Electromechanical integrated blender

The technology of a mixer and a mixing mechanism is applied in the direction of cement mixing devices, chemical instruments and methods, clay preparation devices, etc. It can solve the problems that the materials to be mixed cannot be turned up and down, and the mixing effect is poor, so as to achieve a good mixing effect and maintain a stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

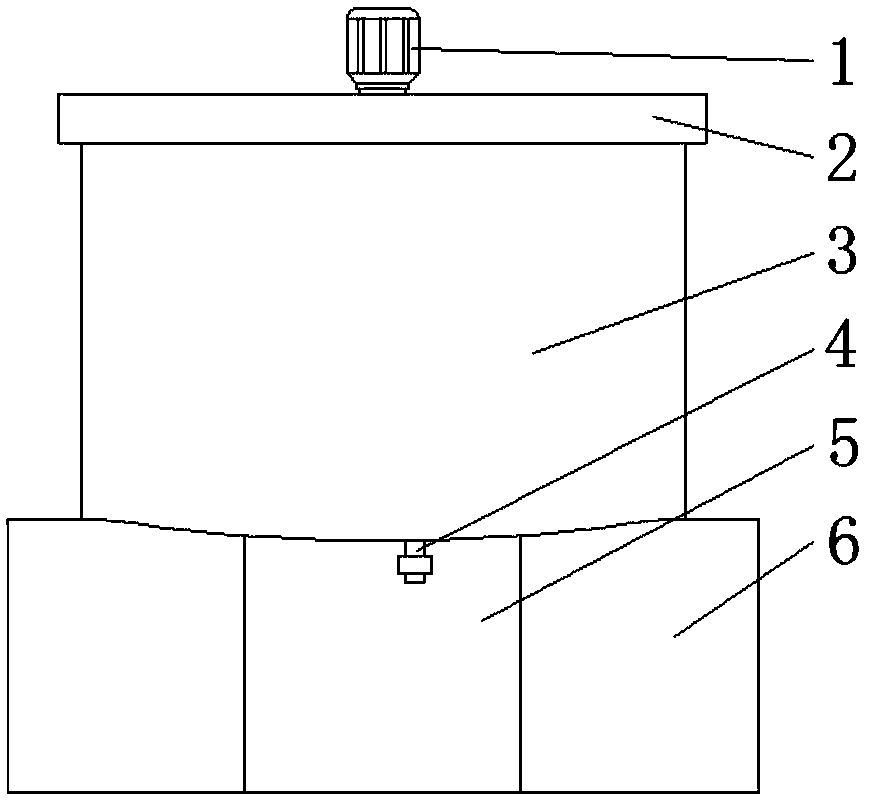

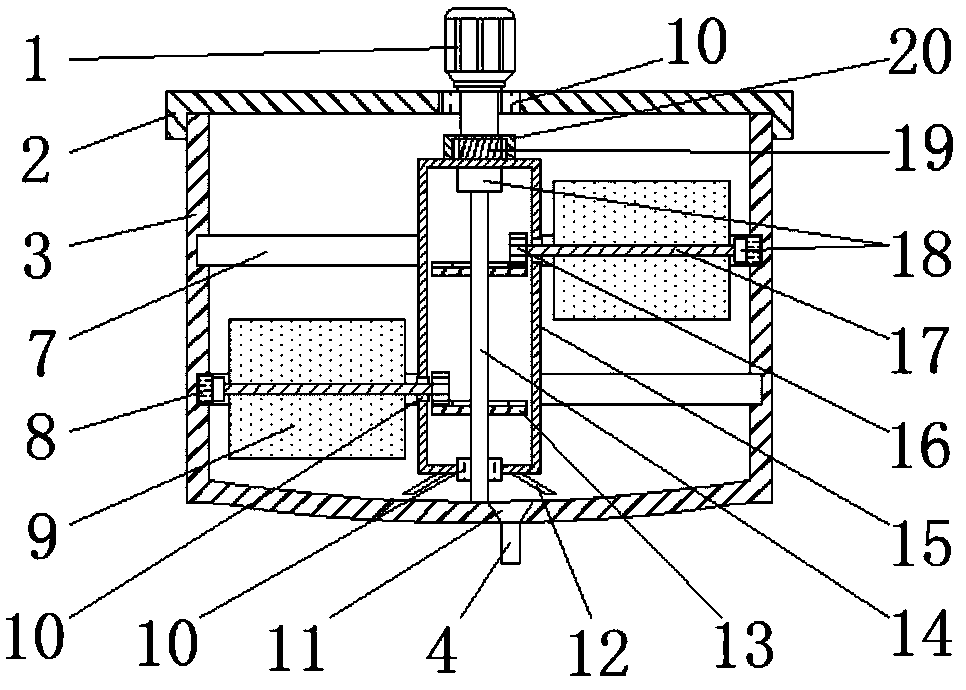

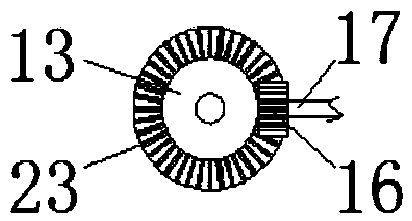

[0025] like figure 1 The shown mechatronic mixer includes a base 6 and a main cylinder 3 fixedly erected on the base 6. The upper end surface of the main cylinder 3 is open and is provided with a cover 2. The main cylinder 3 There is a stirring mechanism inside; such as figure 2 As shown, the stirring mechanism includes a rotating cylinder 15 vertically arranged in the middle of the main cylinder 3, and at least two stirring shafts 17 horizontally connected to the rotating cylinder 15 (two stirring shafts 17 are shown in the figure). , and the two stirring shafts 17 are respectively located in the upper and lower parts of the main cylinder 3) and the stirring blades 9 fixed on the stirring shaft 17, the rotating cylinder 15 is connected to the motor 1, and the output shaft of the motor 1 is vertical Arrangement, one end of the stirring shaft 17 penetrates the inside of the rotating cylinder 15 and is fixedly connected with the gear 16, and the inner bottom center of the main...

Embodiment 2

[0029] The difference between this embodiment and Embodiment 1 is:

[0030] In this embodiment, as figure 2 As shown, the motor 1 is installed at the top center of the cover body 2, and the output shaft of the motor 1 penetrates the cover body 2 and is connected with an outer active sleeve 20 in the shape of a groove with an opening downward. The top is fixed with an inner passive block 19 located inside the outer active sleeve 20, such as Figure 4As shown, the peripheral side of the inner passive block 19 is circular and is evenly provided with inner locking teeth 22, and the inner side surface of the outer active sleeve 20 is circular and is provided with outer locking teeth that engage with the inner locking teeth 22. 21. A sealed bearing 10 is provided on the cover body 2 at the position where the output shaft of the electric motor 1 passes through. When the cover body 2 is closed, the motor 1 realizes the transmission connection with the rotating cylinder 15 through t...

Embodiment 3

[0034] The difference between this embodiment and Embodiment 1 is:

[0035] In this embodiment, as Figure 5 As shown in the figure, scrapers for cleaning the annular chute 7 are fixed on both sides of the slider 8 corresponding to its moving direction, and the upper and lower ends of one side are respectively fixed with the upper and lower ends of the annular chute 7. The end surface scraper 24 for cleaning the end surface and the side scraper 25 for cleaning the side surface of the annular chute 7 are fixed at the rear end of the other side surface. The motor 1 is a forward and reverse rotation motor. When the motor 1 is rotating forward, the end scraper 24 moves with the movement of the slider 8, which can clean the upper and lower end surfaces of the annular chute 7; when the motor 1 is reversed, the side scraper 25 moves with the movement of the slider 8. By moving, the side surface of the annular chute 7 can be cleaned, thereby preventing materials from adhering to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com