Three-jaw chuck

A three-jaw chuck and chuck technology, which is applied in the field of mechanical processing, can solve problems such as poor stability and small clamping force of jaws, and achieve the effect of increasing clamping force and clamping stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

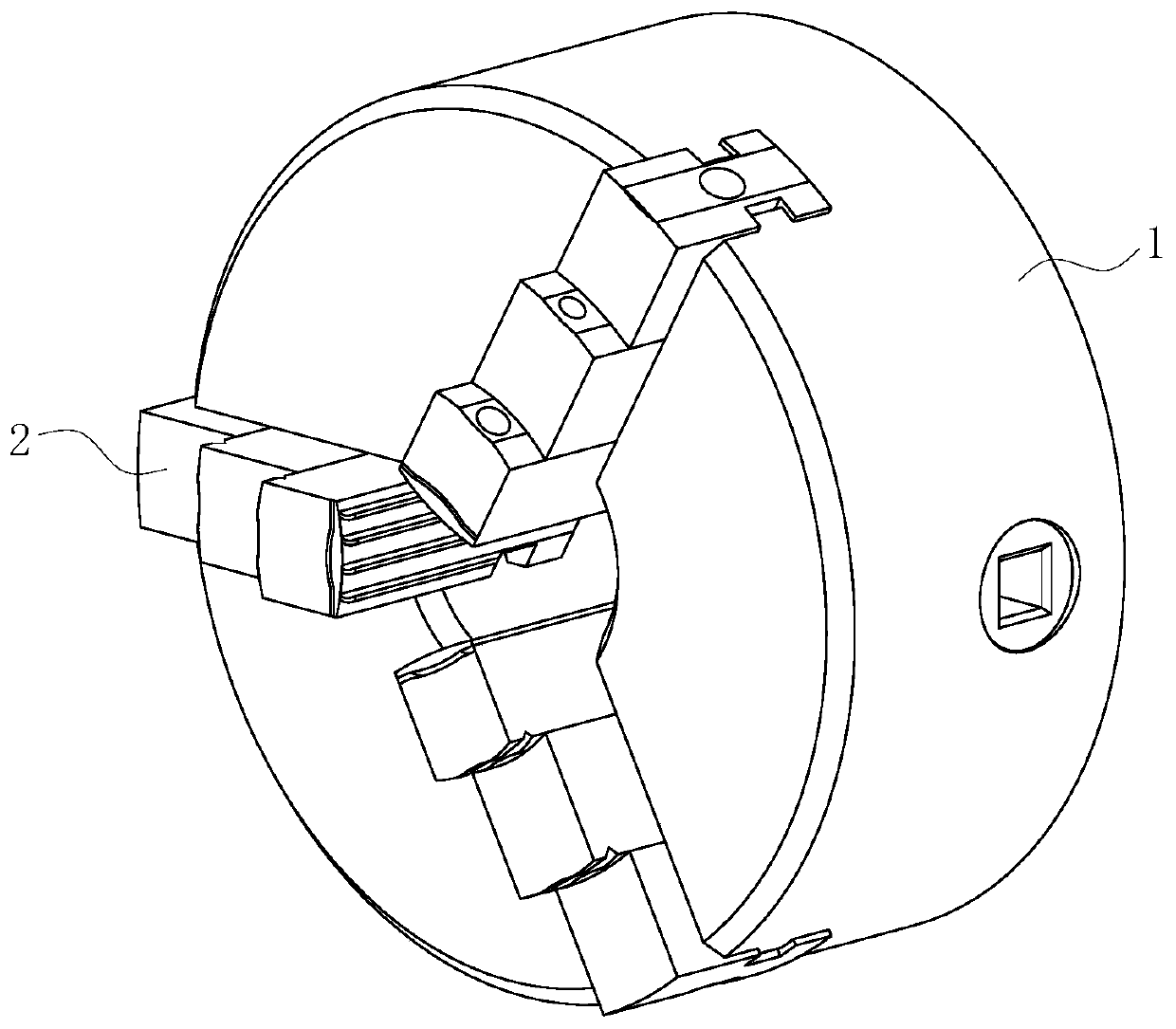

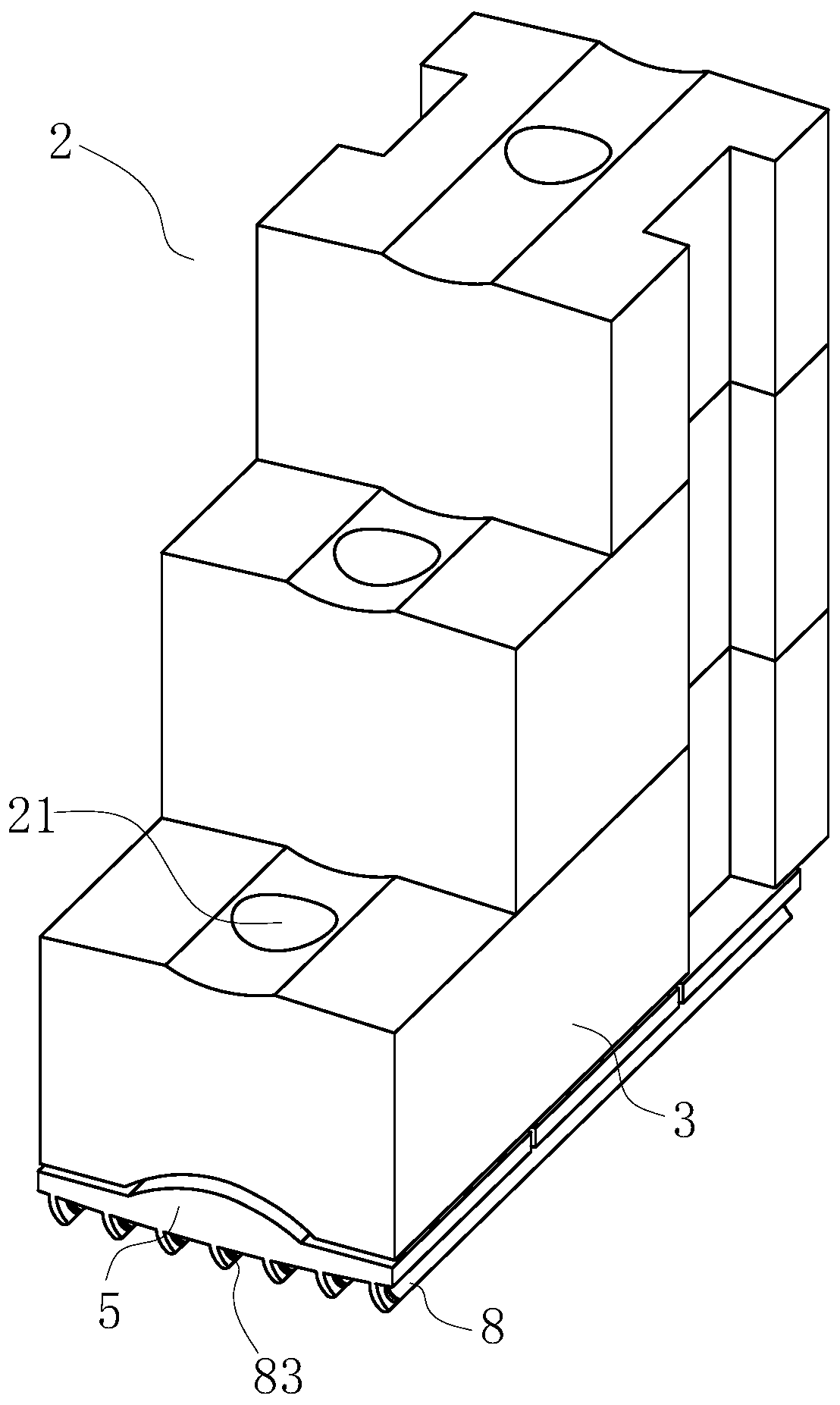

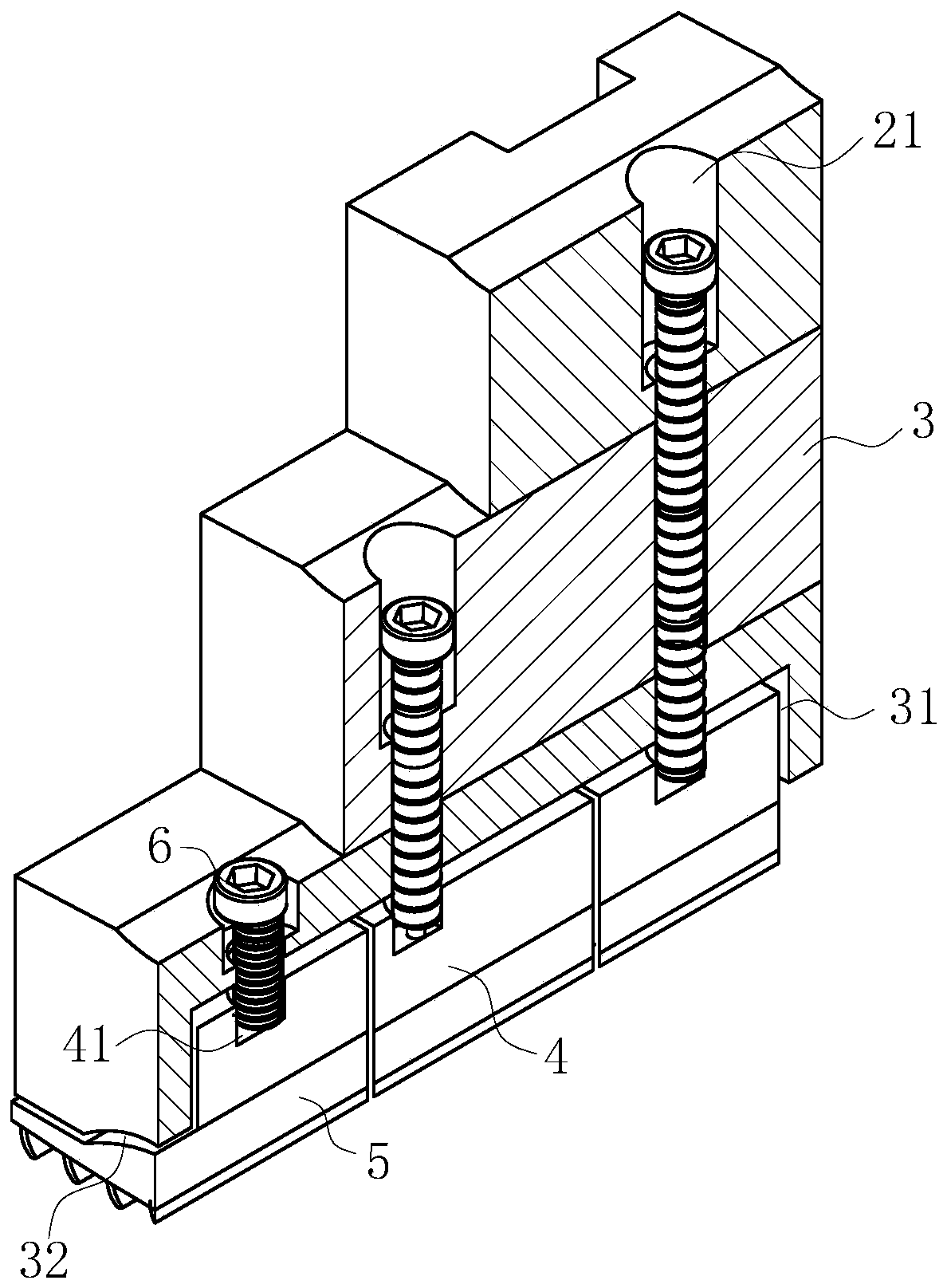

[0022] use Figure 1-Figure 5 A three-jaw chuck according to an embodiment of the present invention will be described as follows.

[0023] Such as Figure 1-Figure 5As shown, a three-jaw chuck according to the present invention includes a chuck body 1 and jaws 2; the jaws 2 have three and are uniformly distributed on the chuck body 1 in the circumferential direction; the structure of the three jaws 2 The same, and the three jaws 2 are all formed by overlapping and splicing three transverse pressing blocks 3; the lengths of the three pressing blocks 3 increase sequentially from top to bottom; The tight block 3 is provided with a guide chute 31 inside, and the bottom end of the guide chute 31 is provided with an engaging groove 32; the slide block 4 is slidably arranged in the guide chute 31, and the bottom end of the slide block 4 is connected with a press The clamping plate 5; the clamping plate 5 and the engaging groove 32 are engaged with each other; the sliding block 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com