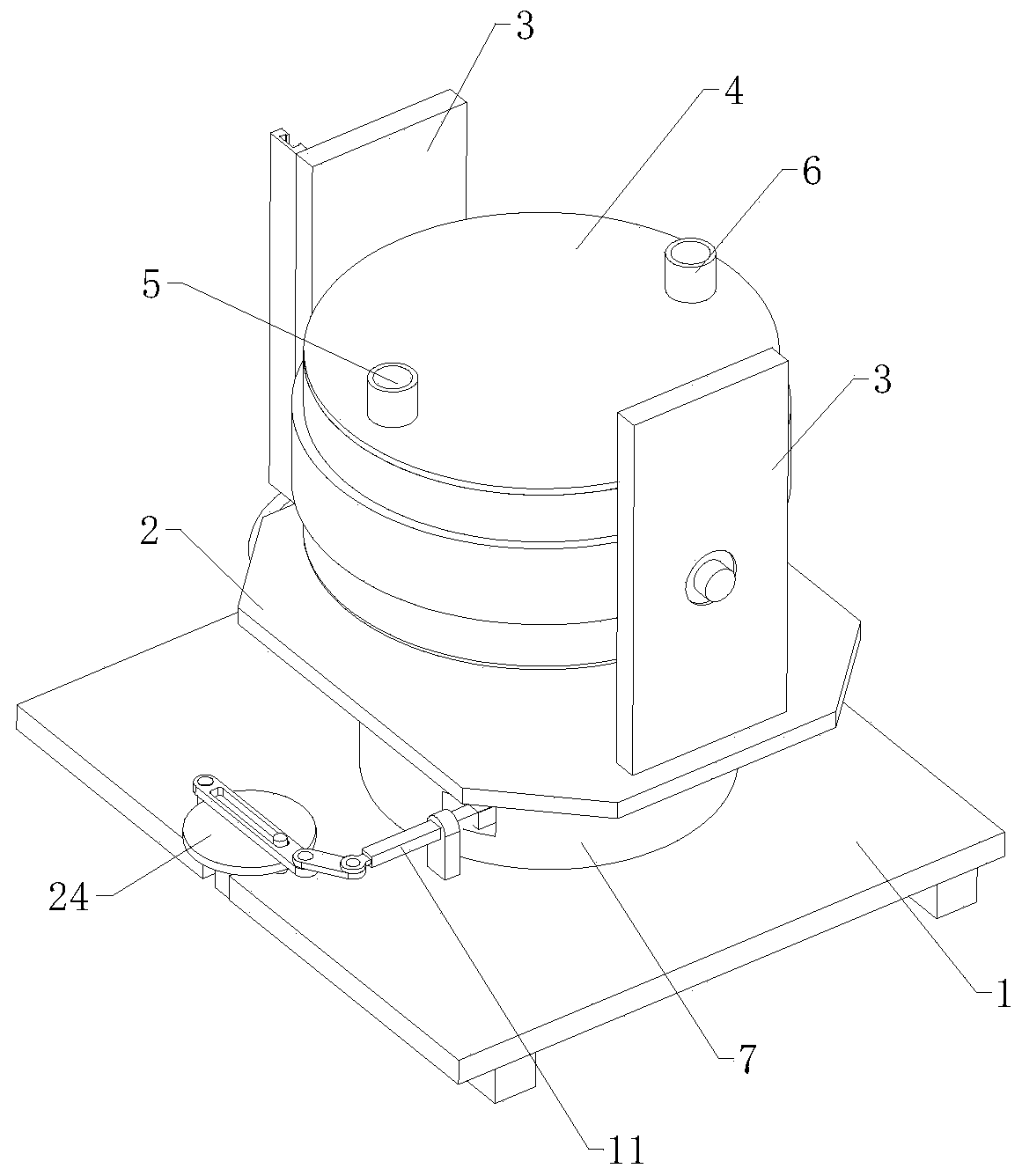

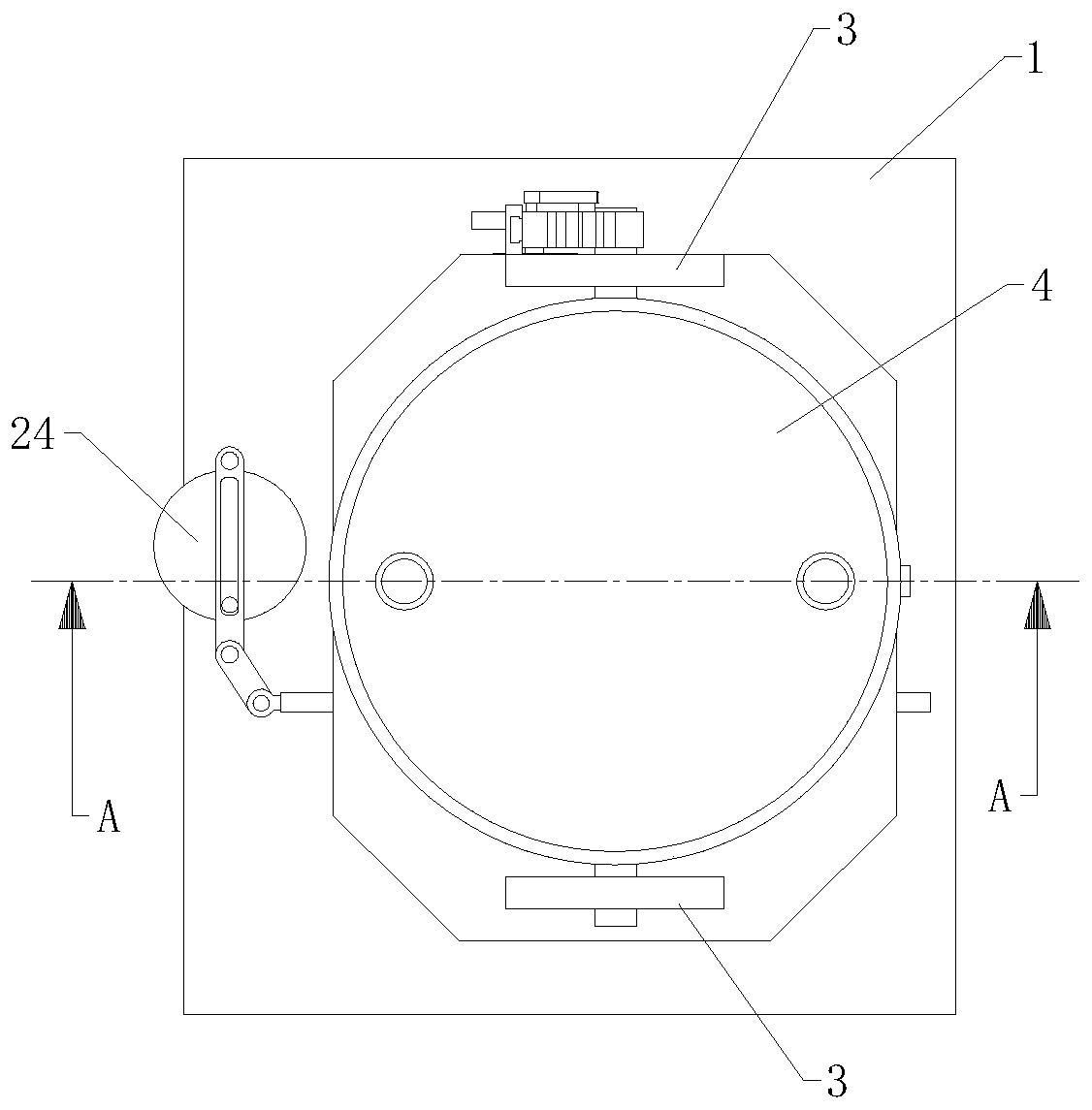

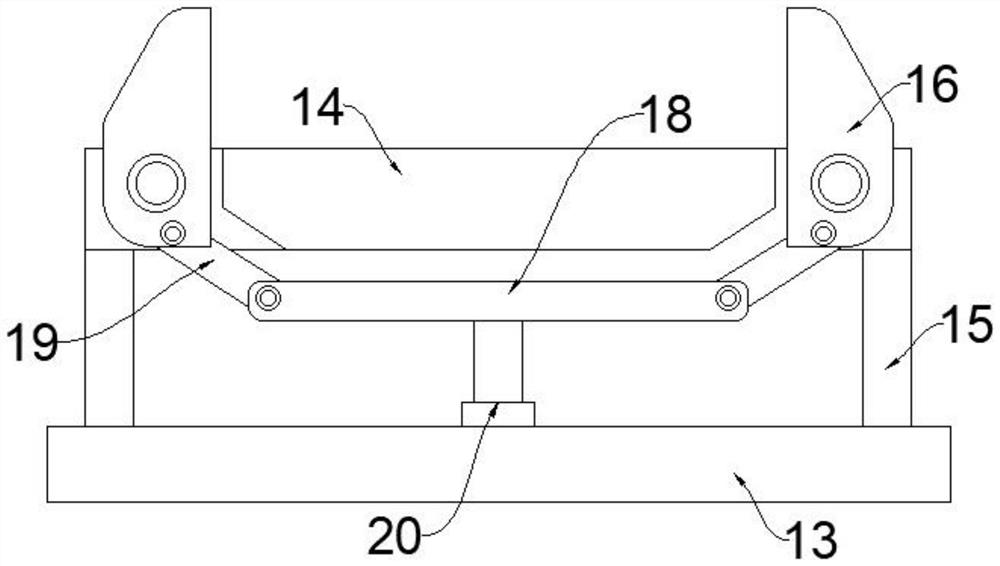

Surface deburring device for manufacturing bearing steel balls

ActiveCN110355680APlay the role of guide limitImprove grinding efficiencyEdge grinding machinesGrinding carriagesSteel ballEngineering

The invention relates to the field of bearing steel ball processing, in particular to a surface deburring device for manufacturing bearing steel balls. The surface deburring device comprises a base and further comprises a grinding mechanism, a rocking mechanism and a horizontal swinging mechanism; the horizontal swinging mechanism comprises a rotating plate capable of doing positive and negative reciprocated motion in the horizontal state, and the rotating plate is horizontally arranged above the base; the rocking mechanism includes two connecting vertical plates, and the two connecting vertical plates are symmetric and are arranged at the top of the rotating plate in a spaced manner; and the grinding mechanism includes a grinding pot, the two ends of the grinding pot are movably arrangedbetween the two connecting vertical plates through a rotating shaft, the inside of the grinding pot is provided with a discharging assembly, and the top of the grinding tank is provided with a liquidinlet pipe and a feeding pipe. The surface deburring device can comprehensively conduct deburring on the steel balls in a large batch, and therefore the deburring efficiency is improved.

Owner:宁波奉化精瑞钢球有限公司

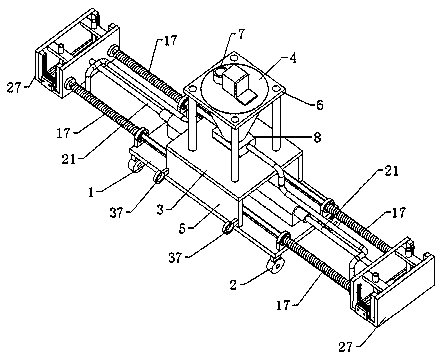

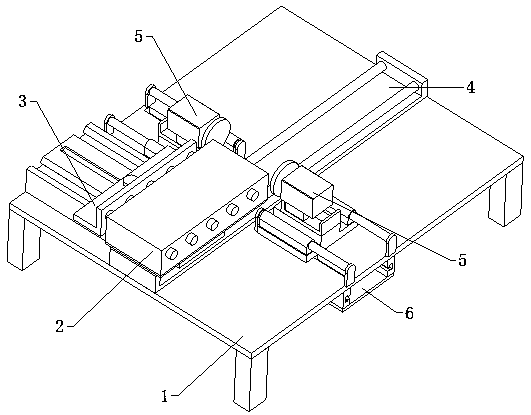

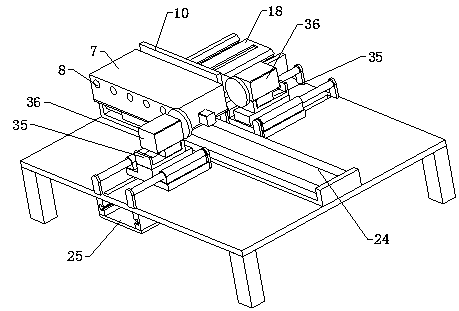

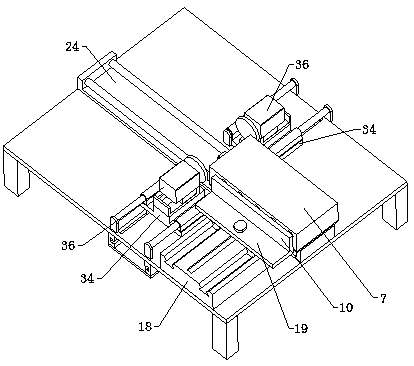

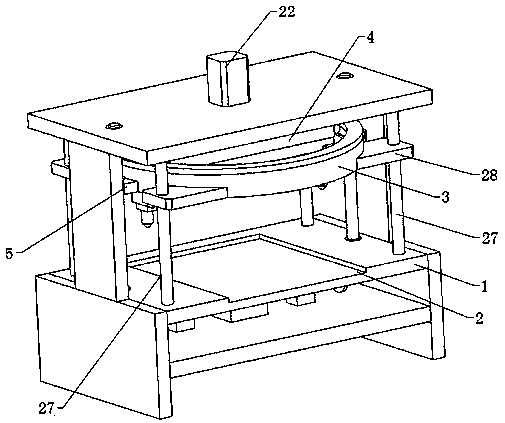

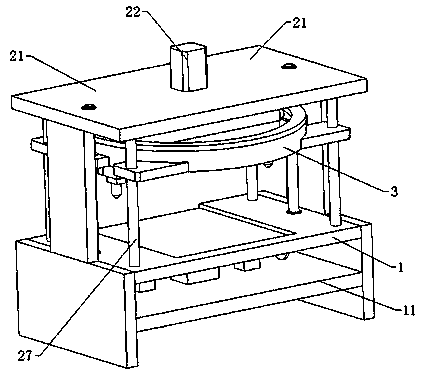

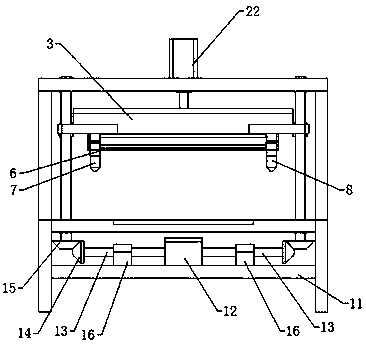

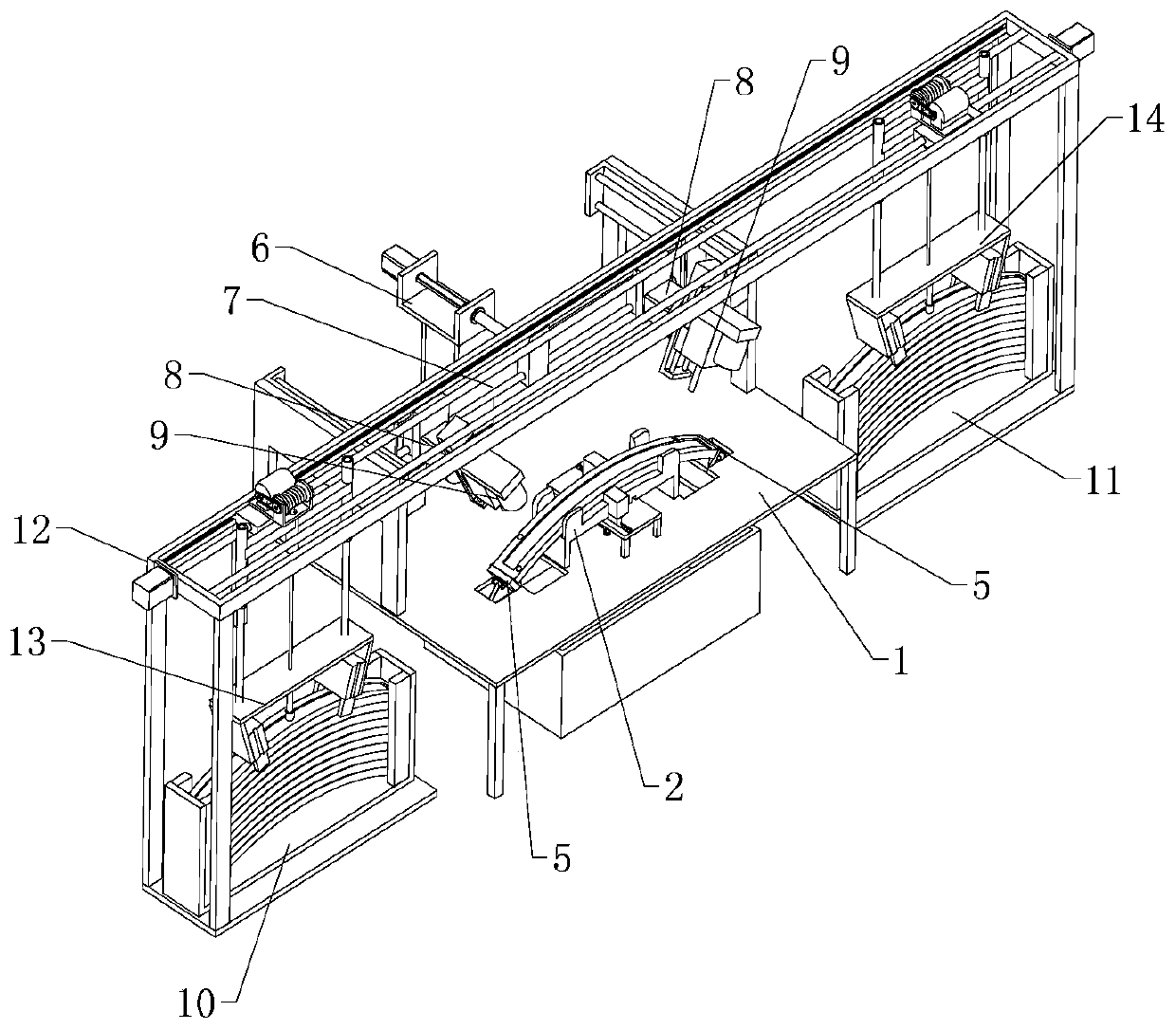

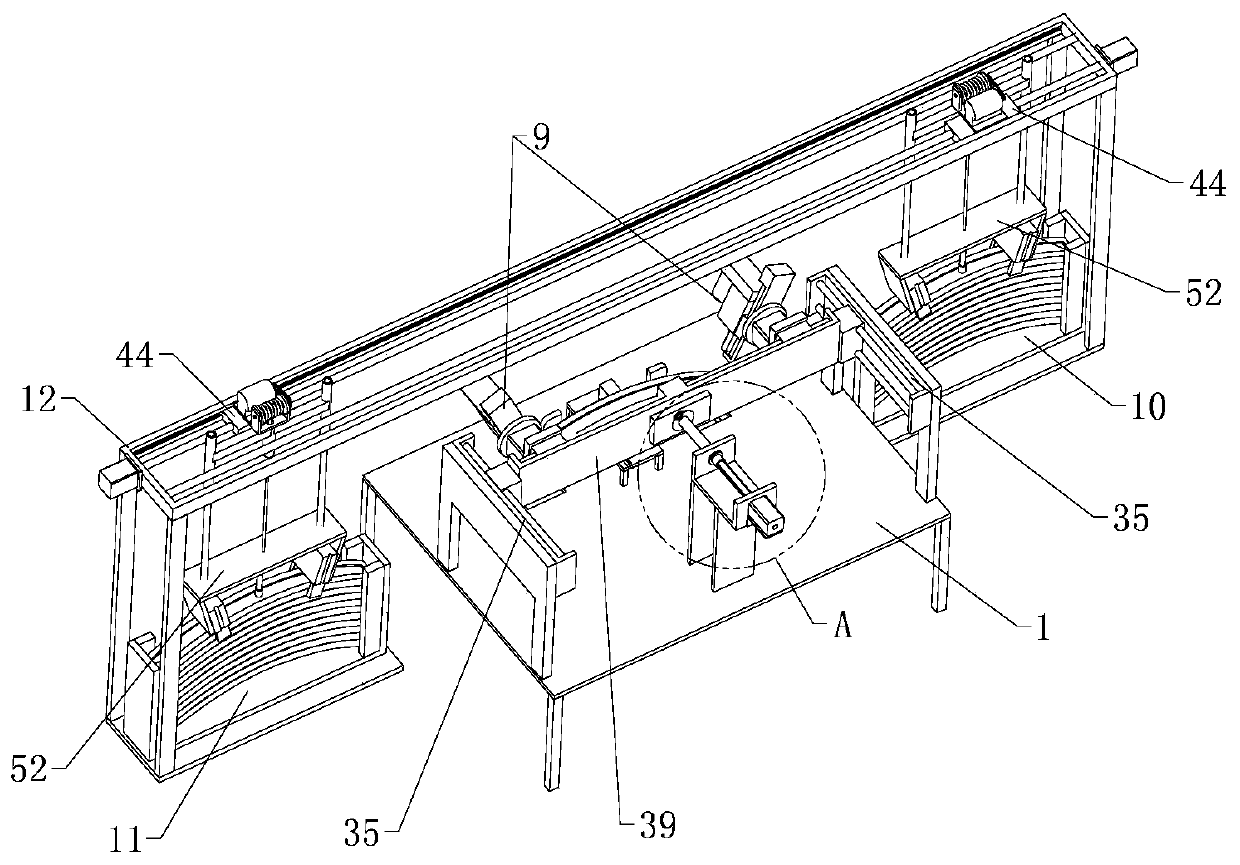

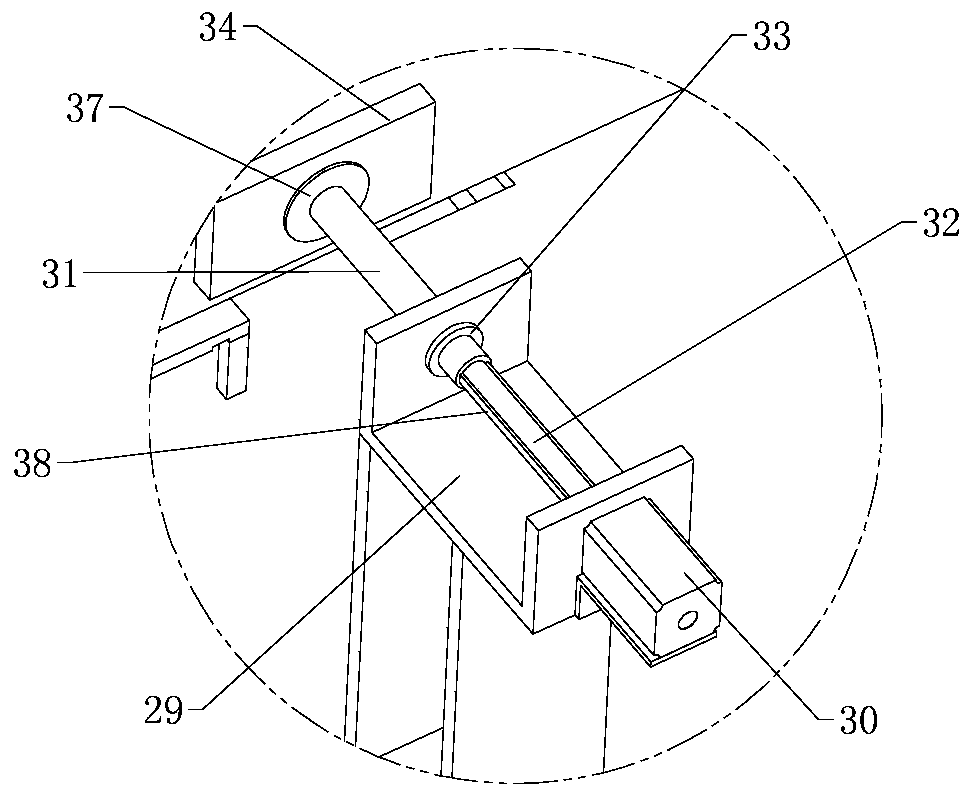

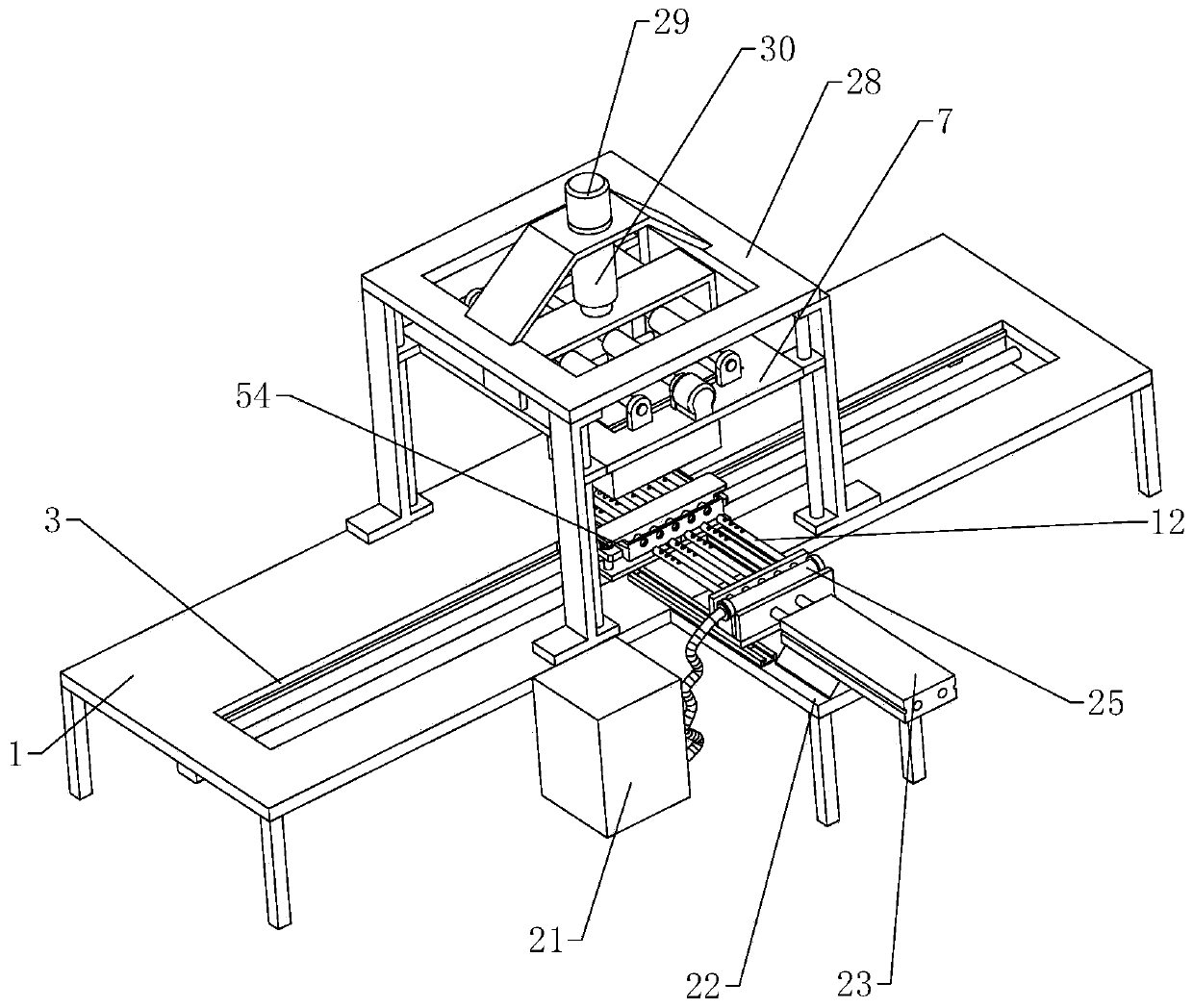

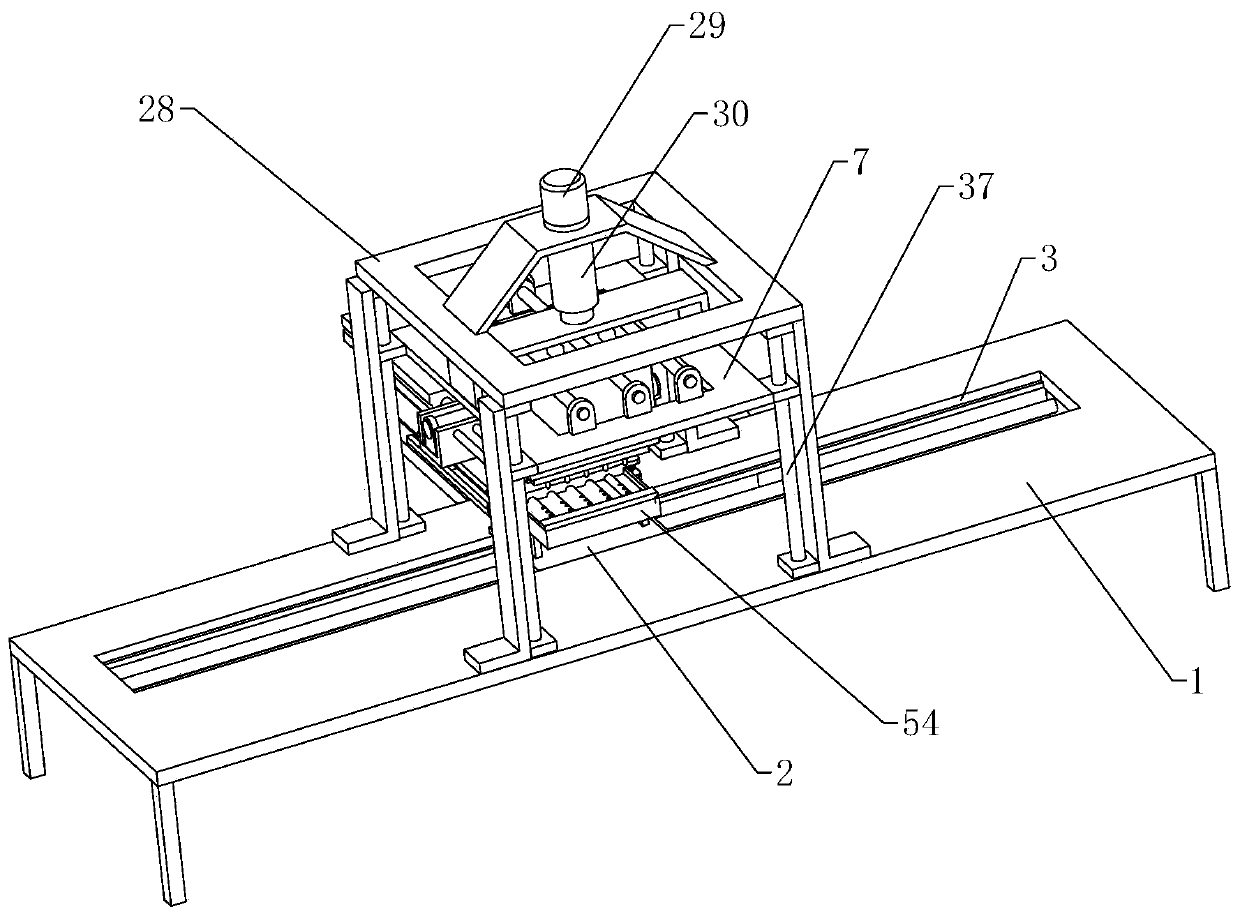

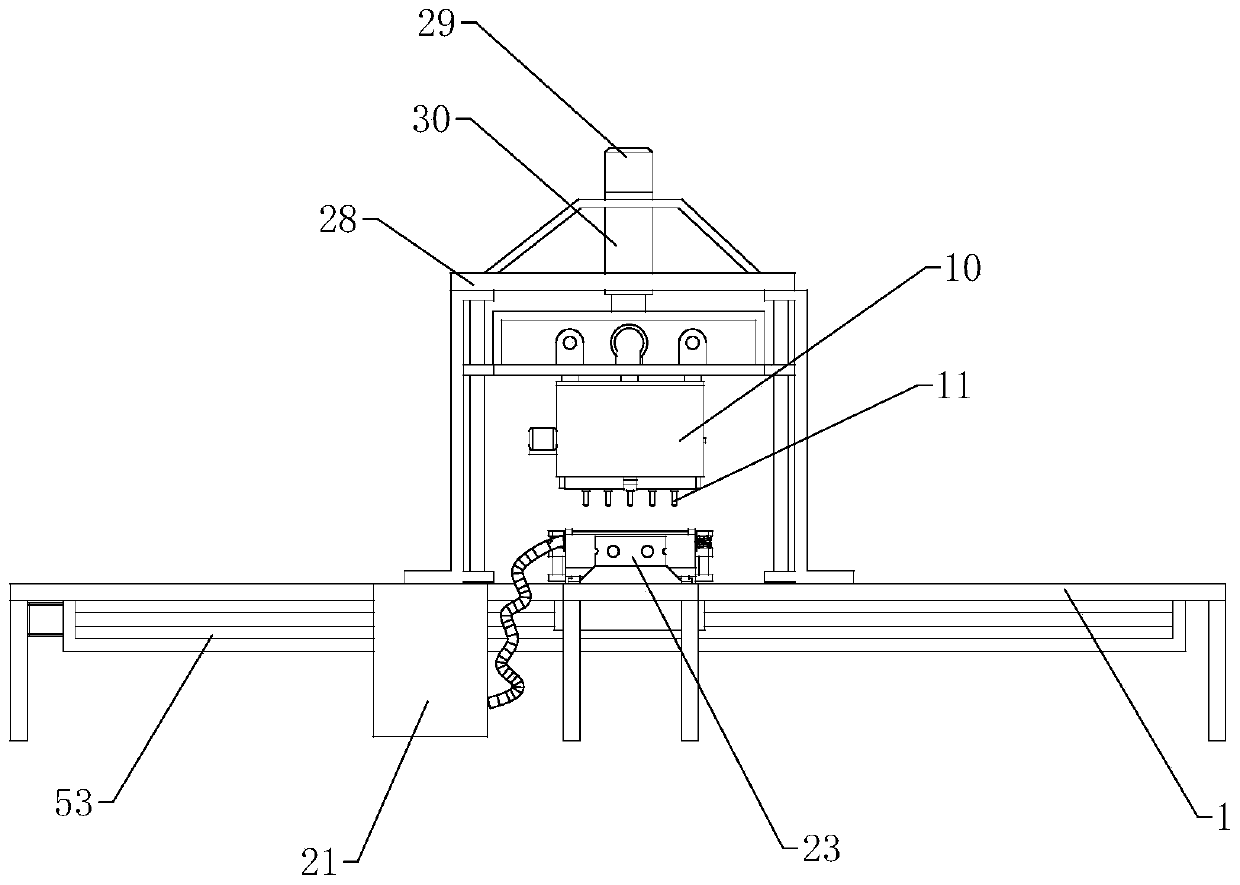

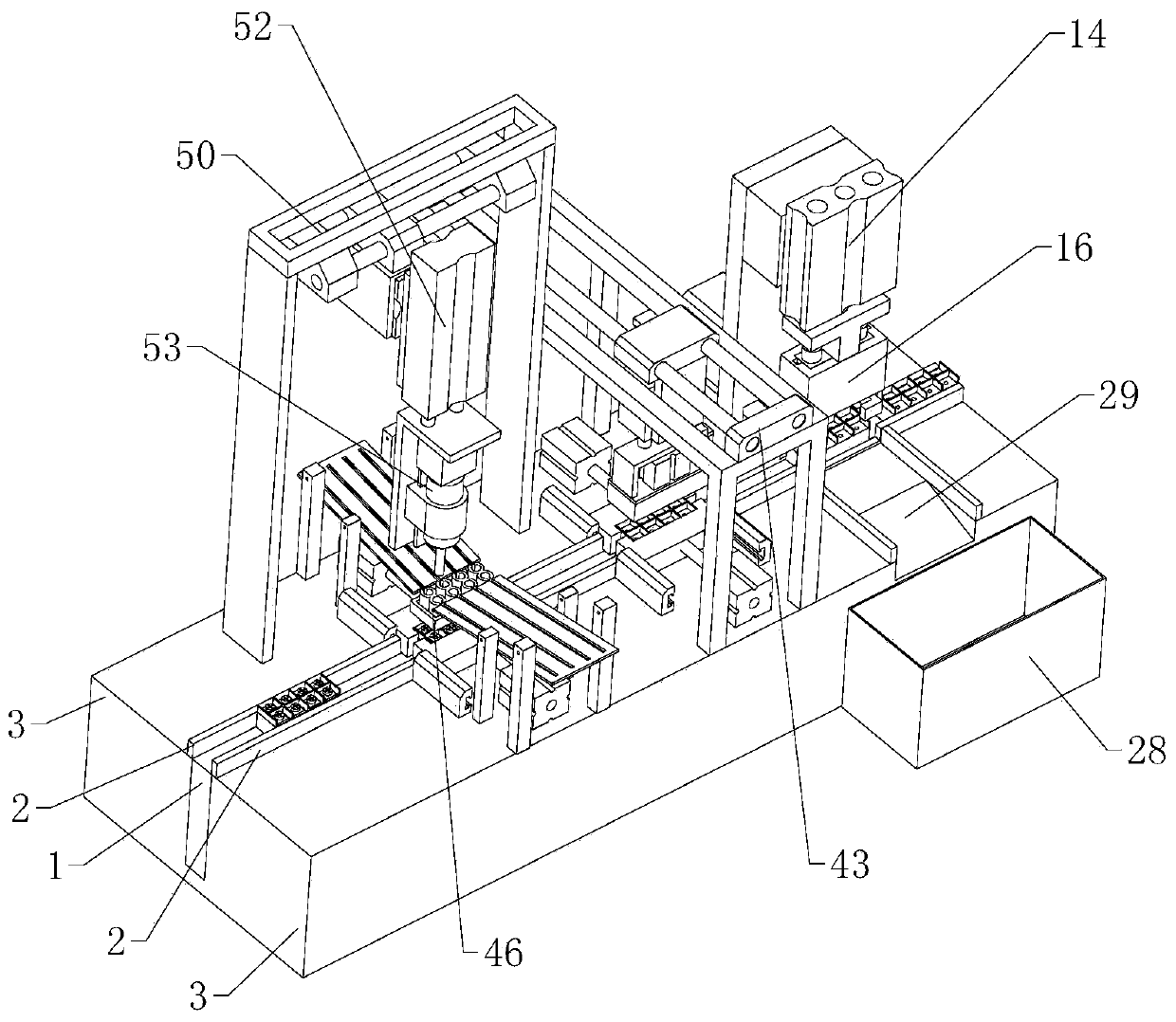

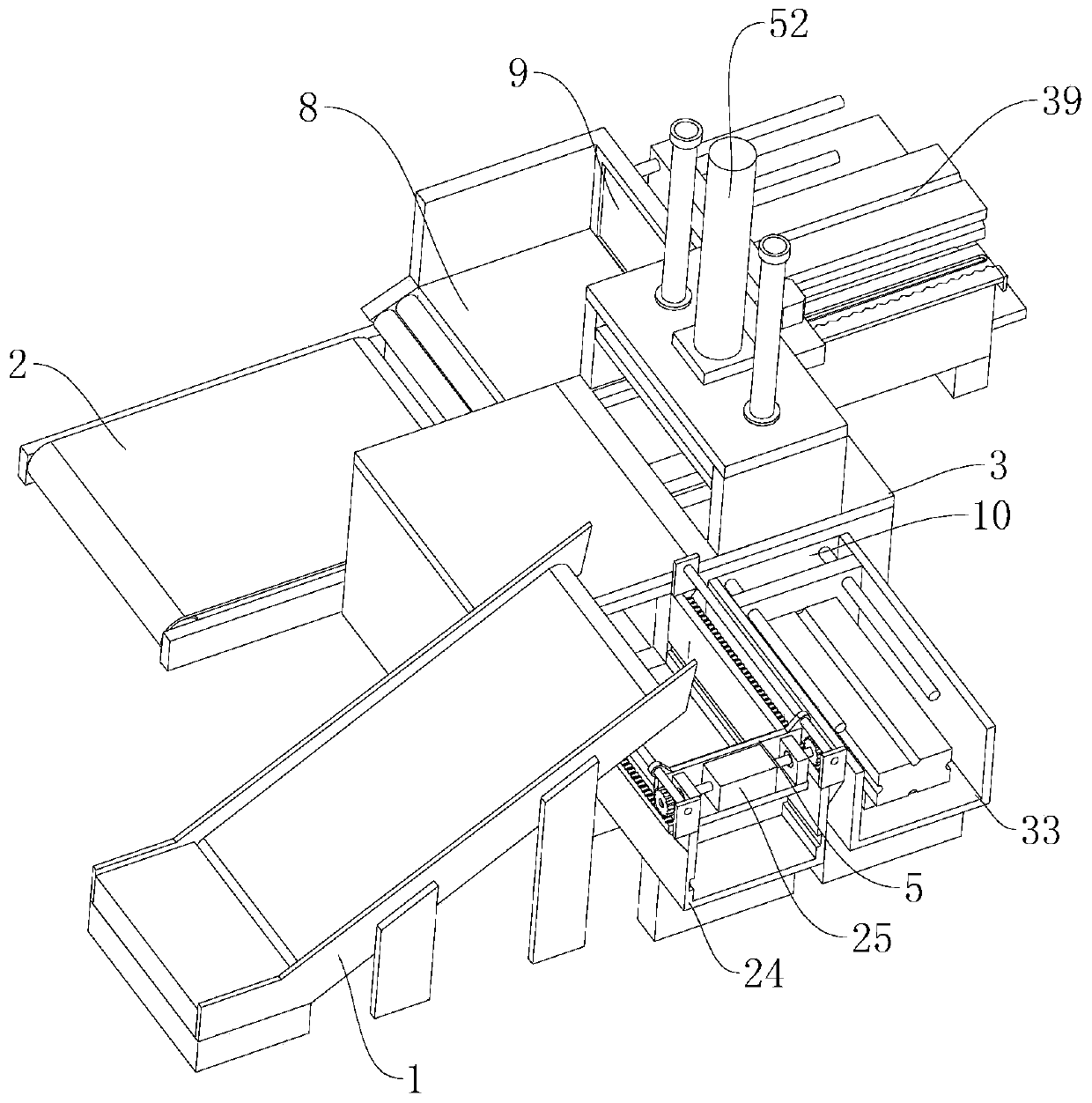

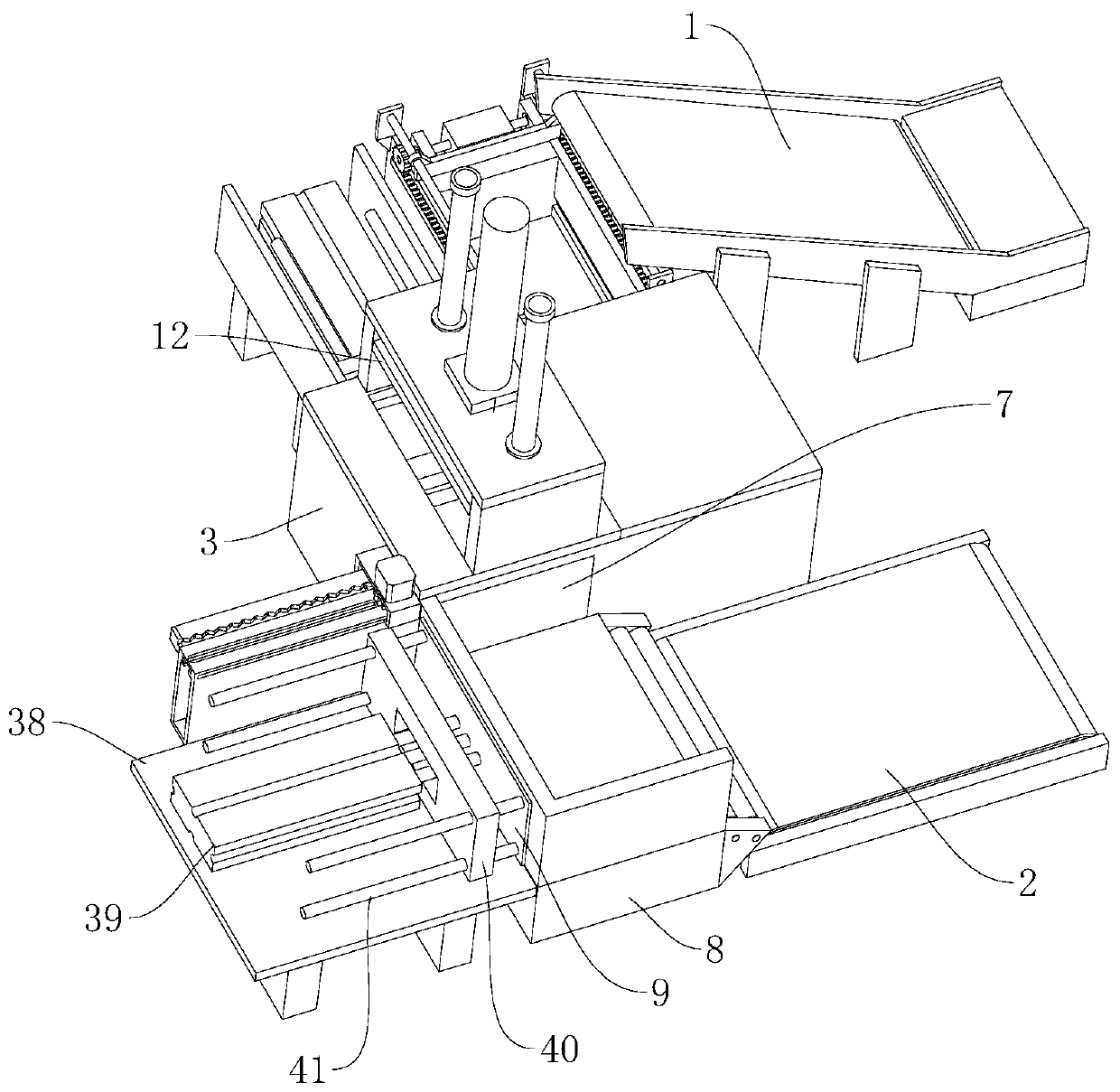

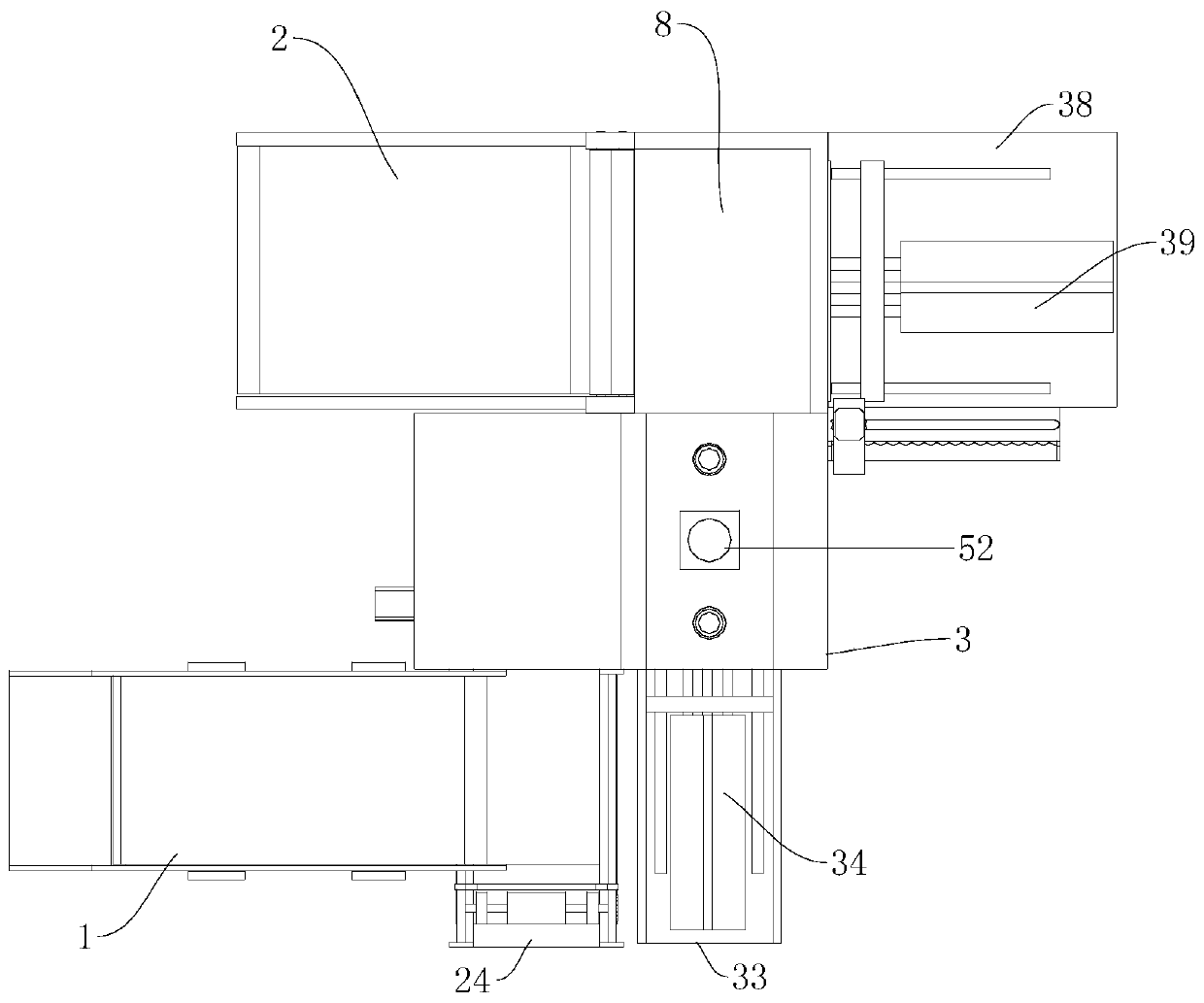

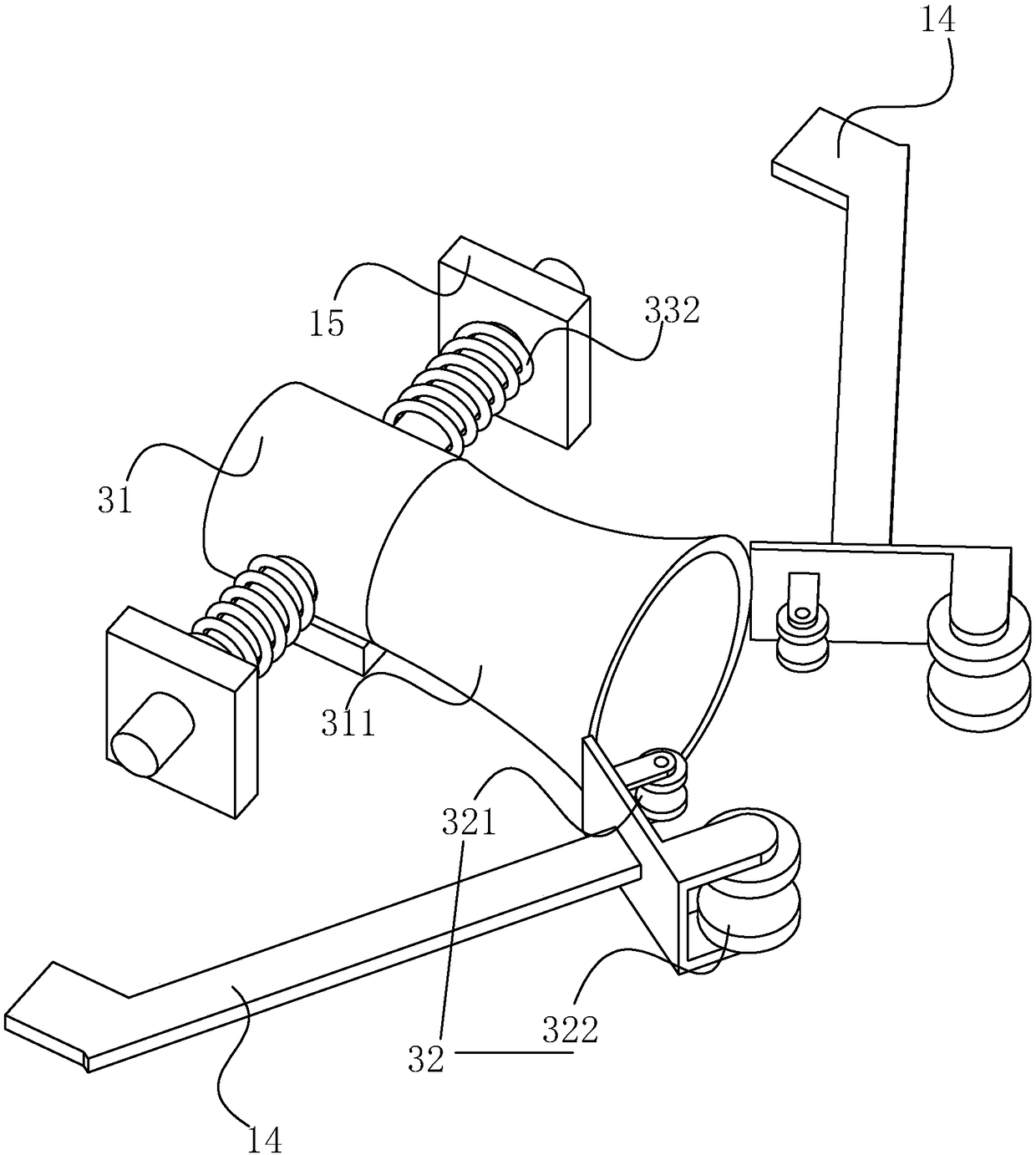

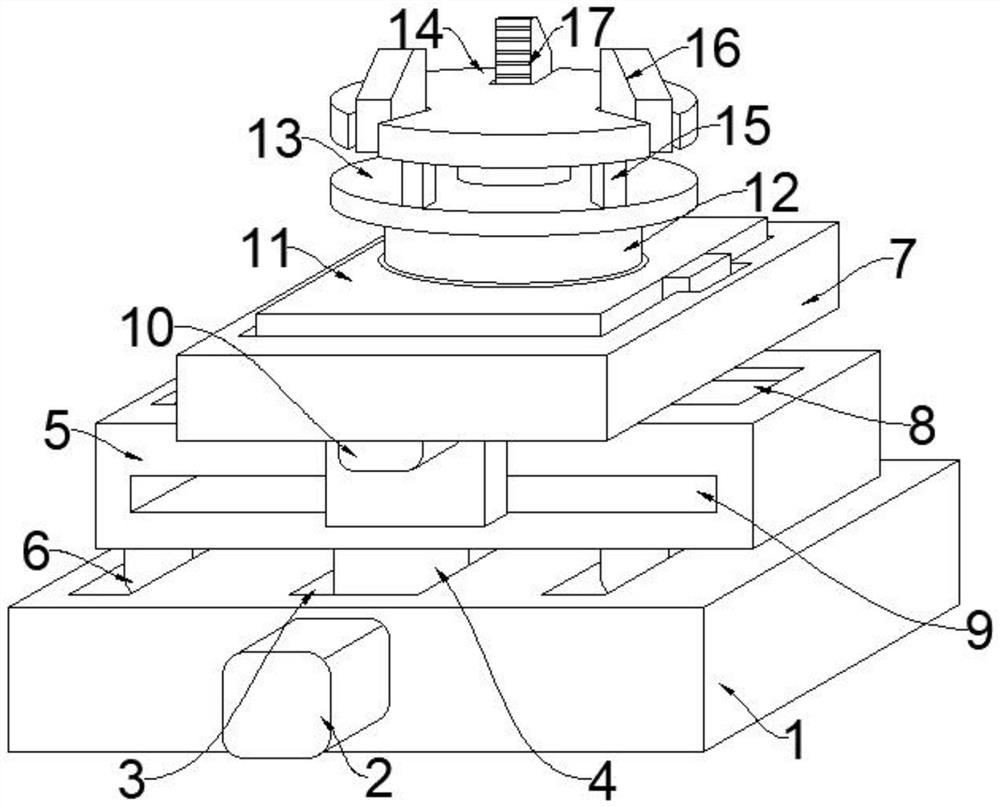

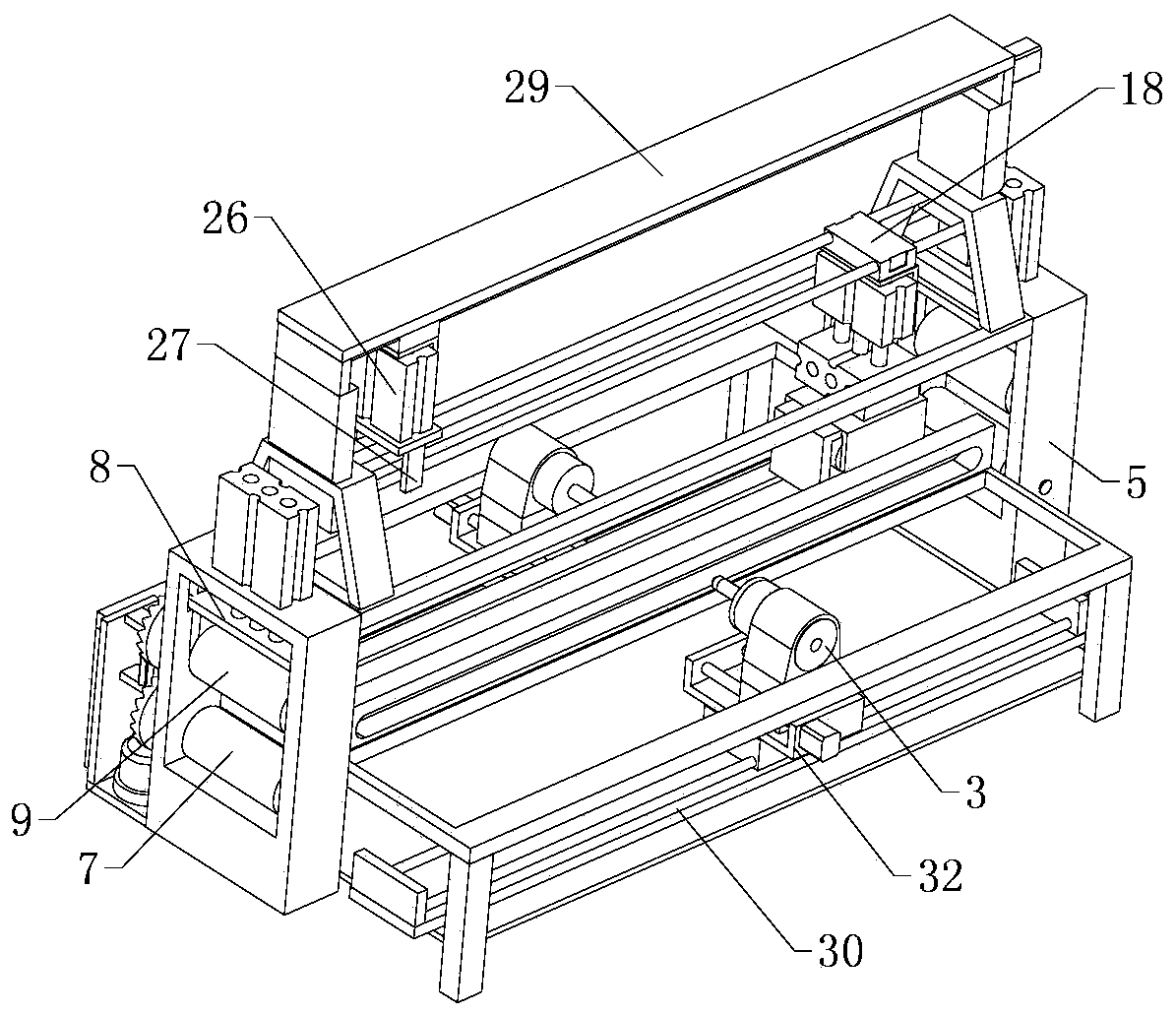

Shaft workpiece end part grinding device

InactiveCN110421427APlay the role of limit movementPlay the role of guide limitGrinding drivesGrinding work supportsEngineeringTransfer mechanism

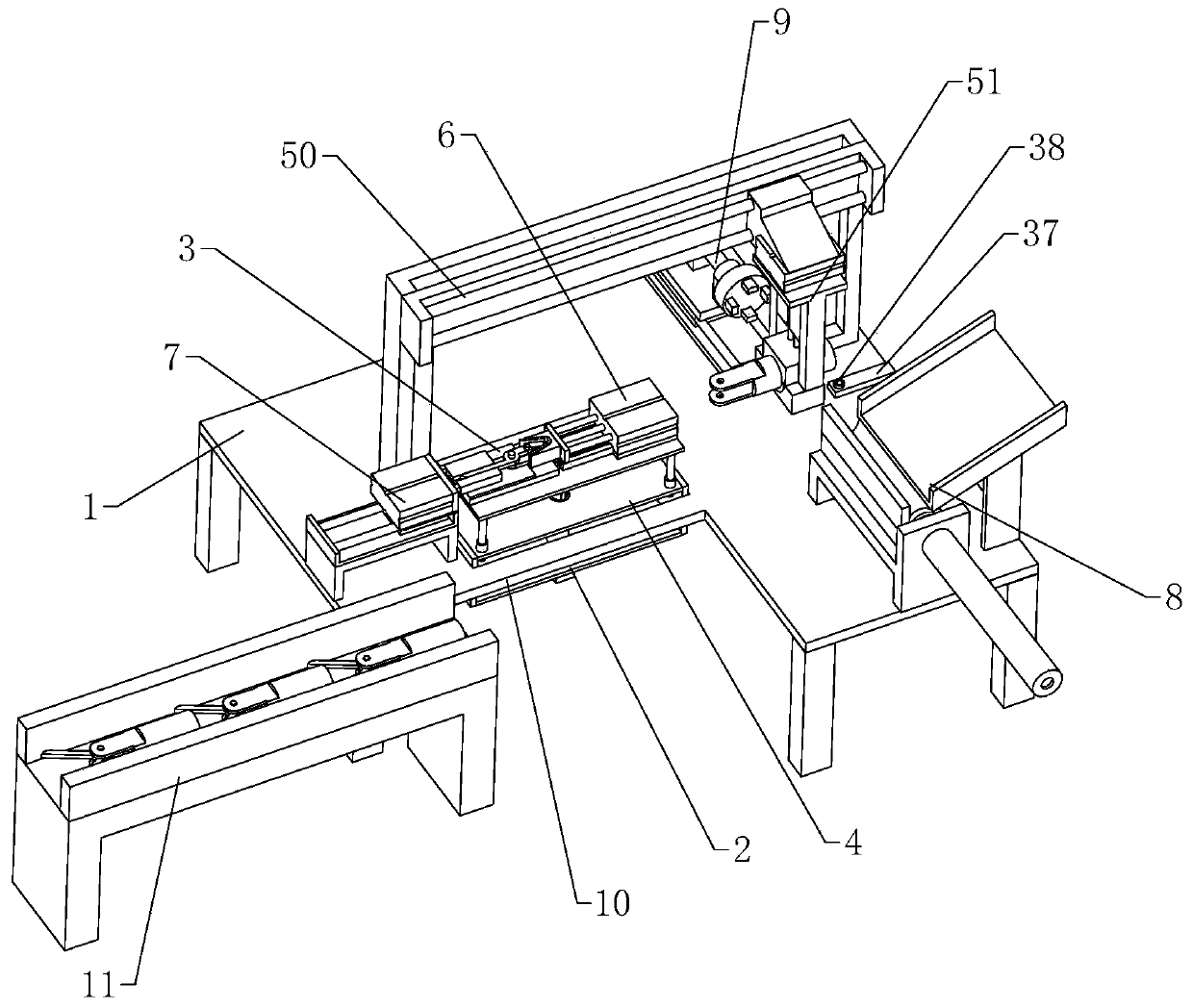

The invention relates to the field of shaft workpiece machining, in particular to a shaft workpiece end part grinding device. The device comprises a workbench, and further comprises a material discharging and transferring mechanism and a grinding mechanism, wherein the material discharging and transferring mechanism comprises a material discharging and clamping assembly, a positioning assembly anda horizontal material transferring assembly, the material discharging and clamping assembly comprises a material discharging bin, a plurality of containing penetrating holes are formed in one side ofthe material discharging bin, one side of the interior of each containing penetrating hole is provided with an abutting pressing block capable of abutting against a shaft workpiece, the positioning assembly comprises a positioning baffle plate, the grinding mechanism comprises two grinding assemblies and a opposite direction driving assembly, the two grinding assemblies are symmetrically arrangedon the two sides of the center of the horizontal material transferring assembly, the opposite direction driving assembly is positioned at the bottom of the workbench, and the interiors of the two grinding assemblies penetrate through the top of the workbench and are fixedly connected with the working end of the opposite direction driving assembly. The device can grind shaft workpieces with different lengths, and can simultaneously grind the two ends of several shaft workpieces, so that the efficiency is improved.

Owner:云和县凯毅德电子设备厂

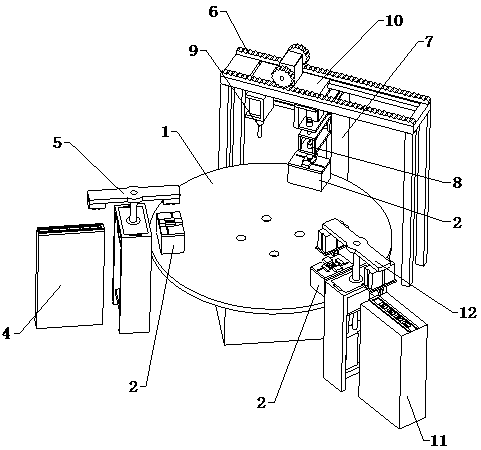

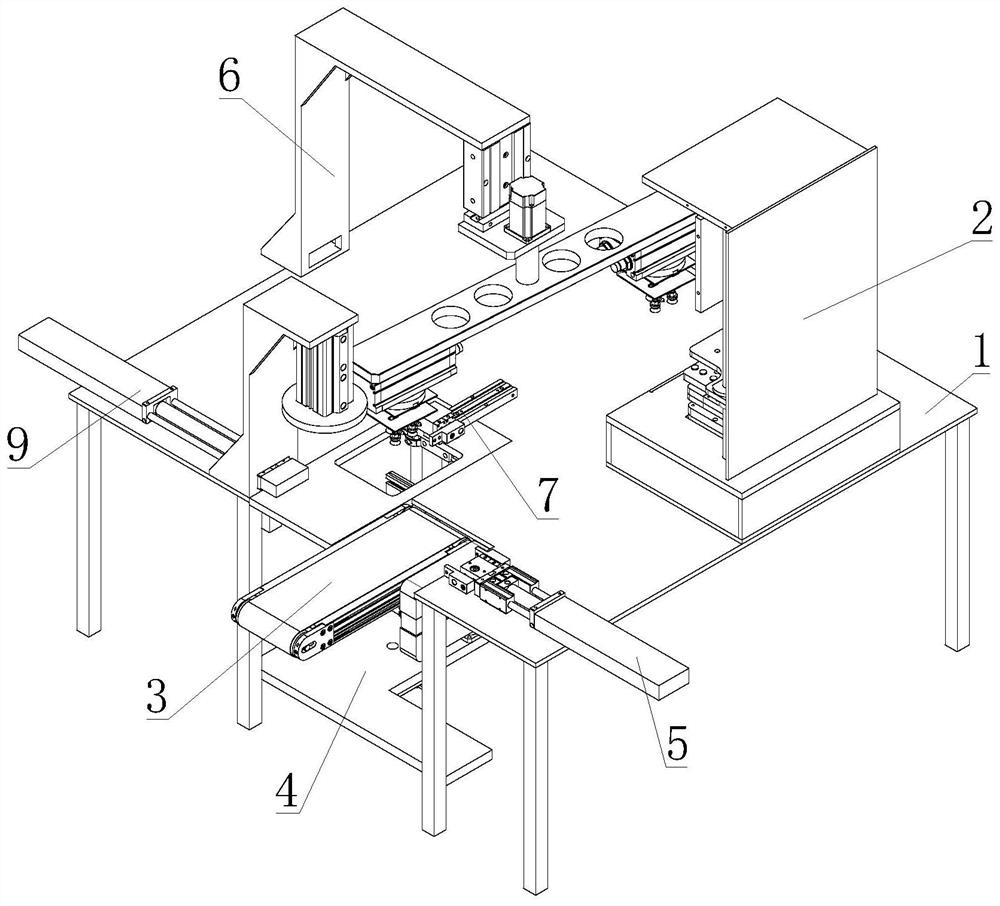

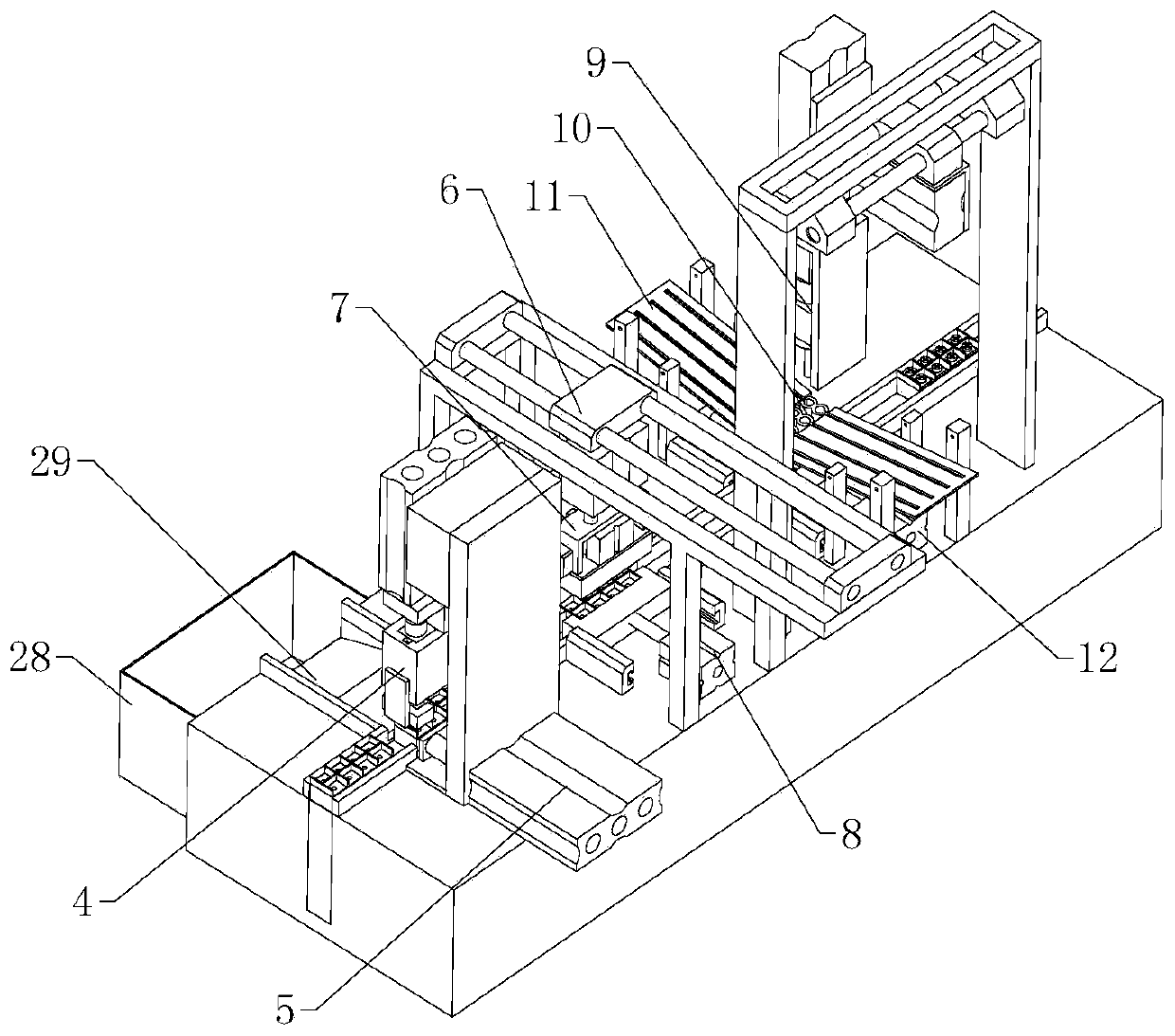

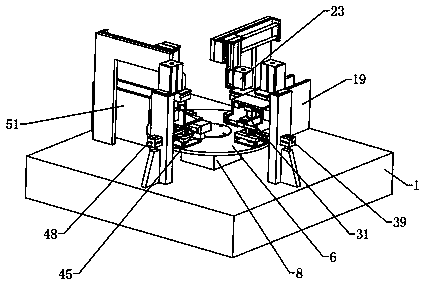

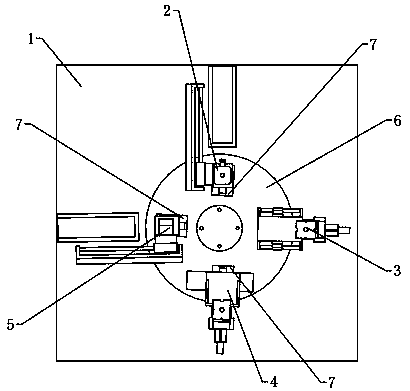

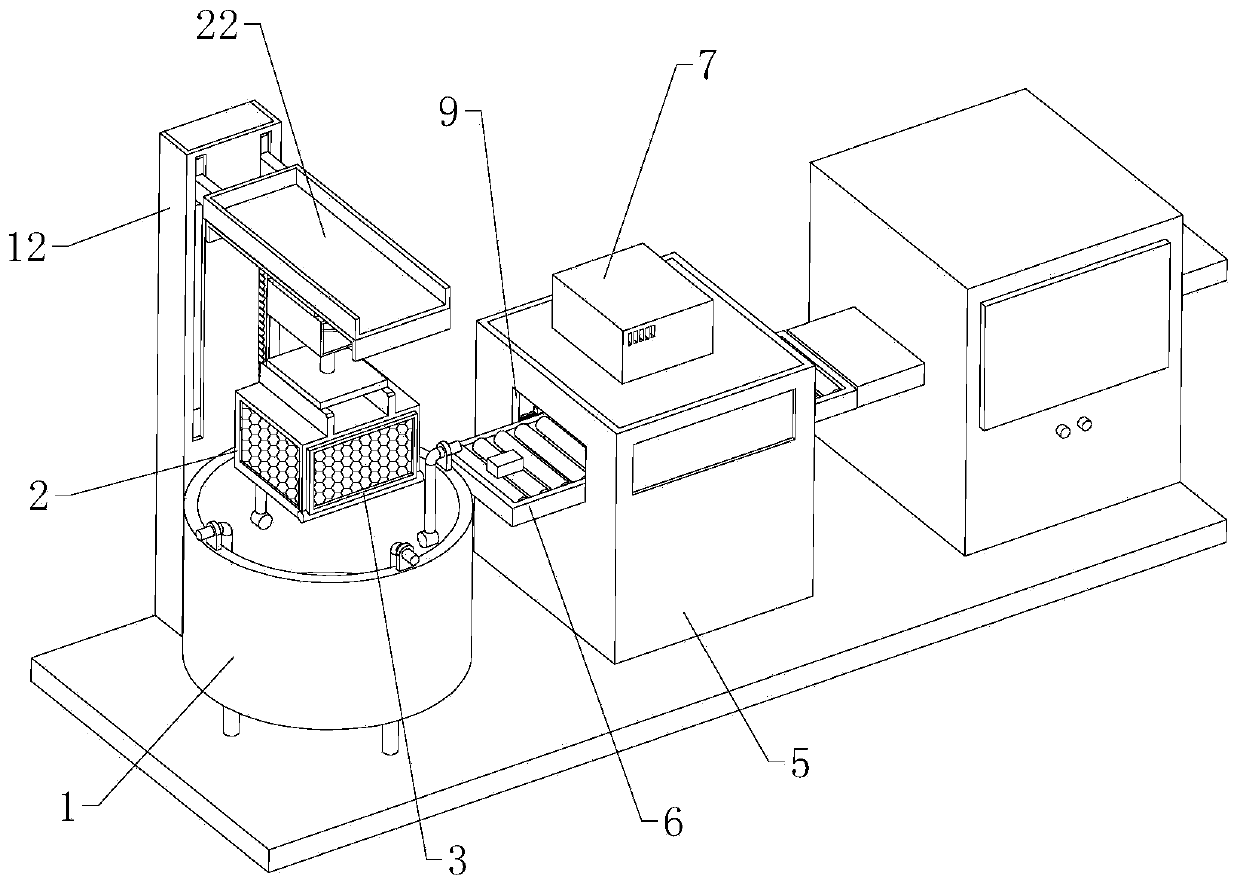

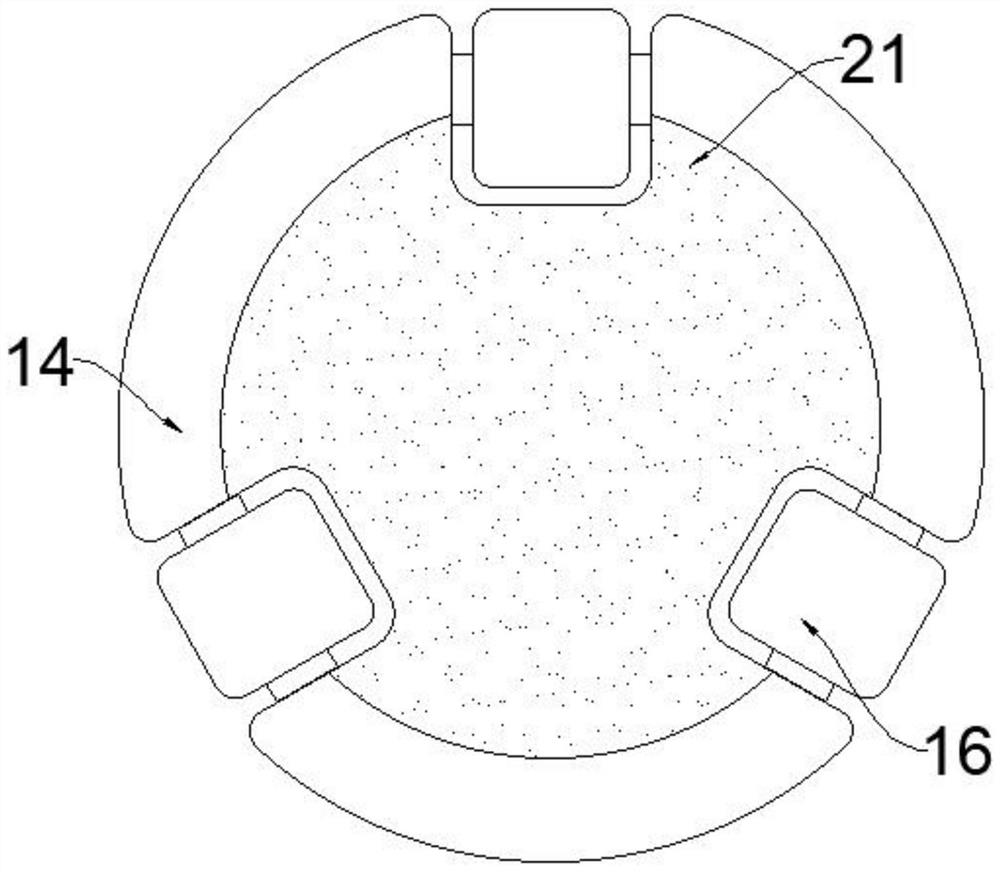

Automatic welding and stamping integrated equipment for point contact type silver contact

ActiveCN110788626AAct as a guide to moveIncrease the feeding speedOther manufacturing equipments/toolsEngineeringMachining

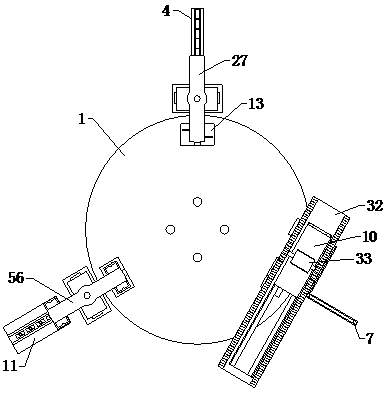

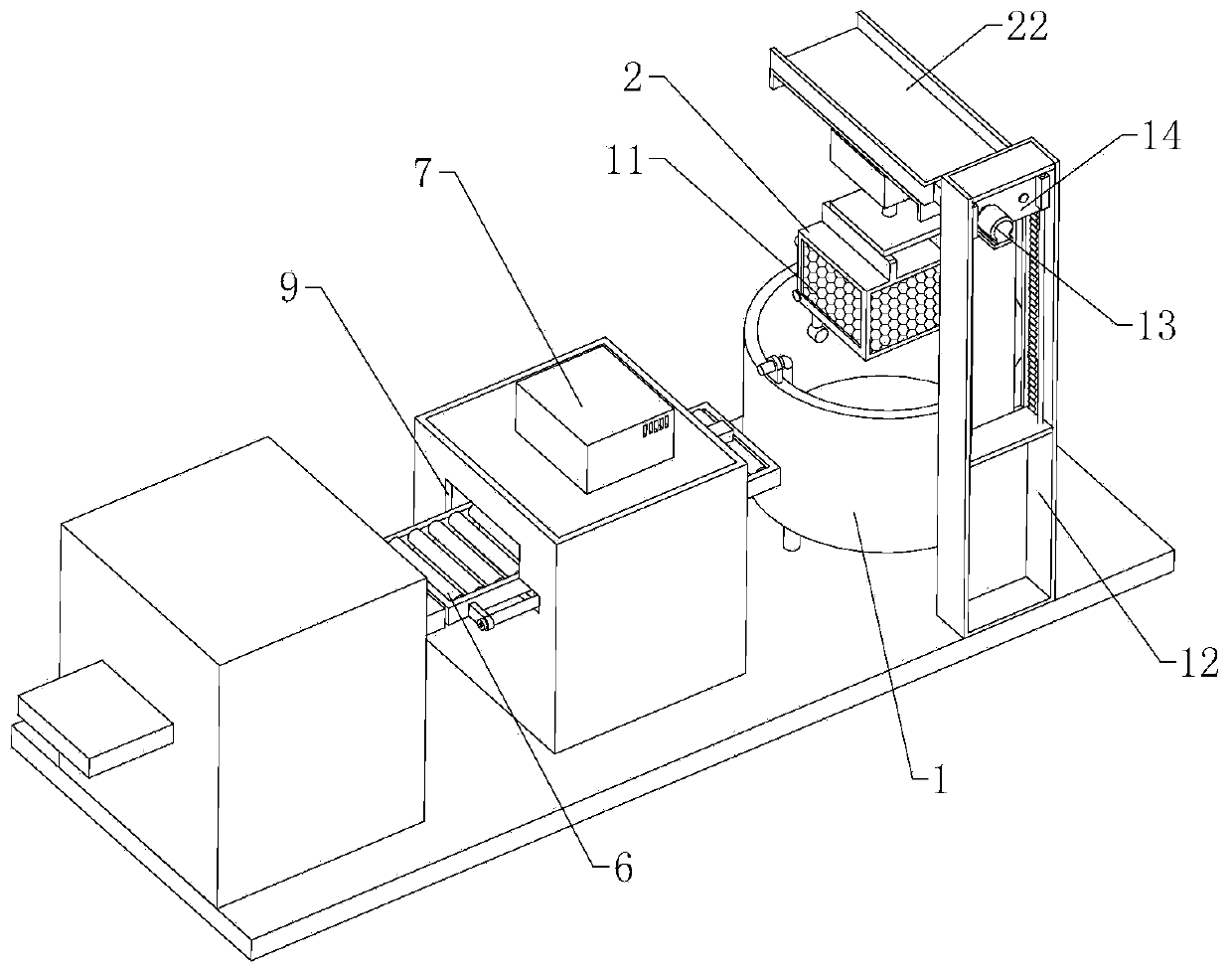

The invention relates to the technical field of silver contact machining, in particular to automatic welding and stamping integrated equipment for a point contact type silver contact. The automatic welding and stamping integrated equipment comprises a rotary disc and further comprises a contact piece feeding mechanism, a silver contact feeding and welding mechanism and a discharging mechanism. Three clamping assemblies evenly distributed around the circumference of the rotary disc are arranged on a table top of the rotary disc. Each clamping assembly is provided with a material bearing jig capable of containing a workpiece. The contact piece feeding mechanism, the silver contact feeding and welding mechanism and the discharging mechanism are located on one sides of the clamping assembliescorrespondingly. The contact piece feeding mechanism comprises a contact piece feeding rail and a contact piece feeding assembly. The silver contact feeding and welding mechanism comprises a horizontal reversing assembly, a silver contact feeding rail, a guiding-in assembly and a welding and stamping assembly. The horizontal reversing assembly is provided with a movable plate. The discharging assembly comprises a discharging rail and a material moving assembly. By means of the equipment, automatic feeding and discharging can be achieved, a contact piece is automatically positioned, the silvercontact can be welded while stamping is conducted, and the production efficiency is improved.

Owner:WENZHOU JUXING ELECTRIC CONTACT TECH

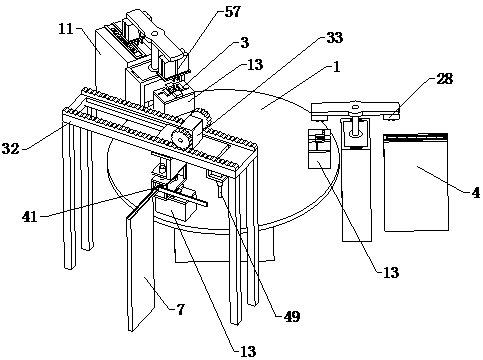

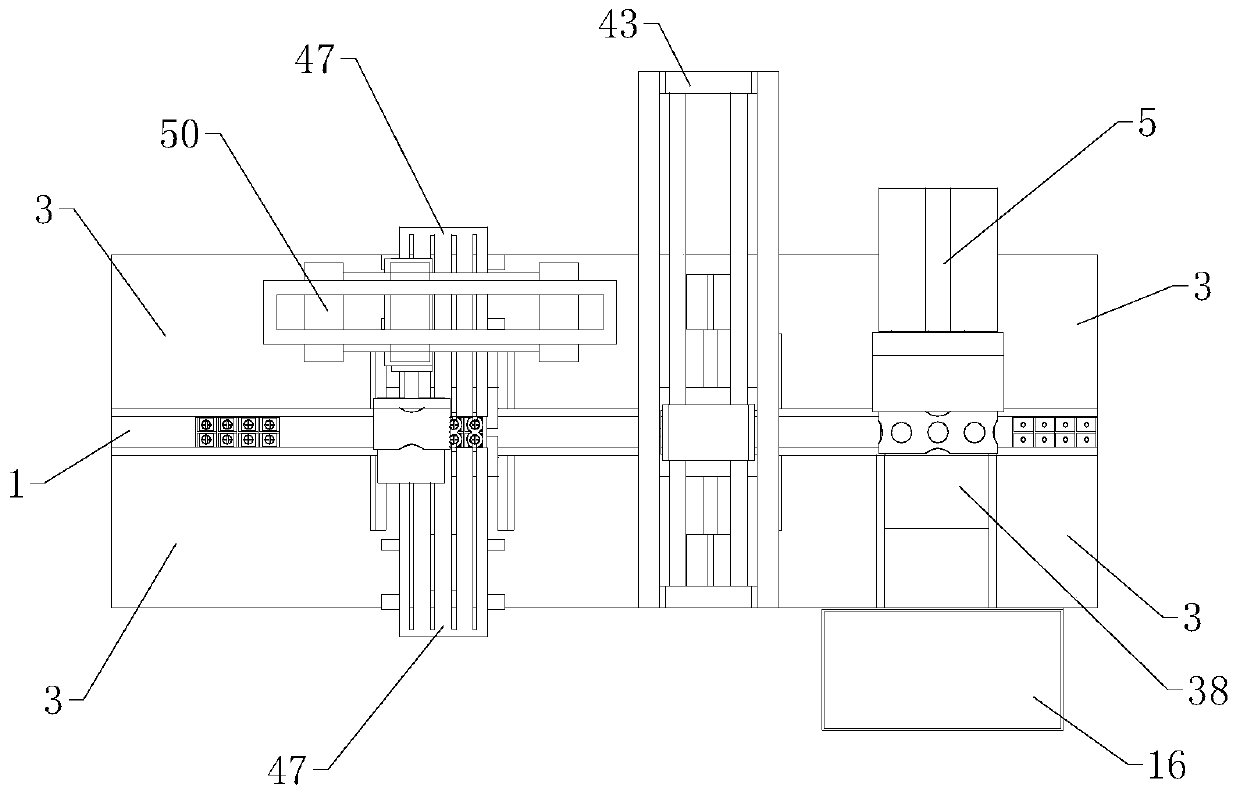

Assembling device for sampling tongs for gastroenterology department

InactiveCN110842543APlay the role of guide limitReliable positioning and clampingSurgeryAssembly machinesGastroenterology departmentMechanical engineering

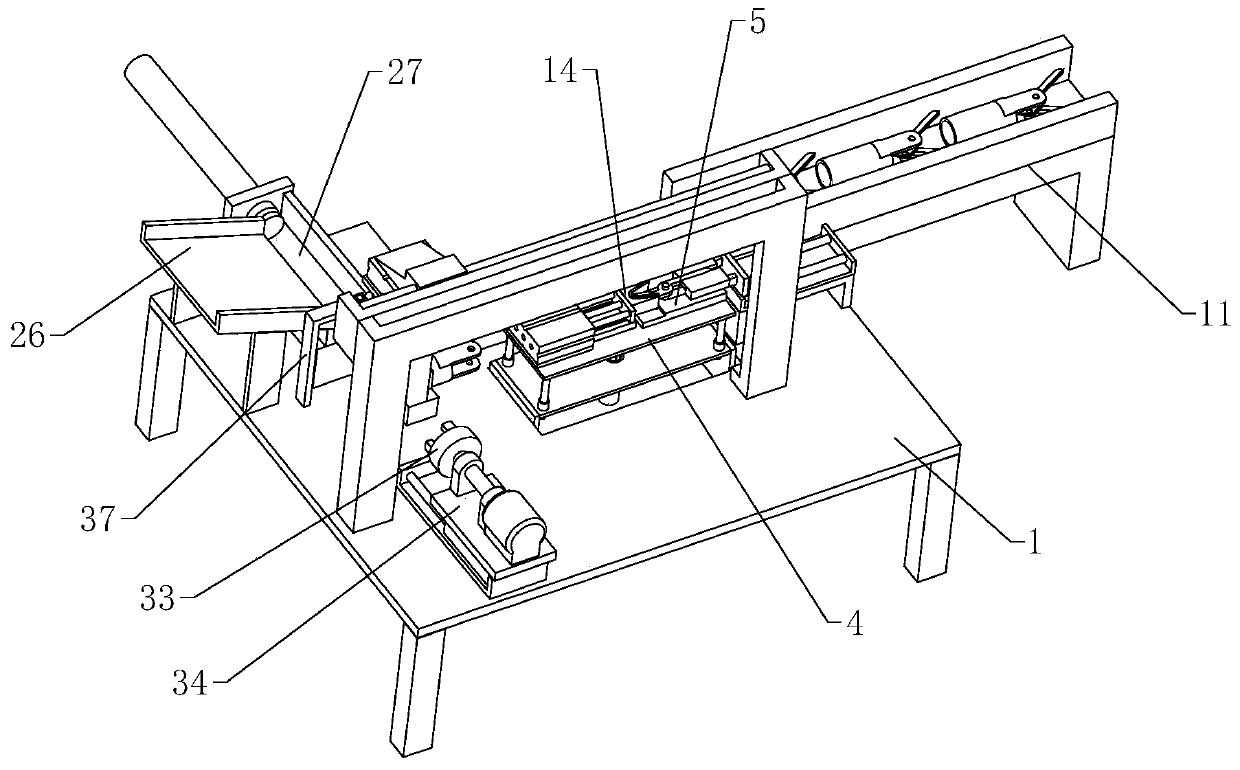

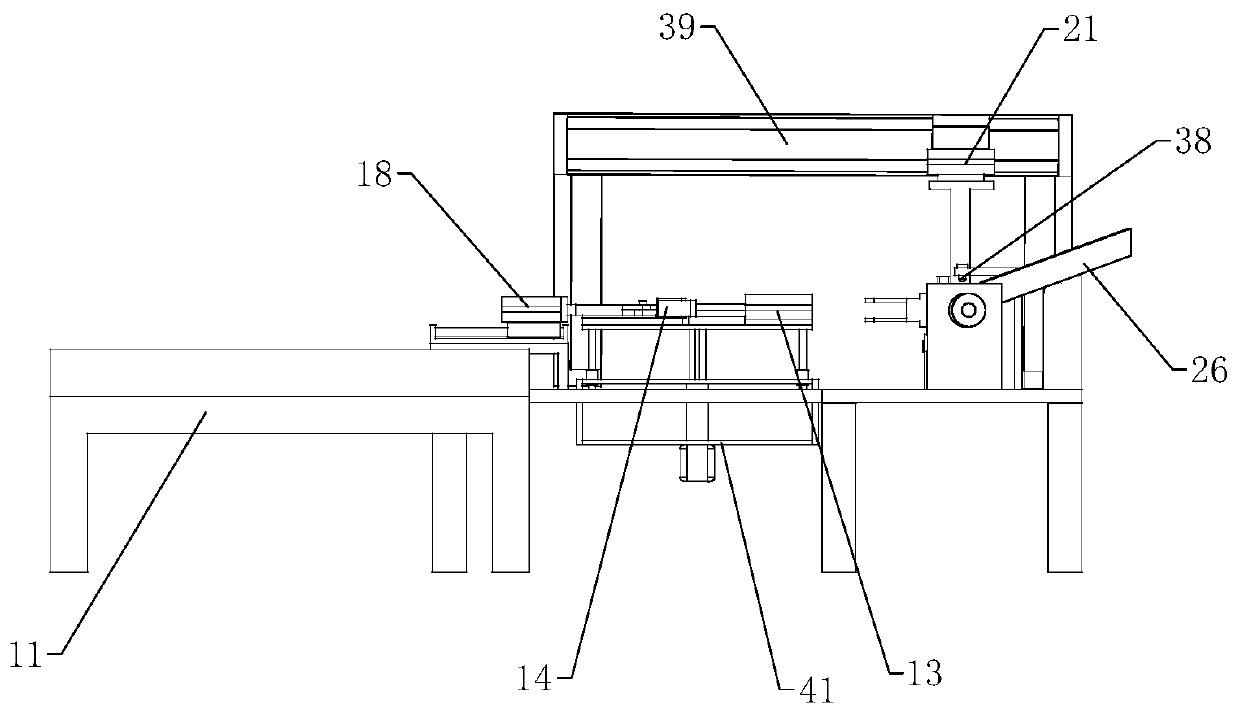

The invention relates to the technical field of processing of medical sampling tongs, in particular to an assembling device for sampling tongs for a gastroenterology department. The assembling devicecomprises a processing table, and further comprises a tong head positioning mechanism, a clamping positioning mechanism, a sleeve tool moving mechanism and a sleeve feeding and correcting mechanism, wherein the tong head positioning mechanism comprises a lifting assembly and an accommodating positioning assembly; the lifting assembly is positioned at the bottom of the processing table, and comprises a lifting plate; the clamping positioning mechanism comprises an accommodating jig capable of accommodating tong heads and an adjusting component, and further comprises a clamping component; the sleeve feeding and correcting mechanism comprises a sleeve feeding component and a sleeve correcting component; the sleeve tool moving mechanism comprises a horizontal moving component and a horizontaloverturning positioning component; an operation incision is formed in one side, close to the lifting plate, of the processing table; and a discharging conveyor is arranged on one side of the operationincision. All that is needed is to place the tong heads on the accommodating jig manually in sequence, the automatic assembly can be realized, and the working efficiency is improved.

Owner:CHENGDU GUANYU TECH

Desktop-level 3D printing and color spraying integrated device

InactiveCN110370634APlay the role of guide limitImprove printing efficiencyManufacturing driving meansManufacturing auxillary operationsColor printingEngineering

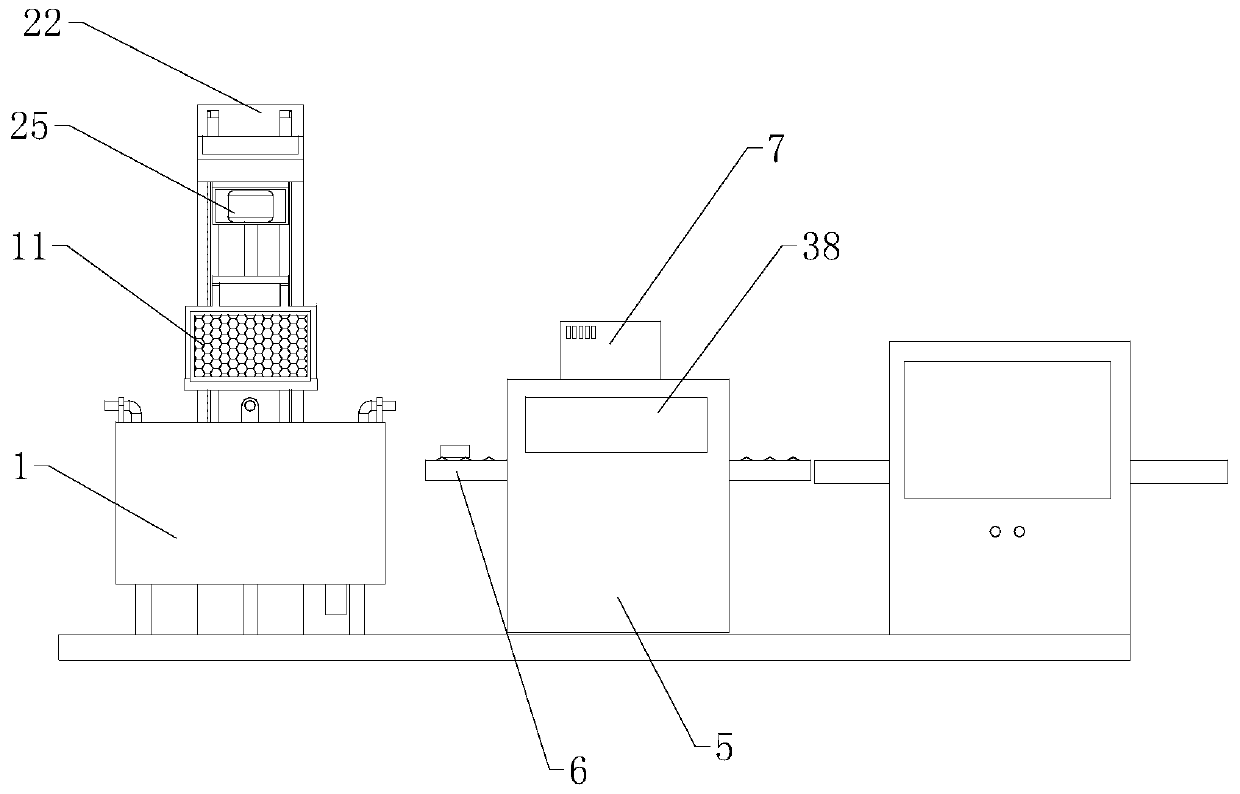

The invention relates to the technical field of 3D printing, specifically relates to a desktop-level 3D printing and color spraying integrated device. The device comprises a processing platform, a lifting mechanism, a horizontal moving mechanism and a rotating mechanism, wherein a material storing groove for storing a workpiece is arranged on the processing platform; the rotating mechanism comprises an annular rail and a rotating plate; the lifting mechanism comprises a lifting synchronizing assembly and two lifting moving assemblies; each lifting moving assembly is correspondingly provided with a lifting plate capable of lifting up and down; the horizontal moving mechanism comprises a horizontal moving rail, a primary printing head and a coloring printing head; the horizontal moving railis horizontally arranged at the upper part of the processing platform; the top part of the horizontal moving rail is fixedly connected with the bottom of the rotating plate; and the primary printing head and the coloring printing head are correspondingly movably horizontally arranged in the horizontal moving rail. According to the device, an annular movement mode is adopted and replaces a traditional XY mode, and meanwhile, a nozzle can be driven to move to any point on the plane, and coloring can be performed simultaneously when printing is performed, so that printing efficiency is improved.

Owner:周小鹏

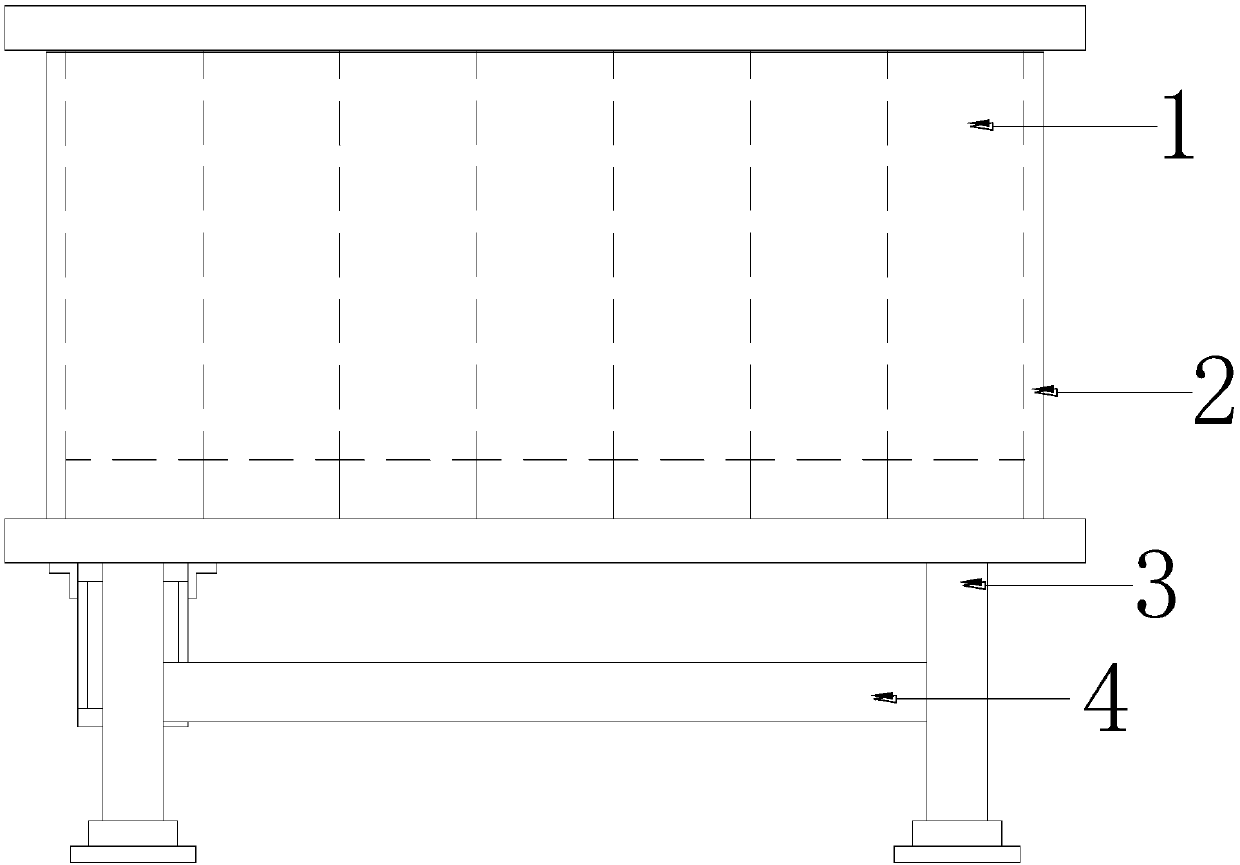

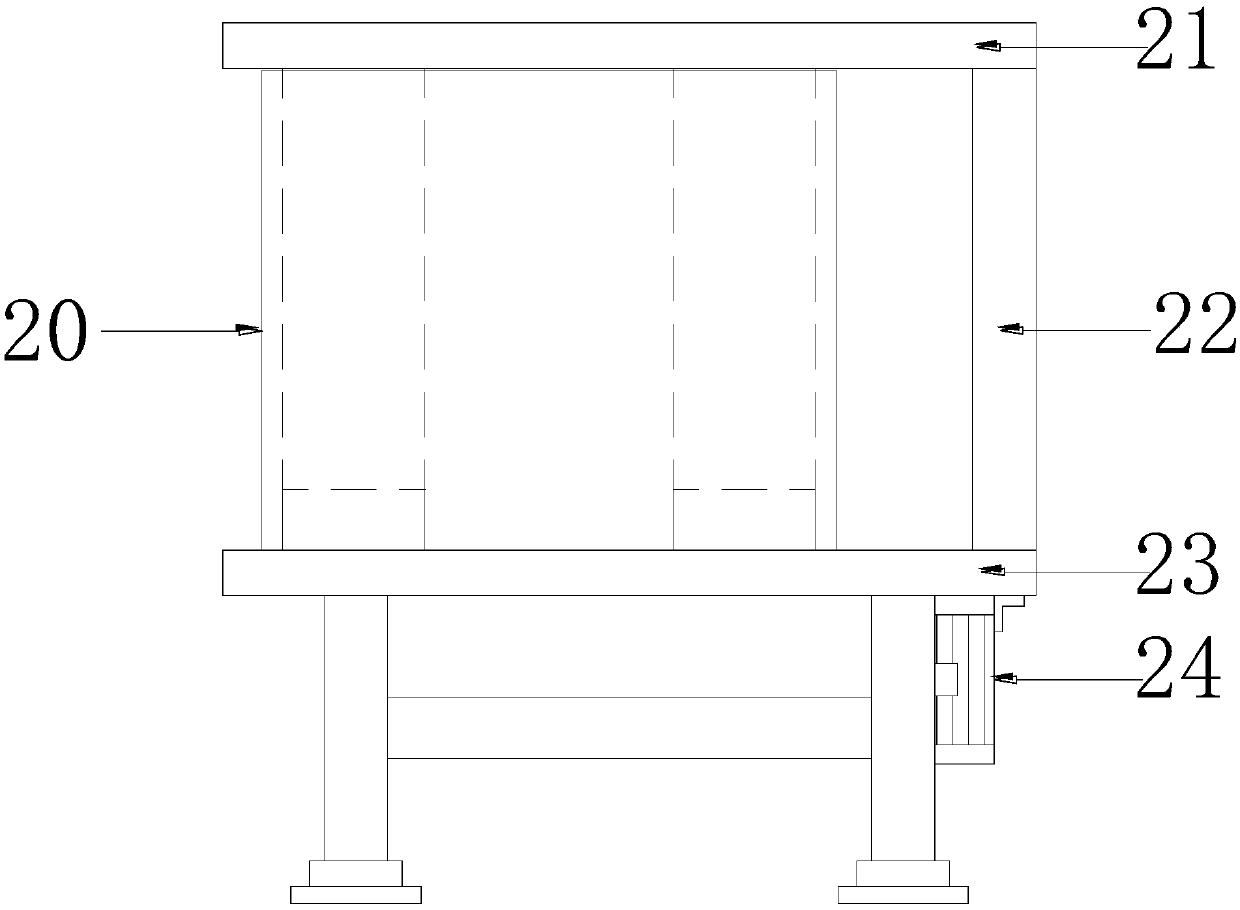

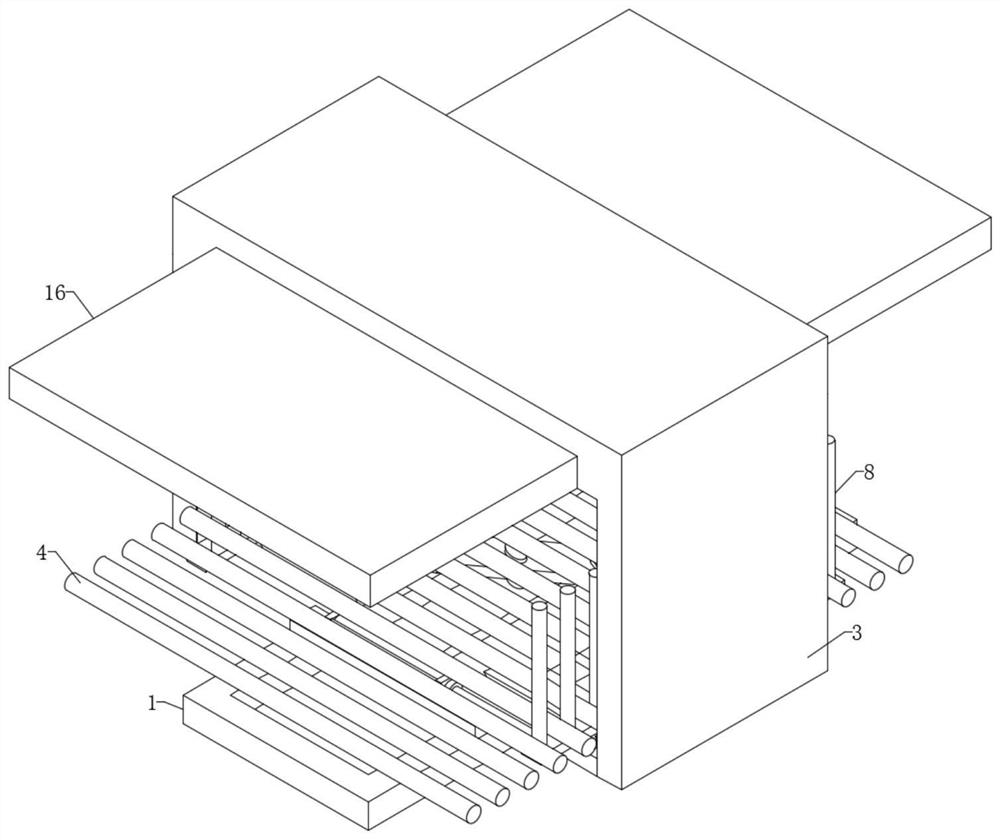

LCP copper-clad plate laminating process based on 5G high-frequency signal transmission

ActiveCN111634103AExpand the scope of useFast feedingLamination ancillary operationsLaminationStructural engineeringManufacturing engineering

The invention discloses an LCP copper-clad plate laminating process based on 5G high-frequency signal transmission. The laminating process is realized through a laminating device. The process comprises the following specific steps: step 1, placing an LCP copper-clad plate needing to be subjected to laminating processing on a feeding mechanism, adjusting the distance between the two groups of sliding support plates according to different sizes and specifications of lCP copper-clad plates processed by laminating, locking and fixing the sliding support plates through locking bolts, and placing acopper-clad plate needing to be laminated on the two groups of sliding support plates; and enabling the first motor to work to drive the driving bevel gear to rotate. The distance between the two groups of sliding support plates is adjusted according to different sizes and specifications of LCP copper-clad plates subjected to laminating processing, the sliding supporting plates are locked and fixed through the locking bolts, the copper-clad plates of different sizes and specifications can be conveyed, the application range of the device is widened, the copper-clad plates can be fed vertically,rapid feeding of the copper-clad plates is achieved, and the processing efficiency of the copper-clad plates is improved.

Owner:江苏胜帆电子科技有限公司

Cement road surface grinding flattening equipment for traffic

ActiveCN110359343APlay a guiding rolePlay the role of limit guideRoads maintainenceRoad engineeringRoad surface

The invention relates to the field of road engineering, in particular to cement road surface grinding flattening equipment for traffic. The cement road surface grinding flattening equipment for the traffic comprises a vehicle body, and further comprises a double-side grinding fattening mechanism and a front-and-rear grinding fattening mechanism, wherein the double-side grinding fattening mechanismcomprises two adjusting grinding flattening assemblies and a first lifting assembly, the two adjusting grinding flattening assemblies each comprise an upward folding assembly and a horizontal foldingassembly, each upward folding assembly and each horizontal folding assembly each comprise a first cement leveling machine, the front-and-back grinding flattening mechanism comprises a front grindingflattening assembly and a rear grinding flattening assembly, the front grinding flattening assembly and the rear grinding flattening assembly each comprise a second lifting assembly and a lifting plate, a plurality of second cement leveling machines are arranged at the bottom of each lifting plate, the lifting plates are horizontally arranged below the second lifting assemblies, and the tops of the lifting plates are in transmission connection with the working ends of the second lifting assemblies. According to the cement road surface grinding flattening equipment for the traffic, people onlyneed to seat on the vehicle body for operation, moreover, adjustment can be performed according to the widths of different roads, and the grinding flattening efficiency is improved.

Owner:王美华

Automatic perforating equipment for automobile bumpers

ActiveCN111360930APlay the role of guide limitImprove processing efficiencyMetal working apparatusStructural engineeringMechanical engineering

The invention relates to the technical field of processing of automobile bumpers, in particular to automatic perforating equipment for the automobile bumpers. The automatic perforating equipment comprises a processing platform; an accommodating jig is arranged at the top of the processing platform; a positioning assembly is arranged in the accommodating jig and comprises two clamping blocks; end straightening assemblies are arranged at the two ends of the accommodating jig; a transverse moving assembly is arranged on one side of the accommodating jig; a bi-directional moving assembly is arranged at the output end of the transverse moving assembly; two symmetrically-arranged perforating assemblies are arranged at the output end of the bi-directional moving assembly; each perforating assembly comprises a perforating machine; a feeding frame and a discharging frame which can accommodate workpieces are arranged on the two sides of the processing platform; a horizontally-arranged hollow frame is arranged above the space between a feeding machine and the discharging frame; a feeding grasping assembly is arranged in the hollow frame; and a discharging grasping assembly is further arrangedin the hollow frame. According to the equipment, automatic feeding and discharging can be performed, and the two ends of the bumpers can be perforated automatically and synchronously, so that the processing efficiency can be improved.

Owner:台州市黄岩超骏塑模有限公司

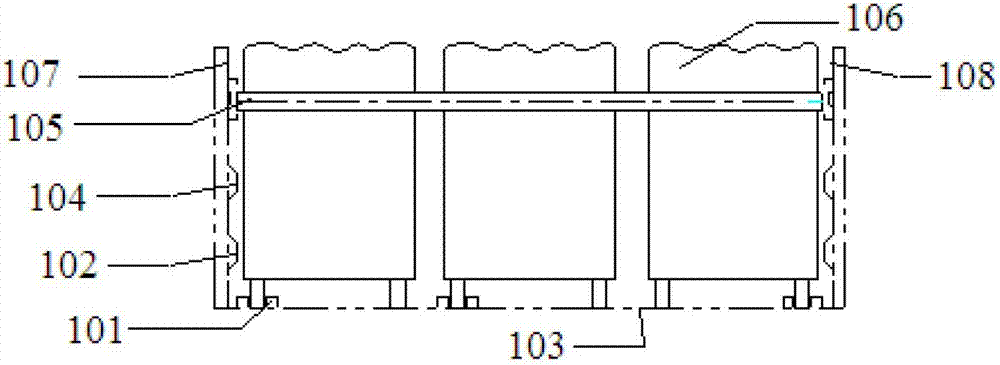

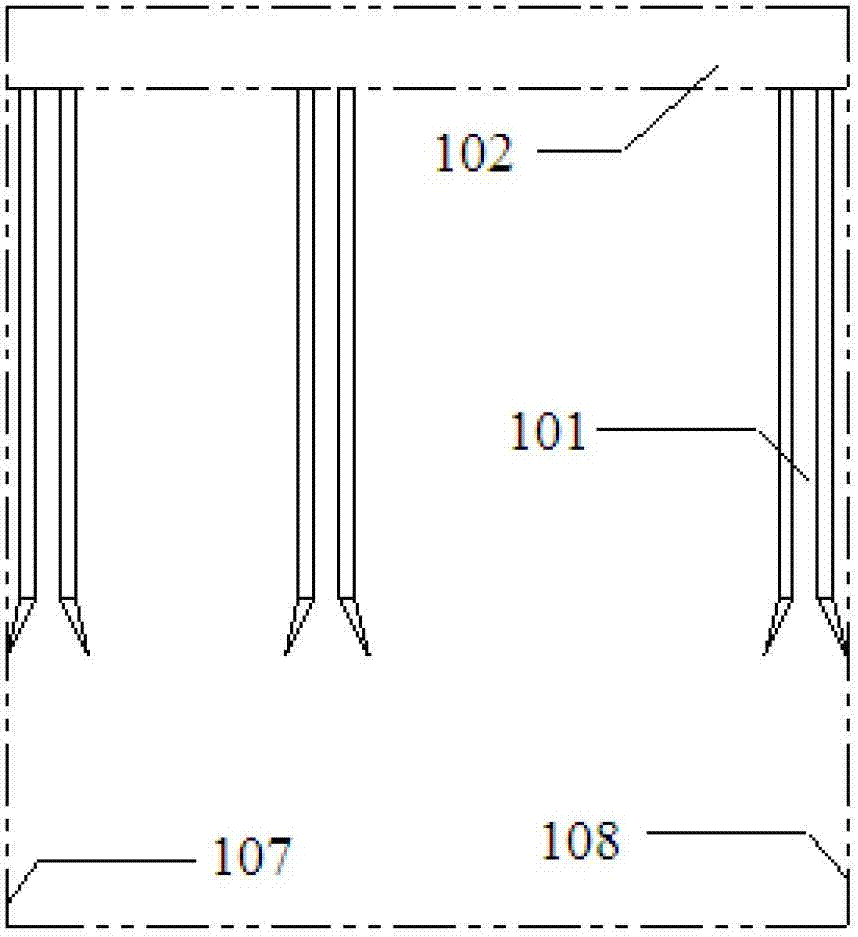

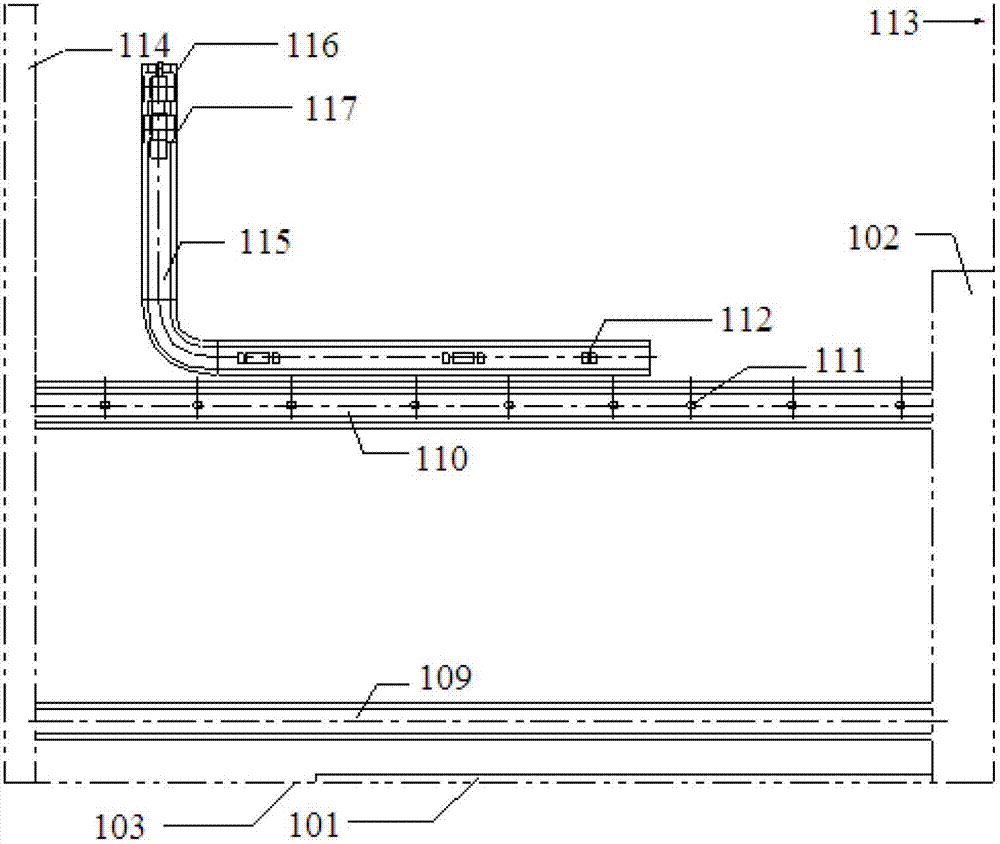

Automatic machining device for internal medicine drainage bodies

ActiveCN110814380APlay the role of guide limitIncrease productivityFeeding apparatusLarge fixed membersEngineeringMachining

The invention relates to the technical field of medical tool processing, in particular to an automatic machining device for internal medicine drainage bodies. The device comprises a machining table, ahorizontal moving assembly is arranged on the machining table, the horizontal moving assembly comprises a movable plate which can move horizontally, a rectangular containing jig is arranged on the movable plate, a plurality of drainage body containing grooves are formed in the containing jig, a clamping assembly is arranged on the containing jig, a lifting assembly is arranged above the containing jig, the lifting assembly comprises a lifting frame capable of ascending and descending, a longitudinal horizontal moving assembly is arranged at the top of the lifting frame, and the lower portionof the longitudinal horizontal moving assembly is provided with a drill bit replacing mechanism which comprises a reversing assembly, a first perforating assembly and a second perforating assembly. Afragment collecting assembly is arranged on one side of the lower side of the reversing box. According to the automatic machining device, automatic drilling can be carried out on the drainage bodies at the same time, all the holes in pipes of the drainage bodies can be machined in the one-time clamping process, chippings generated by machining can be automatically collected, and the production efficiency and the machining precision are improved.

Owner:成都市双流区第一人民医院

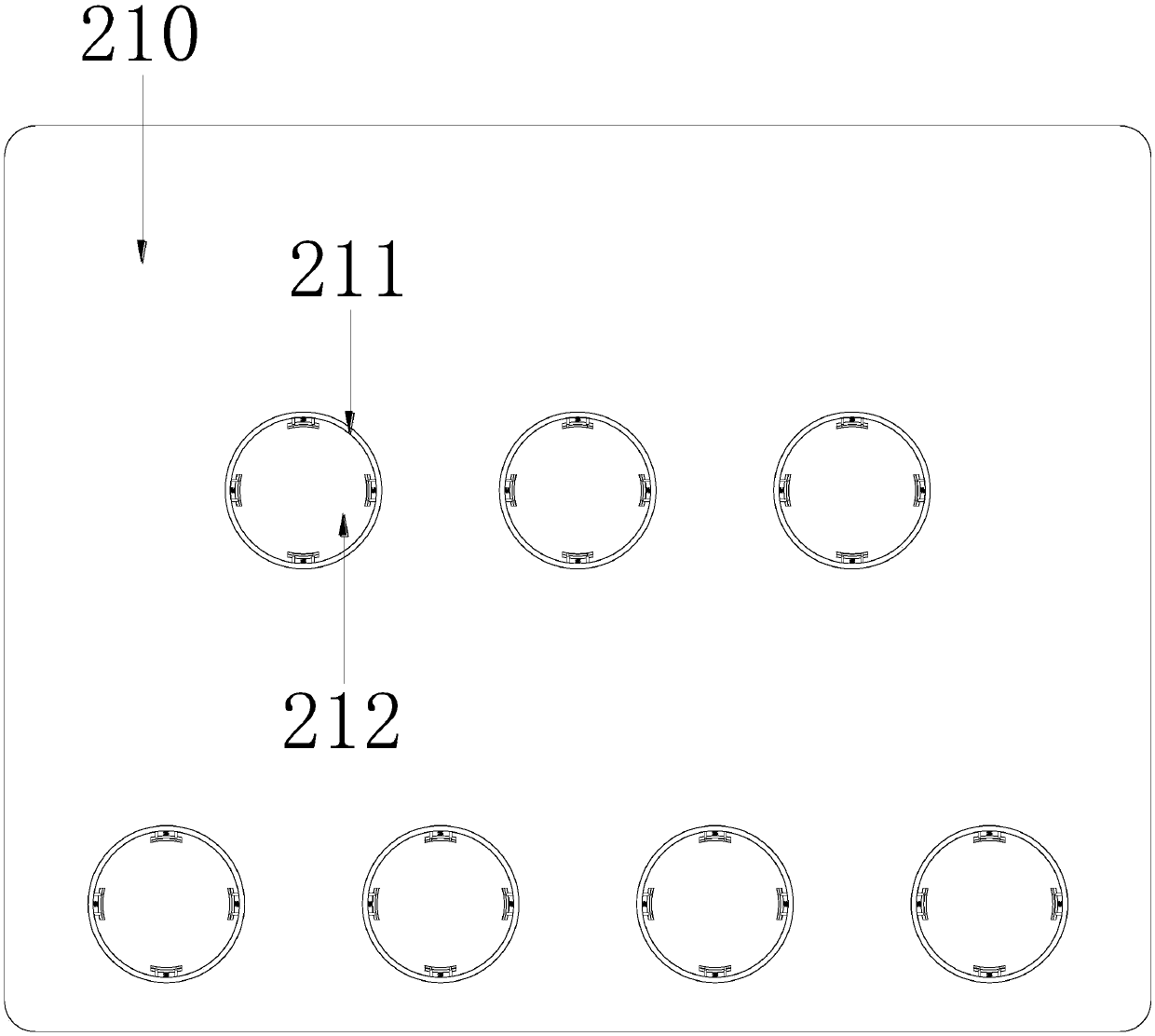

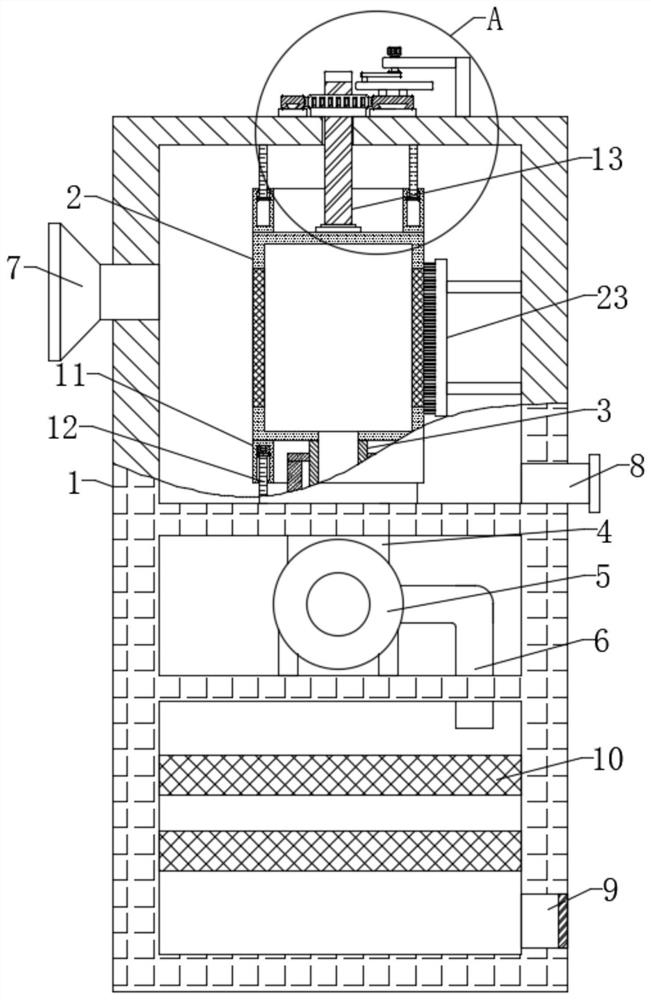

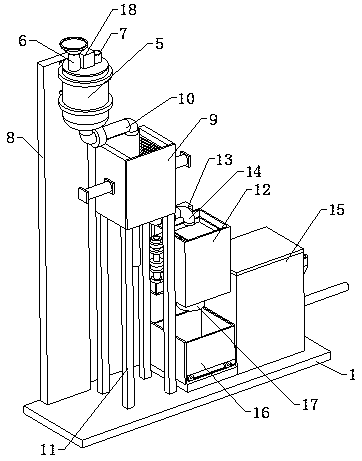

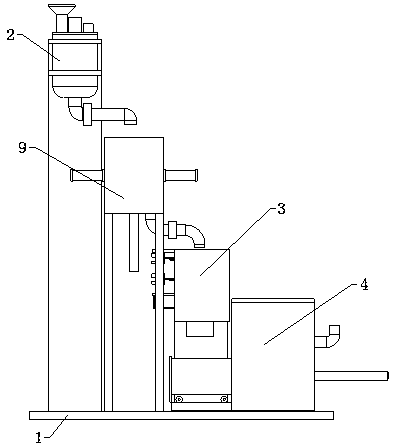

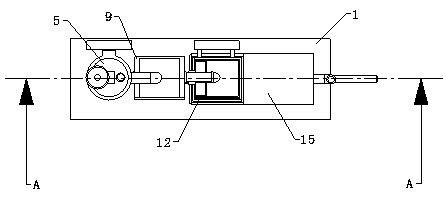

Semi-automatic liquid injection equipment for lithium battery

InactiveCN110492051APlay the role of guide limitRealize automatic liquid injectionCell component detailsEngineeringMechanical engineering

The invention relates to the field of lithium battery processing, and specially relates to semi-automatic liquid injection equipment for the lithium battery; the equipment comprises a processing box,a discharging clamping assembly, a horizontal material moving assembly, a longitudinal moving assembly, a transverse moving assembly and a lifting assembly. The processing box is of a rectangular structure. A discharging opening and a discharging exit are formed in the two ends of the open end of the top of the processing box correspondingly; the longitudinal moving assembly comprises a longitudinal moving plate; the lifting assembly comprises a liquid injection head capable of moving downwards. The horizontal material moving assembly comprises a material moving plate. A notch is formed in the top of the material moving plate; a discharging plate is arranged in the notch; a plurality of accommodating holes for discharging are formed in the top of the discharging plate; the dischargingclamping assembly comprises two clamping plates, the two clamping plates are symmetrically arranged on the two sides of the material moving plate, automatic liquid injection can be achieved only by sequentially placing batteries needing liquid injection into the accommodating holes in the discharging plate and placing the discharging plate on the material moving plate for positioning, and the liquid injection stability and the liquid injection efficiency are improved.

Owner:丽水俊翔信息技术有限公司

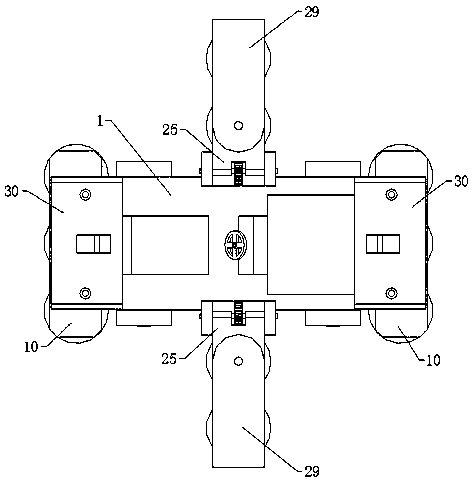

Maintenance and cleaning equipment for urban transportation tracks

ActiveCN110552316APlay the role of guide limitImprove cleaning efficiencyRailway cleaningVehicle frameEngineering

The invention relates to the technical field of urban transportation track maintenance, and in particular to maintenance and cleaning equipment for urban transportation tracks. The maintenance and cleaning device comprises a track frame, wherein a plurality of groups of track wheels are arranged at the bottom of the track frame at intervals; wheel driving components are arranged inside one group of track wheels; a track cleaning mechanism is arranged at one end of the top of the track frame and comprises a water tank, a lifting component and two cleaning components; each cleaning component comprises a top cleaning rolling brush, two side cleaning rolling brushes, two front end spray heads and two rear end spray heads; a dust collection mechanism and an iron suction mechanism are also arranged at one end of the top of the track frame side by side; the dust collection mechanism comprises a first storage box and a suction hood; the iron suction mechanism comprises a horizontal moving component, a second storage box, and a rectangular iron suction block; and a controller is also arranged on the top of the track frame. The maintenance and cleaning equipment can automatically clean the track, sorts and collects different types of garbage, and improves cleaning efficiency and air quality.

Owner:安徽尚成建设工程有限公司

Automatic processing equipment of wiring terminal

InactiveCN110504612APlay the role of guide limitIncrease productivityContact member assembly/disassemblyAssembly machinesAutomatic processingEngineering

The invention relates to the technical field of the wiring terminal processing, and specifically relates to automatic processing equipment of a wiring terminal. The automatic processing equipment comprises a plastic case feeding mechanism, a detection mechanism, a blade terminal feeding mechanism and a crimping screw feeding mechanism; the plastic case feeding mechanism comprises a tool track; thetool track comprises a feeding port and a discharging port; baffle plates are arranged at two sides of the tool track, and worktables are further arranged at two sides of the tool track; the detection mechanism comprises a hole site detection module and a waste pushout module; the blade terminal feeding mechanism comprises a blade terminal loading module, a blade terminal discharging module and two first positioning modules; the crimping screw feeding mechanism comprises a screw locking module, a positioning bush module, two screw feeding modules and two second positioning modules. The equipment can automatically tool the wiring terminal, the unqualified plastic case detected in the production can be automatically classified, and the production efficiency is improved.

Owner:云和县宏峰模具厂

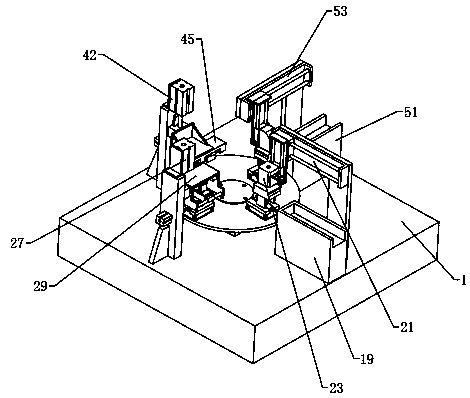

Automatic machining device for automobile flange yoke

ActiveCN111037293APlay the role of guide limitImprove processing efficiencyOther manufacturing equipments/toolsEngineeringMachining

The invention relates to the technical field of automobile flange yoke machining, and particularly relates to an automatic machining device for an automobile flange yoke. The automatic machining device comprises a machining table and further comprises a rotary positioning mechanism, a feeding mechanism, a milling mechanism, a bidirectional drilling mechanism and a discharging mechanism, wherein the rotary positioning mechanism comprises a rotary disc and four positioning assemblies capable of clamping workpieces correspondingly; an index plate is arranged below the rotary disc; the bottom of the index plate is fixedly connected with the table top of the machining table; the output end of the index plate is fixedly connected with the center of the bottom of the rotary disc; the four positioning assemblies are evenly distributed at the edge of the top of the rotary disc in the circumferential direction of the rotary disc; the feeding mechanism, the milling mechanism, the bidirectional drilling mechanism and the discharging mechanism are arranged on the table top of the machining table; and the output end of the feeding mechanism, the output end of the milling mechanism, the output end of the bidirectional drilling mechanism and the output end of the discharging mechanism are in butt joint with the output ends of the positioning assemblies correspondingly. By means of the equipment, the primary blank machining position of the flange yoke can be automatically milled and drilled, and the machining efficiency is improved.

Owner:安徽艾德河汽车部件有限公司

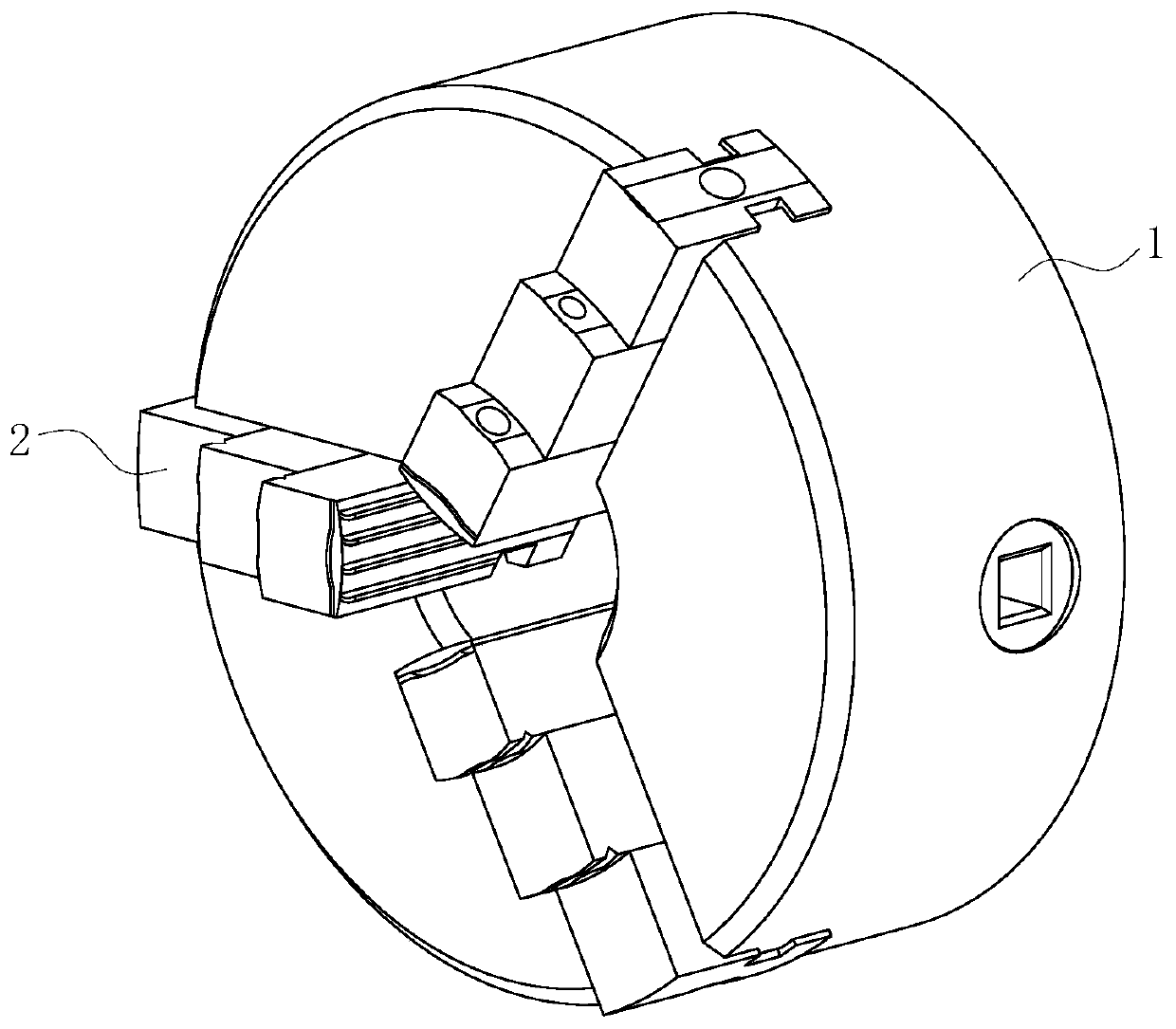

Three-jaw chuck

ActiveCN110695387AIncreased clamping force and clamping stabilityAffect safe operationChucksPhysicsEngineering

The invention belongs to the technical field of machining, and particularly relates to a three-jaw chuck. The three-jaw chuck comprises a chuck body and clamping jaws, wherein each of the three clamping jaws is formed through the mode that three transverse pressing blocks are adopted to mutually be overlapped and spliced, guiding sliding grooves are formed inside the pressing blocks at the bottommost ends of the clamping jaws, and clamping grooves are formed in the bottom ends of the guiding sliding grooves; sliding blocks are slidably arranged in the guiding sliding grooves, and pressing plates are connected to the bottom ends of the sliding blocks; the pressing plates and the clamping grooves are mutually clamped and matched; threaded locking holes are formed in the sliding blocks; countersunk threaded holes are formed in the vertical directions of the clamping jaws; the countersunk threaded holes are in threaded connection with the threaded locking holes through inside hexagonal bolts; the bottom ends of the threaded locking holes are provided with bearings, and rotating columns are connected in the bearings; and inner hexagonal bolts are arranged in the rotating columns in an inserting mode. The phenomenon that the clamping force of the chuck body to a cylinder is small due to the fact that the diameter of the machined cylinder is different, the cylinder breaks or is damaged under the state that the cutting force is large, and therefore the safe operation of the chuck body is influenced is prevented.

Owner:诸暨市港灵科技有限公司

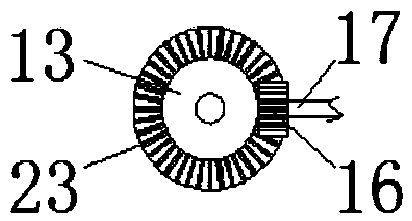

Efficient polishing machine applicable to cylindrical vacuum cup for rapid polishing

ActiveCN109514404APlay the role of guide limitAvoid misalignmentGrinding drivesBelt grinding machinesEngineeringMechanical engineering

The invention discloses an efficient polishing machine applicable to a cylindrical vacuum cup for rapid polishing. The efficient polishing machine structurally comprises the vacuum cup, a polishing machine body, supporting feet and a fastening connection plate. The four corners of the polishing machine body are perpendicularly connected with the supporting feet, the supporting feet are connected together through the fastening connection plate, and the vacuum cup is placed on the polishing machine body. Compared with the prior art, the efficient polishing machine has the beneficial effects thatby means of combined arrangement of a grinding abrasive belt, a top plate, a telescopic dustproof plate, a base and an efficient energy saving motor, by means of ingenious layout of a rotary clampingring and a rotary cup placing tray, the grinding abrasive belt makes contact with multiple guide wheels 232c to be of an S-shaped structure, the grinding abrasive belt can make large-area contact with the outer wall of the vacuum cup, the polishing contact face is increased, polishing time is reduced, the polishing efficiency can be improved, multiple vacuum cups can be polished at a time, and working efficiency is further improved.

Owner:莆田市城厢区诺林贸易有限公司

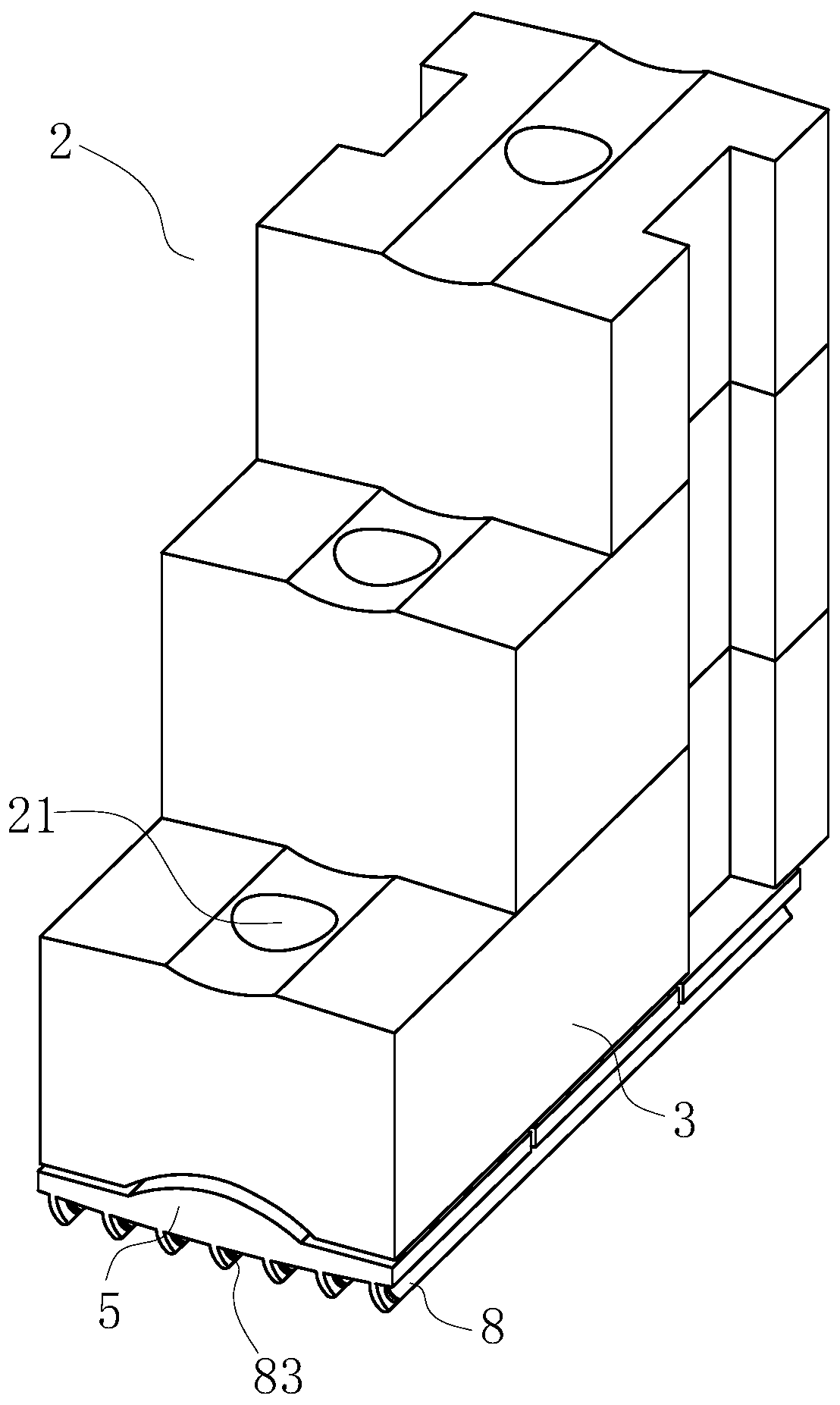

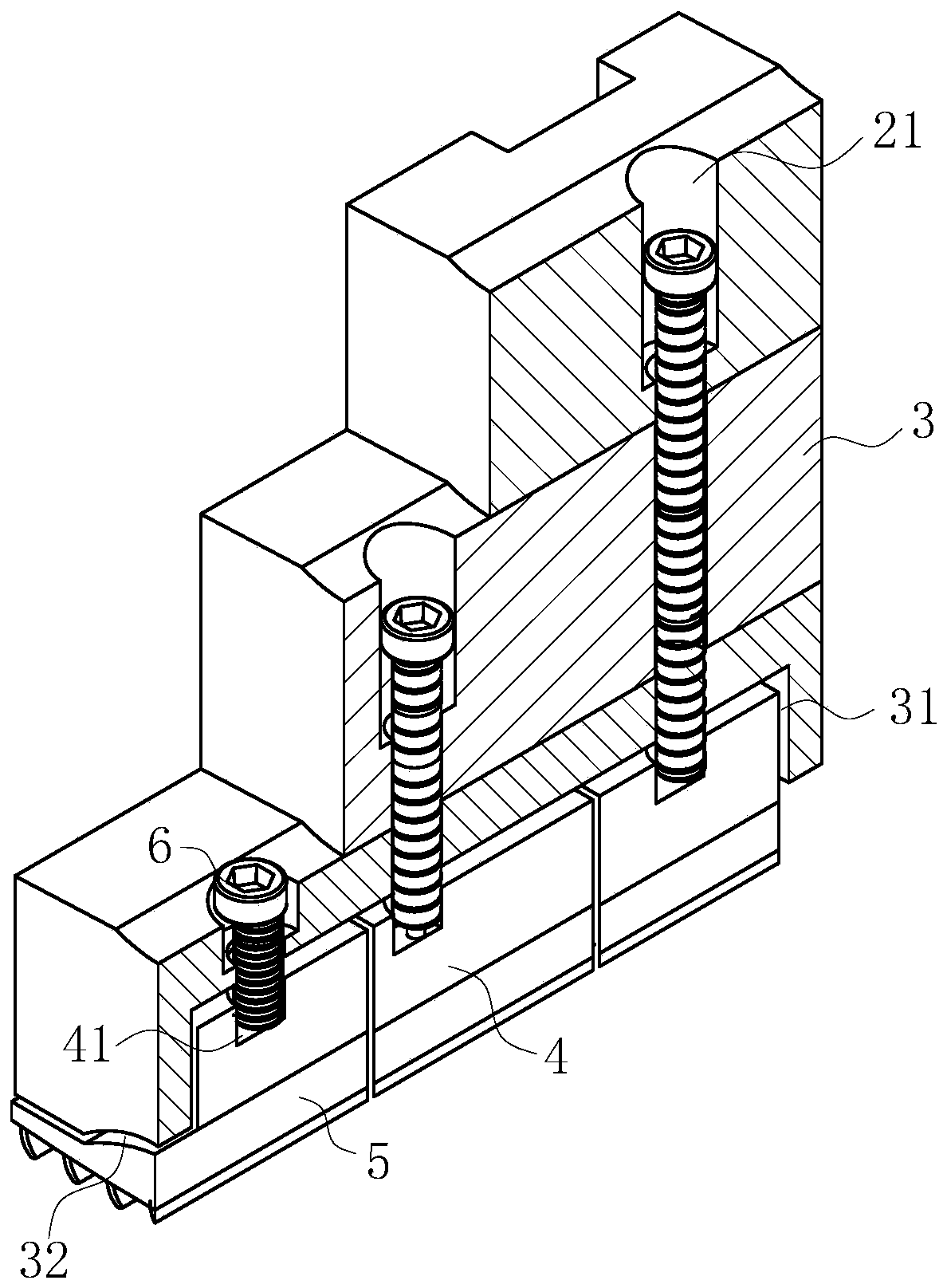

Assorted fixing mechanical device for postal foldable containers in carriage

InactiveCN102848967AEasy to fixPlay the role of guide limitLoad securingLoading-carrying vehicle superstructuresEngineeringCaster

The invention discloses an assorted fixing mechanical device for postal foldable containers in a carriage. The assorted fixing mechanical device comprises slide rails, anti-collision devices, limiting plates and transverse levers; the slide rails are arranged on a floor in the carriage, and casters at bottoms of the postal containers slide into the slide rails to be guided and positioned; the anti-collision devices are disposed o a front wall plate of the carriage and are abutted to the positioned postal containers; the limiting plates are arranged on a left side plate and a right side plate of the carriage and limit the postal containers positioned on the left side and the right side of the carriage; and the transverse levers are arranged between the left side plate and the right side plate of the carriage and fix the positioned postal containers from middles of the postal containers.

Owner:中国邮政集团公司北京市邮区中心局

Briquetting device for scrap metal recycling

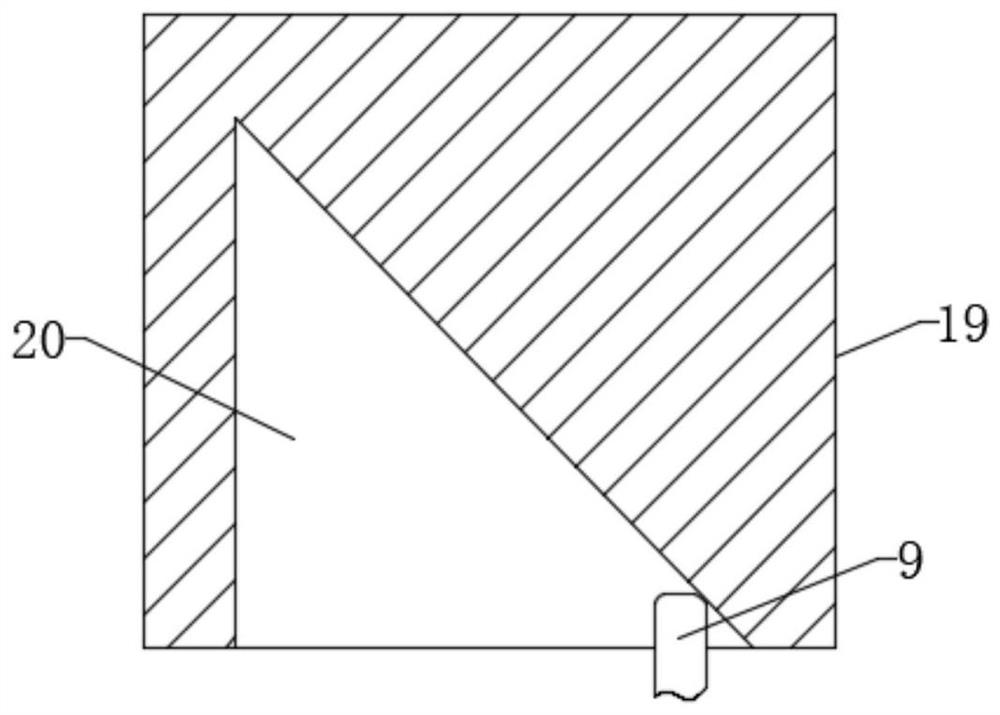

ActiveCN110978601APlay a guiding rolePlay the role of guide limitPressesProcess engineeringMetal recycling

The invention relates to the field of scrap metal recycling, in particular to a briquetting device for scrap metal recycling. The briquetting device includes a feeding conveyor and a discharge conveyor, and further includes a processing bin, a material moving assembly and a briquetting assembly, wherein the material moving assembly and the briquetting assembly are installed on the processing bin.A feed inlet is formed in the side, located at the feeding conveyor, of the processing bin, and a feeding assembly is arranged on the side, located at the feed inlet, of the processing bin. The feeding assembly is provided with a feeding push plate which can move to the feed inlet, and a discharge port is formed in the side, close to the discharge conveyor, of the processing bin. A plate moving assembly is arranged on one side of the discharge port, and the plate moving assembly is provided with a discharge baffle. A material moving track is arranged on one side of the discharge baffle, and amaterial moving push plate is arranged on the material moving track. A discharge push plate is arranged on the end, away from the discharge port, of the processing bin, and a moving bottom frame is arranged at the working end of the material moving assembly. The briquetting assembly is provided with a hydraulic plate capable of extending into the processing bin. The briquetting device is simple tooperate, scrap metal only needs to be fed in sequence, and automatic briquetting and discharge can be performed, so that the briquetting efficiency is improved.

Owner:广西千吉科技有限公司

Paint-spraying die surface treatment device in toy production

ActiveCN110882873AWash evenlyImprove the quality of useLiquid spraying apparatusSpray boothsIndustrial engineeringMotor oil

The invention relates to the technical field of paint-spraying die surface treatment in toy production, and specifically relates to a paint-spraying die surface treatment device in toy production. Thepaint-spraying die surface treatment device in toy production comprises a drying machine, a cooling machine, a cleaning mechanism and a coating mechanism, wherein the cleaning mechanism and the coating mechanism are arranged in a manner of linear distribution; the cleaning mechanism comprises a cleaning tank, a lifting assembly, a horizontal movement assembly and an accommodating net box used foraccommodating a die; a hinge door is arranged at one end of the accommodating net box; a plurality of water guns are arranged in the cleaning tank; the coating mechanism comprises a coating box, a transfer conveyer, a liquid-spraying machine, and a guide spraying assembly; a charge port and a discharge port are formed in the two ends of the coating box separately; the guide spraying assembly comprises a liquid-spraying head capable of moving in an arc shape; and one end of the liquid-spraying head communicates with the liquid-spraying machine. The equipment is capable of automatically cleaning engine oil on the paint-spraying die, and uniformly spraying a fluororesin coating material on the paint-spraying die, so that the later-period use quality of the paint-spraying die is improved.

Owner:云和县鲁祥玩具经营部

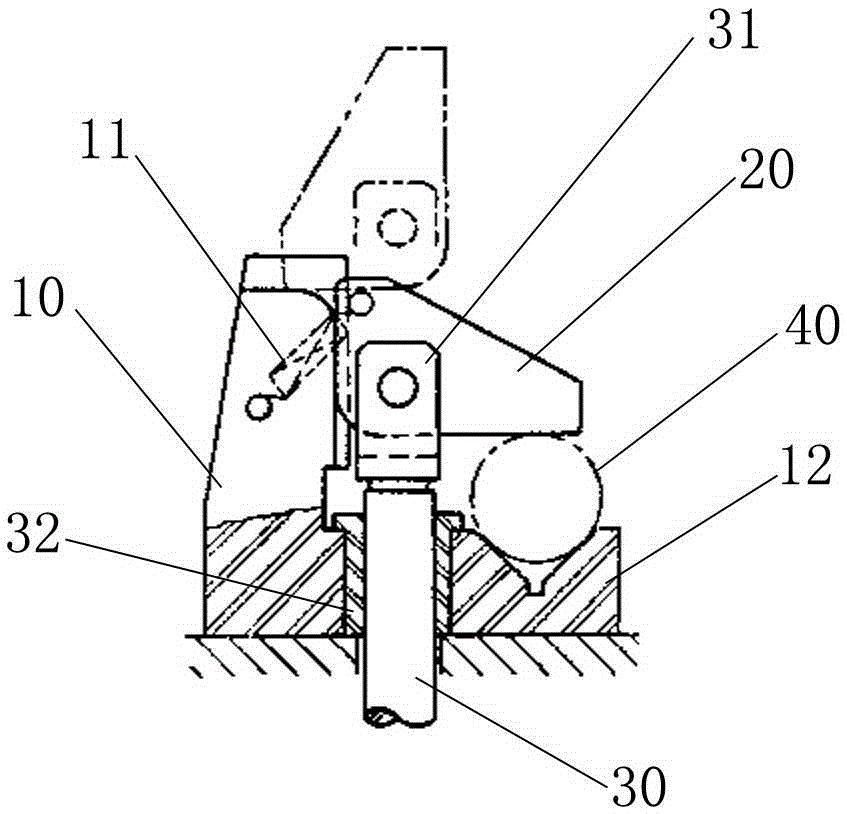

Fixing device for rod work-piece machining

InactiveCN105312436AEasy to fixAvoid wear and tearMetal-working feeding devicesPositioning devicesRight triangleAcute angle

The invention discloses a fixing device for rod work-piece machining. The fixing device comprises a machine frame, a clamping block, a fixing base, a spring, a U-shaped connecting plate and a push rod, wherein the clamping block, the fixing base, the spring, the U-shaped connecting plate and the push rod are sequentially arranged on the machine frame from top to bottom. The lower end of the fixing base and the left side of the machine frame are connected through screws and located through pins. The clamping block is shaped like a right triangle, the right-angle end of the clamping block is hinged to the upper end of the U-shaped connecting plate through dowels, the first acute-angle end of the clamping block is connected to the middle of the fixing base through the spring, and the second acute-angle end of the clamping block is used for pressing the work ends of work-pieces. The bottom end of the U-shaped connecting plate and the push rod are connected and fixed in a threaded mode. A V-shaped block and the right side of the machine frame are connected through screws and located through pins. The fixing device is simple in structure, easy to operate and capable of clamping rods conveniently and fast and improves the straightening efficiency of the rods.

Owner:CHONGQING TENGTONG IND DESIGN

Public health environment-friendly filtering and dust removing equipment

InactiveCN112057981AGuaranteed air tightnessPlay the role of guide limitDispersed particle filtrationTransportation and packagingPublic healthDust control

The invention relates to the technical field of environmental protection, and particularly relates to public health environment-friendly filtering and dust removing equipment. The equipment comprisesa box body, wherein the box body is sequentially provided with a pretreatment cavity, a placement cavity and a filter cavity from top to bottom, an air suction port is formed in the left side of the pretreatment cavity, a slag discharging port is formed in the lower right end of the pretreatment cavity, an air suction pump is fixedly arranged in the placement cavity, one end of the air suction pump is fixedly communicated with an outer pipe, the other end of the air suction pump is fixedly communicated with an auxiliary branch pipe, the auxiliary branch pipe extends into the filter cavity, a filter cartridge is arranged in the pretreatment cavity, telescopic support pieces are arranged at the upper end and the lower end of the filter cartridge, the upper end of the filter cartridge is fixedly connected with a threaded rod, a long-row brush is arranged on the right side of the filter cartridge, and the long-row brush is fixedly arranged on the side wall of the pretreatment cavity through a cross rod. Dust on the surface of the filter cartridge can be further cleaned and swept off, the dust removing efficiency is greatly improved, and the filtering effect of the filter cartridge is guaranteed.

Owner:南昌升升科技有限公司

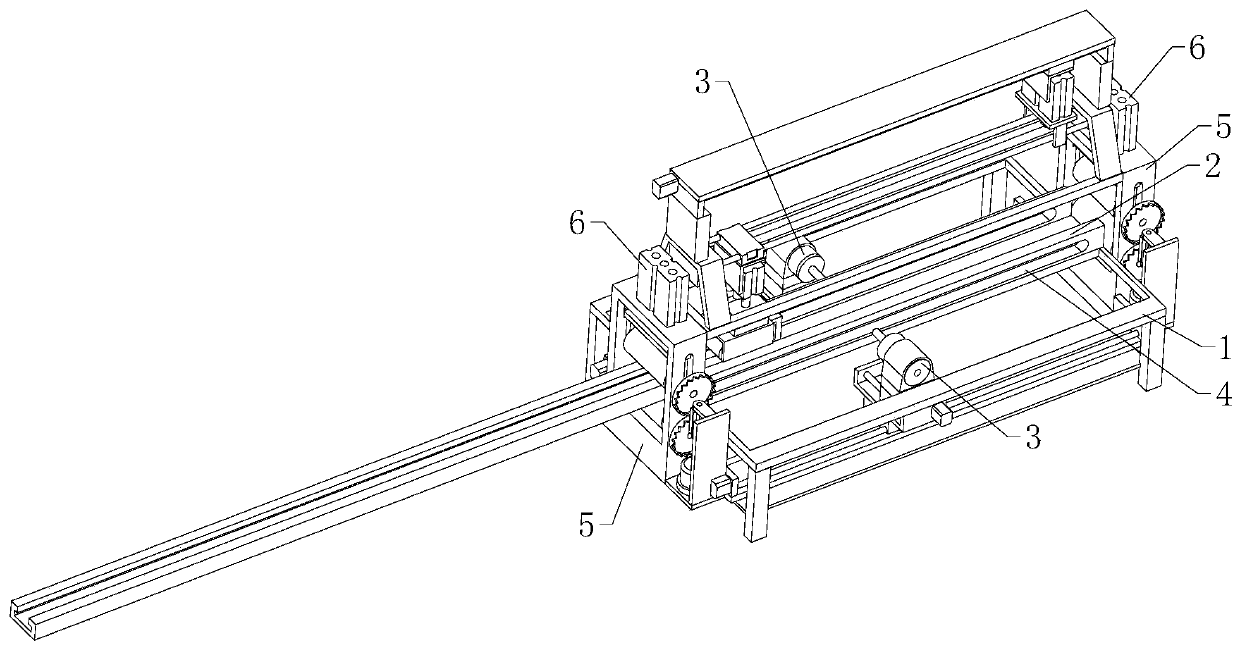

Ton bag sealing rope rubber tube cutting machine

ActiveCN108406875ANot deflectedPlay the role of guide limitMetal working apparatusEngineeringMechanical engineering

The invention discloses a ton bag sealing rope rubber tube cutting machine. According to the technical scheme, the ton bag sealing rope rubber tube cutting machine is characterized by comprising a machine frame, a feeding device located on one side of the machine frame, a conveying device for conveying a rubber tube and a cutting device for cutting the rubber tube. A guide device is arranged between the feeding device and the conveying device, and comprises a guide pipe fixedly arranged on the machine frame, and the end, close to the feeding device, of the guide pipe is in a horn shape. The technical effects that the disc-shaped rubber tube in the feeding device is conveyed into the conveying device from the center position of the guide device, and the end of the cut rubber tube is vertical are achieved.

Owner:青岛平成集装袋有限公司

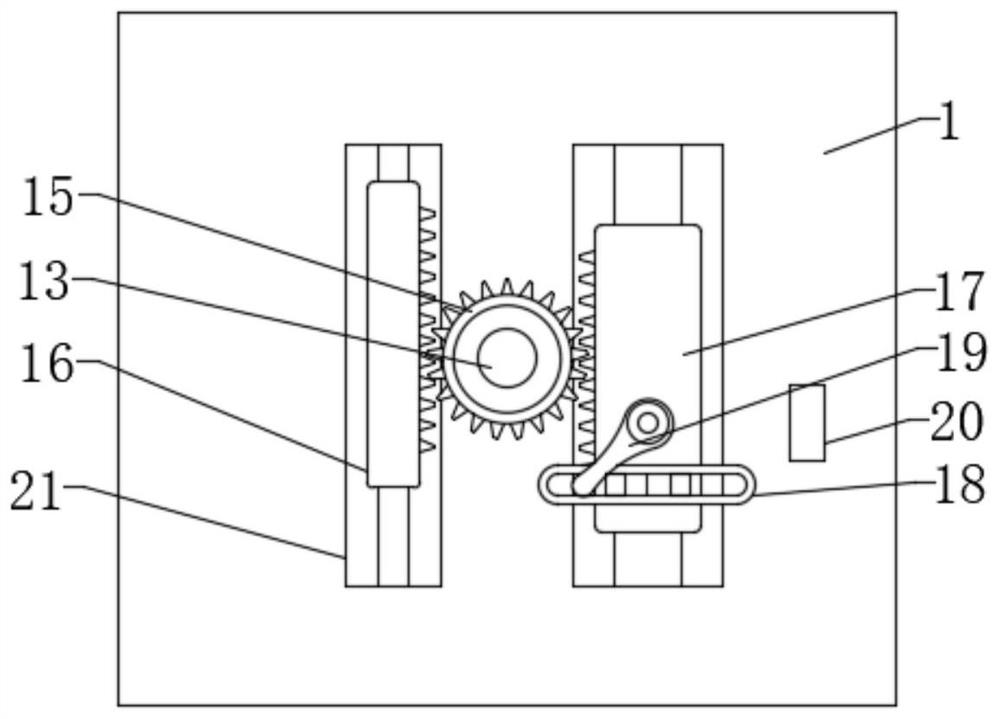

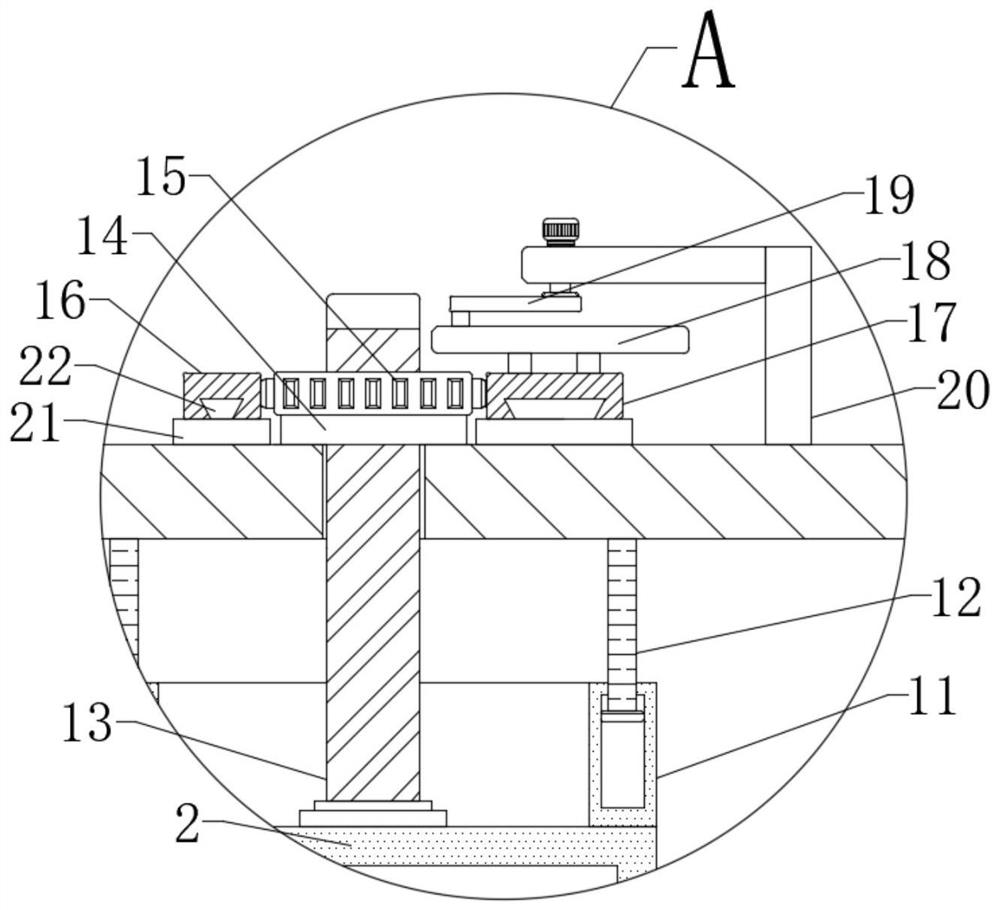

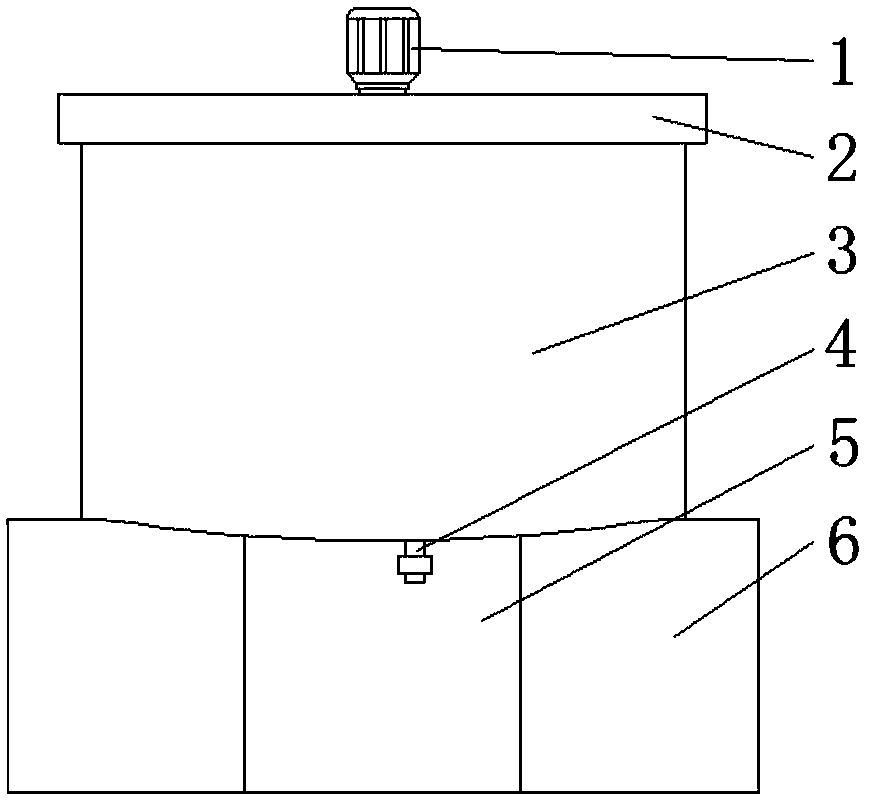

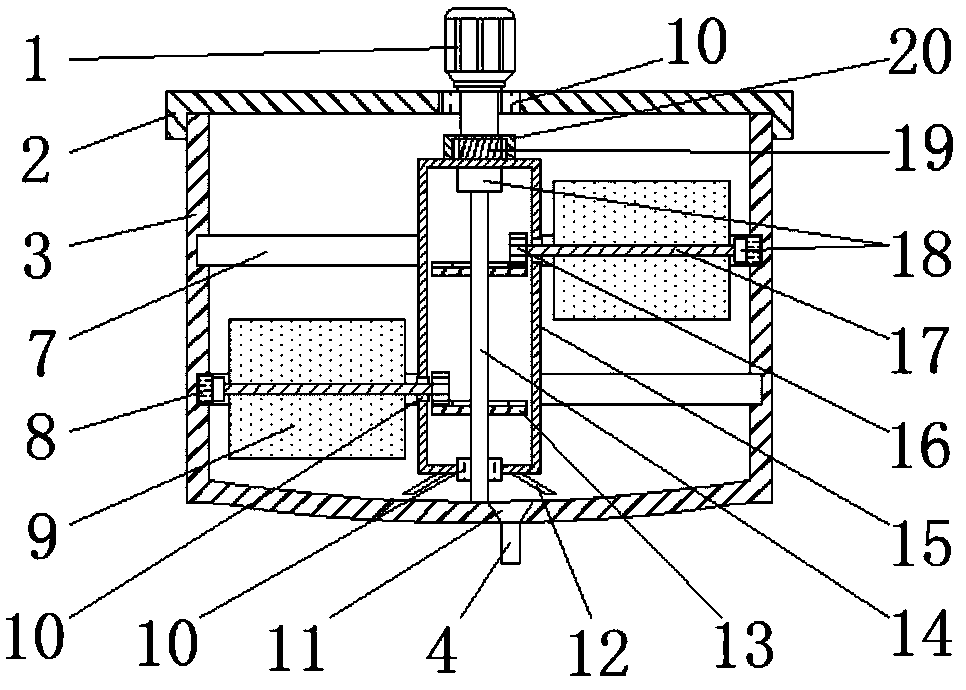

Electromechanical integrated blender

InactiveCN111391122AAchieving stirringFlip up and downDischarging apparatusMixing operation control apparatusCircular discGear wheel

Owner:于波

Multifunctional clamping mechanism for metal welding and cutting all-in-one machine and clamping method of multifunctional clamping mechanism

InactiveCN113084433AAvoid large deviationPlay the role of guide limitWelding/cutting auxillary devicesAuxillary welding devicesMachinePhysics

The invention discloses a multifunctional clamping mechanism for a metal welding and cutting all-in-one machine and a clamping method of the multifunctional clamping mechanism, and relates to the technical field of welding and cutting clamping. The multifunctional clamping mechanism solves the problems that the angle deviation between a clamped metal piece and welding and cutting equipment is large, the metal piece needs to be moved and adjusted, the clamping mode is complex, and when a plurality of point positions of the same metal piece are welded and cut, a large amount of time is wasted, and the welding and cutting efficiency is poor are solved. According to the multifunctional clamping mechanism, a longitudinal adjusting seat is arranged above a base, a transverse adjusting seat is arranged above the longitudinal adjusting seat, a first platform is arranged above the transverse adjusting seat, a second platform is arranged above the first platform, an object placing table is arranged above the second platform, clamping blocks are arranged above the object placing table, the clamping blocks are rotationally connected with the object placing table, a lifting block is arranged below the object placing table, a first electric telescopic rod is arranged between the lifting block and the second platform, and linkage rods are arranged between the three clamping blocks and the lifting block.

Owner:NANJING LINGQUE INTELLIGENT MFG CO LTD

Upwarp-preventing drilling equipment for guide rail production

ActiveCN110802249APlay the role of guide limitReduce volumePositioning apparatusBoring/drilling componentsStructural engineeringMechanical engineering

The invention relates to the technical field of guide rail processing, in particular to upwarp-preventing drilling equipment for guide rail production. The upwarp-preventing drilling equipment for guide rail production comprises a processing table. A horizontally arranged feeding track is arranged on the processing table; extension and retraction assemblies are separately arranged at two ends of the processing table; an upwarp-preventing assembly is arranged above the feeding track; the upwarp-preventing assembly comprises au upwarp-preventing guiding part capable of being in contact with topof a guide rail; a horizontal moving assembly is arranged above the upwarp-preventing assembly; a driving and clamping assembly is arranged at a working end of the horizontal moving assembly; drillingassemblies are separately arranged on two sides of the feeding track; a horizontal stepping assembly is arranged below each drilling machine; and each drilling assembly comprises the drilling machine; and rectangular notches where the drilling machines penetrate are separately formed in two sides of the feeding track. According to the equipment, when the guide rail is processed, the end, which iseasy to upwarp, of the guide rail is prevented from upwarping during feeding and discharging, so that the size of the equipment is reduced and the cost of the equipment is lowered.

Owner:佛山市顺德区海亮五金电器有限公司

Stacking and conveying equipment for vacuum fresh-keeping food fresh-keeping bags

InactiveCN112478573AGuaranteed stabilityNovel structureConveyor partsRoller-waysStructural engineeringRobot hand

The invention relates to the technical field of food fresh-keeping bag processing and conveying equipment application, in particular to stacking and conveying equipment for vacuum fresh-keeping food fresh-keeping bags. The stacking and conveying equipment comprises a conveying table, wherein two sets of supporting bases are fixedly arranged on the conveying table; a deviation rectifying mechanismis arranged on the supporting bases and comprises a left moving strip and a right moving strip; the left moving strip and the right moving strip are driven by a driving device to do linear opposite movement on the supporting bases; the left moving strip and the right moving strip are both fixedly connected to a plurality of stand columns; a plurality of sets of conveying rollers are arranged at the upper end of the left moving strip and the upper end of the right moving strip; n-shaped mounting frames are arranged on the outer sides of the conveying rollers; and two groups of lateral correction plates are rotationally arranged on the n-shaped mounting frame. The stacking and conveying equipment is low in cost; and as direct action is performed through a linear execution hydraulic cylinderwithout rotation action of a traditional mechanical arm, the stacking efficiency is high, and the safety of the stacking procedure is guaranteed.

Owner:黄海

Starch extraction equipment for potatoes

InactiveCN110437342APlay the role of guide limitEasy to adjust temperatureEngineeringMechanical engineering

The invention relates to the field of potato processing, particularly to starch extraction equipment for potatoes. The starch extraction equipment comprises a base, a breaking assembly, an extruding assembly, a filtering assembly and a drying assembly, wherein the breaking assembly comprises a breaking tank, the breaking tank is vertically arranged above the base, the top portion of the breaking tank is provided with a material inlet pipe, the top portion of the breaking tank is further provided with a water inlet pipe, the breaking tank is fixedly connected to the base through a first bracket, the extruding assembly comprises an extruding box, the top portion of the extruding box is an opening structure, the bottom portion of the breaking tank is provided with a first guide pipe, a breaking box is fixedly connected to the base through a second bracket, the filtering assembly comprises a filtering box, the filtering box is fixedly connected to the base through a third bracket, the bottom portion of the breaking box is provided with a second guide pipe, the drying assembly comprises a drying box and a material moving box, and the bottom portion of the filtering box is provided witha third guide pipe. According to the present invention, with the equipment, the peeled potatoes are only required to be sequentially placed into the breaking tank, such that breaking, loading extruding, filtering and filtering can be automatically performed so as to increase production efficiency.

Owner:朱海艳

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com