Patents

Literature

30results about How to "Control dryness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

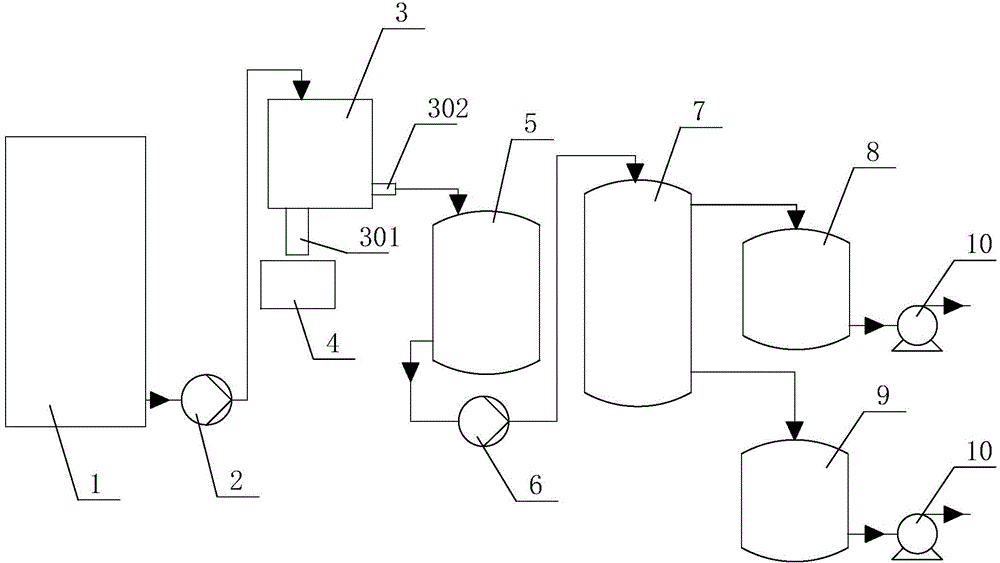

Tar slag separation recycling system

InactiveCN104888516AEasy to separateStrong solid-liquid separation abilityFiltration circuitsMoving filtering element filtersSocial benefitsSlag

The invention provides a tar slag separation recycling system which comprises a tar slag collecting groove, a first delivery pump, a centrifuge, a slag collecting groove, an oil and water collecting groove, a second delivery pump, an oil-water separator, a wastewater groove and an oil groove. Separation effect of tar slag with tar and water is improved due to high solid-liquid separation capability of the filter-type centrifuge, recycling rate of the tar slag and the tar is increased, and quality of the tar slag and the tar is improved. The tar slag and the tar which are separated can be utilized in production, and good environment-friendly benefit and social benefit are generated. The separation recycling system is automatic in feeding and discharging, simple in structure, easy to manufacture, few in personnel involved and easy to regulate and control.

Owner:SHANDONG IRON & STEEL CO LTD

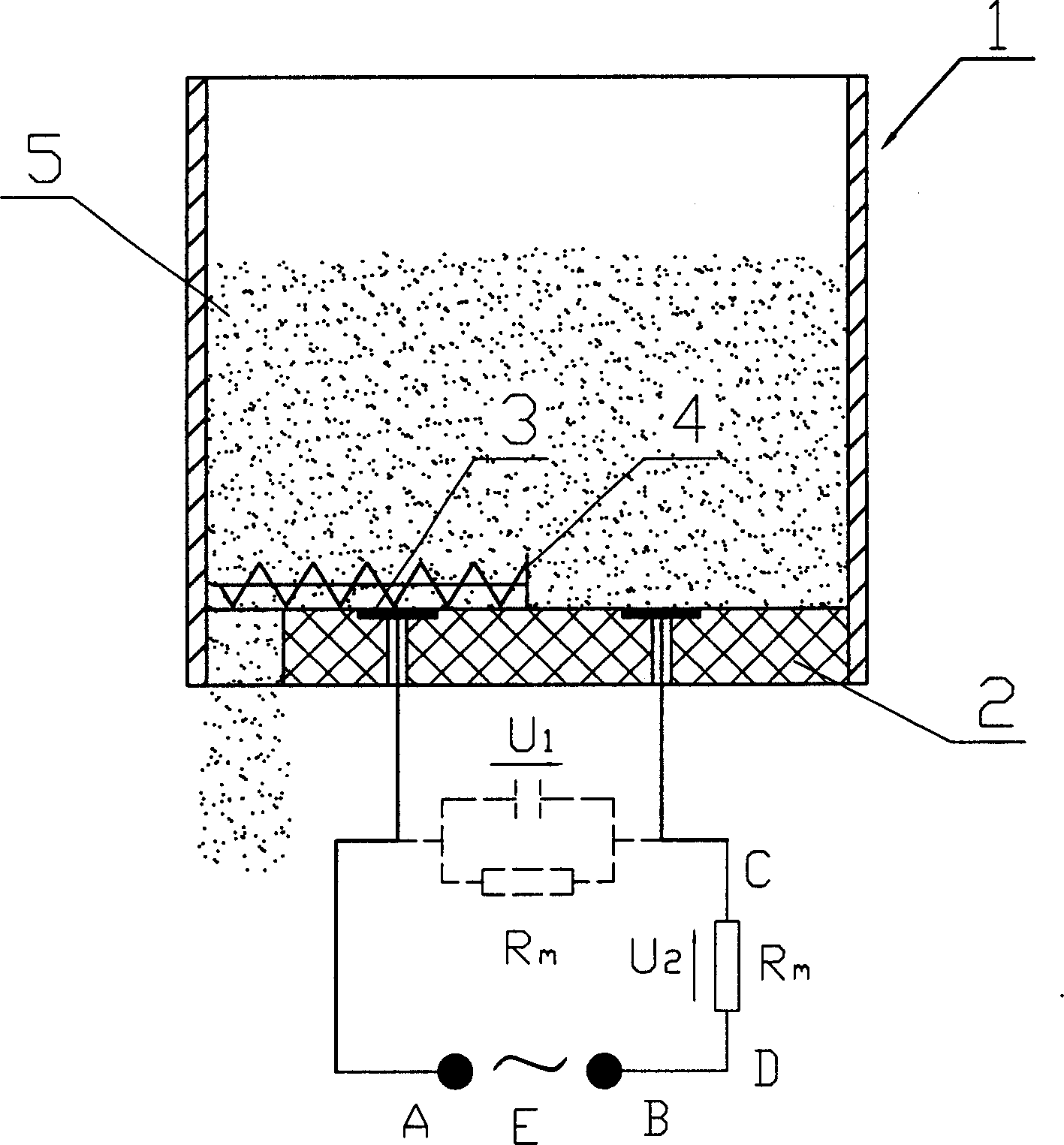

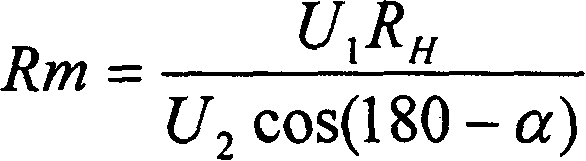

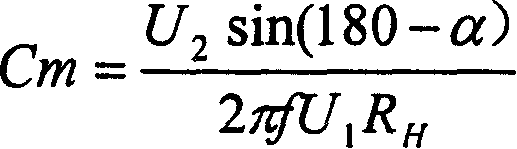

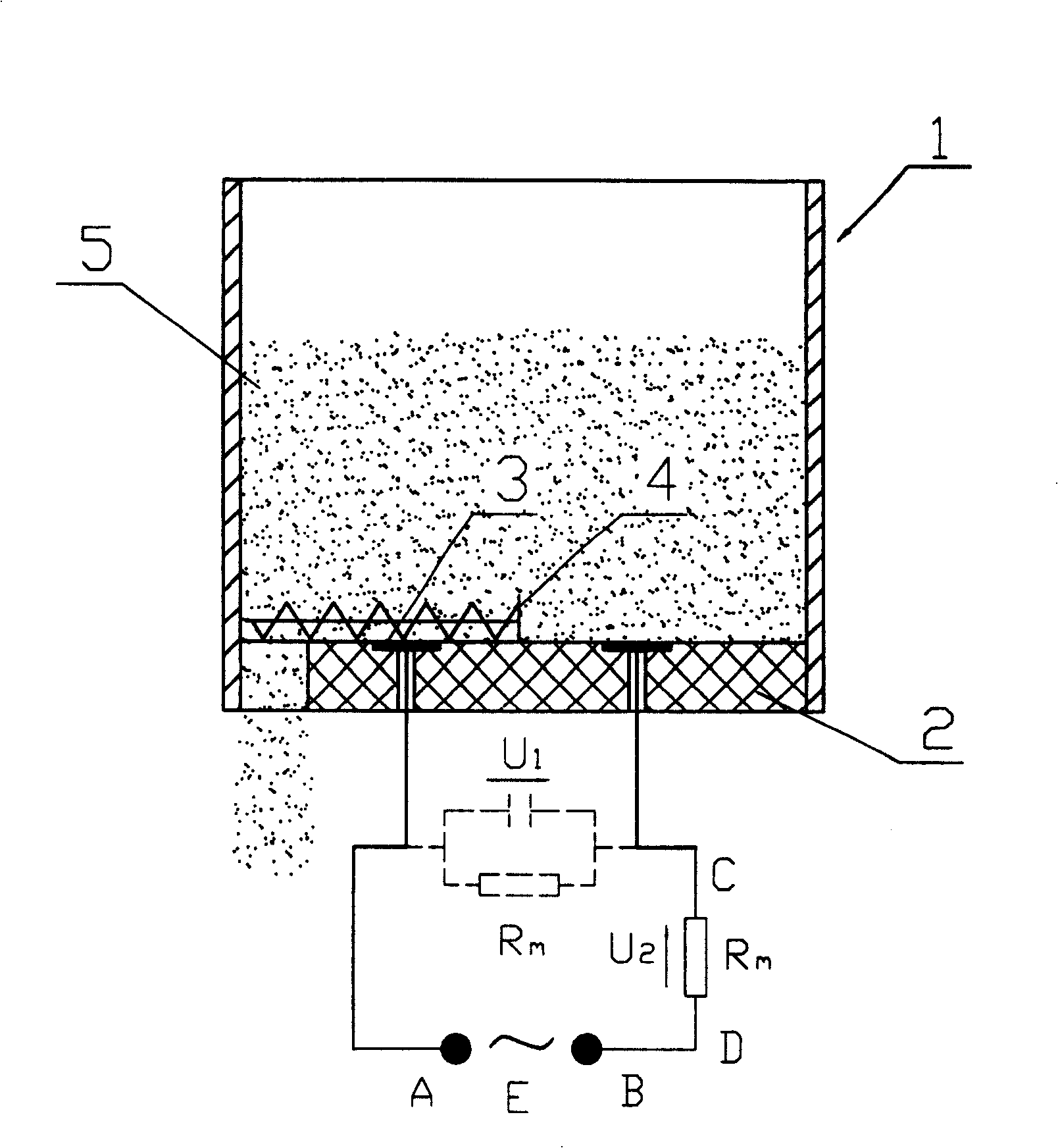

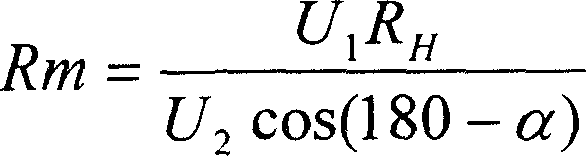

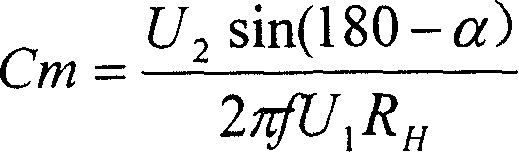

Method for determining water content of grain in spreading type grain drier

InactiveCN1865960AControl drynessSimple structureMaterial impedanceElectrical resistance and conductancePhase difference

The related moisture detection method for dried grain comprises: putting paralleled two plate electrodes on drier sides or bottom with some distance, forcing a high-frequency signal E connected to a standard resistance RH on the electrodes to generate a non-even electric field; detecting the voltage drop U1 of grain and U2 of RH and their phase difference alpha, and obtaining the Rm or Cm and then the moisture omega by electric formula and fitting function. This invention is simple and low cost.

Owner:NANJING AGRICULTURAL UNIVERSITY

Method for making black sound absorption and flame retardation paper through adhesive spraying

ActiveCN103233387AGood colorHigh strengthNon-fibrous pulp additionPaper coatingGlass fiberFilling materials

The invention provides a method for making black sound absorption and flame retardation paper through adhesive spraying. The method comprises the following steps: mixing glass fibers and vegetable fibers through a wet papermaking technology, respectively processing an adhesive and a flame retardant and color past mixture to prepare solutions having certain concentrations, uniformly spraying the surface of raw paper with a prepared adhesive solution, and drying at a controlled drying temperature for a controlled time to guarantee the flattening and no wrinkling of dried paper. The glass fibers and the vegetable fibers selected in the invention are processed through a production technology theory of special paper to obtain black sound absorption and flame retardation paper having the advantages of high strength, strong flame retardation and uniform surface color. In the invention, the excellent performances of the glass fibers and the vegetable fibers are fully performed, and the high-quality black sound absorption and flame retardation paper which can be used in the walls of buildings as a filler is obtained through the wet papermaking technology and an adhesive spraying and drying technology in the preparation of the special paper. The method provided by the invention has the advantages of full utilization of the self characteristics of raw materials, simple preparation process, and excellent performances of finished products.

Owner:SHAANXI UNIV OF SCI & TECH

Substitute tea capable of removing heat and toxic materials, and preparation method of substitute tea

ActiveCN103918823AReduce moisture contentShorten drying timePre-extraction tea treatmentClimate change adaptationBitter gourdToxic material

The invention discloses substitute tea capable of removing heat and toxic materials which contains the following raw materials: dehydrated guava leaves, dried guava fruits, dried bitter gourd, tea leaves, liquorice, dehydrated stigma of corn, dehydrated roselle, pericarpium citri reticulatae, dehydrated stevia rebaudian, dehydrated semen cassia, chrysanthemum, dehydrated gynostemma pentaphylla, dehydrated lotus leaf, pink rose, broadleaf holly leaf and the like, wherein the raw materials are dehydrated and dried till the water content is controlled to be 5%-8%. In addition, the invention further discloses a preparation method of the substitute tea. The preparation method comprises the following steps: selecting fresh tea material, cleaning the fresh tea material, finishing, blanching, cooling, carrying out vacuum dewatering under variable pressures, drying with combination of solar energy and dehumidification, grinding raw materials, mixing and stirring, packing with small filter-bags. The technical solution provided by the invention overcomes the defects in the traditional series substitute tea processing methods, energy consumption and production cost are reduced, influences of weather are avoided, the drying is fast, the product quality is good, and the product meets the national standard related to food hygiene.

Owner:GUANGZHOU QINGXIANG AGRI PROD CO LTD

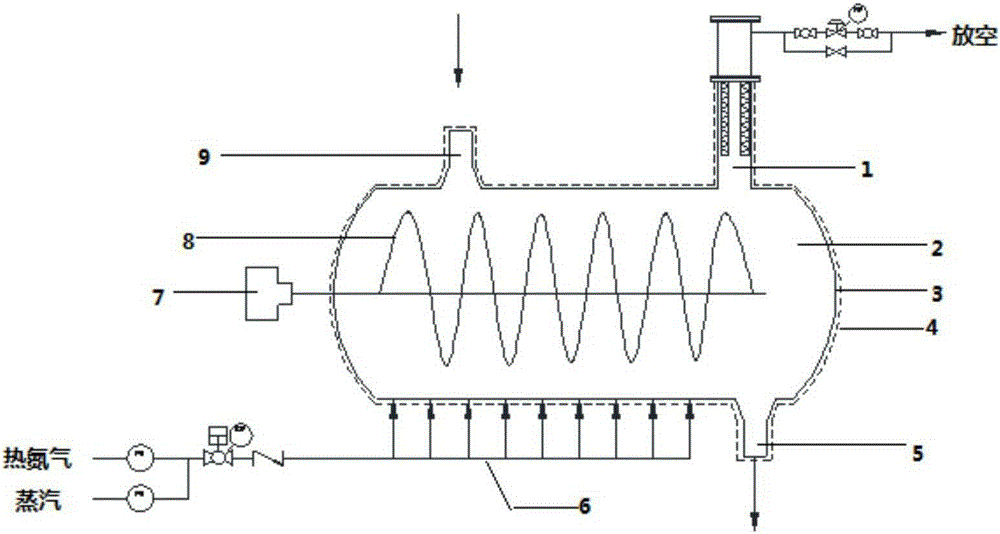

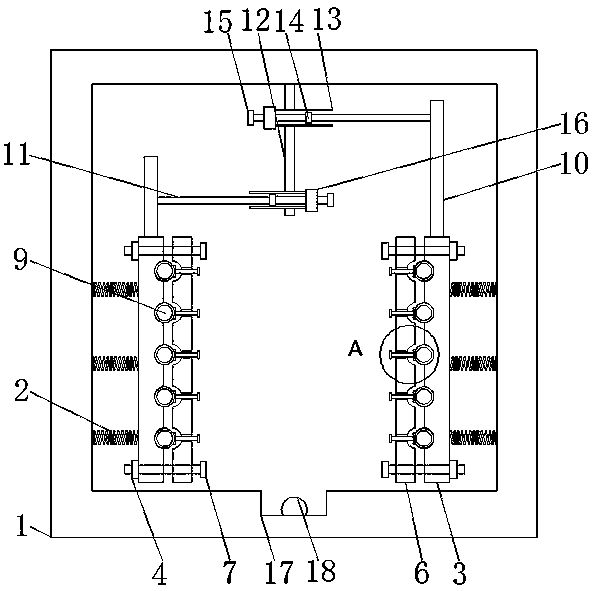

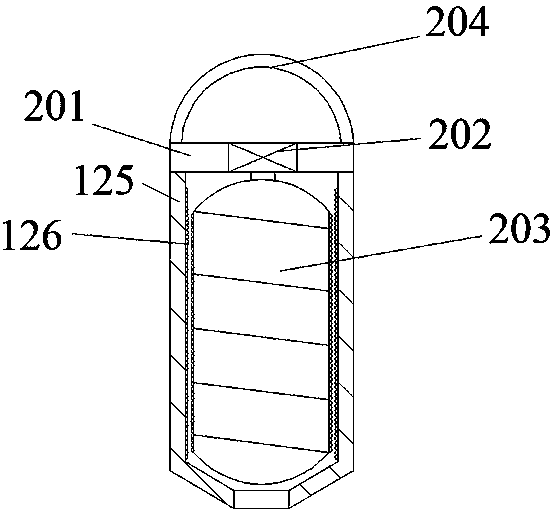

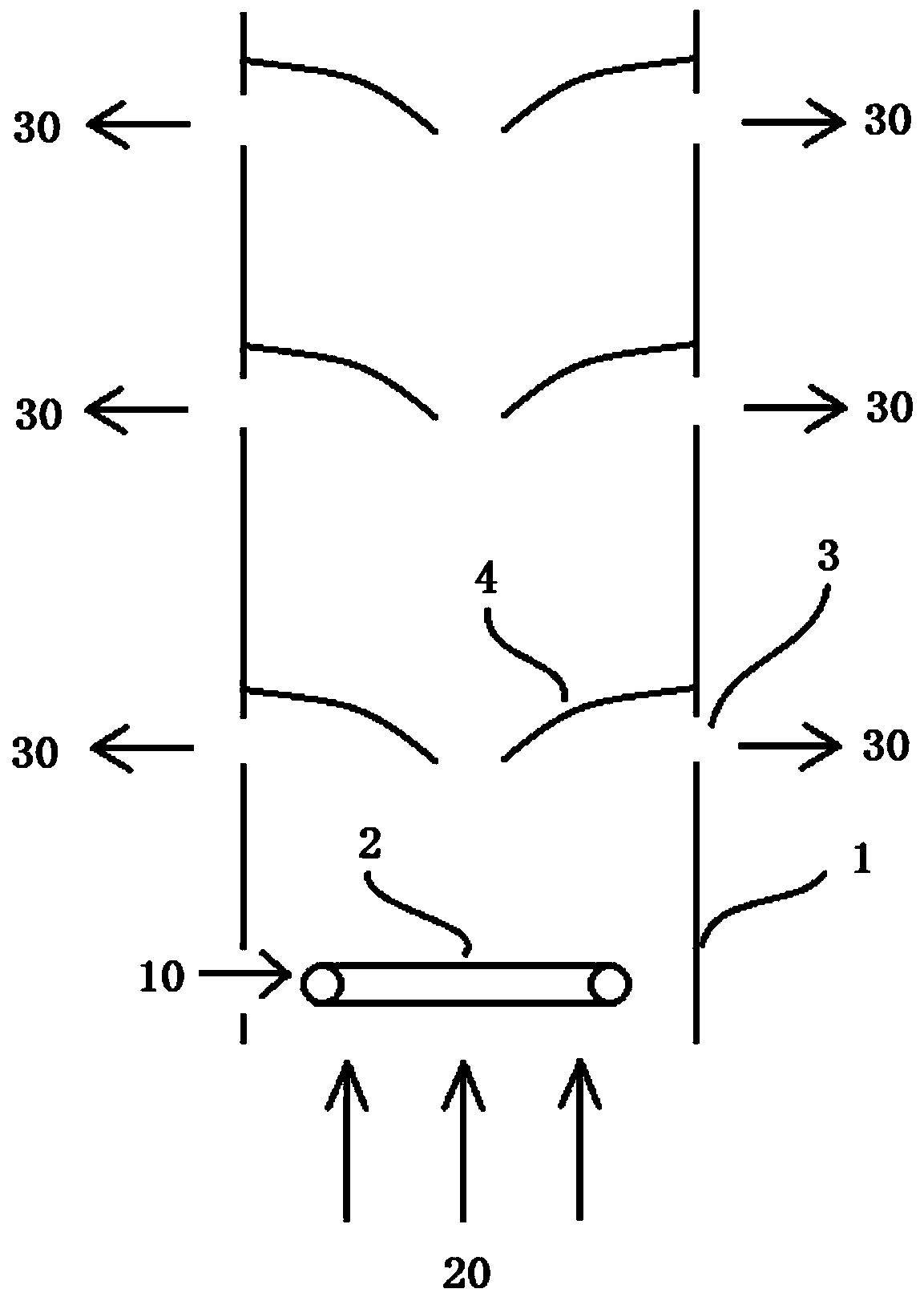

Polymer powder volatile component removing apparatus and polymer powder volatile component removing method

The invention relates to a polymer powder volatile component removing apparatus, which comprises a gas phase full mixing flow container having a horizontal stirrer, and a filter, wherein the gas a stirring implementing mechanism is arranged at the center axis line position of the left side of the gas phase full mixing flow container, the gas phase full mixing flow container top portion side away from the stirring implementing mechanism is provided with the filter, the gas phase full mixing flow container top portion side close to the stirring implementing mechanism is provided with a material inlet, the gas phase full mixing flow container bottom portion side away from the stirring implementing mechanism is provided with a material discharging port, and the bottom portion of the gas phase full mixing flow container is provided with uniformly distributed holes. The invention further relates to a polymer powder volatile component removing method, wherein polymer powder enters the volatile component removing apparatus from the volatile component removing apparatus top portion side close to the stirring implementing mechanism, the mixed gas of hot nitrogen and steam uniformly enters from the bottom portion of the volatile component removing apparatus in a dispersed manner, the polymer completely contacts the mixed gas, volatile component removing is performed, the gas is filtered through the filter on the gas phase full mixing flow container top portion side away from the stirring implementing mechanism and then is vented, and the polymer is discharged from the bottom portion side away from the stirring implementing mechanism.

Owner:PETROCHINA CO LTD

Whole-course plane dry breeding process for laying ducks

The invention provides a whole-course plane dry breeding process for laying ducks. According to the process, a breeding area is divided into an activity area and a laying area; the activity area adopts a net bed structure, a feces scraping device is arranged under a net bed, and scraped feces is exposed under the blazing sun for drying and then mixed with dry mud according to a proportion to obtain a dry feces mixture, wherein the proportion is 1:(5-10); the area of the laying area is equal to that of the activity area, the laying area is connected with the activity area without blockage, straw, rice chaff, hay and the dry feces mixture are adopted as padding and applied in the laying area, and the height of the padding is 10-20 cm; the laying time is 2-5 am., and the environment is maintained dark; a duck shed is erected above the breeding area, and fences are arranged around the duck shed for isolation; a temperature control device is installed in the duck shed to make the temperature in summer drop to 30 degrees or below, and a venting device is installed in the duck shed; a humidity control device is installed above the activity area, and clean water is sprayed at regular time;when ducks eat their feathers, the beaks of the ducks are cut off. A drinking pipe is placed on the net bed in the activity area, and a feed barrel is placed in the activity area or the laying area.

Owner:安徽滨江农业科技股份有限公司

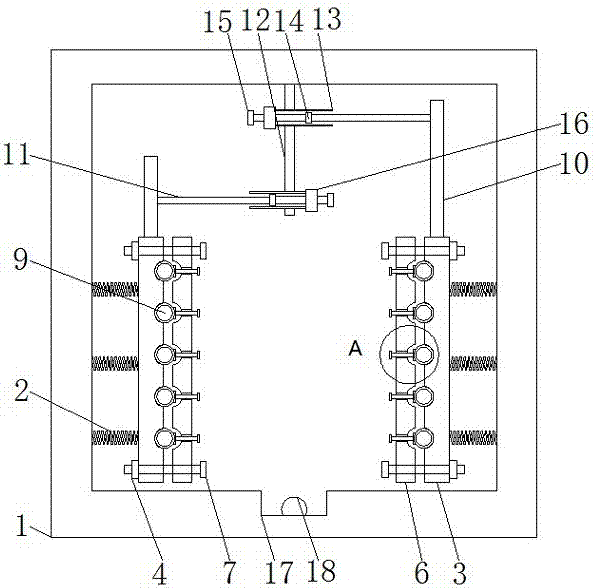

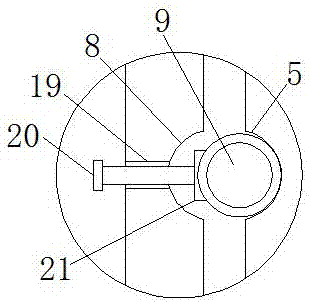

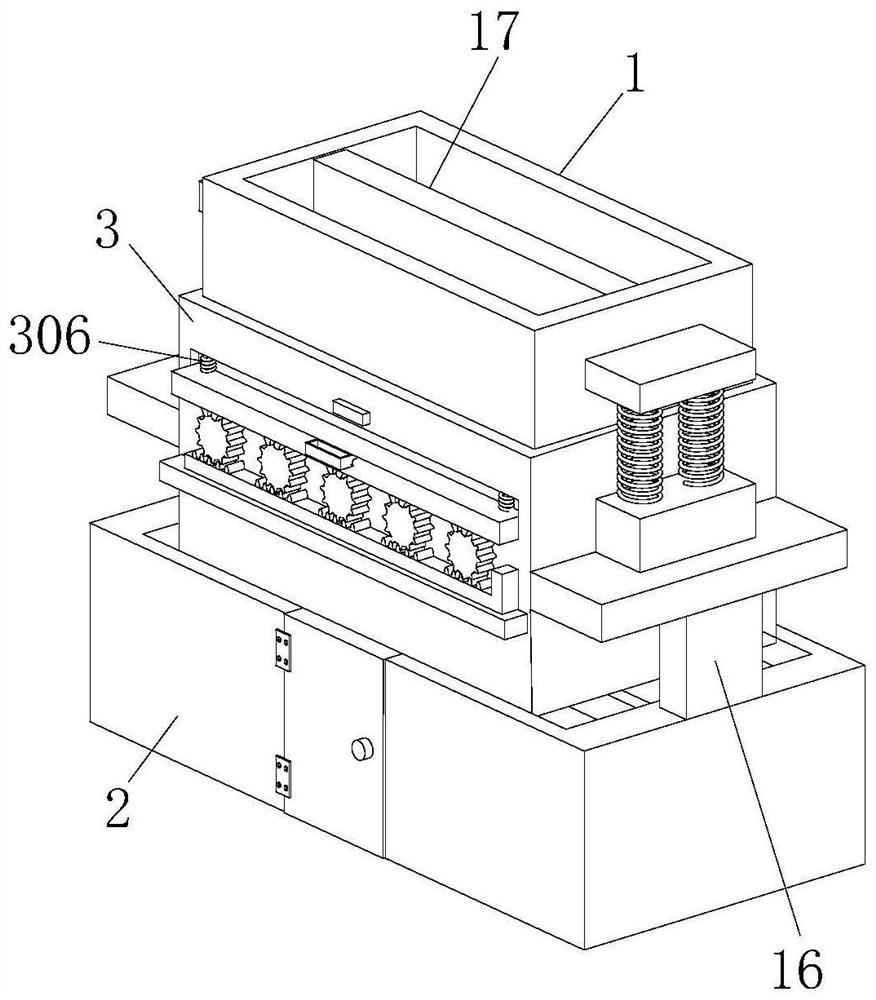

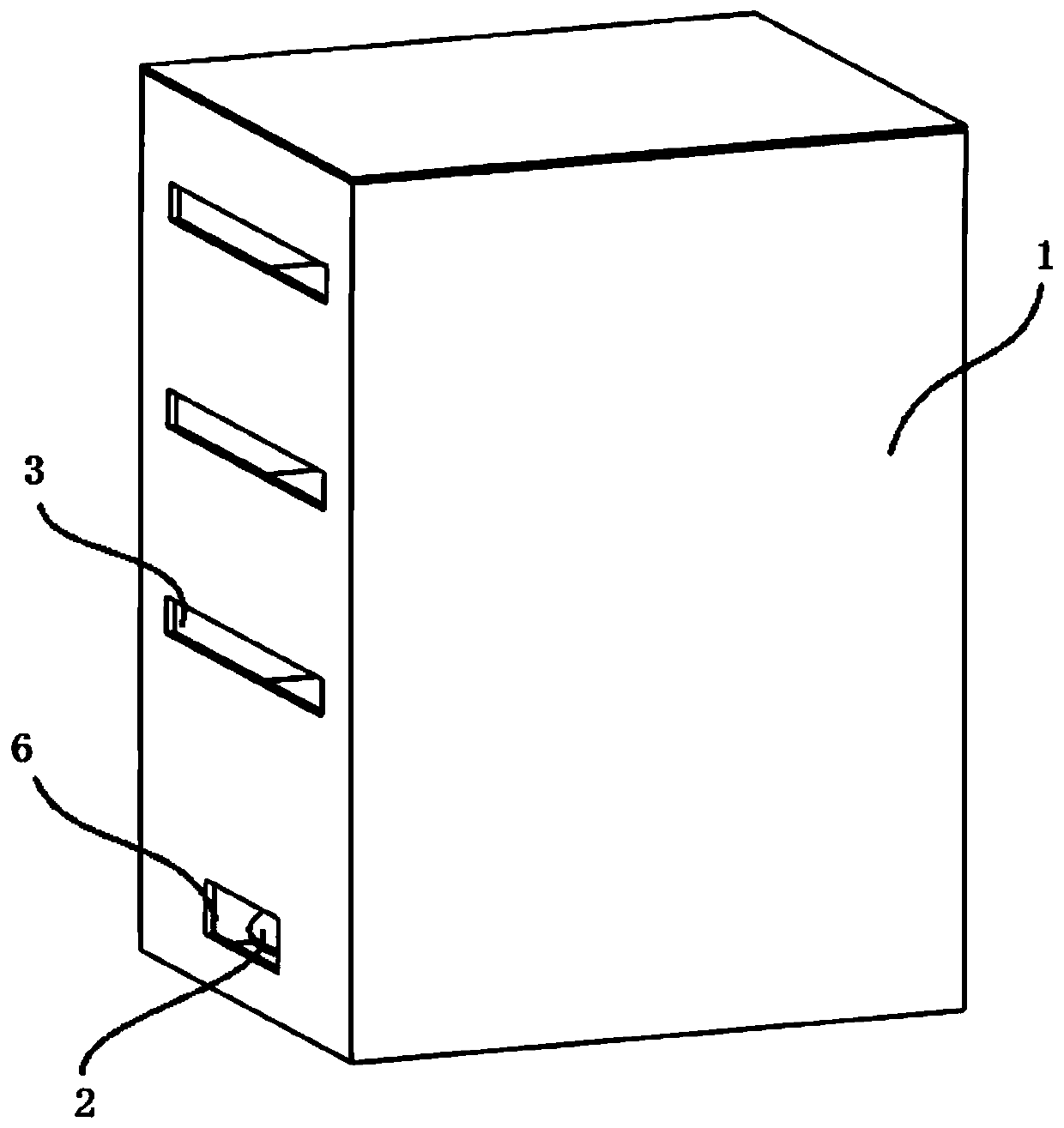

Drying device for wood processing

ActiveCN107127853AControl drynessNo need to change heating temperatureWood treatment detailsWood heatingEngineeringHeating temperature

The invention discloses a drying device for wood processing. The drying device comprises a drying box, an installing plate is connected to one side of a connecting spring, a clamping plate is arranged on one side of the installing plate, connecting bolts are arranged at the top and the bottom of one side of the clamping plate, and one side of each connecting bolt penetrates the clamping plate to be in threaded connection with a first nut; an electric heating pipe is clamped between a first clamping groove and a second clamping groove, an adjusting rod is connected to the top of the installing plate, and a support is connected to the top of an inner cavity of the drying box; a movable block is arranged in an inner cavity of a through pipe, one side of the movable block is connected with a strut, a threaded rod is movably connected to one side of the movable block, and the middle of the inner side of a second nut is in threaded connection with the threaded rod. The drying device for wood processing has the beneficial effect that the heating temperature in the drying device does not need to be adjusted; and the problem that when the wood drying degree is controlled, the heating temperature of the drying device needs to be adjusted, and consequently the service life of the drying device can be influenced is solved.

Owner:常熟市维摩剑门绿茶有限公司

Laser drying box

The invention discloses a laser drying box, and belongs to the field of drying devices. The laser drying box comprises a box body, laser emitters and a laser receiving box. The laser emitters are arranged on the inner wall of the box body. The laser receiving box is arranged in the box body. The laser drying box is simple in structure and convenient to use. Materials are placed in the laser receiving box and can be rapidly dried through the high temperature generated by the laser emitters, the drying effect is good, the drying efficiency is high, and the production efficiency of enterprises is improved.

Owner:NANJING HAIYUAN CHINESE HERBAL PIECES CO LTD

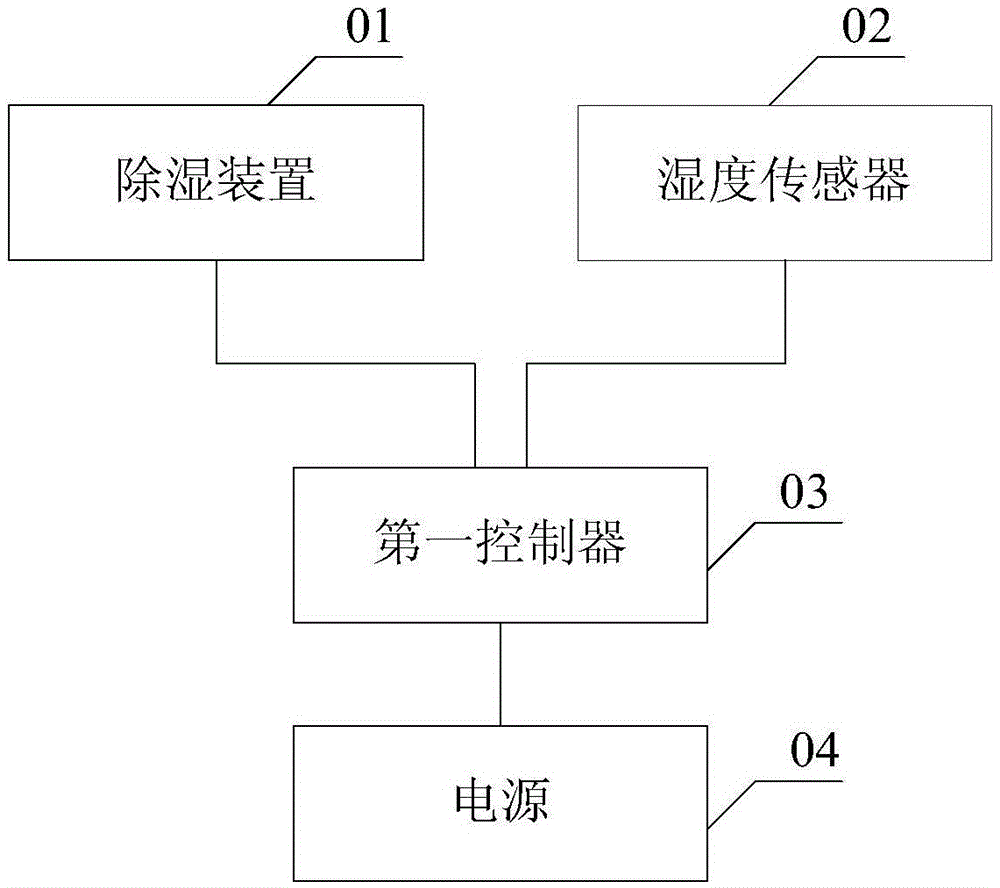

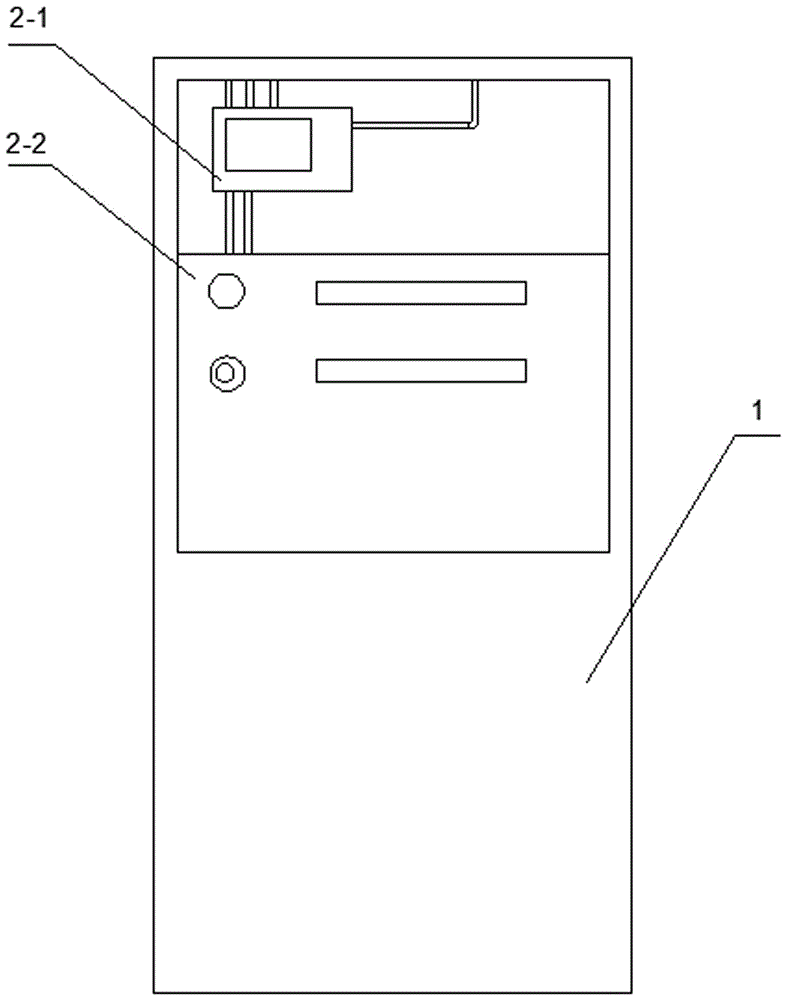

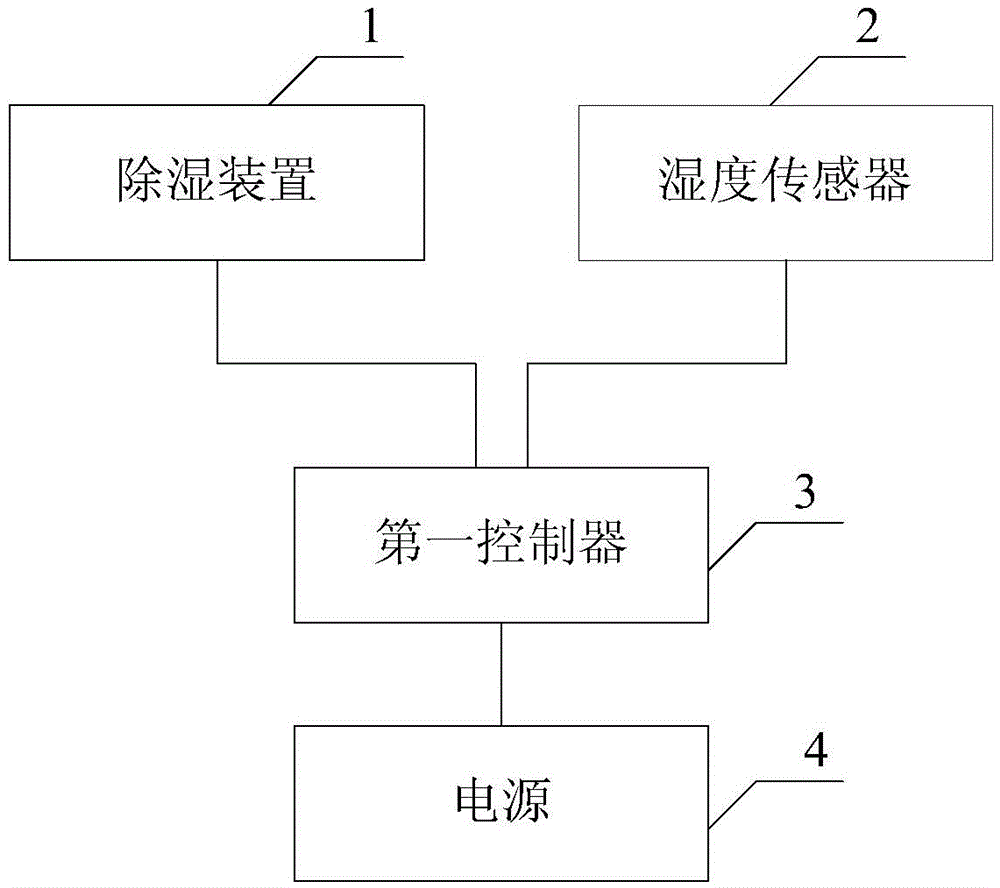

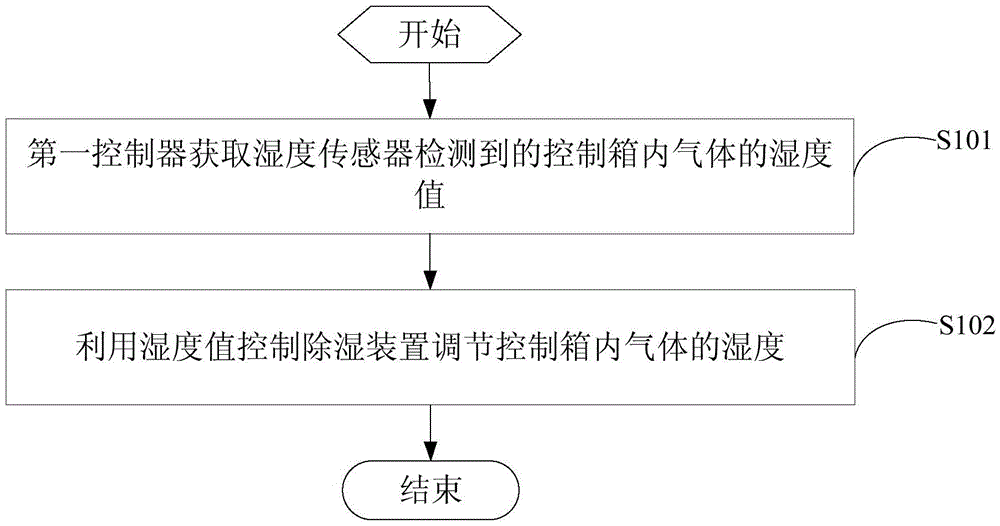

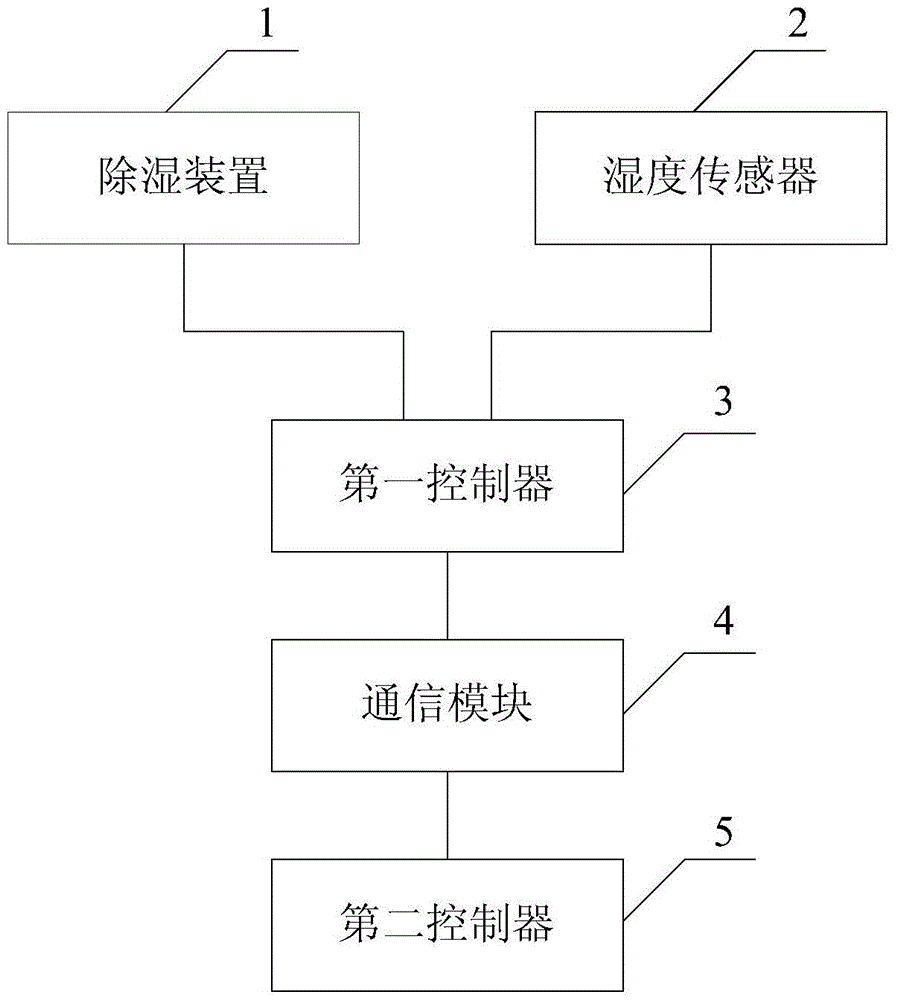

Dehumidifying method and system

The invention provides a dehumidifying method and system. A humidity sensor detects the humidity value of gas in a control box, and a first controller controls a dehumidifying device with the humidity value detected by the humidity sensor to adjust the humidity of gas in the control box, thus controlling the dryness in the control box of transformer equipment, and solving the problem of frequent grid accidents caused by the reason that components in the control box are easily damped to influence the safety operation of the transformer equipment.

Owner:STATE GRID ZHEJIANG NINGBO FENGHUA POWER SUPPLY CO LTD +2

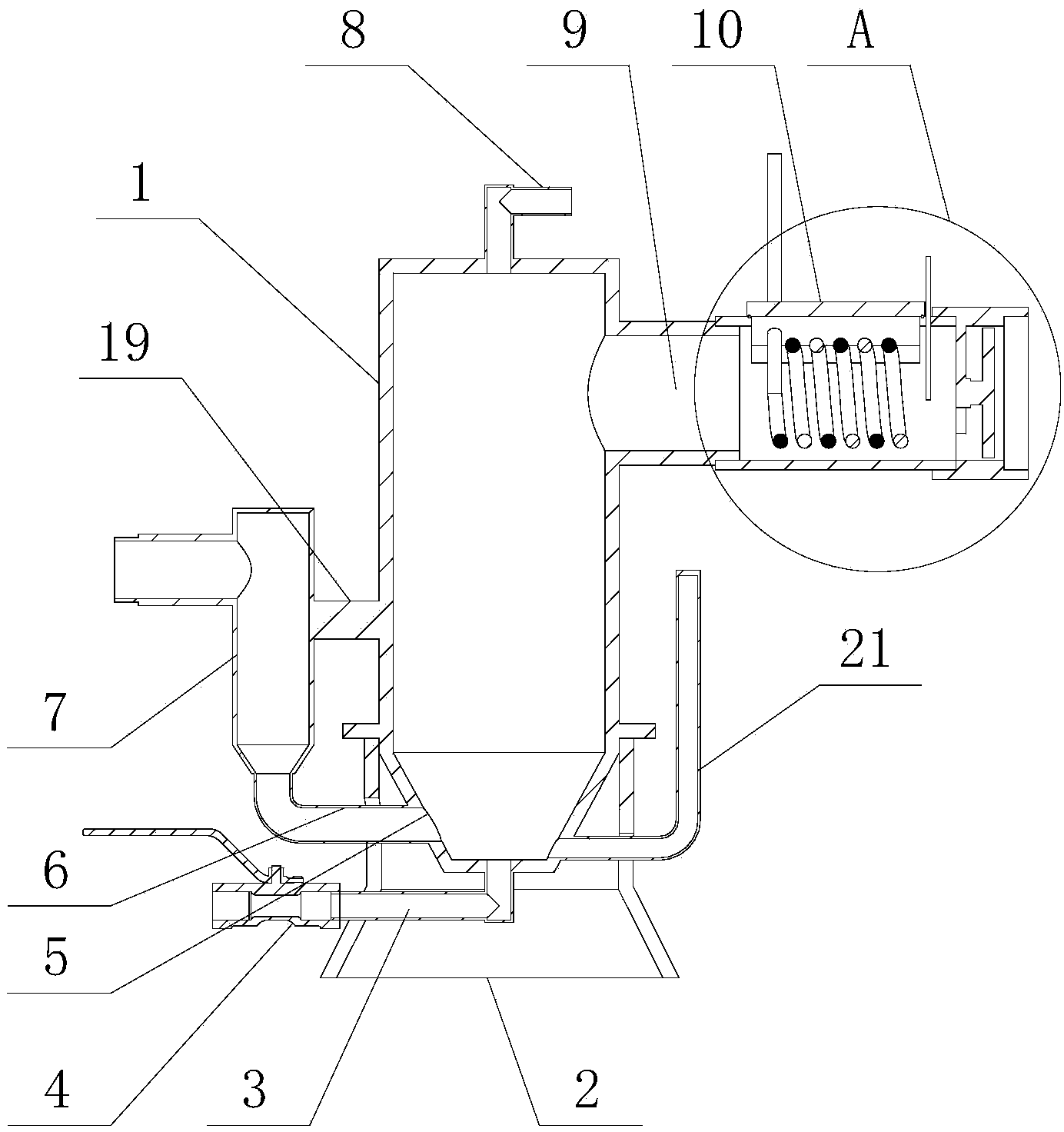

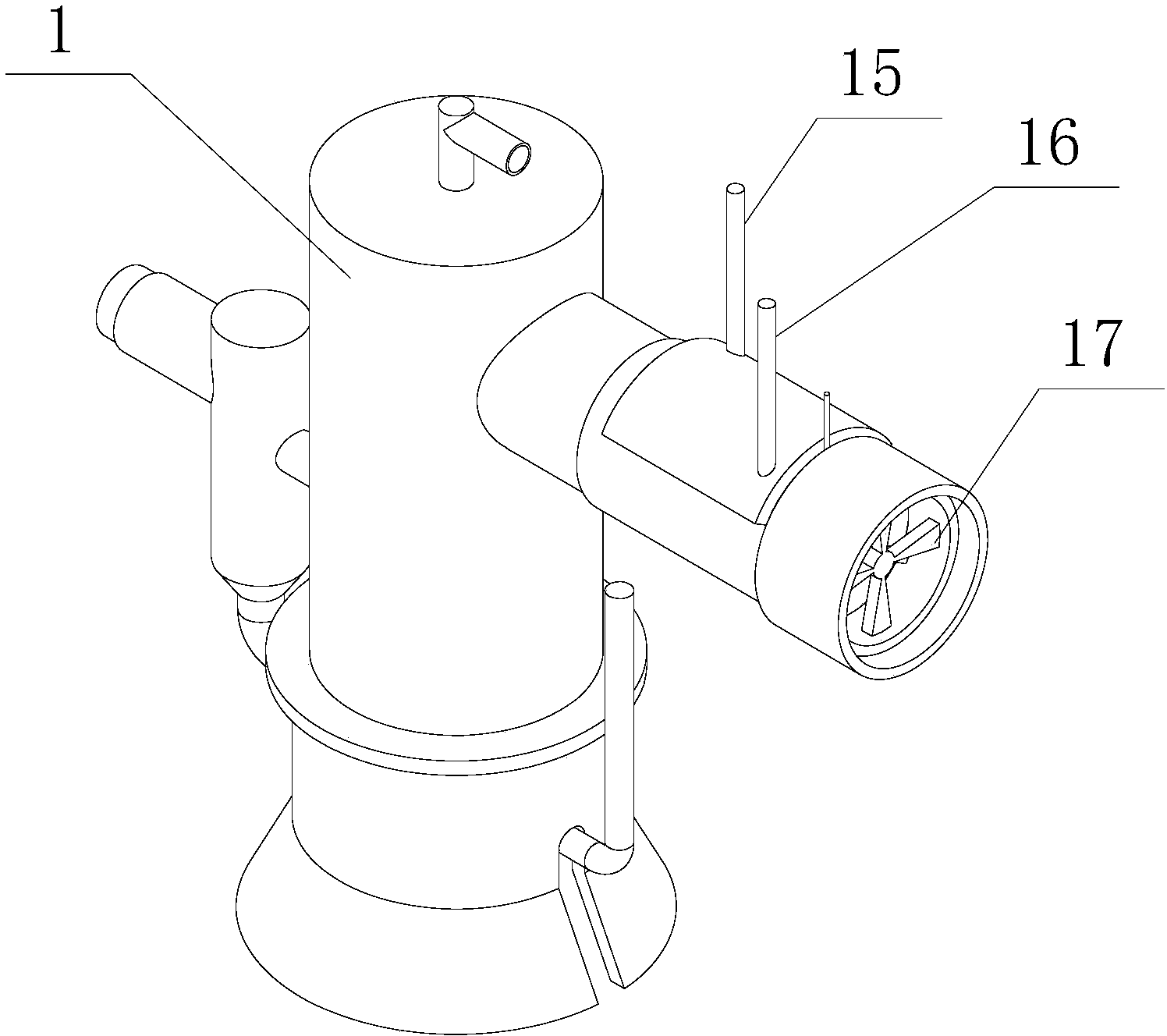

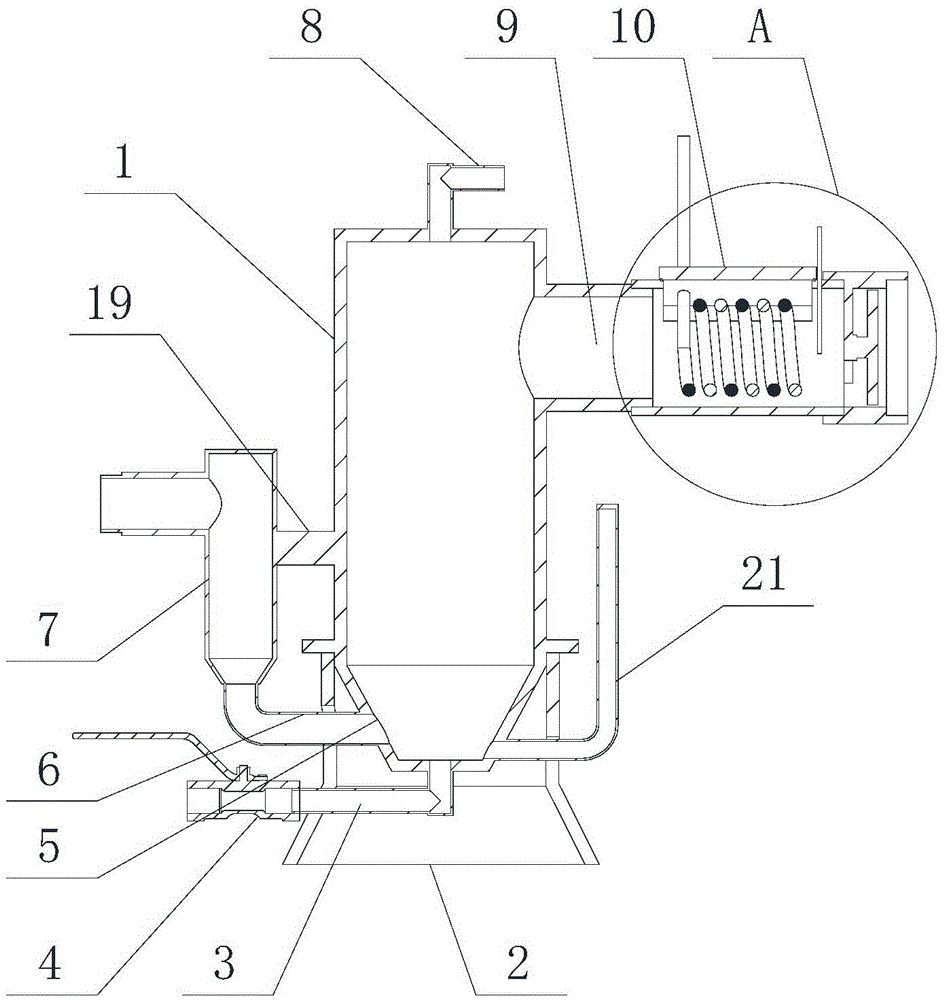

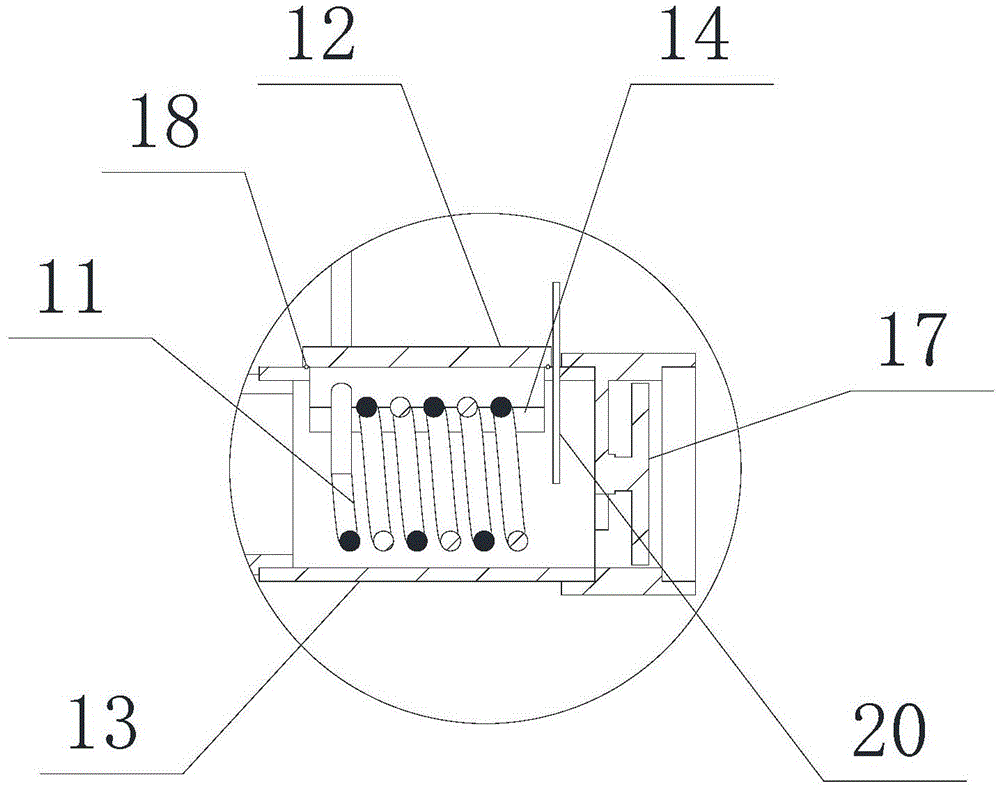

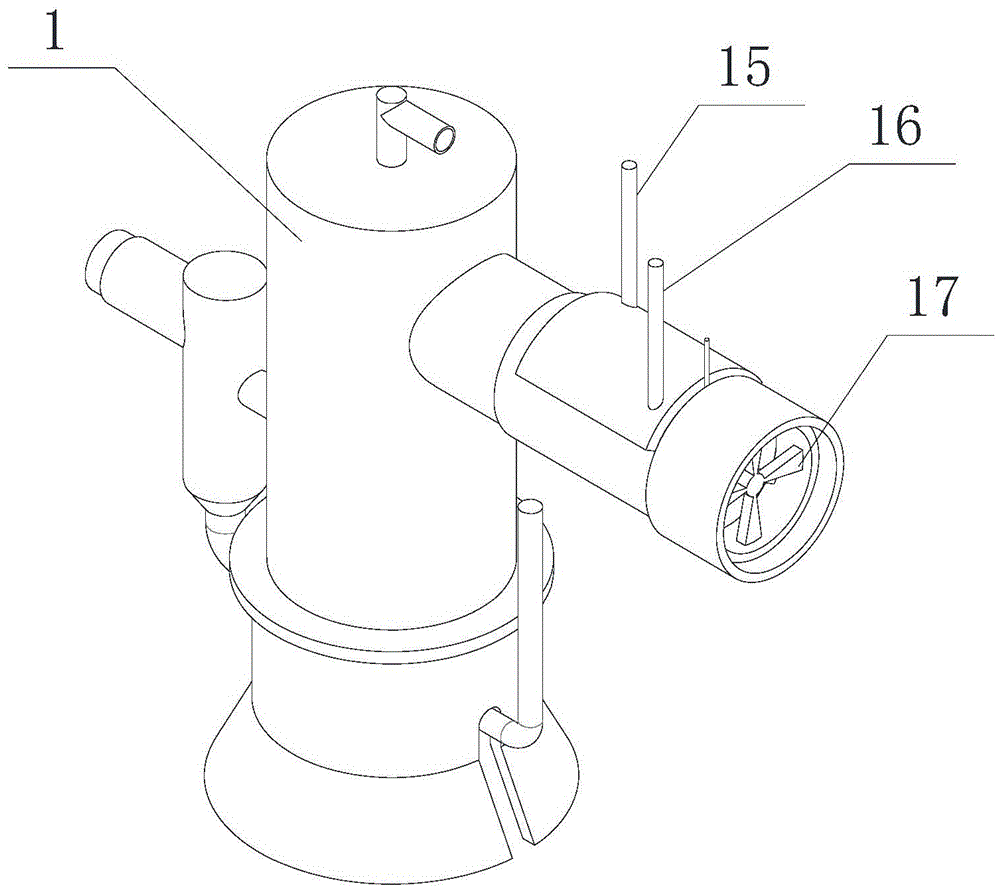

Gas turbine air filter and application method thereof

ActiveCN104265459AQuality assuranceMonitor the water levelGas turbine plantsTurbine/propulsion air intakesAir filterFiltration

The invention discloses a gas turbine air filter. The gas turbine air filter comprises a vertically arranged filtration tank, wherein the filtration tank is cylindrical; a support rack is arranged at the lower end of the filtration tank; the bottom of the filtration tank is conical; a water outlet is formed in the bottom of the filtration tank; a valve is arranged at the water outlet; an air inlet is formed in the outer wall of the lower end of the filtration tank and is communicated with one end of a first horizontal air pipe; the other end of the first air pipe bends to extend upward and is communicated with a second vertical air pipe; the second air pipe is connected with an air booster; a water inlet is formed in the upper end of the filtration tank; an air outlet is formed in the outer wall of the upper end of the filtration tank and is communicated with a heater; the heater is communicated with an air inlet of a gas turbine. The invention also provides an application method of the gas turbine air filter. The gas turbine air filter is simple in structure, convenient to operate, low in cost and long in service life, is capable of filtering salt, dust and corrosion matters in the air by virtue of water, and has an obvious filtration effect.

Owner:江苏华强新能源科技有限公司

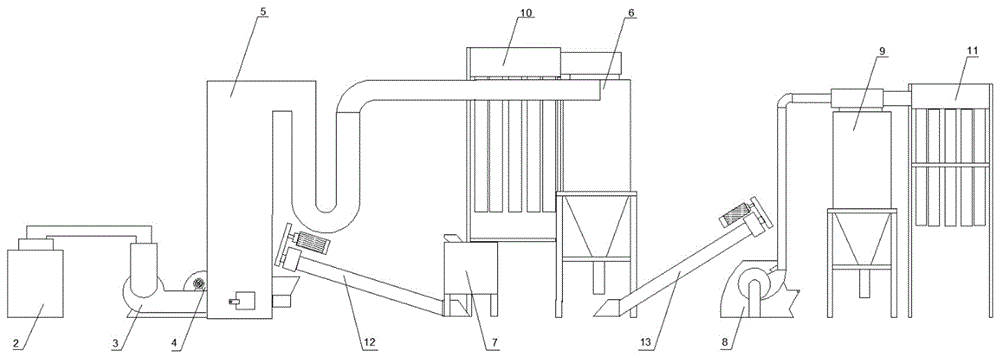

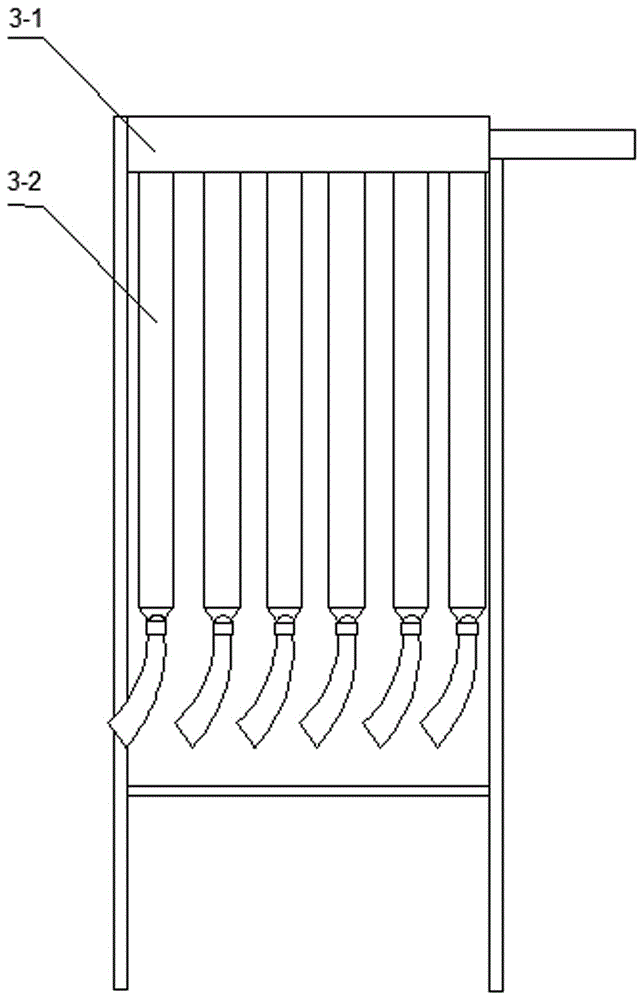

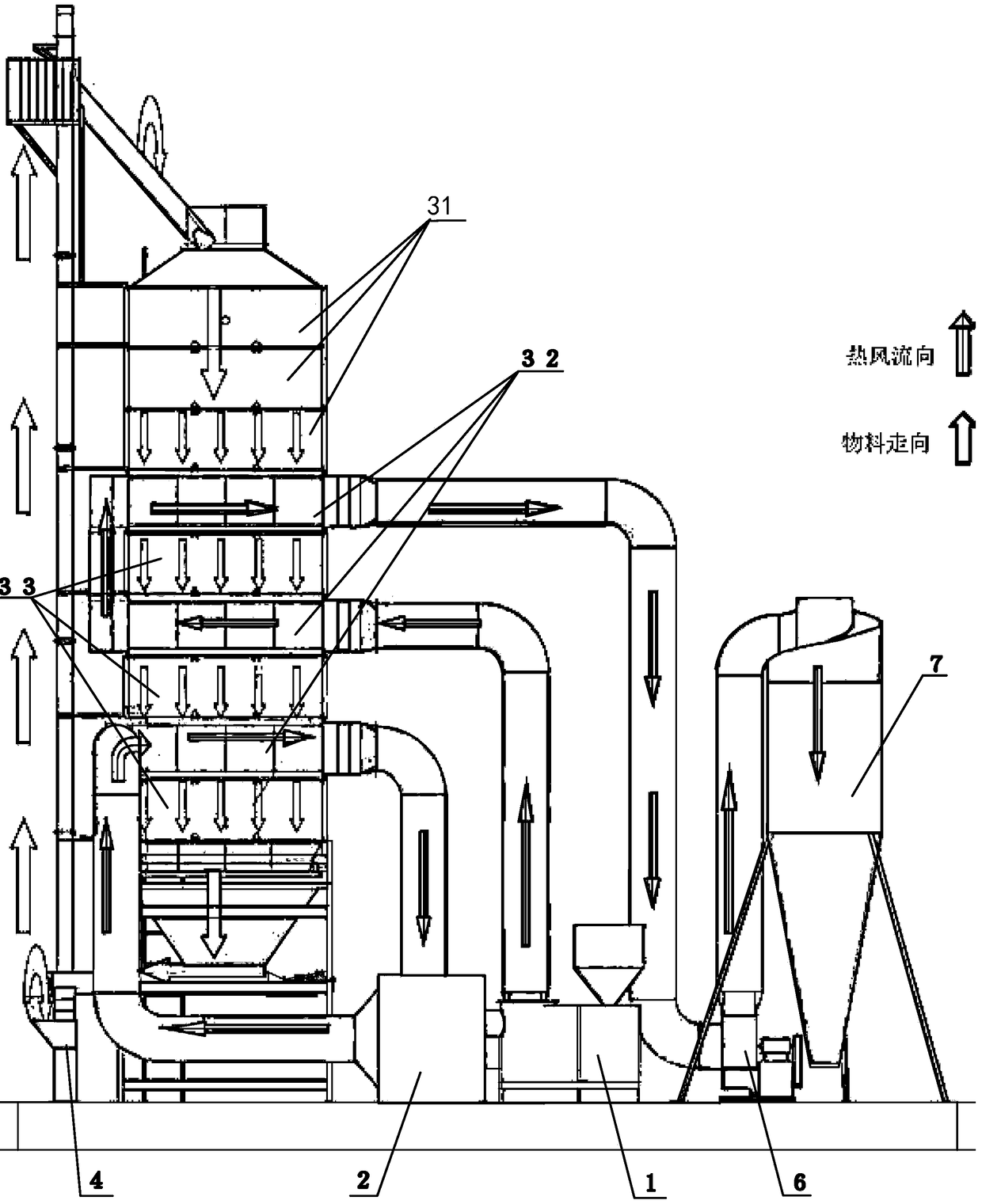

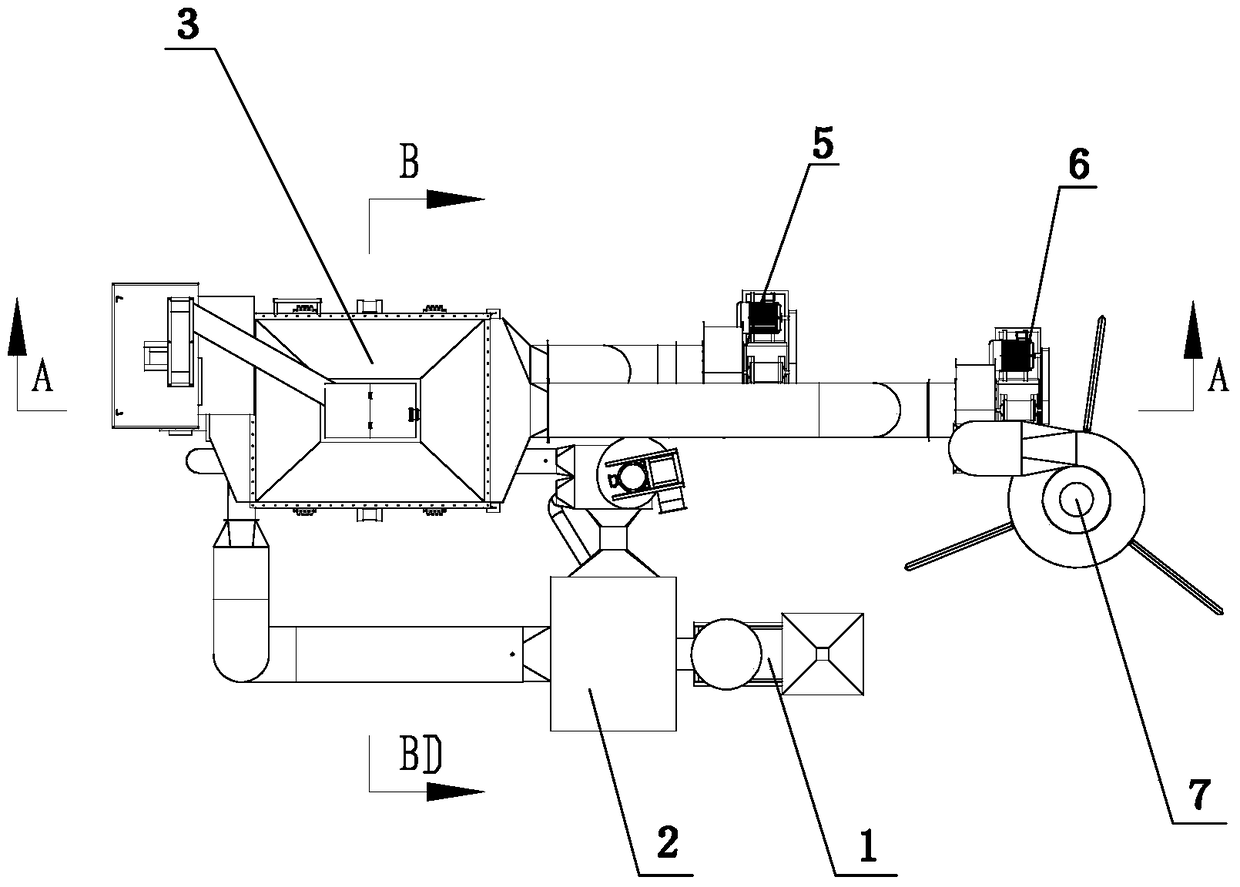

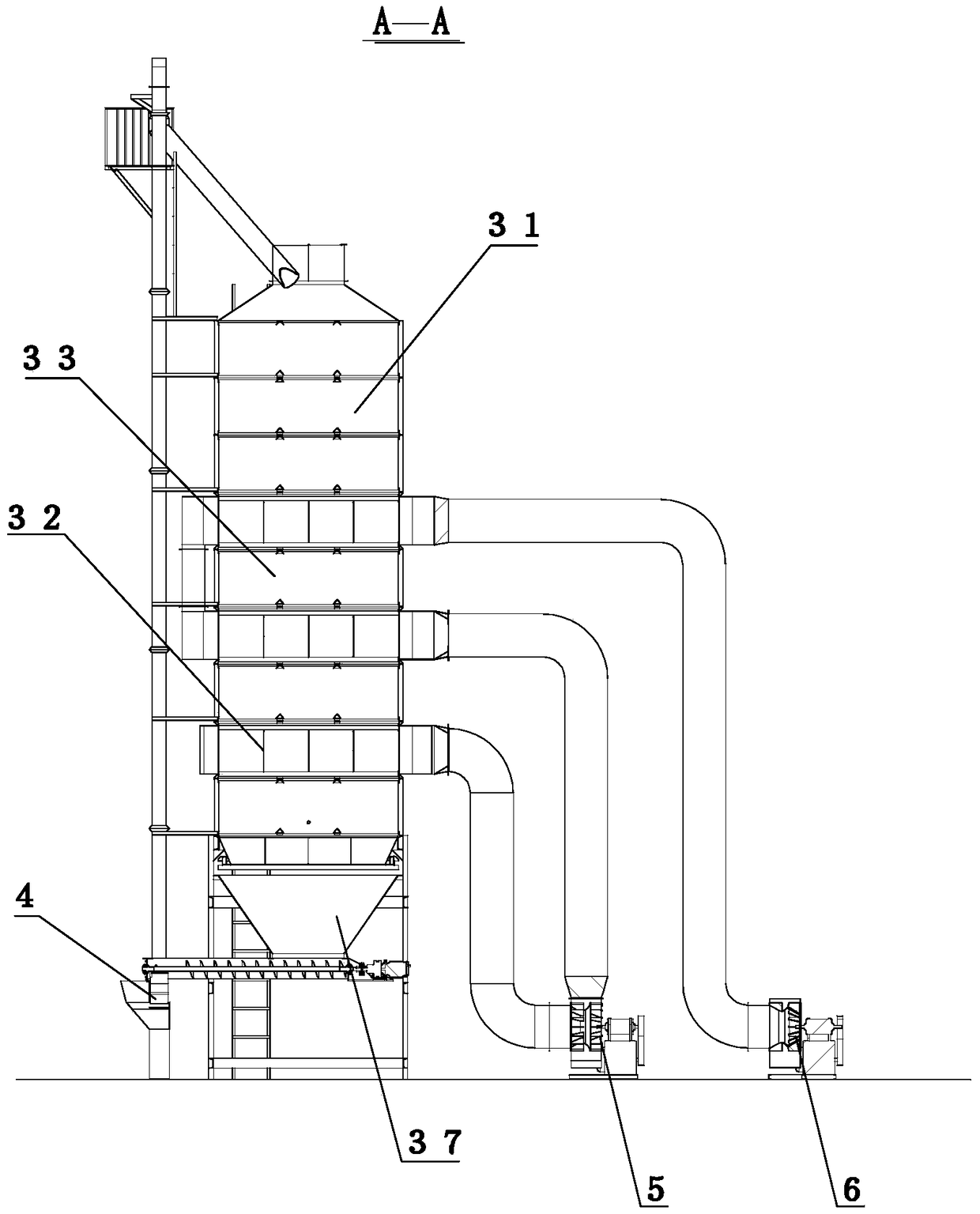

Device for rapidly preparing feed through sugarcane tail tips

ActiveCN105996087ASolve the problem of easy accumulation in the bearing and cause blockageTroubleshoot issues like downtimeFeeding-stuffCycloneTower

Provided is a device for rapidly preparing a feed through sugarcane tail tips. The device comprises a hot-blast stove, a main blower, a secondary blower, a drying tower, a main cyclone separator, pulverizers, a secondary cyclone separator and impurity collecting devices; the hot-blast stove is connected with the drying tower through the main blower, the secondary blower is installed on the other side of the drying tower and connected with a standby blast orifice of the drying tower, a feed inlet of a feeding auger conveyor is connected with the main pulverizer, a discharge hole of the feeding auger conveyor is connected with a feed inlet of the drying tower, the main cyclone separator is installed at the discharge end of the drying tower, an impurity outlet formed in the upper portion of the main cyclone separator is connected with the main impurity collecting device, a feed inlet of an auger conveyor is formed in the lower portion of the discharge hole of the main cyclone separator, a discharge hole of the auger conveyor is connected with the secondary pulverizer, a discharge hole of the secondary pulverizer is connected with the secondary cyclone separator, and a secondary impurity connecting device is installed at an impurity outlet formed in the upper portion of the secondary cyclone separator.

Owner:AGRI PROD PROCESSING INST GUANGXI ACADEMY OF AGRI SCI +1

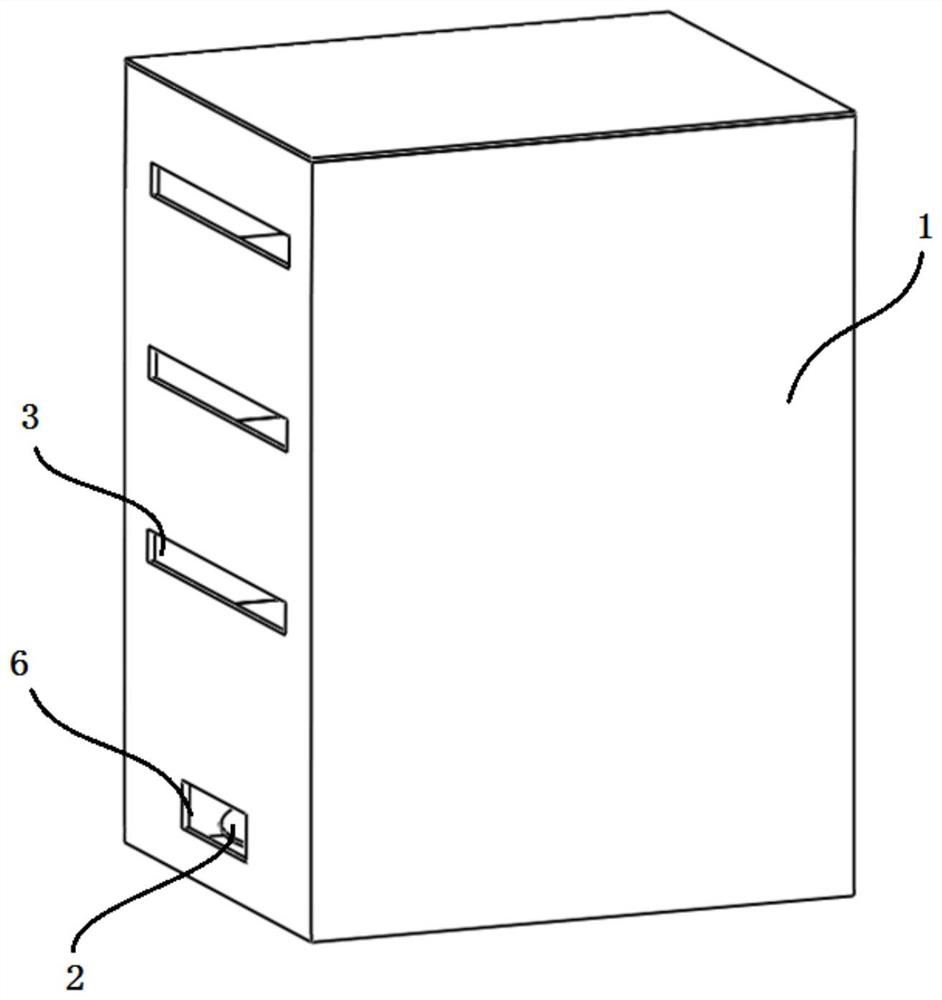

Gas filter in operating room

InactiveCN113218031AAchieve replacementAchieve cleaning effectCombination devicesMechanical apparatusOperating theatresMechanical engineering

Owner:漯河市第一人民医院

Dehumidifying method and system

The application provides a dehumidifying method and system. The dehumidifying method and system is characterized in that a humidity sensor detects the humidity value of a gas in a control box, a first controller utilizes the humidity value detected by the humidity sensor to control a dehumidifying device to control the humidity of the gas in the control box, so that the drying degree control in the control box of the power transformation equipment is realized, and the problem that the elements in the control box are affected with damp easily to influence the safe operation of the power transformation equipment and cause the frequent power grid accidents is avoided.

Owner:STATE GRID ZHEJIANG NINGBO FENGHUA POWER SUPPLY CO LTD +2

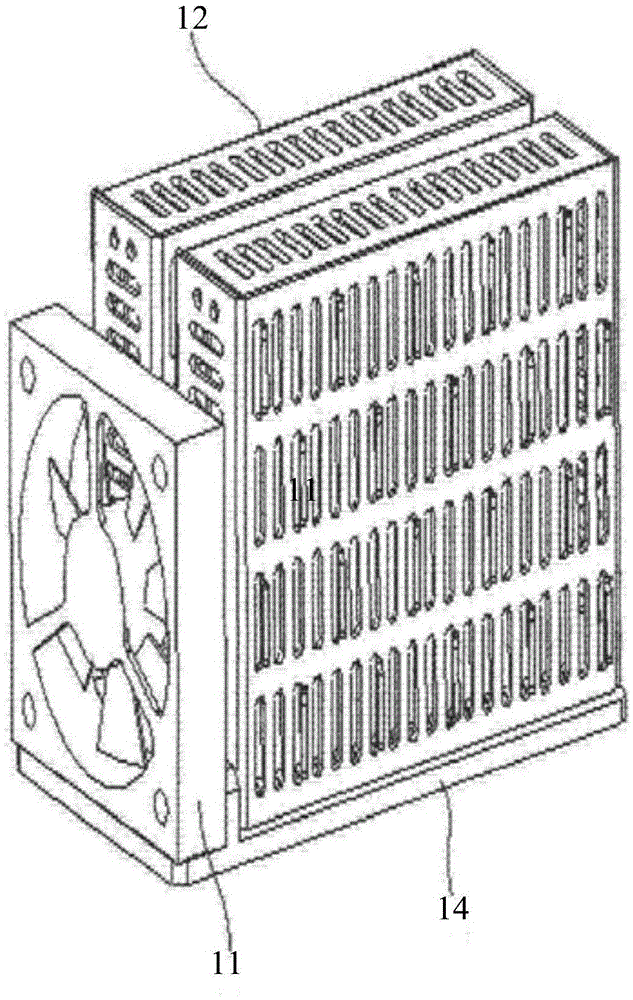

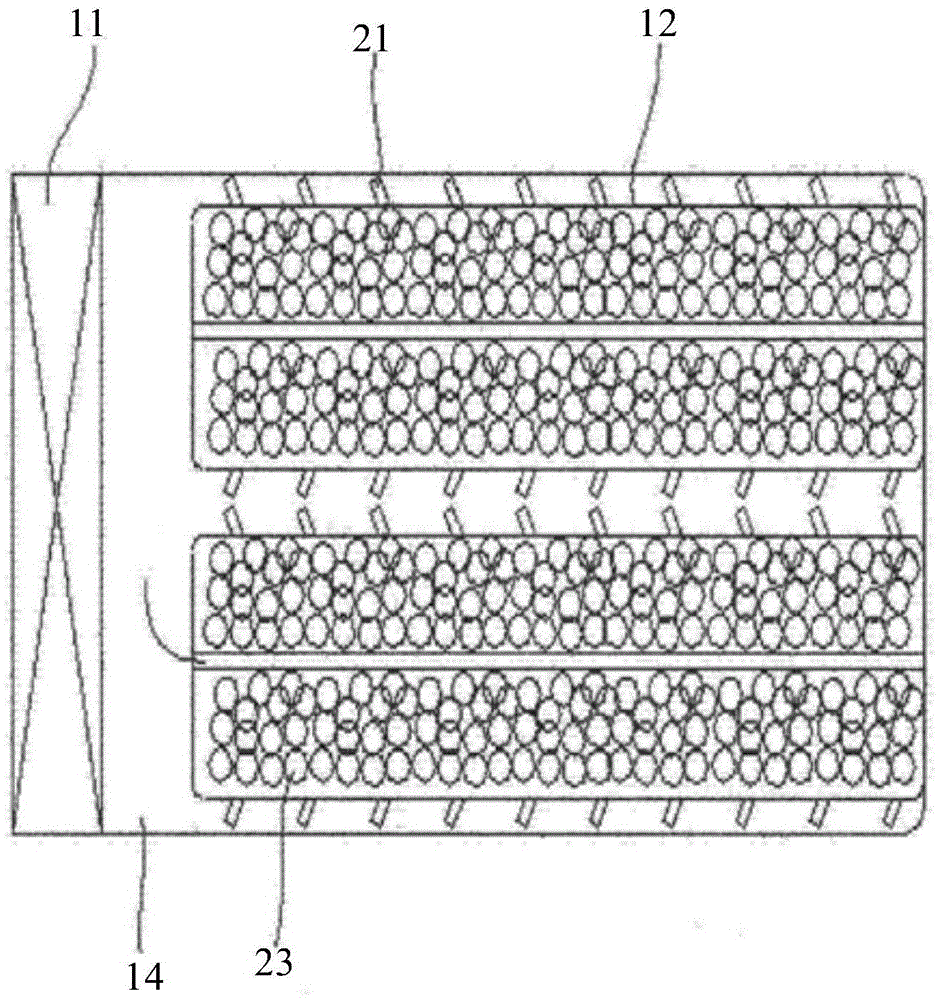

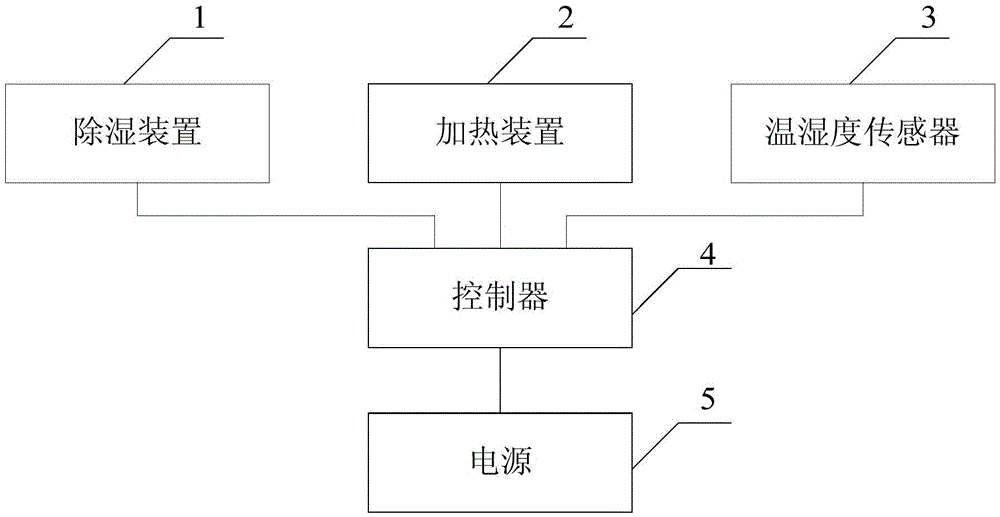

Dehumidifying system

InactiveCN105487583AControl drynessAvoid the frequent occurrence of accidents affecting the power gridSimultaneous control of multiple variablesTransformerPower grid

The invention provides a dehumidifying system. A humiture sensor detects the humiture value of the gases in a control cabinet, a controller controls a dehumidifying device and / or a heating device to adjust the gas humidity in the control cabinet by means of the humiture value detected by the humiture sensor so as to control the drying degree in the control cabinet of a transformer, so that the problems that the safe running of the transformer is influenced and the power grid accidents frequently occur because the components in the control cabinet are easy to damp can be prevented.

Owner:STATE GRID ZHEJIANG NINGBO FENGHUA POWER SUPPLY CO LTD +2

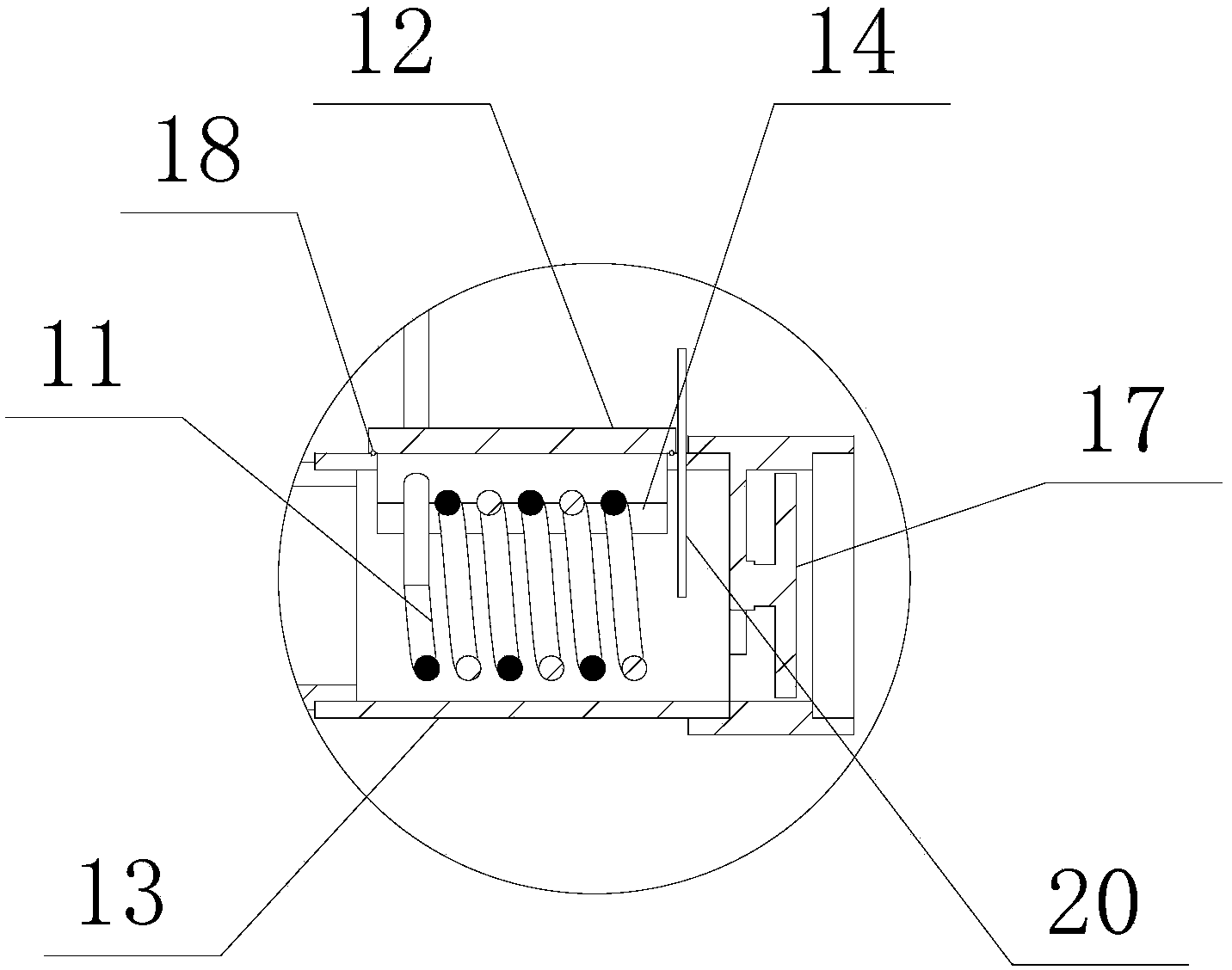

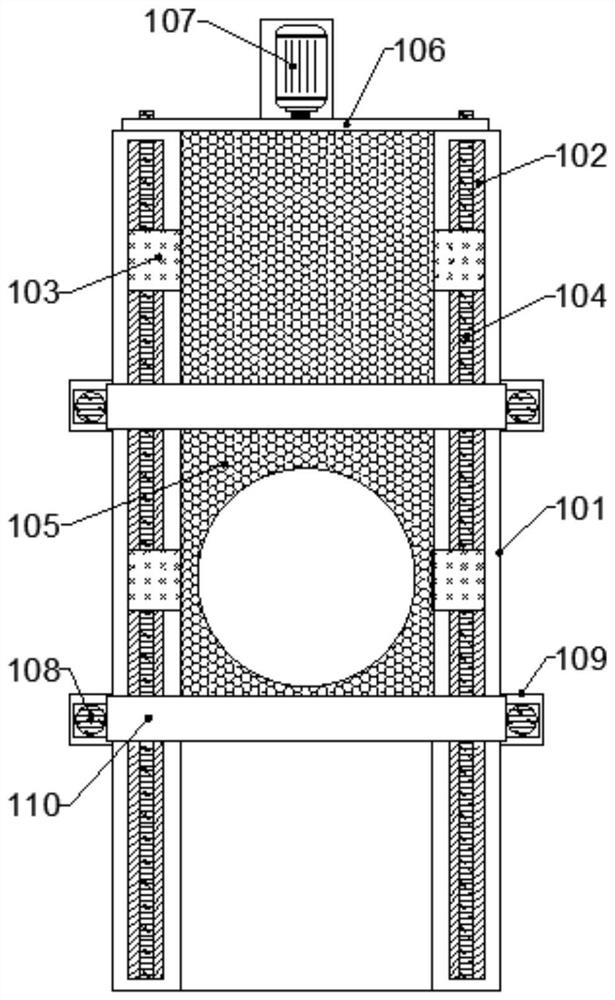

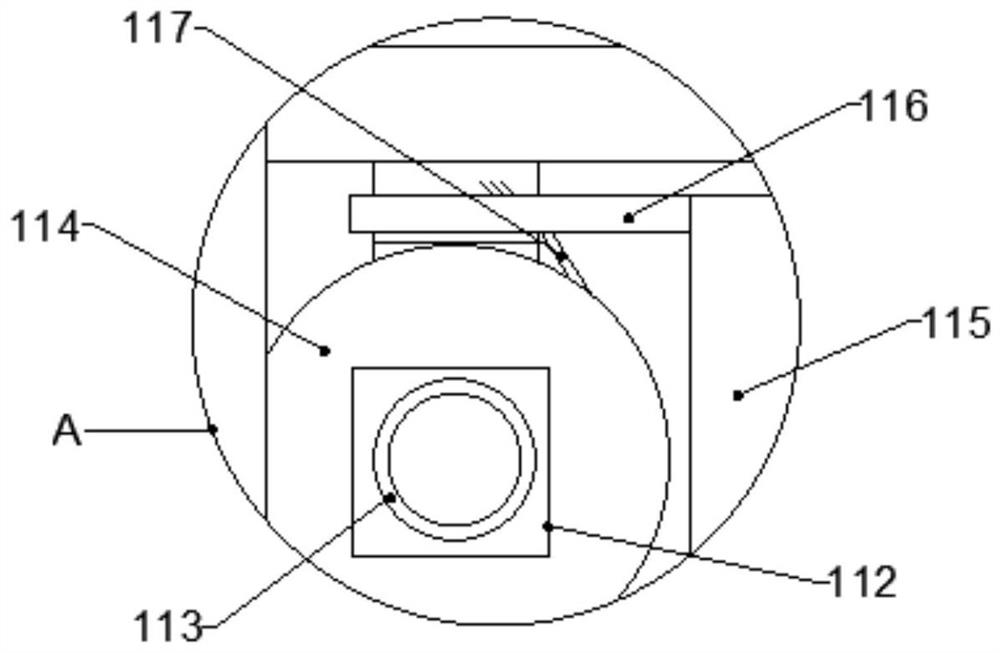

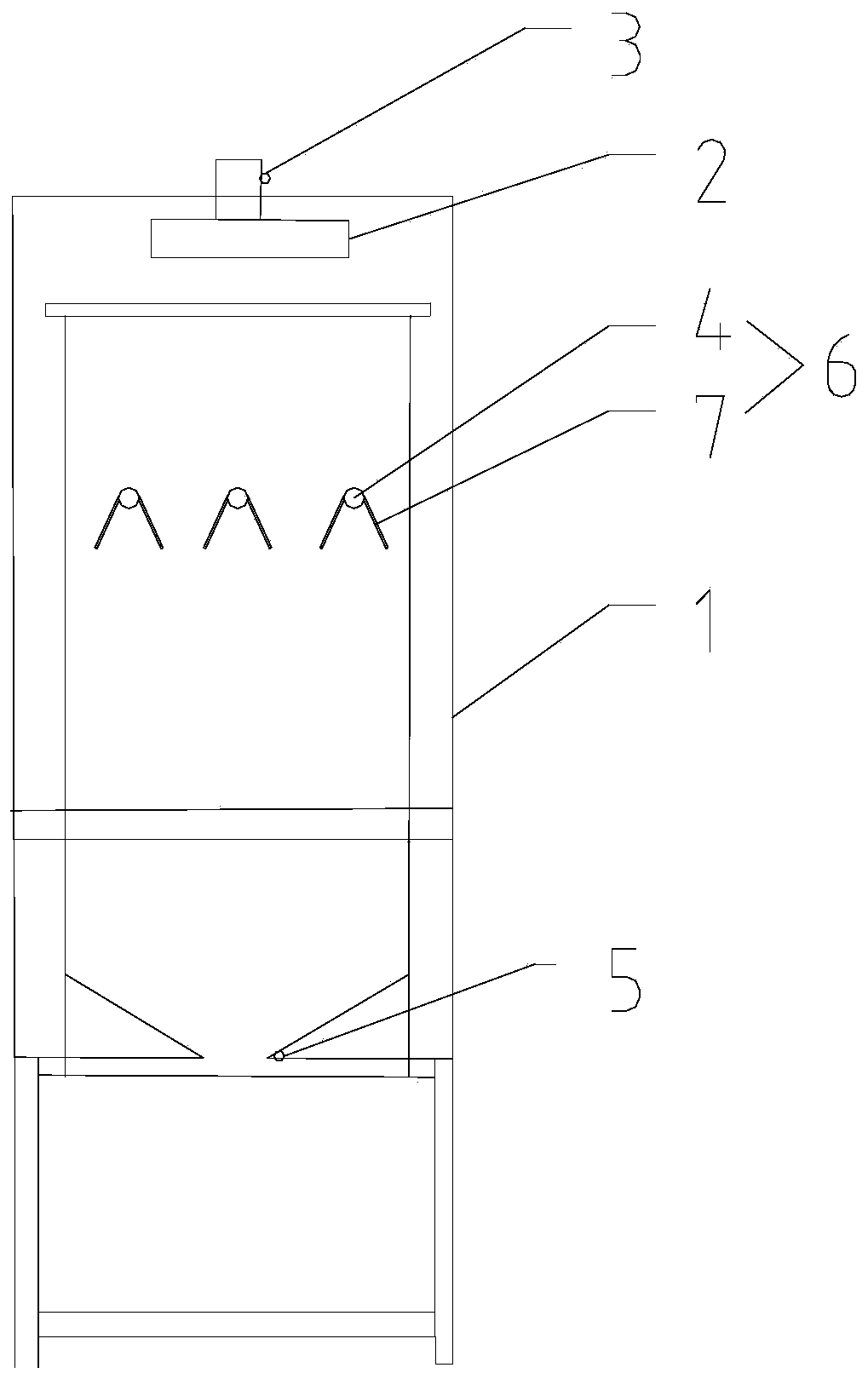

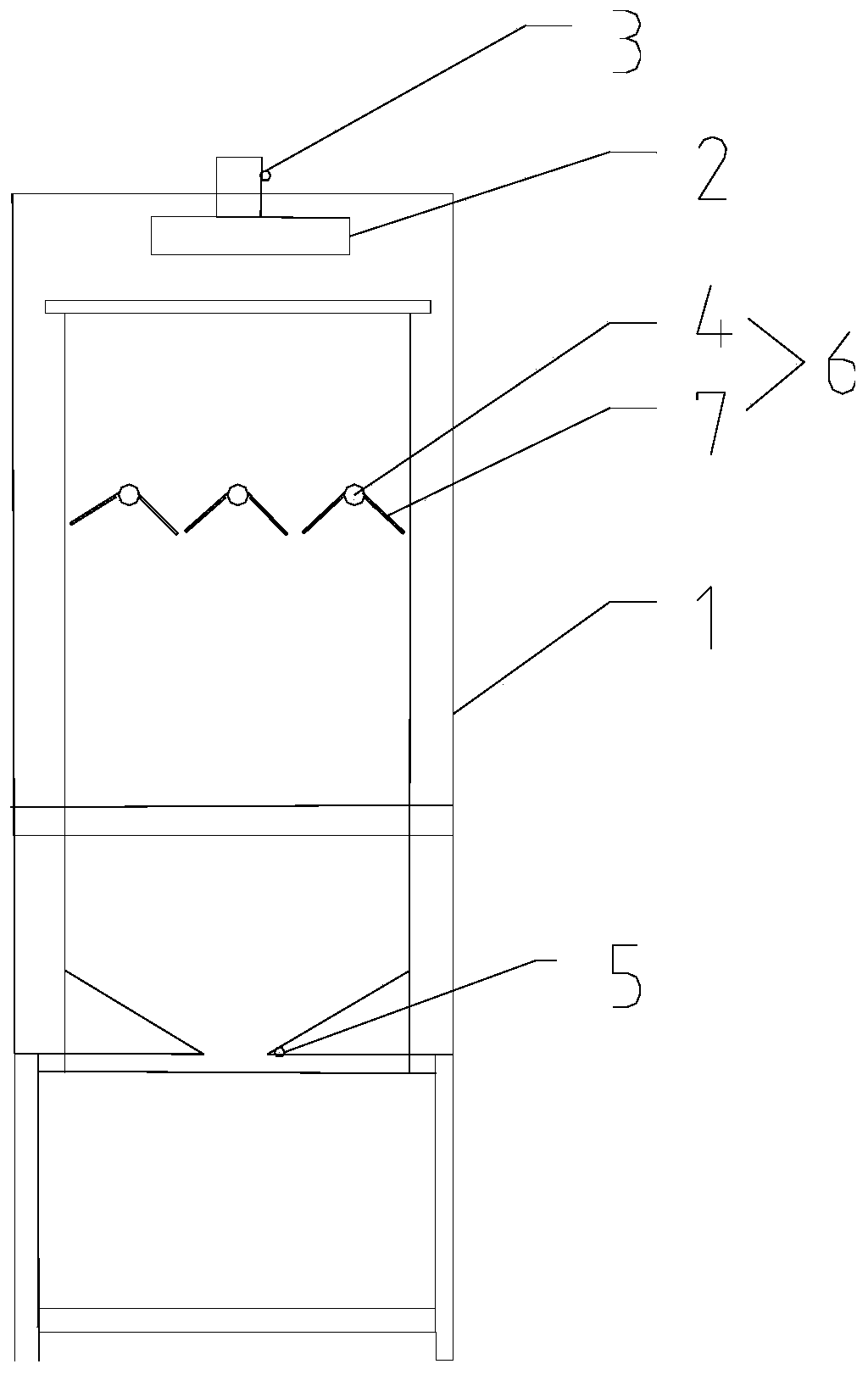

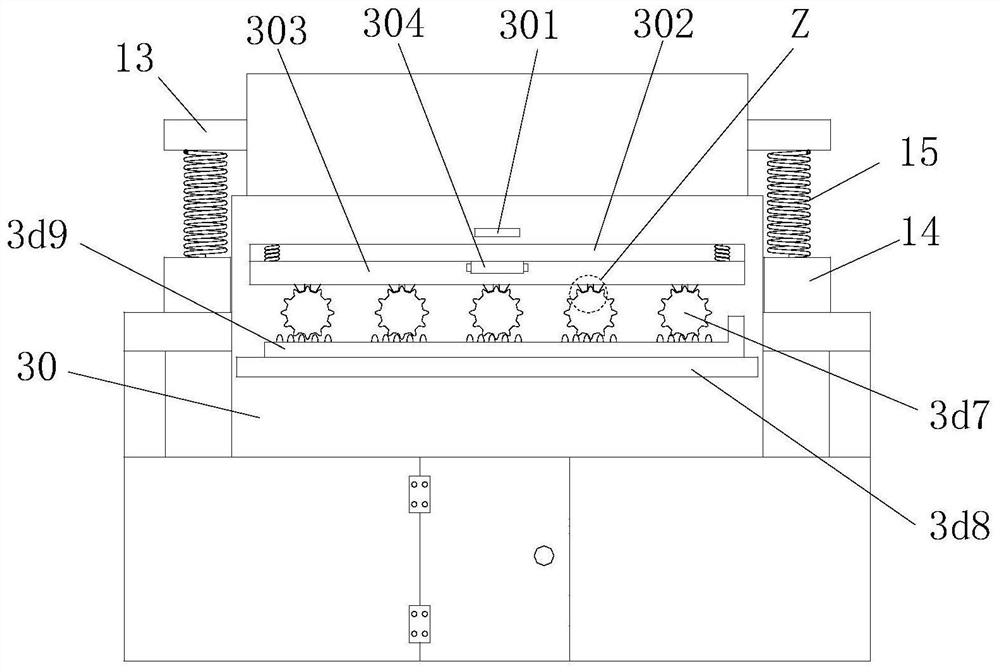

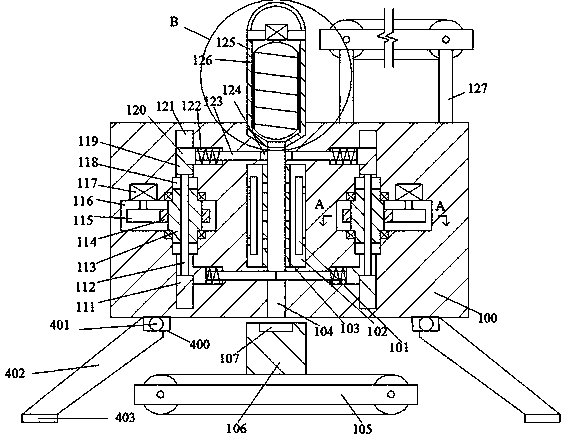

Grain drying machine

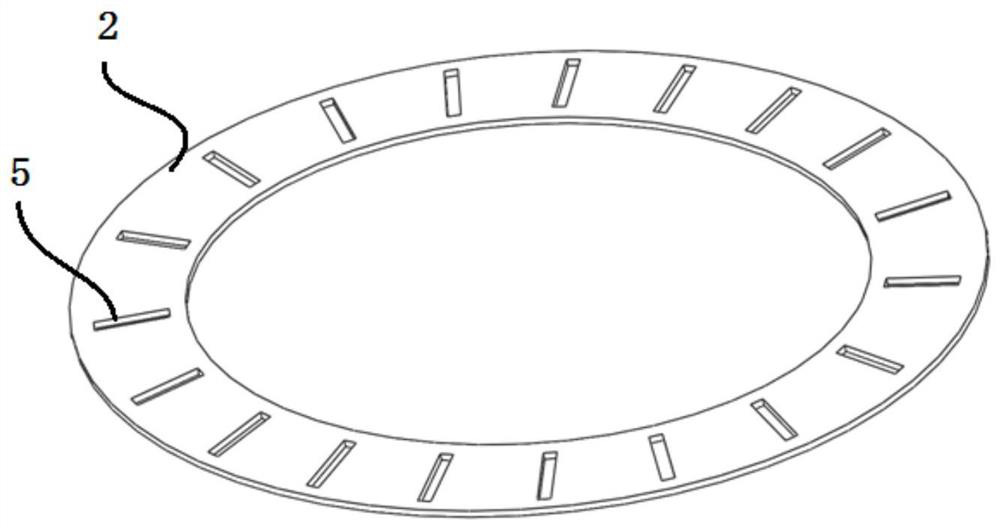

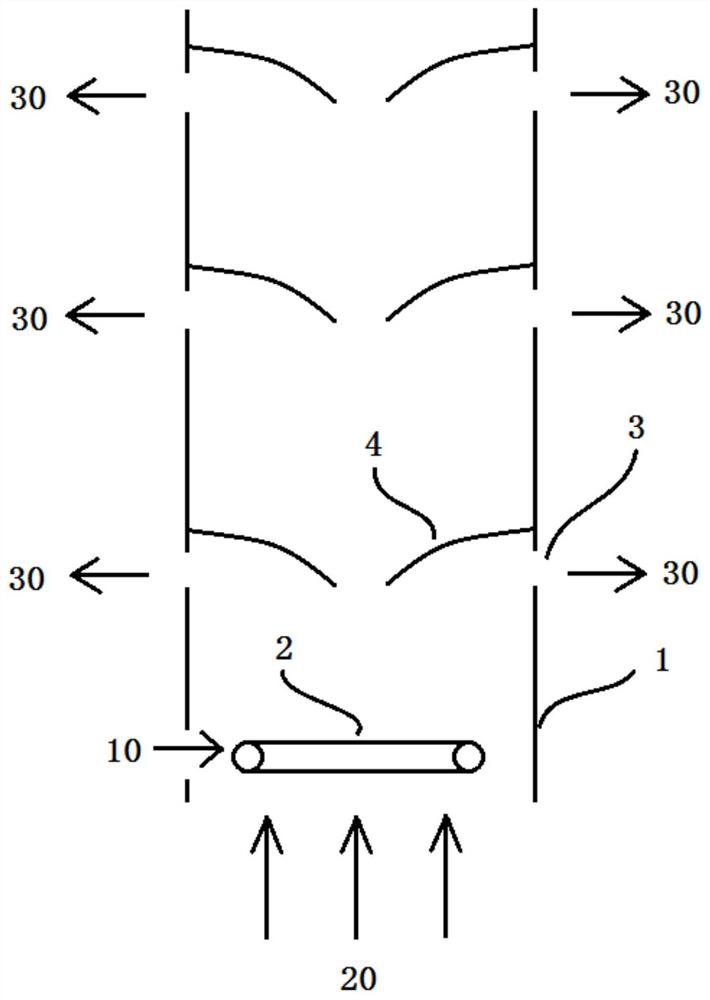

InactiveCN109874864AExtend exercise timeControl drynessSeed preservation by dryingMoisture sensorMechanical engineering

The invention provides a grain drying machine. The grain drying machine includes a drying chamber, and further includes: a feeding port disposed above the drying chamber and a distributing device connected to the feeding port; the feeding port is provided with a first humidity sensor; a discharge port is disposed under the drying chamber; the discharge port is provided with a second humidity sensor; a guiding device is disposed in the drying chamber, the guiding device comprises a guiding shaft, a guiding plate and a control device, the guiding plate is arranged on the guiding shaft in a rotation mode and is parallel to a falling direction of the grain when the force is not affected, and moves in a direction perpendicular to the falling parallel direction of the grain when the force is affected; a control device is communicatively coupled to the first humidity sensor and the second humidity sensor for controlling the rotation of the guiding plate along the guiding shaft. The grain drying machine can adjust the drying time of the grain in the drying machine.

Owner:安徽省沃昇机电科技有限公司

Gas turbine air filter and method of use thereof

ActiveCN104265459BQuality assuranceMonitor the water levelGas turbine plantsTurbine/propulsion air intakesFiltrationAir filter

The invention discloses a gas turbine air filter. The gas turbine air filter comprises a vertically arranged filtration tank, wherein the filtration tank is cylindrical; a support rack is arranged at the lower end of the filtration tank; the bottom of the filtration tank is conical; a water outlet is formed in the bottom of the filtration tank; a valve is arranged at the water outlet; an air inlet is formed in the outer wall of the lower end of the filtration tank and is communicated with one end of a first horizontal air pipe; the other end of the first air pipe bends to extend upward and is communicated with a second vertical air pipe; the second air pipe is connected with an air booster; a water inlet is formed in the upper end of the filtration tank; an air outlet is formed in the outer wall of the upper end of the filtration tank and is communicated with a heater; the heater is communicated with an air inlet of a gas turbine. The invention also provides an application method of the gas turbine air filter. The gas turbine air filter is simple in structure, convenient to operate, low in cost and long in service life, is capable of filtering salt, dust and corrosion matters in the air by virtue of water, and has an obvious filtration effect.

Owner:江苏华强新能源科技有限公司

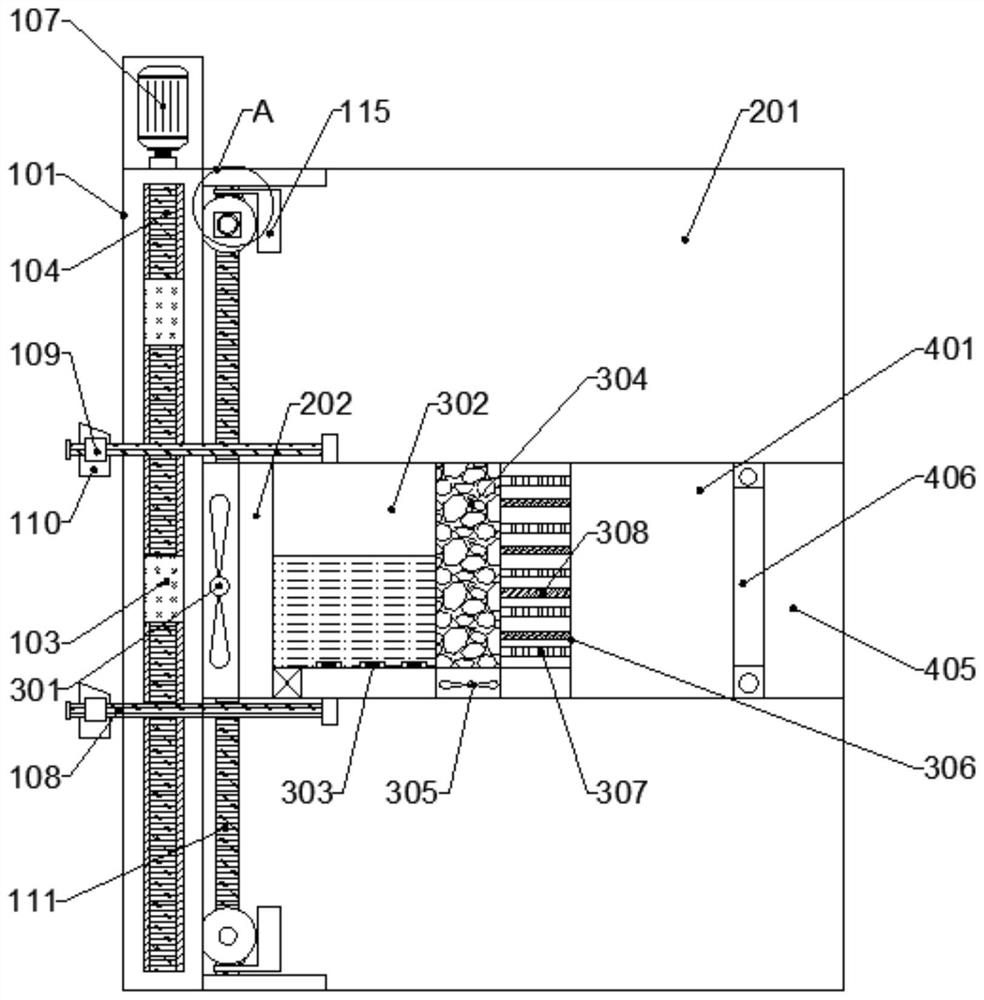

A grain dryer

The invention relates to a grain dryer. An inner cavity of a drying tower of the grain dryer comprises a feeding bin and a multi-stage drying bin and tempering bin alternate arrangement structure from top to bottom, a discharging bin is arranged below a tempering bin on the lowermost layer, hollow partitioning plates are arranged inside drying bins, cavities of the hollow partitioning plates are ventilated, grain passes through the gap between every two adjacent hollow partitioning plates, through holes are formed in the faces of the hollow partitioning plates, air channels comprise hot air channels and secondary hot air channels, hot air is transmitted layer by layer between the drying bins from bottom to top through hot air conveying pipelines, and in the drying bin on each layer, the hot air passes through the through holes in the corresponding hollow partitioning plates from the corresponding hot air channels to permeate into material channels and then permeates into the corresponding secondary hot air channels to enter the drying bin on the upper layer. The grain is dried inside the drying tower in a clockwise or anticlockwise mode, heat exchange is performed between the high-temperature hot air and the grain high in water content and low in temperature, the temperature of the grain is increased rapidly to evaporate water inside, the grain enters the tempering bins to be tempered for a period of time after being dried, the water inside the grain permeates outwards, next-time drying is performed, and evaporation of the water inside the grain is completed in a gradient mode.

Owner:山东宇龙机械有限公司

A drying device for wood processing

ActiveCN107127853BControl drynessNo need to change heating temperatureWood treatment detailsWood heatingEngineeringHeating temperature

Owner:常熟市维摩剑门绿茶有限公司

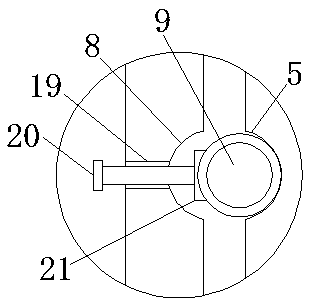

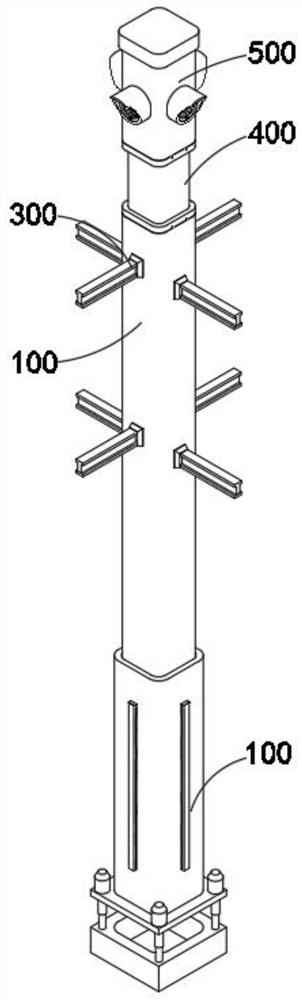

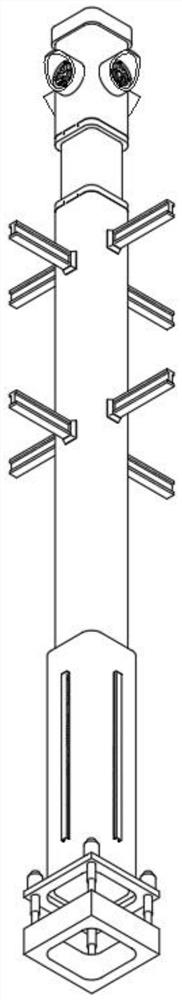

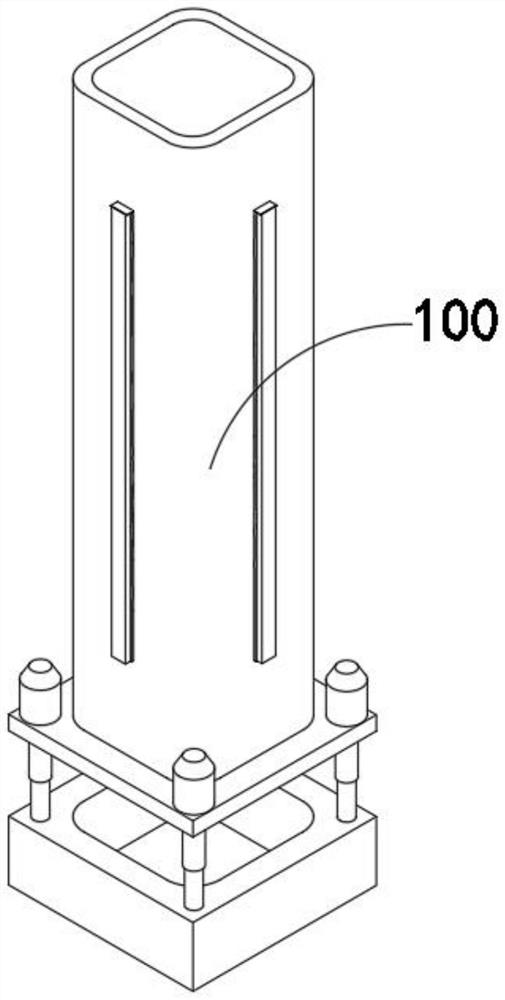

Rustless efficient fabricated building steel cross beam in steel frame structure factory building and bearing column thereof

PendingCN113775047APrevent rustAvoid damageBuilding constructionsConstruction engineeringSteel frame

The invention discloses a rustless efficient fabricated building steel cross beam in a steel frame structure factory building and a bearing column thereof. The rustless efficient fabricated building steel cross beam comprises a bearing mechanism, a manufacturing mechanism, a cross beam bridging mechanism, a sealing mechanism and an airflow dredging mechanism, wherein the bearing mechanism comprises a pressing part and an auxiliary fixing part, and the pressing part comprises a steel frame shell, a screw rod and a pressing block, wherein the screw rod and the pressing block are connected into the steel frame shell. According to the rustless efficient fabricated building steel cross beam, the screw rod and the pressing block are movably arranged in the steel frame shell, and a limiting combination and a base are arranged at the bottom end of the steel frame shell; and during use, a concrete vertical pile is inserted into an inner cavity of the steel frame shell in a matched mode through a prefabricated part, the concrete vertical pile is inserted into the steel frame shell, the pressing block is controlled by adjusting the screw rod to integrally fix and clamp the steel frame shell on the outer side of the concrete vertical pile, meanwhile, the base is arranged at the root of the concrete vertical pile, so that the inner wall of the steel structure bearing column can be prevented from being damaged, and then the corrosion of external factors to a metal layer of the device is avoided.

Owner:江苏千禧杭萧装配式建筑科技有限公司

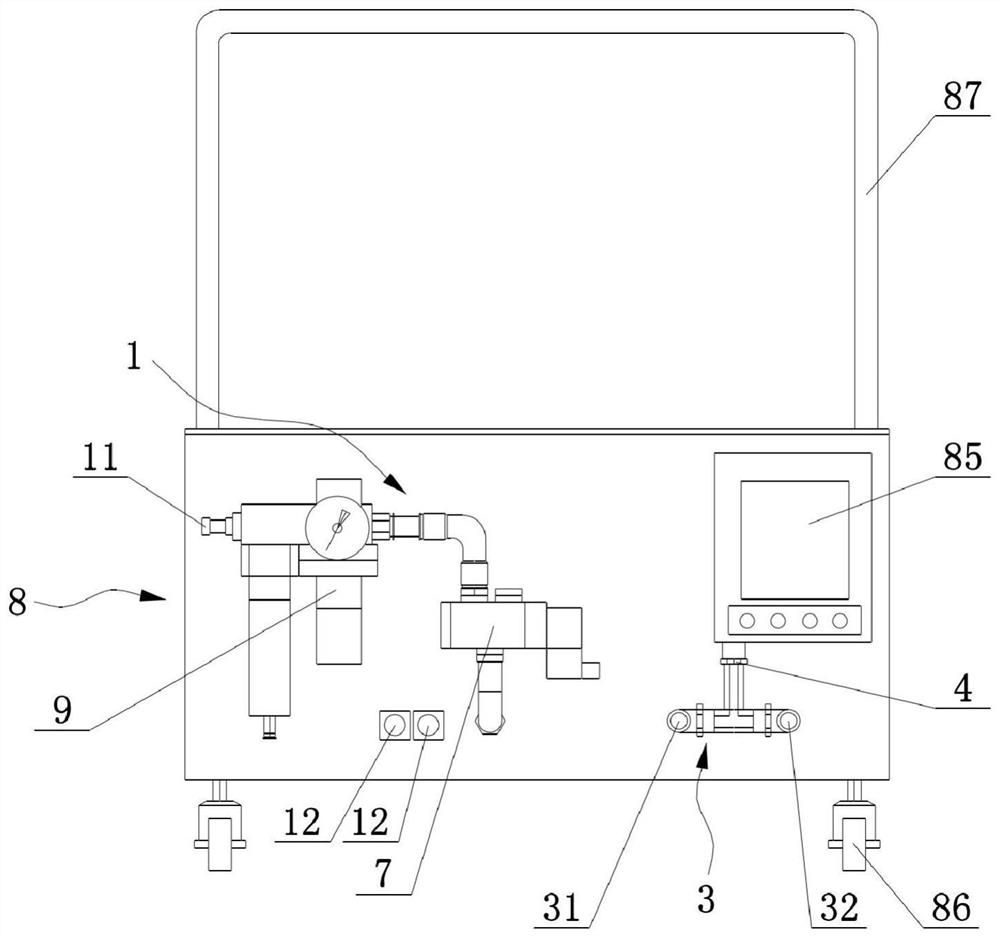

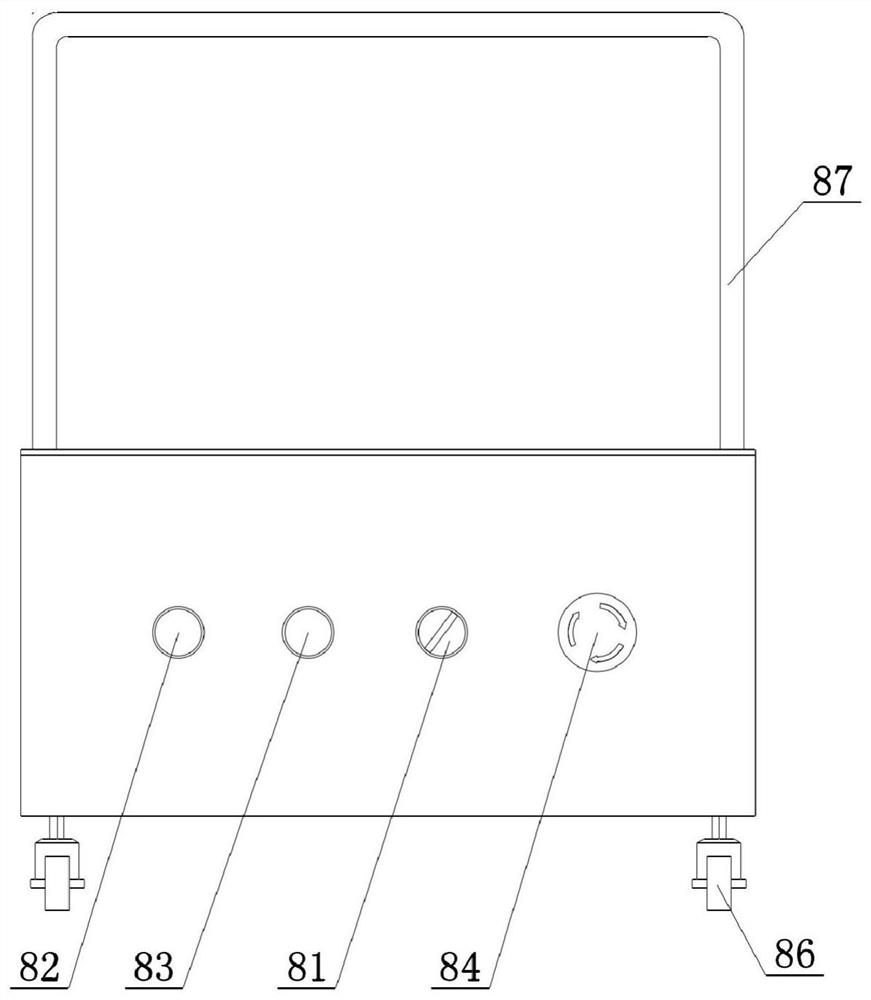

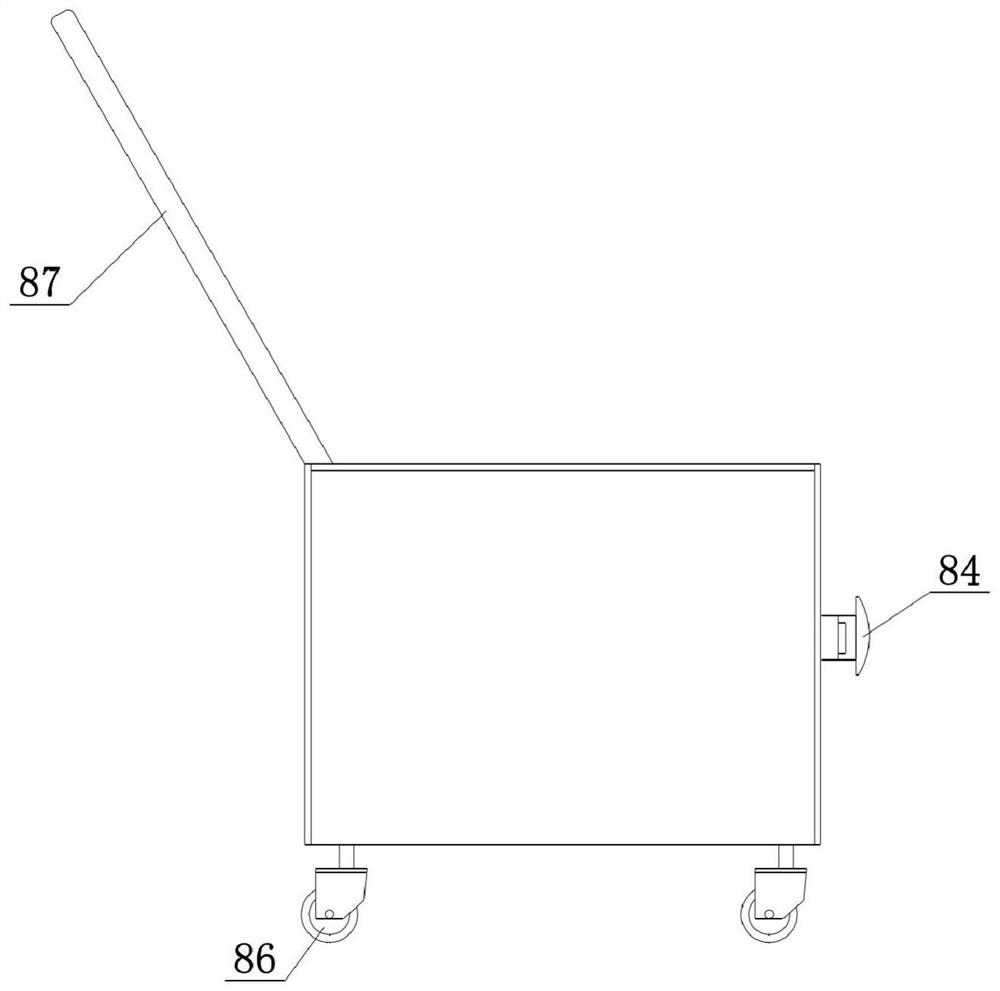

Dehumidification system

InactiveCN105610070AControl drynessSubstation/switching arrangement cooling/ventilationPower gridComputer module

The invention provides a dehumidification system. A gas humidity value in a control box is detected by a humidity sensor; the humidity value detected by the humidity sensor is transmitted to a second controller by a first controller via a communication module, so that the second controller controls a corresponding dehumidification apparatus to adjust the gas humidity in the control box based on the humidity value so as to realize control for the gas drying degree in the control box of power transformation equipment. The problem of frequent power grid accidents caused by influenced safe operation of the power transformation equipment due to that components and parts are affected with damp easily in the control box is avoided.

Owner:STATE GRID ZHEJIANG NINGBO FENGHUA POWER SUPPLY CO LTD +2

Method for making black sound absorption and flame retardation paper through adhesive spraying

ActiveCN103233387BGood colorHigh strengthNon-fibrous pulp additionPaper coatingGlass fiberFilling materials

Owner:SHAANXI UNIV OF SCI & TECH

A drying device and drying method

ActiveCN109654821BImprove drying efficiencyControl drynessDrying gas arrangementsDrying solid materialsSewage outfallProcess engineering

The invention belongs to the technical field of drying treatment, and discloses a drying device and a drying method. Wherein, the drying device includes a blowing pipeline, a heater, a detection pipeline, a humidity sensor and a controller. One end of the blowing pipeline is the air inlet, the other end is the blowing port, the heater is set on the blowing pipeline, one end of the detection pipeline is the air return port, the other end is the sewage outlet, the humidity sensor is set on the detection pipeline, and the controller is connected to The heater and the humidity sensor, the controller has a manual mode and an automatic mode. In the automatic mode, when the humidity sensor detects that the humidity value of the gas discharged from the cavity outlet is lower than the first set value, the controller controls the drying device to stop. Among them, the drying method uses the above-mentioned drying device. In the present invention, the arrangement of the heater in the blowing pipeline effectively improves the drying efficiency of the drying device. On this basis, the coordinated arrangement of the humidity sensor and the controller can accurately control the drying degree of the product to be dried.

Owner:CHINA NTAIONAL NUCLEAR TIANJIN MACHINERY

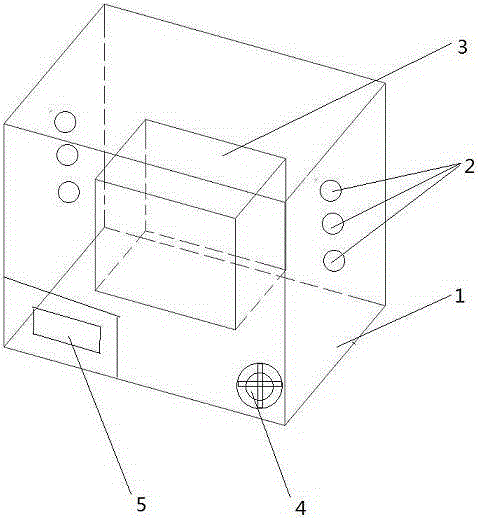

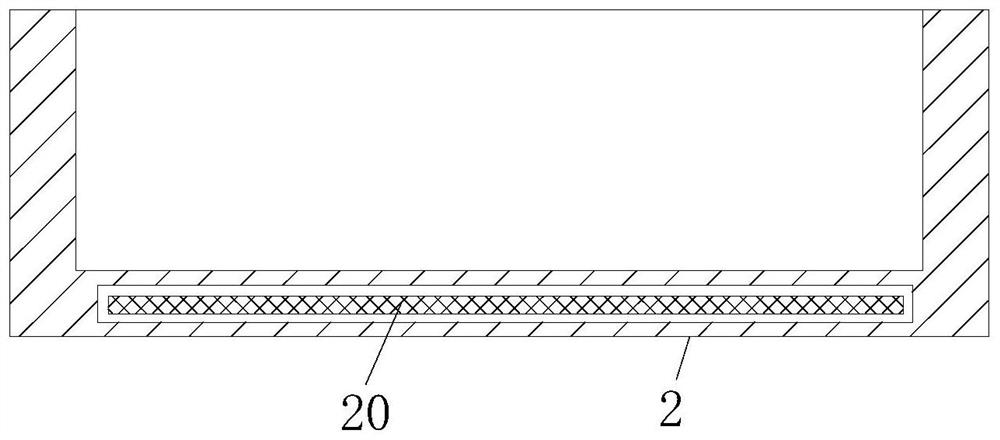

Dry-mixed mortar production raw material drying and screening treatment system

ActiveCN113280615AControl flow rateControl drynessSievingSand dryingProcess engineeringIndustrial engineering

The invention relates to a dry-mixed mortar production raw material drying and screening treatment system which comprises a material screening box, a material collecting box and a drying device. The material collecting box is arranged under the material screening box, the lower end of the material collecting box is connected with the existing ground, and the drying device is arranged between the upper end of the material collecting box and the lower end of the material screening box. Dry-mixed mortar production raw materials in the falling process can be dried through hot air flow, mounting rods drive trapezoidal blocks to ascend and descend, wedge-shaped blocks do linear motion in the direction away from or close to the mounting rods, the effect of adjusting the sizes of vent holes can be achieved, the flow speed of the hot air flow can be controlled, and therefore the drying degree of the hot air flow on the dry-mixed mortar production raw materials can be controlled so as to enhance the drying effect.

Owner:沂水城投天元建材科技有限公司

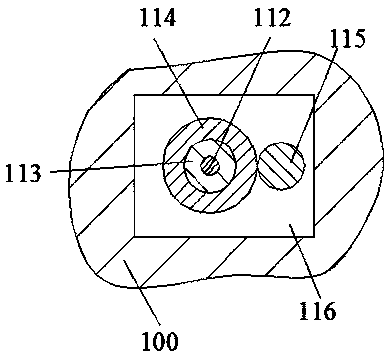

Novel spice mill

InactiveCN108325713AImprove transmission stabilityImprove work coordinationGrain treatmentsHeating arrangementEngineeringControl valves

The invention discloses a novel spice mill. The novel spice mill comprises a box shell. A drying cavity is fixedly formed in the box shell. High-temperature resistors are correspondingly and fixedly arranged on the left end wall and the right end wall of the drying cavity in a left-right symmetric manner. A fixing block is arranged in the portion between the upper end wall and the lower end wall of the drying cavity in a communicated manner. Through pipes vertically symmetrical are arranged in the upper end wall and the lower end wall of the drying cavity in a communicated manner. The throughpipes are communicated with the fixing block. An open box is arranged in the upper end wall of the through pipe on the upper side. The open box upwardly extends out of an external space. A milling cavity with an upward opening and communicating with the corresponding through pipe is fixedly formed in the open box. The through pipe on the lower side communicates with the external space. A conveyordriven by a motor is arranged below the through pipe on the lower side. A storage box is arranged on the conveyor in an abutted manner. The novel spice mill is simple in structure and convenient to use; and by the adoption of the equipment, a linkage type control valve structure is adopted, drying and milling of spice are controlled effectively, and the controllability of the forming process is improved effectively.

Owner:何志达

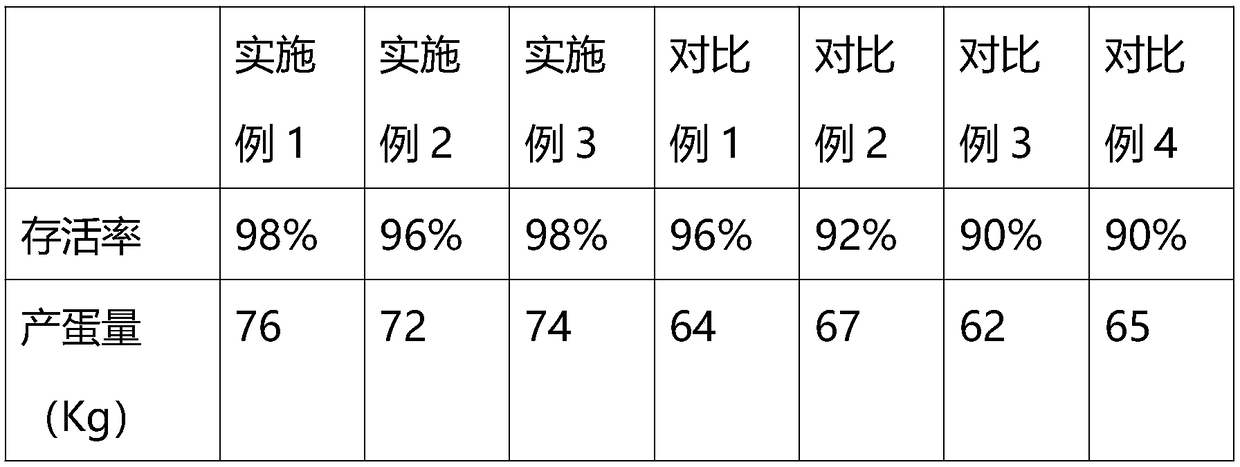

Egg-duck whole-course flat dry feeding process

InactiveCN109479820AIncrease egg productionAvoid breedingAnimal housingBird housingsEngineeringControl equipment

The invention provides an egg-duck whole-course flat dry feeding process, which comprises a feeding area, wherein the feeding area comprises an active area and an egg-producing area; a net bed structure is adopted in the active area, a scraping manure device is arranged below the net bed, and the scraped manure is mixed with the dry soil at 1:5-10 after insolating and drying to obtain a dry manuremixture; the area of egg-producing area is the same as that of the active area and is connected without obstacle, the mixture of straw, husk, hay and dry manure is used as litter in the egg-producingarea, and the height of the litter is 10-20 cm; egg laying time is 2:00 to 5:00 in the morning, and the light should be kept dim; an enclosure is arranged above the feeding area and the perimeter ofthe enclosure are provided with isolation; temperature control equipment is installed in the enclosure, which will cool down to below 30 degrees in summer, and exhaust equipment is installed in the enclosure; humidity control equipment is arranged above the active area, so as to spray clean water regularly; the beak of an egg-duck shall be broke when eating the wool; a drinking water pipe should be placed on the net bed in the active area and a feed bucket should be placed in the active area or the egg-producing area.

Owner:赵永祥

A whole-process planar dry raising process for laying ducks

The invention provides a whole-process planar dry raising process for laying ducks, comprising: the feeding area includes an activity area and an egg-laying area; the activity area adopts a net bed structure, and a manure scraping device is used under the net bed, and the scraped manure is mixed with dry soil after being exposed to the sun and dried Mix 1:5‑10 to obtain a dry manure mixture; the egg production area is consistent with the activity area and connected without obstacles. The egg production area uses a mixture of rice straw, rice bran, hay and dry manure as litter, and the height of the litter is 10‑ 20cm; egg laying time is 2‑5 o'clock in the morning, keep the light dim; build a barn above the breeding area, with isolation around the barn; install temperature control equipment in the barn, cool down to below 30 degrees in summer, and install exhaust equipment in the barn Install humidity control equipment above the activity area and spray clean water regularly; beak trimming should be performed when hair eating occurs; the drinking water pipe should be placed on the net bed in the activity area, and the feed bucket should be placed in the activity area or egg production area.

Owner:安徽滨江农业科技股份有限公司

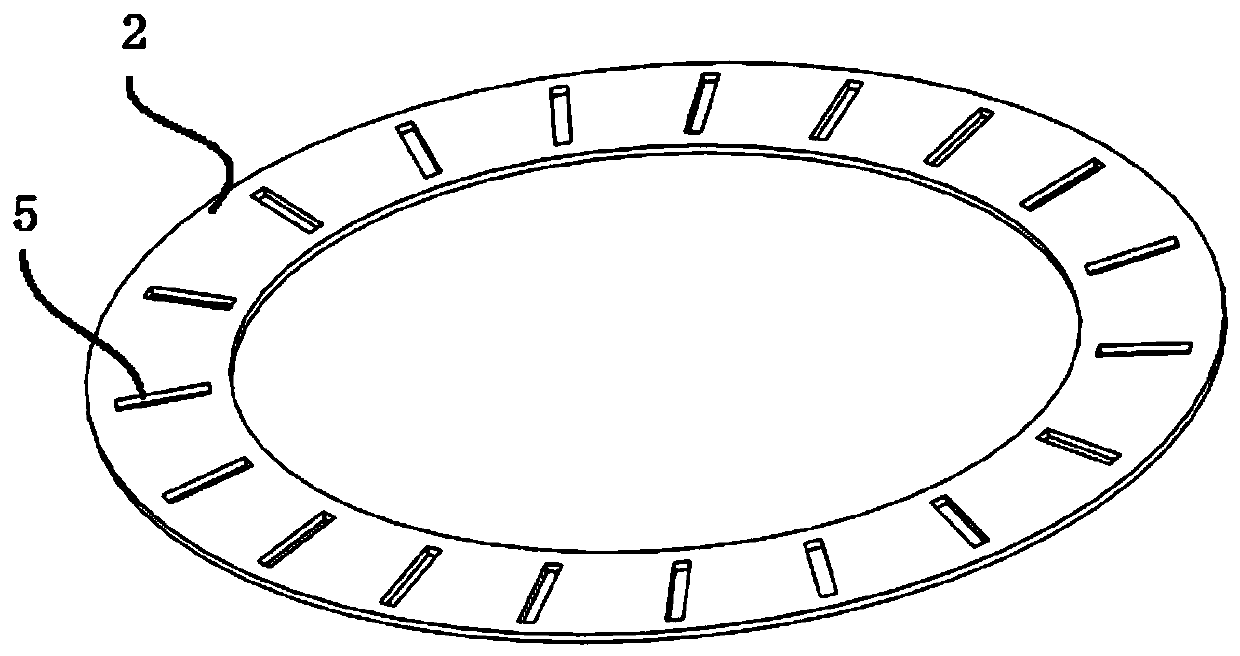

A solid material drying system

ActiveCN110779316BEfficient dryingPrevents uneven dryingDrying solid materials with heatGranular material dryingThermodynamicsEngineering

The invention discloses a solid material drying system, which includes a drying tower and a closed endless conveyor belt located at the bottom of the drying tower, the solid material enters the drying tower through the conveyor belt, and the first air flow is passed The bottom end of the tower passes through the conveyor belt and moves towards the top of the drying tower; wherein, the side wall of the drying tower is provided with several openings, and the second airflow moves from the inside of the drying tower to the outside of the drying tower, so A baffle plate capable of closing the opening is arranged inside the drying tower close to the top of the opening, and the baffle plate is hinged to the side wall of the drying tower. The invention is suitable for drying solid materials, especially granular or bar-shaped fertilizers. It can be used for drying various types of solid materials efficiently and universally, and it can dry solid materials with different sizes, moisture content, quantity, and dryness requirements. dry.

Owner:TOBACCO RES INST CHIN AGRI SCI ACAD

A heat-clearing and detoxifying substitute tea and its preparation method

ActiveCN103918823BSame health benefitsThe preparation process is similarPre-extraction tea treatmentClimate change adaptationBitter gourdToxic material

The invention discloses substitute tea capable of removing heat and toxic materials which contains the following raw materials: dehydrated guava leaves, dried guava fruits, dried bitter gourd, tea leaves, liquorice, dehydrated stigma of corn, dehydrated roselle, pericarpium citri reticulatae, dehydrated stevia rebaudian, dehydrated semen cassia, chrysanthemum, dehydrated gynostemma pentaphylla, dehydrated lotus leaf, pink rose, broadleaf holly leaf and the like, wherein the raw materials are dehydrated and dried till the water content is controlled to be 5%-8%. In addition, the invention further discloses a preparation method of the substitute tea. The preparation method comprises the following steps: selecting fresh tea material, cleaning the fresh tea material, finishing, blanching, cooling, carrying out vacuum dewatering under variable pressures, drying with combination of solar energy and dehumidification, grinding raw materials, mixing and stirring, packing with small filter-bags. The technical solution provided by the invention overcomes the defects in the traditional series substitute tea processing methods, energy consumption and production cost are reduced, influences of weather are avoided, the drying is fast, the product quality is good, and the product meets the national standard related to food hygiene.

Owner:GUANGZHOU QINGXIANG AGRI PROD CO LTD

Method for determining water content of grain in spreading type grain drier

InactiveCN100419413CControl drynessSimple structureMaterial impedanceSpecial data processing applicationsElectrical resistance and conductancePhase difference

The related moisture detection method for dried grain comprises: putting paralleled two plate electrodes on drier sides or bottom with some distance, forcing a high-frequency signal E connected to a standard resistance RH on the electrodes to generate a non-even electric field; detecting the voltage drop U1 of grain and U2 of RH and their phase difference alpha, and obtaining the Rm or Cm and then the moisture omega by electric formula and fitting function. This invention is simple and low cost.

Owner:NANJING AGRICULTURAL UNIVERSITY

Solid material drying system

ActiveCN110779316AEfficient dryingPrevents uneven dryingDrying solid materials with heatGranular material dryingStructural engineeringMechanical engineering

The invention discloses a solid material drying system which comprises a drying tower and a closed ring-shaped conveying belt located at the bottom of the drying tower. Solid materials enter the drying tower through the conveying belt, and in addition, first airflow passes through the conveying belt from the bottom end of the drying tower so as to move towards the top end of the drying tower. Multiple openings are formed in the side wall of the drying tower, and second airflow moves towards the outer portion of the drying tower from the interior of the drying tower. A partition plate capable of sealing the openings is arranged at the position, close to the openings, of the upper portion of the interior of the drying tower. The partition plate is hinged to the side wall of the drying tower.The solid material drying system is suitable for drying solid materials, especially particulate or bar-shaped fertilizer, the solid material drying system can be suitable for drying various types ofsolid materials efficiently and universally, and solid materials with different sizes, water content, numbers and drying degree demands are dried.

Owner:TOBACCO RES INST CHIN AGRI SCI ACAD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com