Patents

Literature

89results about How to "Uniform surface color" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

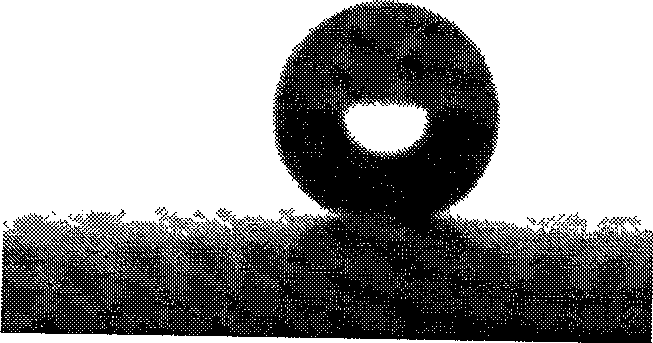

Preparation method of polymer hydrophobic surface

InactiveCN101456016AExcellent superhydrophobic propertiesUniform surface colorPretreated surfacesPolyester coatingsCoated surfacePolymer science

The invention provides a method for preparing a polymer hydrophobic surface and belongs to the technical field of polymer chemical material. The method comprises: preparing a polymer desperation and hydrophobic silica desperation; uniformly mixing the polymer desperation and the hydrophobic silica desperation for preparing a hydrophobic coating; spraying the hydrophobic coating onto a completely cleaned base surface uniformly with a spray gun; and finally, subjecting the sprayed base surface to heat treatment and cooling the base surface to obtain the polymer hydrophobic surface. The surface of a coating processed by the method is obvious in super-hydrophobic performance, uniform in luster and stable in performance, free from damage caused by scrubbing to the super-hydrophobic performance, simple in preparation process, low in preparation process implementation cost and applicable surfaces made from various materials without damaging the original materials by corrosive materials.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

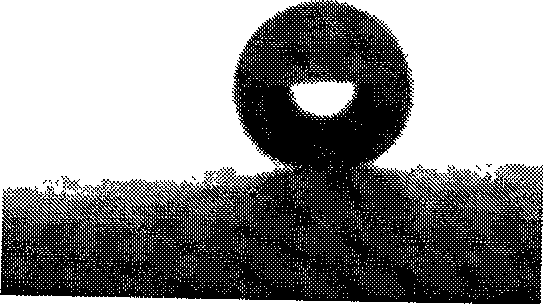

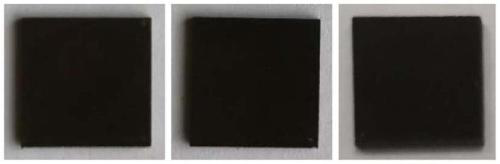

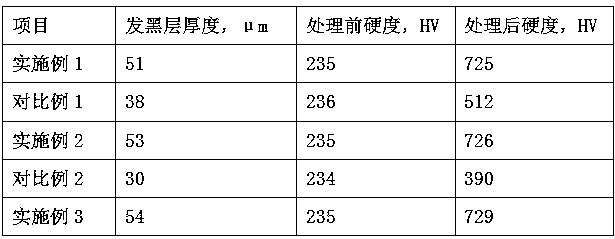

Electrolyte used for preparing black ceramic film through micro-arc oxidation, preparation method of electrolyte and micro-arc oxidation method

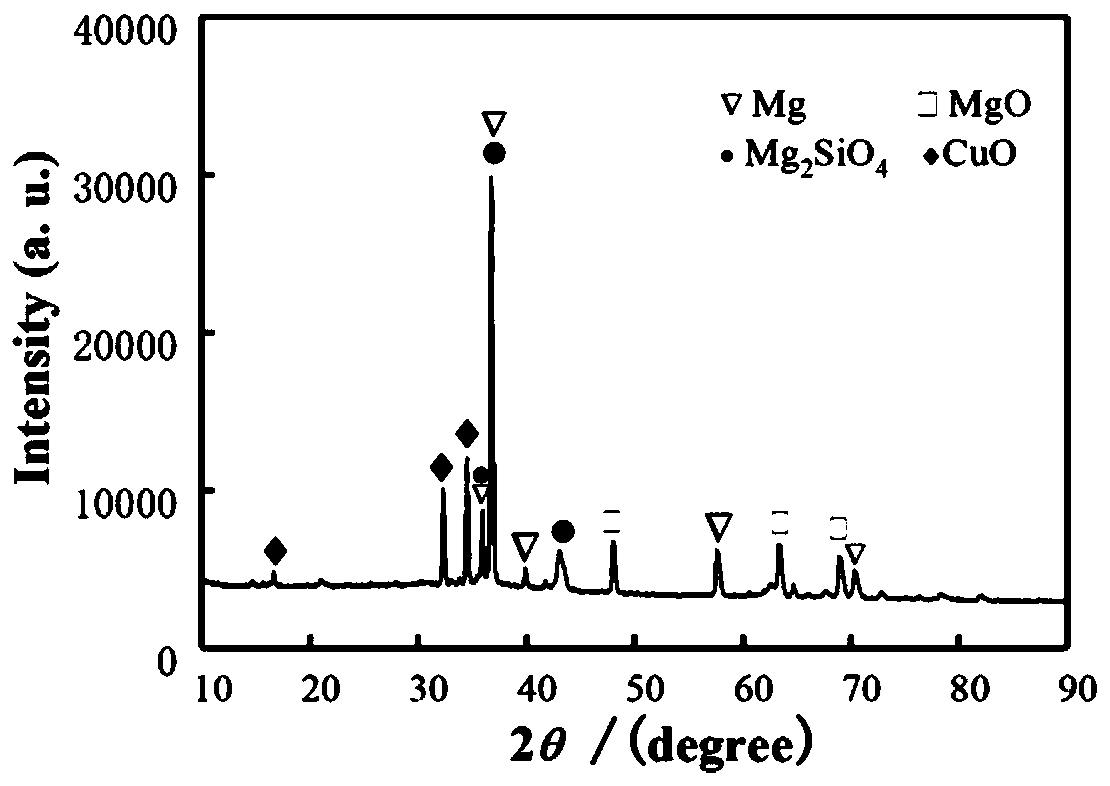

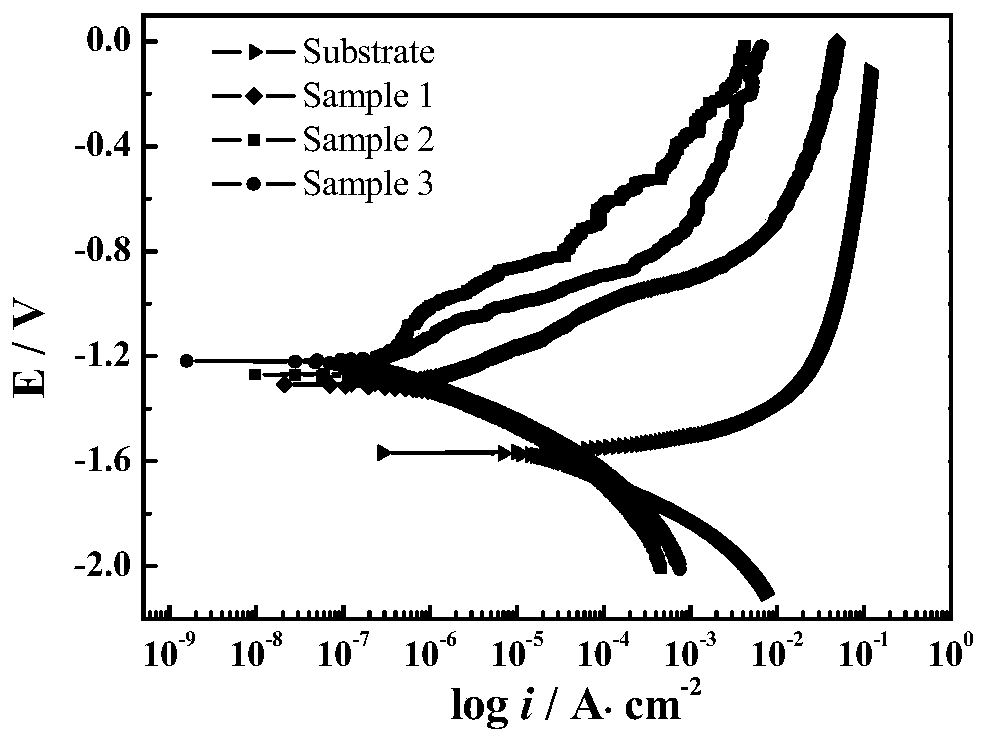

ActiveCN111058077ABlack saturationUniform surface colorAnodisationElectrolytic agentMicro arc oxidation

The invention belongs to the technical field of surface treatment of magnesium alloy materials, and discloses an electrolyte used for preparing a black ceramic film through micro-arc oxidation, a preparation method of the electrolyte and the micro-arc oxidation method. The technological method for obtaining the black morphology on the surface of a magnesium alloy is provided, and by preparing theelectrolyte synthesized by a first coloring liquid and a second coloring liquid according to a most suitable ratio, setting key technical parameters and adopting the first constant-pressure and constant-current two-step micro-arc oxidation method, the method obtains the black ceramic film with a thickness of about 15-30 [mu]m on the surface of the magnesium alloy. The process provided by the invention has good repeatability, the electrolyte has good stability and can be recycled, the obtained black ceramic film has uniform color, and good corrosion resistance and wear resistance, so that an application range of the magnesium alloy in electronic products is further expanded.

Owner:CHANGZHOU UNIV

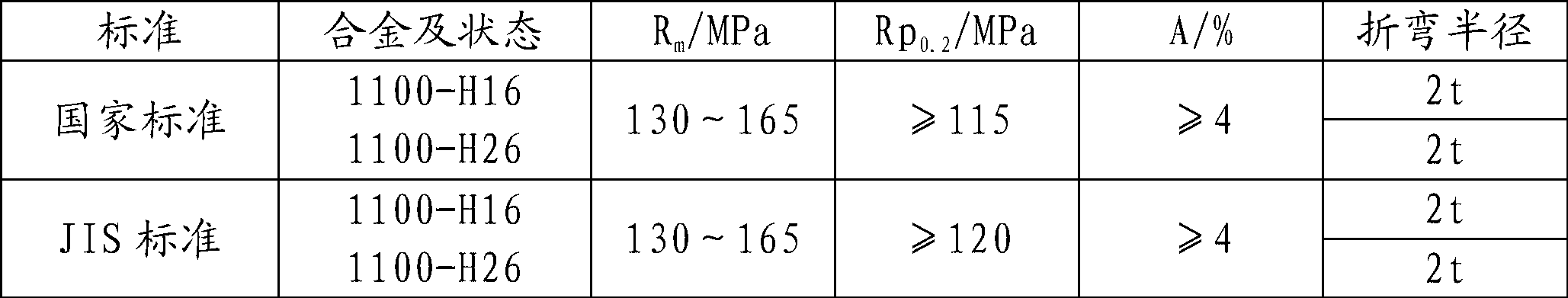

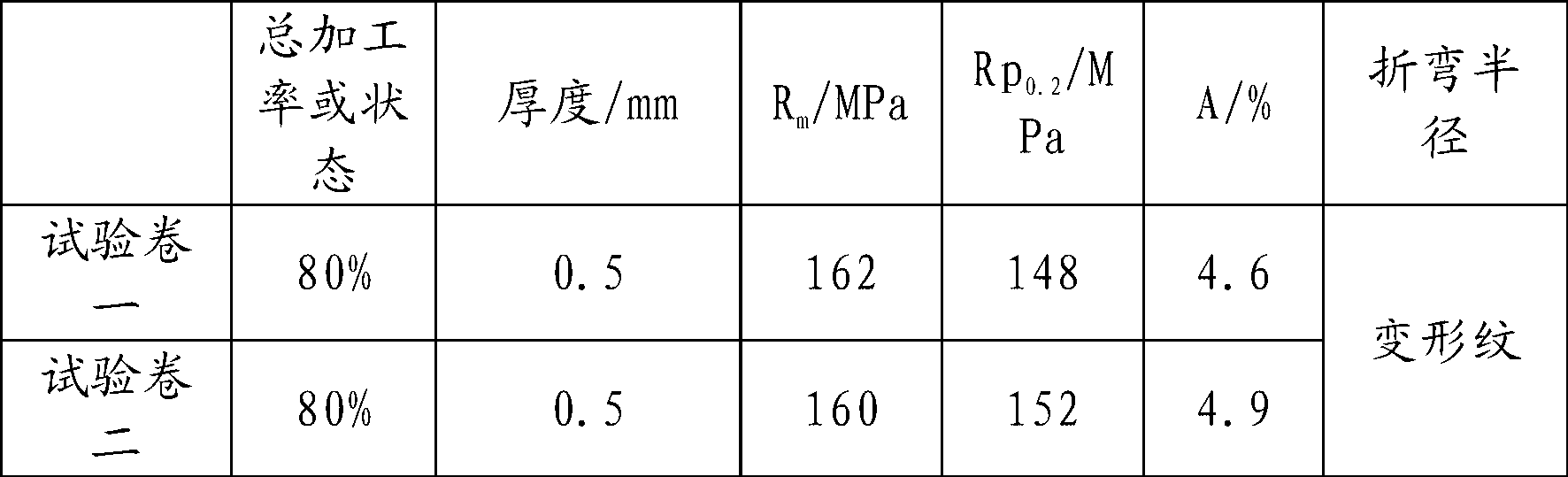

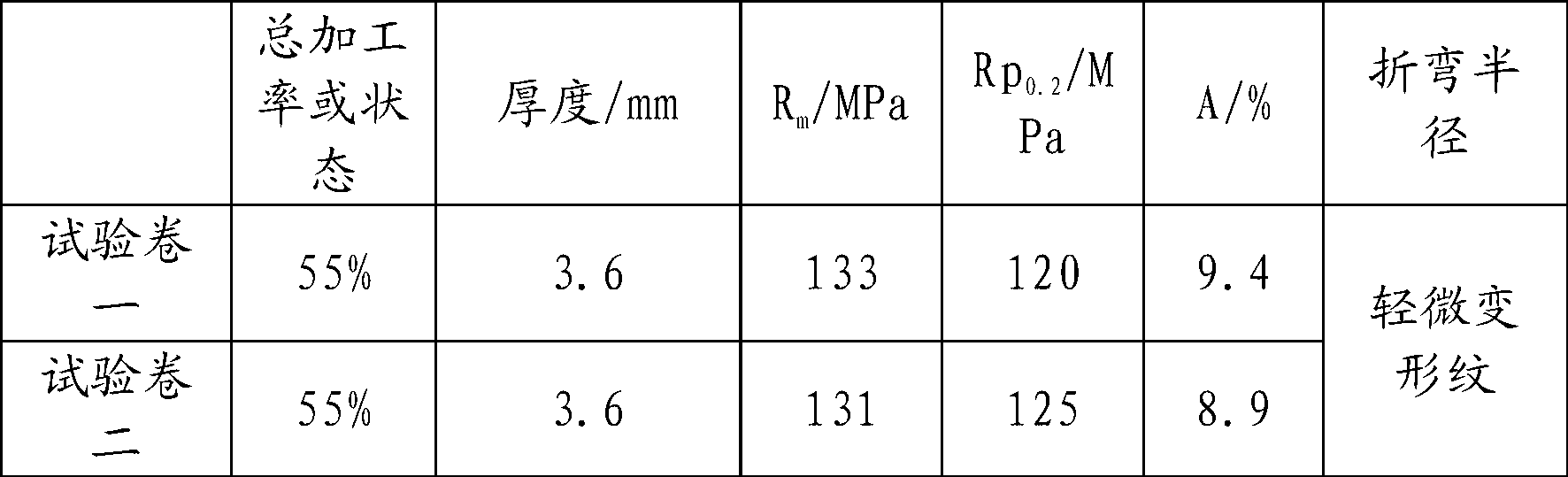

1100-H16 aluminum alloy plate/strip and production method thereof

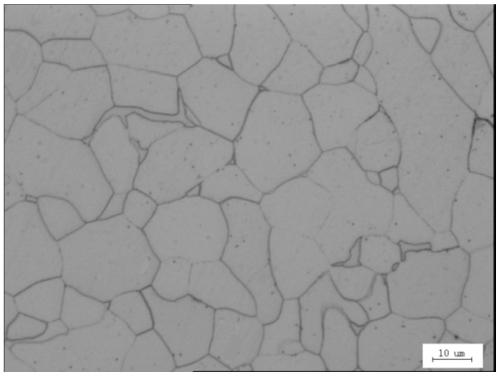

ActiveCN103060621AEliminate unevennessEliminate coarse grainsMetal rolling arrangementsChemical compositionIngot

The invention discloses a 1100-H16 aluminum alloy plate / strip and a production method thereof. The production method comprises the following steps of casting, sawing, surface milling, heating, hot rolling and cold rolling. A cast ingot obtained by casting comprises, by mass, less than or equal to 0.20% of Si, 0.30 to 0.60% of Fe, 0.05 to 0.20% of Cu, less than or equal to 0.05% of Mn, less than or equal to 0.05% of Mg, less than or equal to 0.05% of Zn, 0.01 to 0.03% of Ti, less than or equal to 0.10% of total impurities and the balance Al, wherein and the content of a single impurity is less than or equal to 0.02% by mass. A melting temperature is in a range of 740 to 760 DEG C, a refining temperature is in a range of 735 to 755 DEG C, a casting temperature is in a range of 685 to 705 DEG C, and a casting rate is in a range of 55 to 65mm / min. The hot rolling process comprises that a hot rough rolling cogging-down process is carried out at a temperature of 450 to 500 DEG C; a finish rolling temperature is in a range of 310 to 330 DEG C; and coiling thickness is in a range of 2.5 to 8mm. The production method guarantees table and qualified mechanical properties of the 1100-H16 aluminum alloy plate / strip, shortens a production flow and improves production efficiency.

Owner:ALUHOUSE TECHGD CO LTD

Method for preparing heat control coating layer on surface of magnesium alloy

The invention discloses a method for preparing a heat control coating layer on the surface of magnesium alloy, which relates to a method for preparing a heat control coating layer on the surface of alloy. The invention solves the problem of large mass of the heat control coating layer of aluminum alloy as a base body. The preparation method is realized according to the following steps of: preprocessing the surface of magnesium alloy; preparing magnesium alloy microarc oxidation electrolyte; adding the magnesium alloy microarc oxidation electrolyte into a microarc oxidation electrolytic bath; placing the preprocessed magnesium alloy into the magnesium alloy microarc oxidation electrolyte to be used as an anode; supplying power by a pulse microarc oxidation power supply to react for 5-40 minutes; then washing the surface of magnesium alloy with distilled water and drying to obtain the heat control coating layer on the surface of the magnesium alloy. The density of the magnesium alloy used by the invention is small, is just 1.73g / cm3 and is about two thirds of the density of the aluminum alloy. Compared with a method by adopting the aluminum alloy, the heat control coating layer obtained by the method reduces weight by 30 percent.

Owner:HARBIN INST OF TECH

Formulation of baked and oil resion scented nut and its treatment method

InactiveCN1533715AUniform coatingGood adhesionSeed preservation by coatingFruits/vegetable preservation by coatingAlcoholPolyresin

A formula for parching and flavouring the nut contains the fried-in-oil roasted cashew and / or peanut and / or almond (90-98 wt%), salt (1.5-3), and oil resin (1-3.0) deluted by absolute alcohol. A process for preparing the flavouring nut is also disclosed.

Owner:科学和工业研究委员会

Hot-rolled pickled steel plate for electrogalvanizing and production method thereof

InactiveCN111455259AEasy to shapeQuality improvementFurnace typesMetal rolling arrangementsElectrogalvanizationSurface roughness

The invention provides a hot-rolled pickled steel plate for electrogalvanizing and a production method thereof. The hot-rolled pickled steel plate for the electrogalvanizing is prepared from the components: 0.010-0.080% of C, less than or equal to 0.030% of Si, 0.10%-0.40% of Mn, less than or equal to 0.015% of P, less than or equal to 0.010% of S, 0.020%-0.060% of Al, less than or equal to 0.0050% of N, and the balance of Fe and inevitable impurities. Compared with the prior art, the hot-rolled pickled steel plate for the electrogalvanizing is produced by precisely controlling the componentsin steel and through the processes of hot rolling, pickling and leveling. According to the hot-rolled pickled steel plate produced by the method, in mechanical performance, the yield strength is 200-300MPa, the tensile strength is 320-440MPa, the A50 tensile elongation is greater than or equal to 35%, a surface roughness Ra value is 0.6-1.5[mu]m, the product thickness is 1.5-6.0 mm, the plate shape is good and surface quality is high, the surface color is uniform, and the requirements of the electrogalvanizing can be met.

Owner:MAANSHAN IRON & STEEL CO LTD

Production method of hot-rolled structural steel for clad layer with yield strength of 460MPa

InactiveCN101623714ASolve quality problemsSolve the strength problemTemperature control deviceMetal rolling arrangementsSheet steelUltimate tensile strength

A production method of hot-rolled structural steel for clad layer with a yield strength of 460MPa orderly comprises the steps of steel making, continuous casting, plate blank heating, hot continuous rolling and laminar flow cooling, and coiling. The production method is characterized in that the chemical ingredients by weight percent in the steel making process include 0.05-0.10% of C, at most 0.04% of Si, 1.30-1.65% of Mn, at most 0.030% of P, at least 0.012% of S, 0.01-0.06% of ALs, 0.035-0.060% of Nb, and balance of Fe and inevitable impurities. The product manufactured by the steel plate of the invention has good clad layer quality and uniform and consistent surface color, and the invention solves the problems that the steel plate produced using the prior method has poor galvanization quality, relatively low intensity and the like, and reduces production cost.

Owner:WUHAN IRON & STEEL (GROUP) CORP

Watermelon suspension cultivation method and cultivation pergola thereof

The invention relates to a watermelon suspension cultivation method and a cultivation pergola thereof. The invention discloses the watermelon suspension cultivation method which comprises the following steps that after a watermelon seedling is planted, a vine leading rope which is vertically arranged in a watermelon field is used for leading vines; when a main vine grows to be 40cm to 50cm long and side wines grow to be more than 15cm, pruning is carried out once every 3 to 5 days, and pruning is stopped after the watermelon vines bear fruit; the watermelon vines are pinched, and the watermelon fruits are supported through a tuck net on the vine leading rope. According to the cultivation method, not only can every watermelon seedling be managed conveniently, is the quality of every watermelon ensured, is the illumination on the watermelons uniform and is the surface color uniform, but also the watermelons grow by being supported by the tuck net, the possibility that the watermelons become oval is smaller, and the appearance of the watermelons is better.

Owner:安徽滨江农业科技股份有限公司

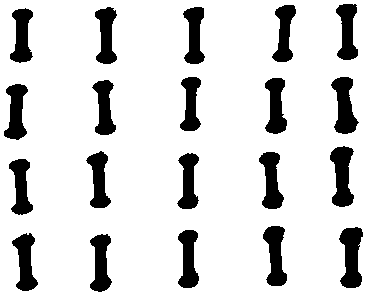

High-cycle-use feedstock for metal-power injection molding (MIM) and preparation method thereof

The invention discloses a high-cycle-use feedstock for metal-power injection molding (MIM) and a preparation method thereof. The high-cycle-use feedstock is prepared from binding agent total components and a metal power component according to the formula proportion; the binding agent total components is prepared from the components in percentage by weight: 80-90wt.% of copolyoxymethylene, 2-10wt.%of backbone high polymer, 2-5wt.% of thermoplastic elastomer, 0.1-3wt.% of an antioxidant, 0.1-1wt.% of an absorbing agent, 0.1-5wt.% of a compatilizing agent and 0.1-5wt.% of a coupling agent; and the weight percentage of the binding agent total components to the metal power component is 1to (10-11). The preparation method comprises the step of extruding and granulating through a double-screw extruding machine. According to the high-cycle-use feedstock for MIM and the preparation method thereof, optimization is carried out from the angle of the binding agent and the angle of the equipment technology, the cycle use life of the feedstock is prolonged, through a test, the color of the surface of a workpiece which is subjected to injection molding by the high-cycle-use feedstock is uniform and has no dark lines and flow lines, meanwhile, the number of times of cycle of a drainage opening material is much, the degreasing rate at the later stage is high and can maintain at a certain stablelevel, and no desirable influence occurs to the appearance of a product.

Owner:深圳市众德祥科技有限公司

Method for making black sound absorption and flame retardation paper through adhesive spraying

ActiveCN103233387AGood colorHigh strengthNon-fibrous pulp additionPaper coatingGlass fiberFilling materials

The invention provides a method for making black sound absorption and flame retardation paper through adhesive spraying. The method comprises the following steps: mixing glass fibers and vegetable fibers through a wet papermaking technology, respectively processing an adhesive and a flame retardant and color past mixture to prepare solutions having certain concentrations, uniformly spraying the surface of raw paper with a prepared adhesive solution, and drying at a controlled drying temperature for a controlled time to guarantee the flattening and no wrinkling of dried paper. The glass fibers and the vegetable fibers selected in the invention are processed through a production technology theory of special paper to obtain black sound absorption and flame retardation paper having the advantages of high strength, strong flame retardation and uniform surface color. In the invention, the excellent performances of the glass fibers and the vegetable fibers are fully performed, and the high-quality black sound absorption and flame retardation paper which can be used in the walls of buildings as a filler is obtained through the wet papermaking technology and an adhesive spraying and drying technology in the preparation of the special paper. The method provided by the invention has the advantages of full utilization of the self characteristics of raw materials, simple preparation process, and excellent performances of finished products.

Owner:SHAANXI UNIV OF SCI & TECH

Hot-rolled pickling steel plate for deep drawing quality electro-galvanizing and production method thereof

The invention discloses a hot-rolled pickling steel plate for deep drawing quality electro-galvanizing and a production method of the hot-rolled pickling steel plate. The hot-rolled pickling steel plate comprises the following chemical components of, by weight percentage, C <= 0.008%, Si <= 0.030%, 0.10%-0.40% of Mn, P <= 0.015%, S <= 0.010%, 0.020%-0.060% of Al, Ti <= 0.080%, and N <= 0.0050%. The hot-rolled pickling steel plate is prepared through molten iron pretreatment, converter smelting, alloy fine adjustment, RH furnace refining, continuous casting, casting blank heating, hot rolling, laminar cooling, coiling, pickling and leveling. The thickness range of the hot-rolled pickling steel plate can be controlled within 1.5-6.0 mm. The hot-rolled pickling steel plate can be used to produce thick galvanized steel sheets with surface quality above FB and uniform surface color, and requirements of galvanization can be met.

Owner:MAANSHAN IRON & STEEL CO LTD

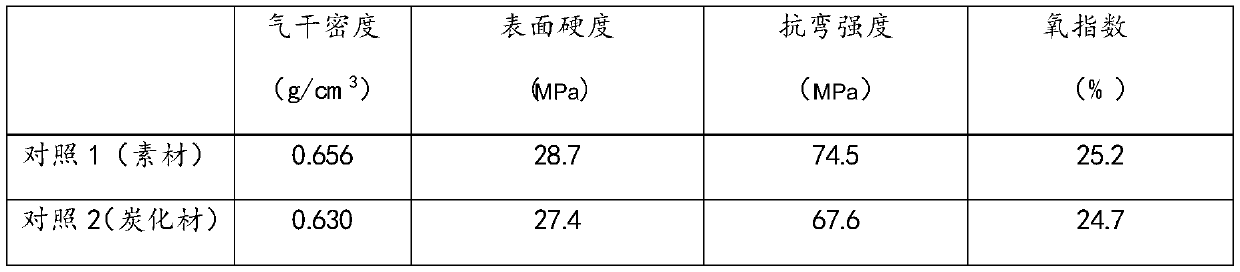

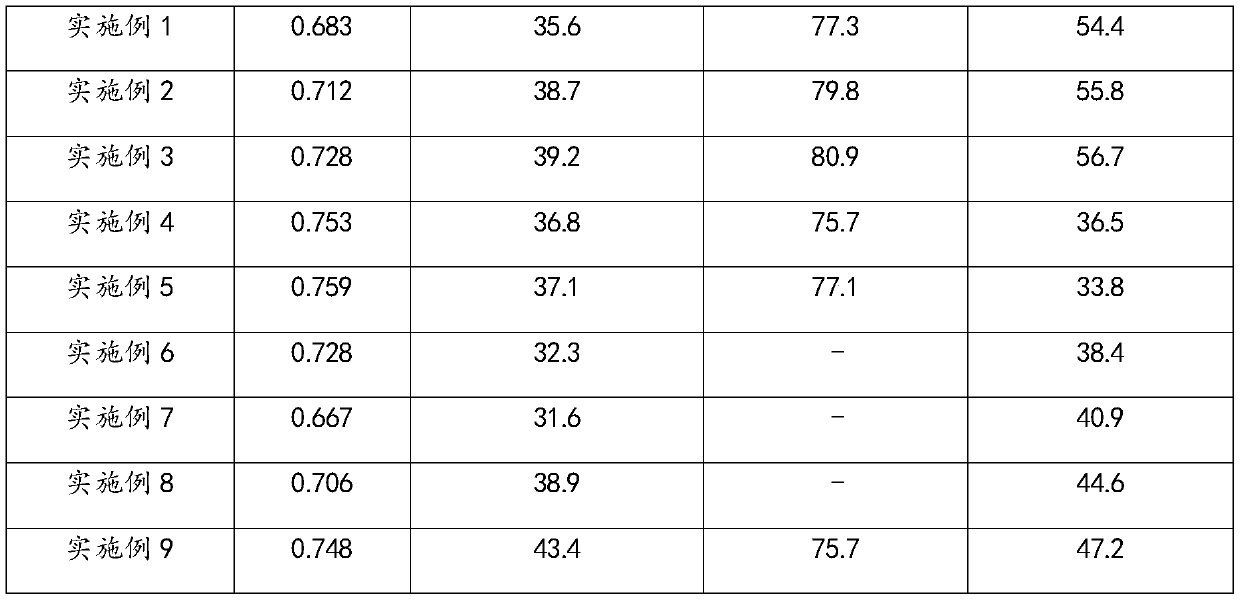

Method for preparing reinforced and flame-retardant carbonized rubber and wood board

ActiveCN110355845AReduce anti-corrosion treatment processOptimizing the drying/charring processWood treatment detailsPressure impregnationRubbertreeCarbonization

The invention belongs to the technical field of wood board processing, and concretely relates to a method for preparing a reinforced and flame-retardant carbonized rubber and wood board. The method comprises a high temperature carbonization treatment process and a flame retardation and reinforcement integrated treatment process. The high temperature carbonization treatment process includes preheating treatment, low temperature drying treatment, high temperature carbonization treatment and cooling treatment. The flame retardation and reinforcement integrated treatment process includes preparation of a flame retarding and reinforcing solution and low temperature pressure impregnation treatment. The method reduces the anticorrosion treatment process of conventional rubber wood processing, saves the cost, optimizes a conventional rubber and wood drying / carbonizing process, realizes one-time drying / carbonizing, shortens the drying / carbonizing time, realizes the flame retardation and reinforcement one-time treatment, saves the time and cost, and enhances the flame retardant property of the board. The reinforced and flame-retardant carbonized rubber and wood board has the advantages of improved density, improved dimensional stability, improved surface strength, improved flame retardant performance, uniform surface color and high yield, and solves the problem of easy deformation of a thin board, caused by drying / carbonization.

Owner:RUBBER RES INST CHINESE ACADEMY OF TROPICAL AGRI SCI

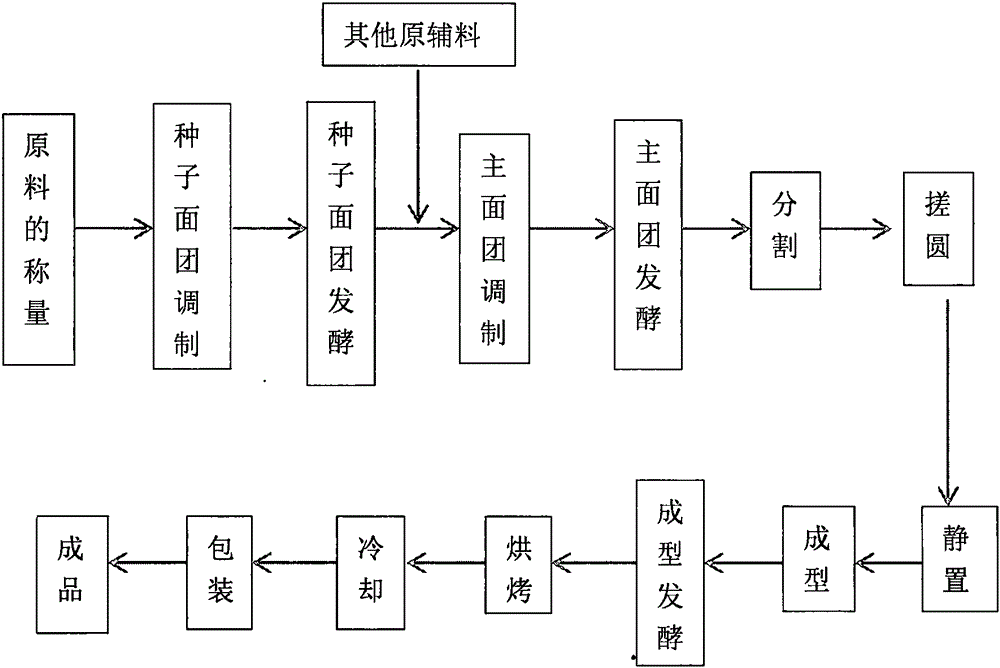

Technology adopting secondary fermentation method for making bread

InactiveCN105028568AComplete formPlumpPre-baking dough treatmentBakery productsDough fermentationRaw material

The invention discloses a technology adopting a secondary fermentation method for making bread, and relates to the technical field of bread making. The technology mainly comprises the steps that raw materials are prepared and weighed, seed dough is made through mixing and fermented, main dough is made through mixing and fermented, the dough is divided and rubbed to be round and stands, formed dough is fermented and baked, and then a baked product is taken out of an oven to be placed on an airing frame, cooled at indoor temperature and then packaged. The defects in the prior art can be overcome, the technology for making the bread is simple, by the adoption of the secondary fermentation method, the made bread is complete in form, plump, free of black foams or obvious burned dots, even and normal in surface color and luster, fine, smooth and elastic in internal tissue, even in pore, clear in grain, slow in aging, softer and more agreeable to the taste, and is in a sponge shape, and a stuffing membrane is thin.

Owner:金怀蕊

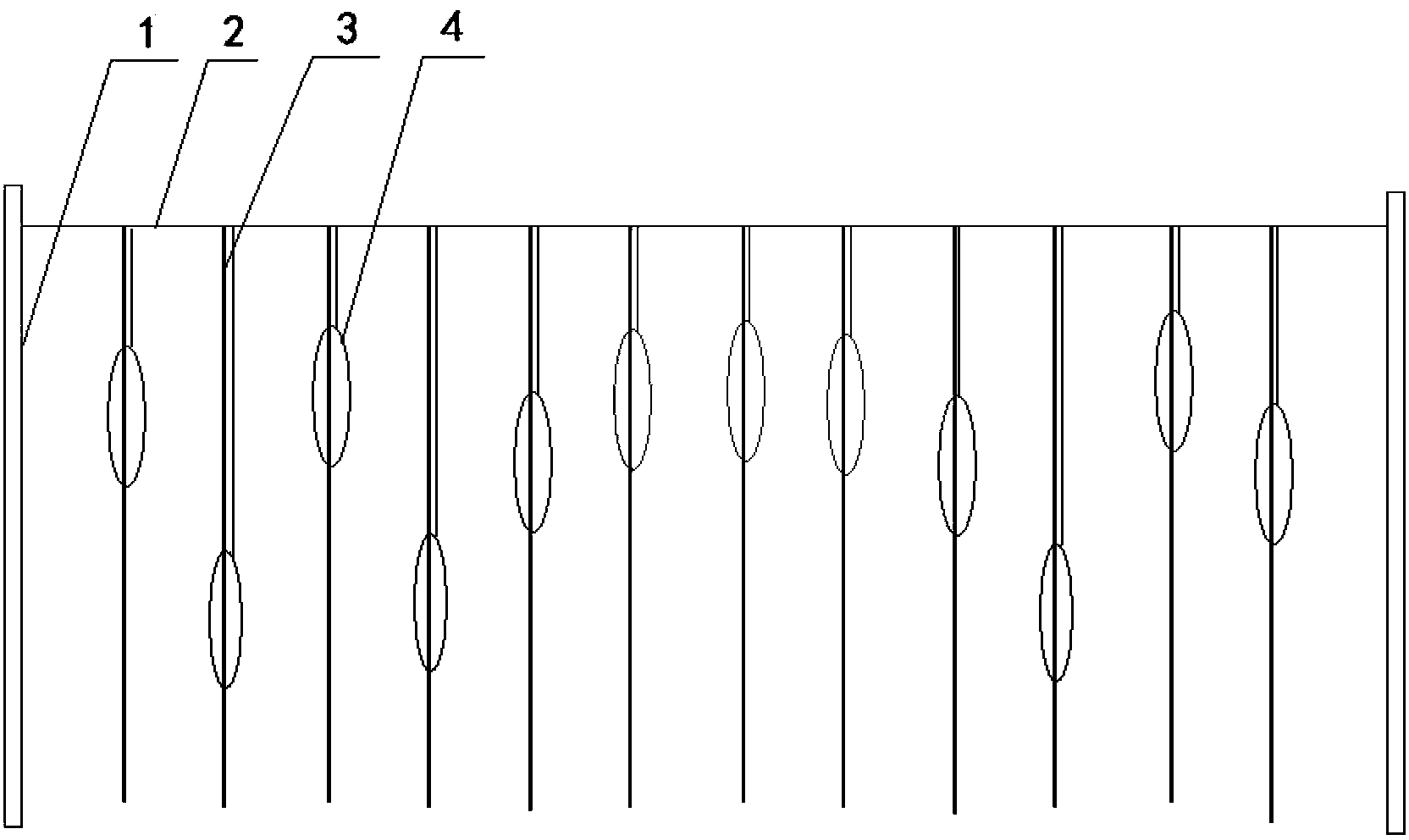

Glass fiber-reinforced bi-component pultruded polyurethane material and application thereof in magnetic steel batten of direct-driven permanent magnetic synchronous wind turbine

PendingCN107383846ARich sourcesGood value for moneyMagnetic circuit characterised by magnetic materialsWind energy generationYarnFiber

The invention provides a glass fiber-reinforced bi-component pultruded polyurethane resin material which is at least prepared from the following components: alkali-free glass fiber yarn, glass fiber fabrics, bi-component polyurethane resin, a special flame retardant agent for bi-component polyurethane resin and color paste. The polyurethane material is rich in source of raw materials and low in preparation cost; a magnetic steel batten of a direct-driven permanent magnetic synchronous wind turbine prepared from the polyurethane material is flat and smooth in surface, free of bubbles and exposed fibers, unlikely to be contaminated by oil, uniform in surface color, and unlikely to have cracks, delaminate and produce mechanical scars.

Owner:南京经略复合材料有限公司

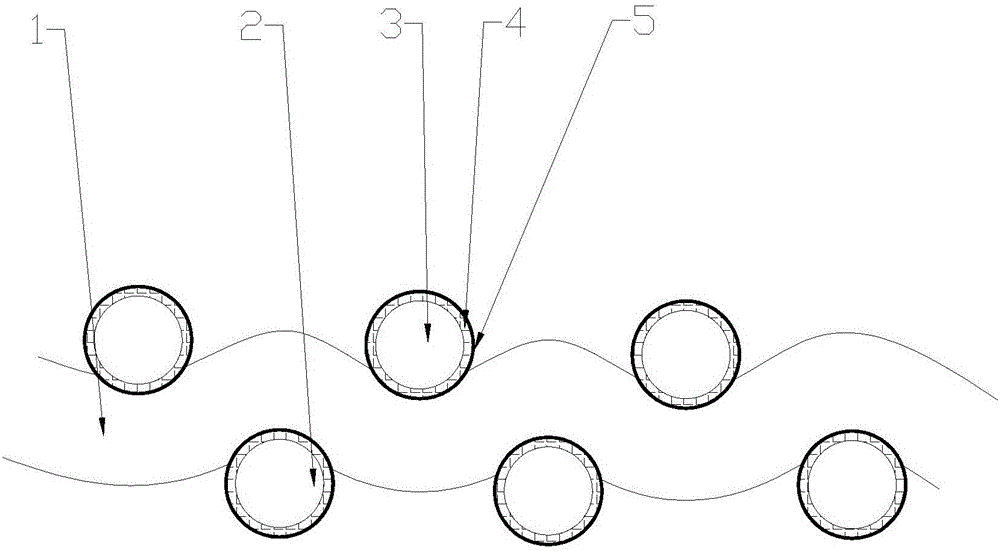

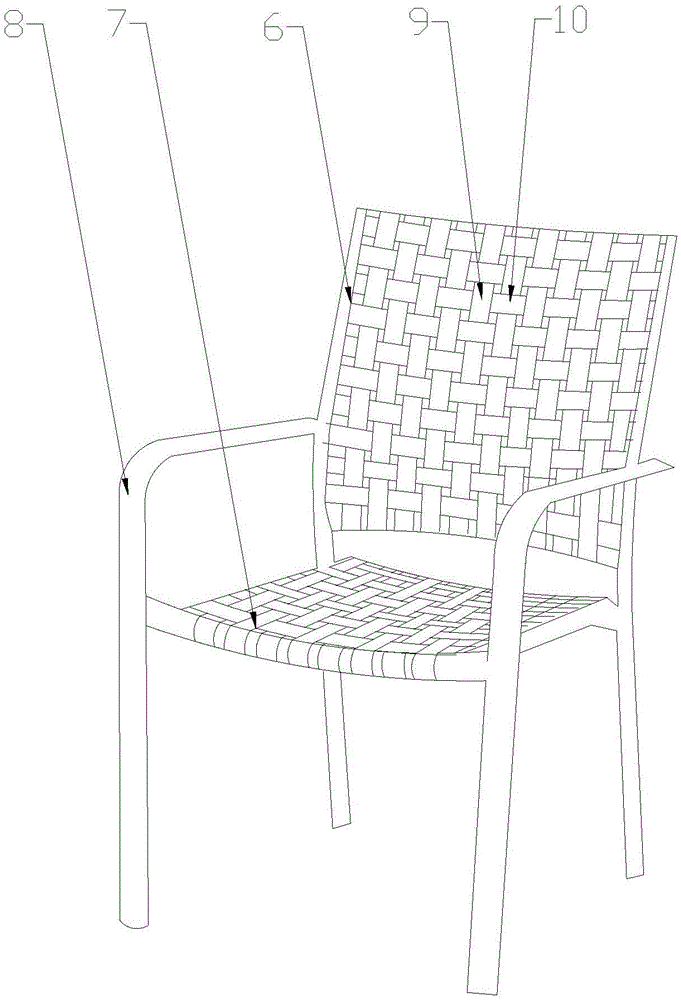

Braid, braid manufacturing method and outdoor chair with braid

InactiveCN105780243AUniform color effectConsistent and uniform multi-color effectStoolsWoven fabricsPolyesterFiber

The invention discloses a braid, a braid manufacturing method and an outdoor chair with the braid. The braid comprises a braid body, wherein the braid body is formed by woven warps and wefts; the warps and the wefts are both made of polyester silk in a woven manner; and the polyester silk is made of a plurality of loose fibers of different colors in a combined manner. The loose fiber is covered by an ultraviolet layer. A chair back and a chair seat both comprise a plurality of warp-wise braids and weft-wise braids which are woven together; the warp-wise braids and the weft-wise braids are both made of the braids. By adopting the braid, the problems that in the prior art, a multi-color braid is not uniform in color, a finished product needs to be dyed, and the service life of an outdoor chair is short can be solved, and the invention provides the braid which is uniform in color and high in color fastness and an outdoor chair which is long in service life.

Owner:海宁市辉腾织带有限公司

Method for treating surface blackening of automobile wheel hub

The invention discloses a method for treating the surface blackening of an automobile wheel hub. The method comprises the following operation steps: (1) cleaning the formed automobile wheel hub, spraying modification liquid to the surface, putting the automobile wheel hub into a nitriding furnace for preheating treatment for 10 to 15 min; (2) putting the automobile wheel hub treated in the step (1) into a salt bath furnace, and heating to 520 to 540 DEG C for salt bath treatment for 60 to 70 min; and (3) putting the automobile wheel hub treated in the step (2) into blackening liquid for soaking treatment for 3 to 5 min, and taking out and cleaning the automobile wheel hub, thus obtaining a finished product. The automobile wheel hub prepared through the method provided by the invention is uniform in surface color, high in glossiness and excellent in quality, and the surface is excellent in corrosion resistance and oxidization resistance, and particularly has excellent wear resistance; and the surface hardness is high, so that the service life of the automobile wheel hub is greatly prolonged.

Owner:刘珍

Method for rolling pure titanium strip by using Sendzimir 20-high mill

ActiveCN106734204AMeet quality requirementsUniform surface colorTemperature control deviceTension/compression control deviceStrip millStrip steel

The invention discloses a method for rolling a pure titanium strip by using a Sendzimir 20-high mill. The method comprises the steps of (1) profile control achieved by designing roll system configuration; (2) thickness control including the step of correcting correction coefficients of each thickness interval of a thickness gauge by using titanium plate thickness standard plates; and (3) surface control including the step of strictly controlling strip steel temperature and rolling technology parameters when rolling is carried out. By utilization of an existing stainless steel 20-high Sendzimir mill, through thickness gauge adjustment, roll system configuration and rolling technology control, satisfactory profile, thickness, surface and yield are obtained.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Nickel-phosphorus alloy plating solution for chemical plating of truck tire mold surface and chemical plating method

InactiveCN103805974AHigh hardnessAccelerated corrosionLiquid/solution decomposition chemical coatingSodium acetateChemical plating

The invention discloses a nickel-phosphorus alloy plating solution for chemical plating of a truck tire mold surface and a chemical plating method. The nickel-phosphorus alloy plating solution is adopted so as to effectively form a chemical plating layer on a cast steel material surface, thereby remarkably improving the wear resistance, the corrosion resistance and the hardness of the truck tire mold surface and enhancing the surface color uniformity and the appearance quality of a processed tire. The nickel-phosphorus alloy plating solution, which takes water as a solvent, comprises the following components by weight: 20-40 g / l of nickel sulfate, 15-30 g / l of sodium hypophosphite, 2-7 g / l of sodium citrate, 11-18 g / l of sodium acetate and 0.001-0.003 g / l of thiourea, wherein the pH value of the nickel-phosphorus alloy plating solution is 4.2-4.8. By using the nickel-phosphorus alloy plating solution, a nickel-phosphorus plating layer can be formed on the truck tire mold surface of the cast steel material, thus the wear resistance, the corrosion resistance and the hardness of a mold are remarkably improved.

Owner:QINGDAO MESNAC PRECISE PROCESSING IND

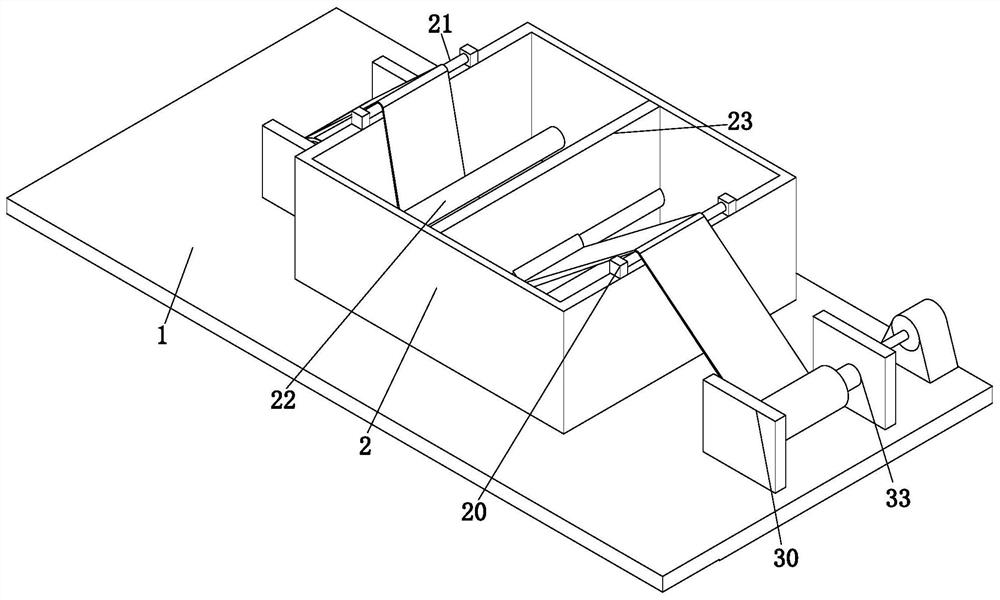

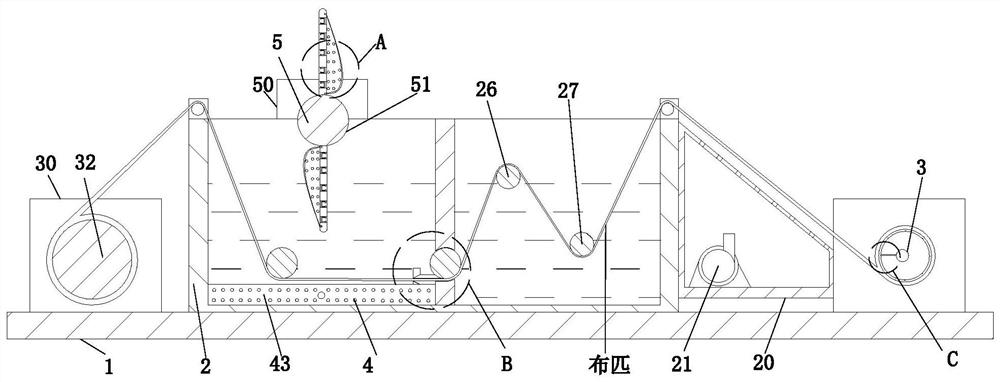

Textile cloth dip dyeing process

InactiveCN112323306AAffect the dyeing effectAvoid shadesMechanical cleaningPressure cleaningPulp and paper industryMaterials science

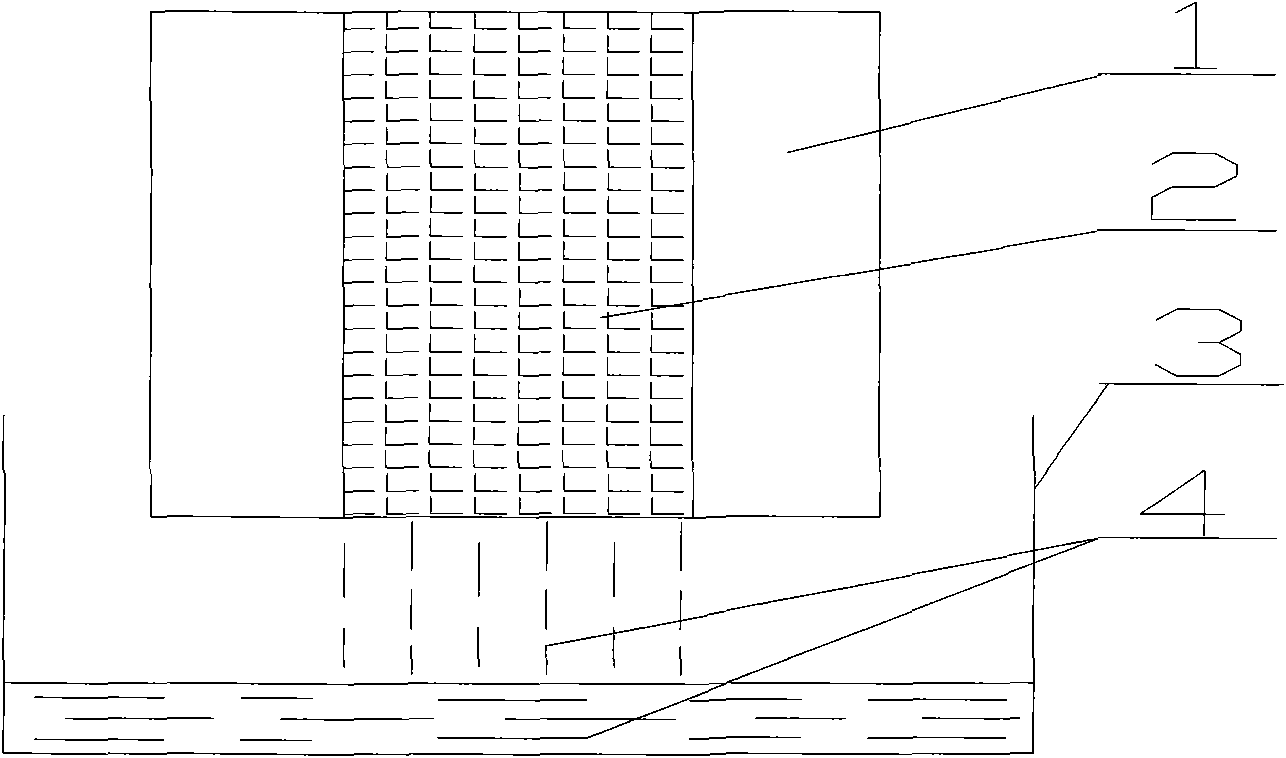

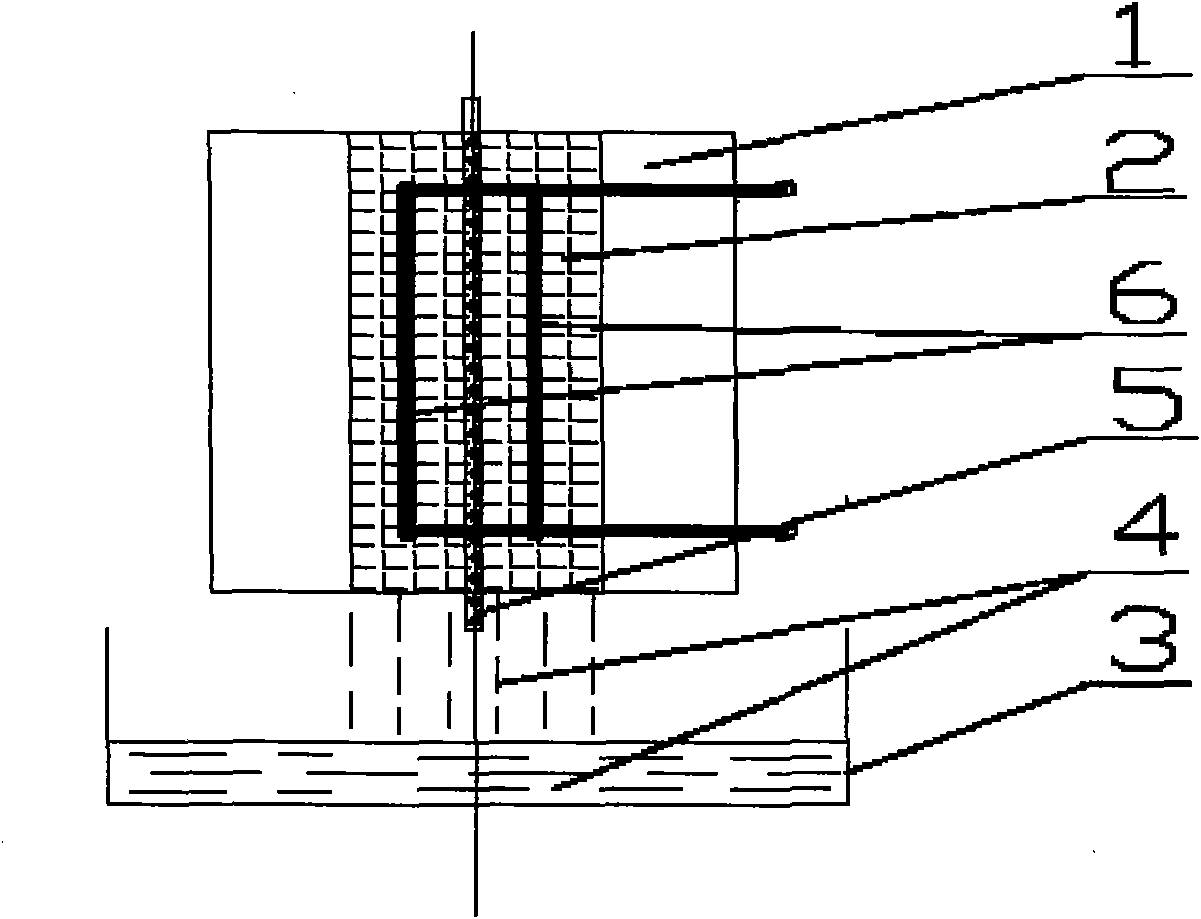

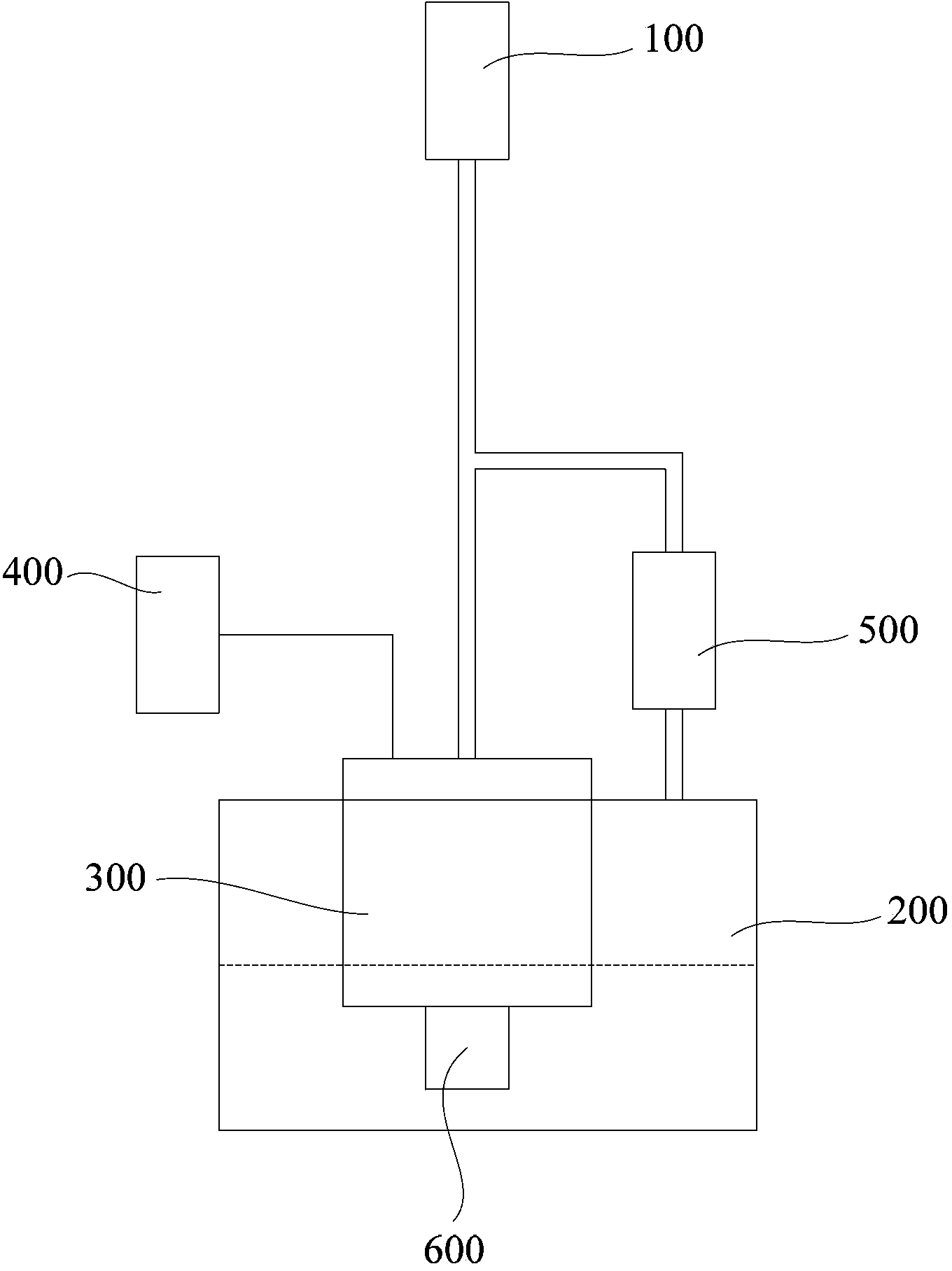

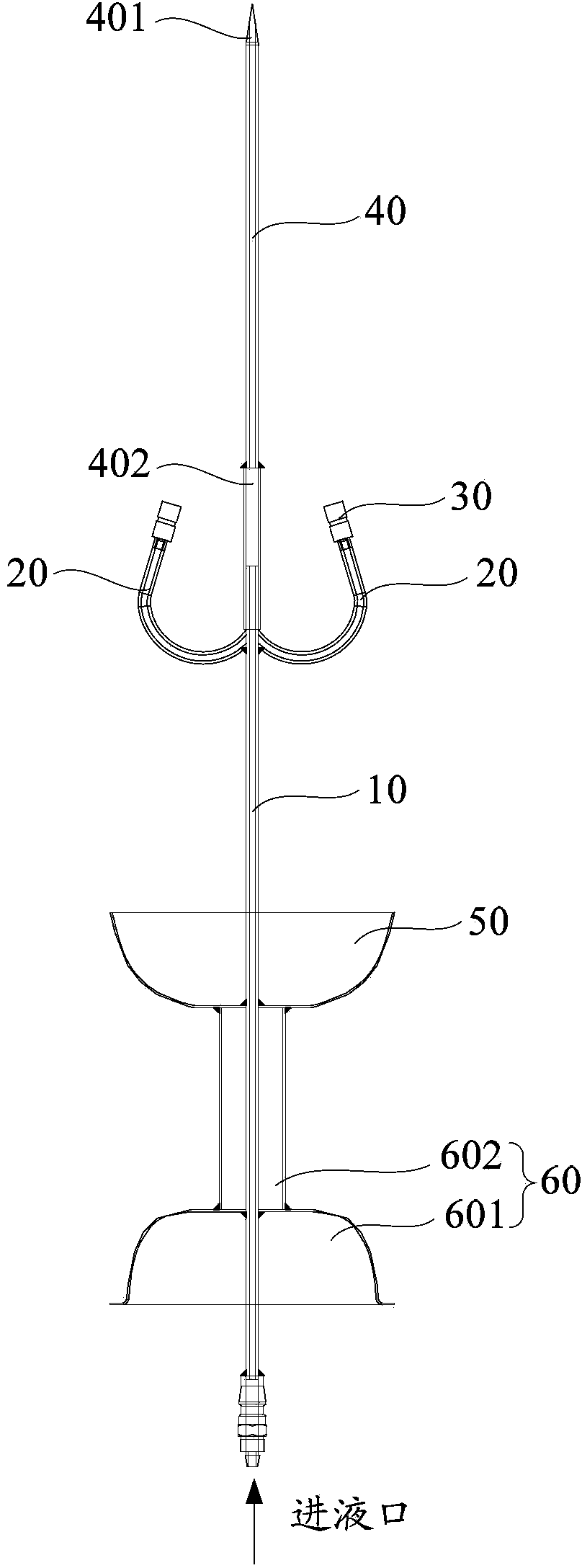

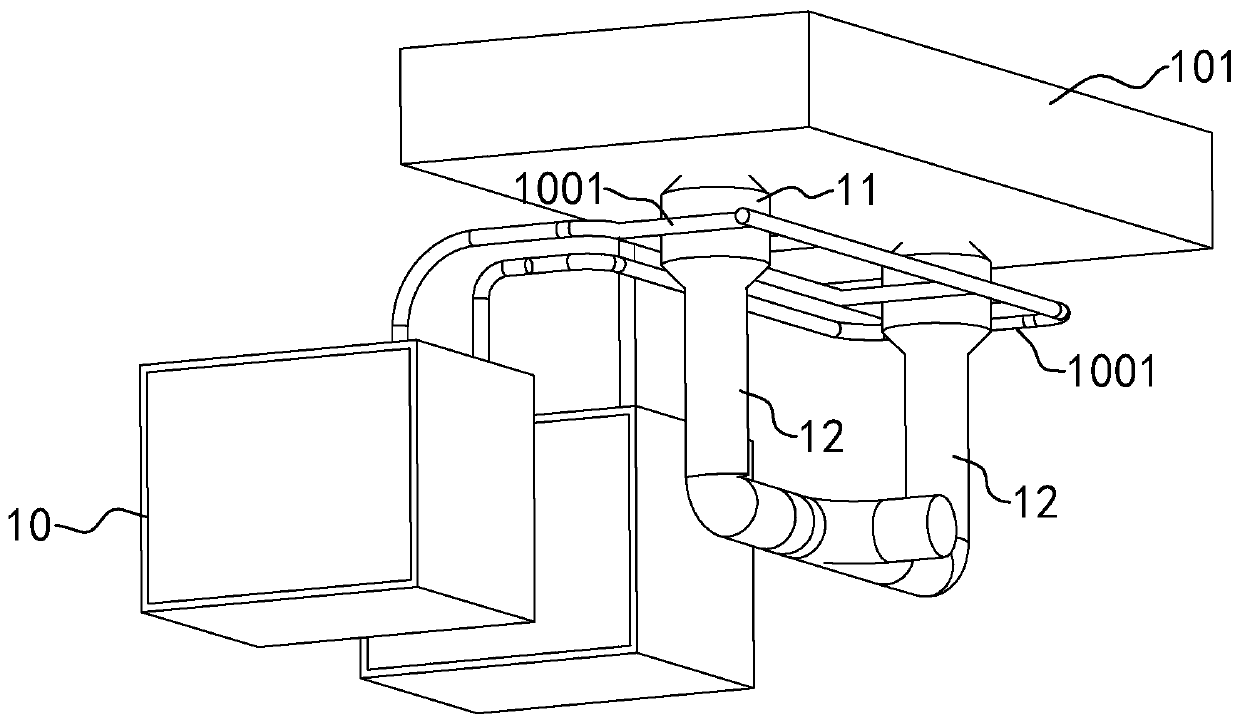

The invention relates to a textile cloth dip dyeing process. The textile cloth dip dyeing process uses a textile cloth dip dyeing device. The textile cloth dip dyeing device comprises a workbench, a dye pool, an intermittent transmission mechanism, a clearing mechanism and a filtering mechanism, the dye pool is installed in the middle of the upper end face of the workbench, and the dye pool is ofa rectangular cavity structure with an opening in the upper end; and the intermittent transmission mechanism is installed on the upper end face of the workbench, the clearing mechanism is arranged inthe dye pool, and the filtering mechanism is arranged on the upper portion of the clearing mechanism. The adopted clearing mechanism can clear and scrape impurities on the surface of textile cloth inthe dip dyeing process, so that the surface of the cloth is fully dip-dyed in the dip dyeing process, and the phenomenon of irregularity and the like is avoided; and meanwhile, through the adopted filtering mechanism, the impurities scraped off from the textile cloth float on the surface of dye liquor and then are fished and filtered, and the situation that the dip dyeing effect of the textile cloth is affected due to the fact that the impurities continue to remain in the dye liquor is avoided.

Owner:邓倩

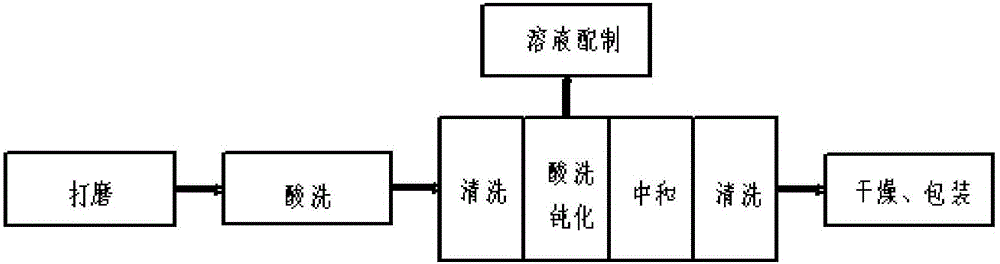

Surface treatment process for stainless steel

InactiveCN106756975AUniform colorImprove internal and external surface qualityMetallic material coating processesSlagTreatment field

The invention belongs to the surface treatment field and particularly relates to a surface treatment process for stainless steel. According to the surface treatment process, the surface quality of stainless steel equipment can be improved. The surface treatment process comprises the following steps: (A) pretreatment: firstly polishing the stainless steel surface, removing welding slag and spatter, removing oil stain and oxides on the surface and in a weld joint by virtue of acid pickling paste, and finally, removing internal and external impurities with clean water; (B) dipping the stainless steel into acid pickling passivation liquid until a silver white passivation film is formed on the surface and the color is uniform; (C) dipping the stainless steel into neutralizing liquid; and (D) soaking the stainless steel with clean water so as to remove surface-adhering solutions and impurities, and drying. The surface treatment process has the advantages that the surface color of the stainless steel is uniform and good in consistency, the surface quality of the stainless steel is high, furthermore, the service life of equipment or a part can be prolonged, the cost is low, the efficiency is high, and the like.

Owner:LUZHOU NORTH CHEM IND

Method for carbonizing ultra-temperature hot-pressing wood surface

ActiveCN104369245AGuaranteed mechanical strengthLess investmentWood compressionWood charring/burningMechanical propertyPaper sheet

A method for carbonizing an ultra-temperature hot-pressing wood surface comprises the following steps that (1) wood is selected and preprocessed, (2) a bottom liner plate is laid, (3) wood to be processed is laid, (4) tin foil paper or a thin stainless steel plate used as the liner plate is laid on the wood, (5) hot-pressing processing is carried out, and (6) discharging, cooling and temperature and humidity regulation are carried out. By means of the method for carbonizing the wood surface, the technology is simple, production cycle is short, production cost is low, energy conservation is obvious, pollution is avoided, processed wood can not be warping and crack, color of the surface is uniform, the surface is good in water repellency, and original mechanical property of the wood can be well kept.

Owner:ZHEJIANG FORESTRY UNIVERSITY

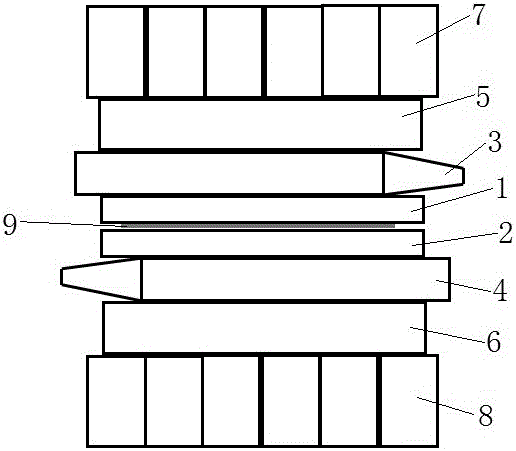

Pickling method of stainless steel covered by acid-proof cloth

The invention introduces a pickling method of stainless steel covered by acid-proof cloth; the method comprises the following steps: covering multi-layer acid-proof cloth on the surface of the stainless steel, supplying pickling solution on the surface of the acid-proof cloth and continuously updating, adding the updated original pickling solution into a solution recovery tank; ensuring that the concentration of the pickling solution is in the optimal process range through changing the concentration of the original pickling solution in the solution recovery tank and continuously updating the acid in the pickling cloth. the temperature of the pickling solution can also be ensured within the optimal process range by removing the bubbles under the cloth by the acid-proof tool and heating and controlling the pickling temperature to. The method can ensure the optimal pickling temperature and concentration, the pickling has good quality; the method can remove an oxidation film thoroughly without overpickling; after pickling, the steel plate has uniform color and metal gloss on the surface; the pickling cloth and pickling solution can be used repeatedly, the pickling cost is low; thus avoiding environmental pollution caused by the waste pickling paste.

Owner:LUOYANG SHUANGRUI METAL COMPOSITE MATERIAL

Steak processing device

The invention discloses a s teak processing device. The steak processing device comprises a fire spraying assembly, a liquid storage groove, a liquid drive part and a control circuit. A feeding port of the liquid drive part is communicated with the liquid storage groove, a discharging port of the liquid drive part is communicated with a feeding port of the fire spraying assembly, and the control circuit is electrically connected with the liquid drive part. The steak processing device is a novel steak processing device and can solve the problem that steaks are poor in inside moisture retention and non-uniformed in surface color and luster after being processed in the prior art.

Owner:王波

Method for producing high-shielding and high-gloss sheet

InactiveCN102658659AImprove environmental protection effectHigh glossPlastic recyclingFlat articlesPolycarbonate plasticPlastic materials

The invention relates to the technical field of sheets made from styrene copolymer or polycarbonate plastic, in particular to a method for producing a high-shielding and high-gloss sheet. The method comprises the following steps of: mixing the common plastic raw material particles and pigment or paint; co-extruding the mixture and color raw material particles to form a double-layer or multi-layer color high-shielding and high-gloss film; classifying the recycled plastic material, crushing, cleaning, drying and recycling; attaching and extruding the recycled plastic and the color high-shielding and high-gloss film to form a high-gloss sheet; forming a high-gloss shell by using a surface non-contact compressed air forming machine; and cutting a semi-finished shell to form a three-dimensional shape. By the method, the requirements of a product on high gloss and exquisite appearance are met, the shielding rate is high, the recycling rate of industrial wastes is improved, and the pollution of the wastes to the environment is reduced; the production process is simple, and equipment investment is reduced; the paint spraying process is eliminated, and the environment-friendly requirement of recycling the plastic material is met.

Owner:上海旭坤塑胶原料有限公司

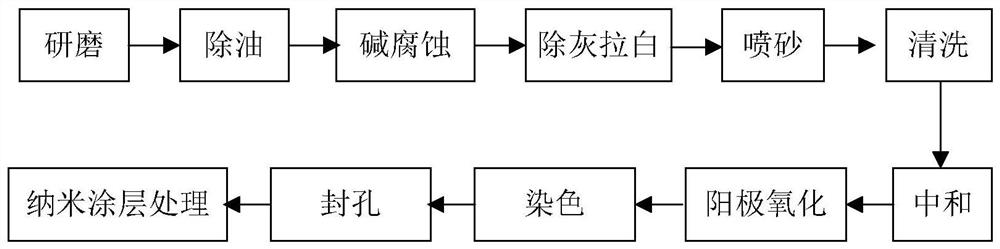

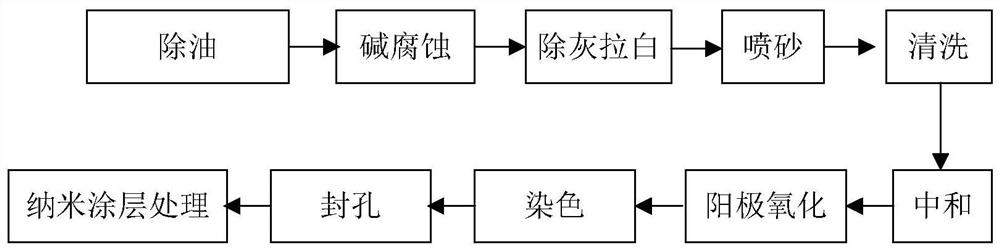

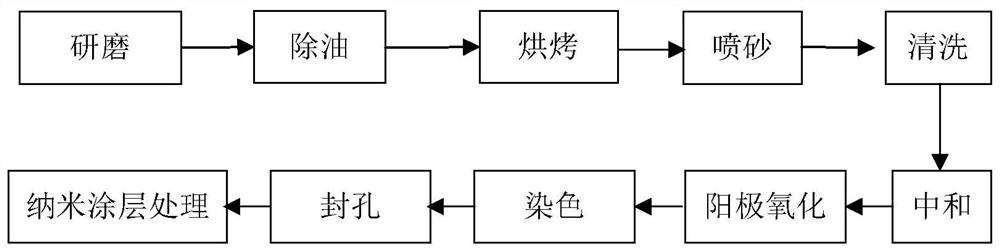

Composite surface treatment method for aluminum alloy die-casting part

The invention provides a composite surface treatment method for an aluminum alloy die-casting part. The composite surface treatment method comprises the following steps: performing surface treatment on the surface of the aluminum alloy die-casting part to remove oil stains and dirt; performing sand-blasting treatment or wire-drawing treatment on the surface of the aluminum alloy die-casting part; cleaning and neutralizing the aluminum alloy die-casting part; performing anode oxidizing treatment on the surface of the aluminum alloy die-casting part, and performing dyeing and hole-sealing treatment on the surface of the treated aluminum alloy die-casting part; performing nano coating treatment on the surface of the aluminum alloy die-casting part with organic silicon modified paint which comprises nano silicon dioxide and a base material. According to the technical scheme adopted by the invention, the aluminum alloy die-casting part is even in surface color, and is as good as a common aluminum alloy machined part in appearance, and has better corrosion resistance.

Owner:SHENZHEN JINMING AVIATION TECH CO LTD

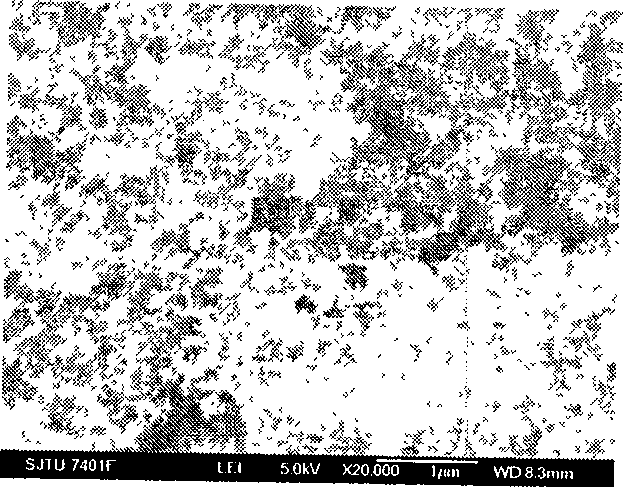

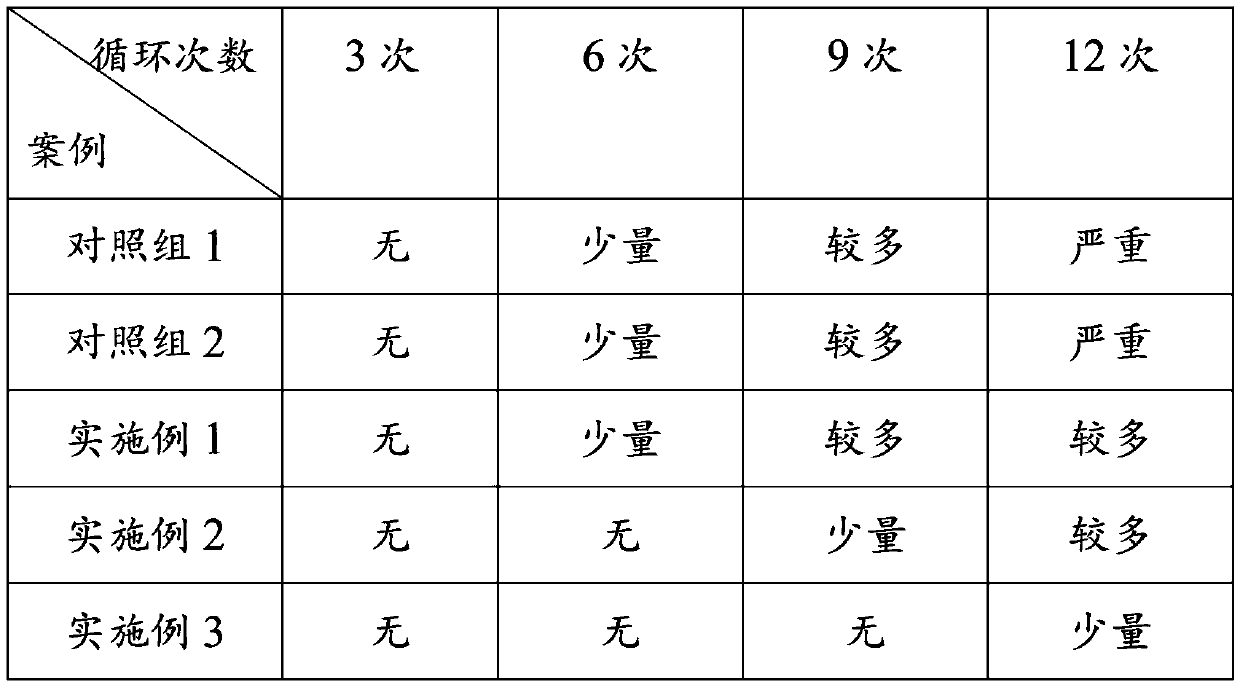

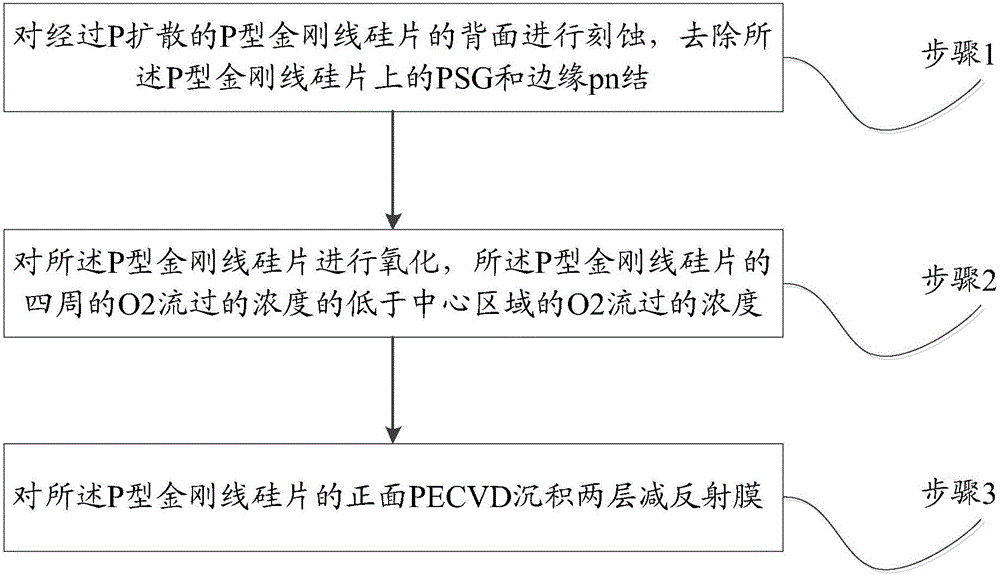

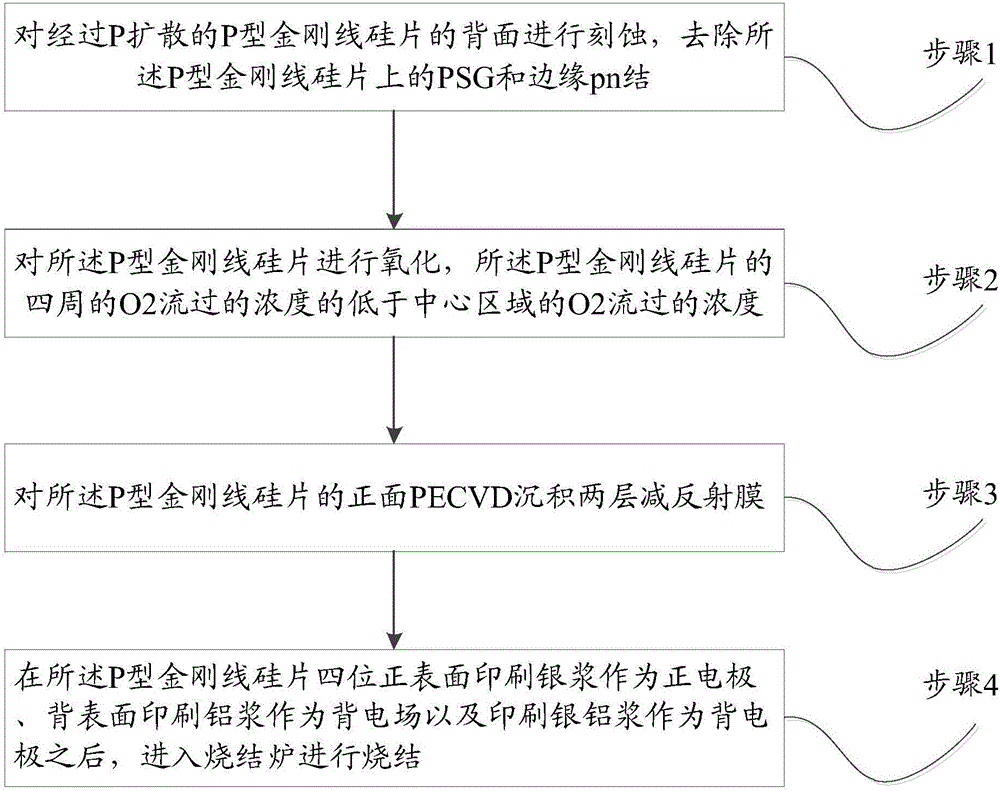

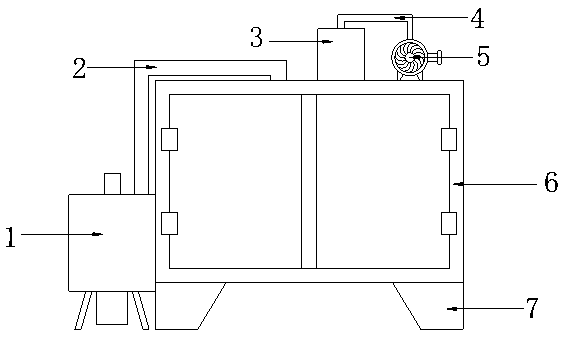

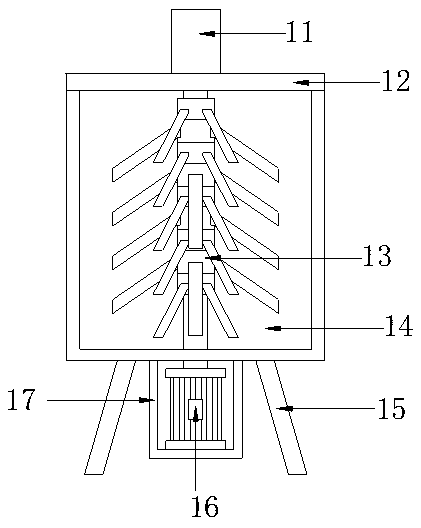

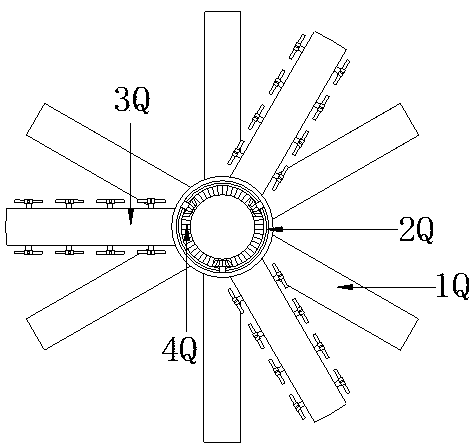

Manufacturing method and apparatus of black silicon cell

ActiveCN105957919AUniform surface colorImprove qualityFinal product manufactureSemiconductor devicesSilicon chipOxide

The invention discloses a manufacturing method and apparatus of a black silicon cell. The manufacturing method includes the steps: 1) etching the back of a P type diamond wire silicon chip which is processed through P diffusion, and removing the PSG and the edge pn junction on the P type diamond wire silicon chip; 2) oxidizing the P type diamond wire silicon chip, wherein the concentration of the O2 of the surrounding, flowed by O2, of the P type diamond wire silicon chip is lower than the concentration of the O2 of the central area, flowed by O2, of the P type diamond wire silicon chip; and 3) depositing two layers of anti-reflection films on the front PECVD of the P type diamond wire silicon chip. As the manufacturing method and apparatus of a black silicon cell enable the thickness of the oxide layer deposited at the central position of the diamond wire silicon chip to be higher than the thickness of the surrounding during the oxidation process and enable the thickness of the surrounding of the two layers of anti-reflection films to be higher than the thickness of the central area during the subsequent process of deposition of the two layers of anti-reflection films on the PECVD, the film thickness of the surface of the diamond wire silicon chip is uniform; the color of the diamond wire silicon chip is uniform; and the quality of the P type diamond wire silicon chip is improved.

Owner:ZHEJIANG JINKO SOLAR CO LTD +1

Environment-friendly type hardware paint spraying machine high in safety

The invention discloses an environment-friendly type hardware paint spraying machine high in safety. The structure of the environment-friendly type hardware paint spraying machine high in safety comprises a paint box device, a paint conveying pipe, a purifying pipe, a connection pipe, an air pump, a paint spraying machine body and supporting legs. The supporting legs are fixedly connected with thebottom of the paint spraying machine body. The top of the paint spraying machine body is provided with the purifying box and the air pump. The purifying box communicates with the air pump through theconnection pipe. Compared with the prior art, the environment-friendly type hardware paint spraying machine high in safety has the beneficial effects that transverse stirring and longitudinal stirring of the paint can be both achieved and are simultaneously conducted, the transverse and longitudinal bidirectional stirring manner enables the paint to be fully mixed, the situations that the upper layer of the paint is light, and the lower layer of the paint is thick are avoided, the surface of a painted hardware product is uniform in color and luster and uniform in thickness, the paint on the inner layer and the paint on the outer layer can release solvent and are dried at the same speed, the paint surface is prevented from deforming, the smoothness and flatness of the paint surface can beguaranteed, and the quality of the hardware product is improved beneficially.

Owner:付小梅

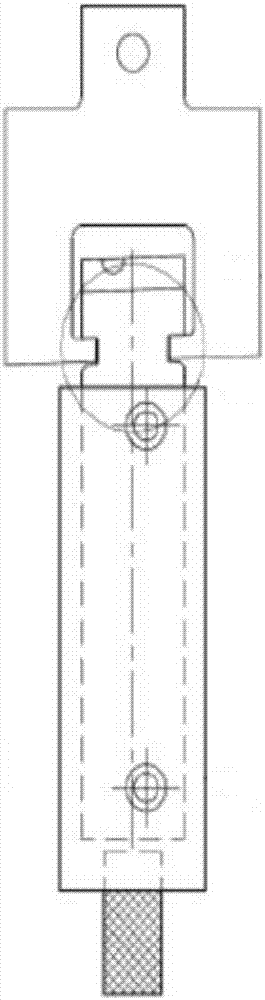

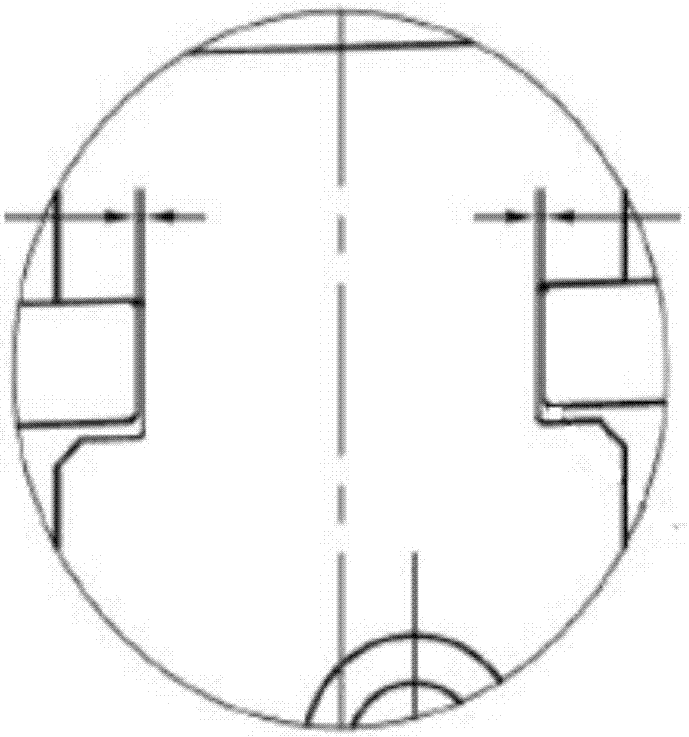

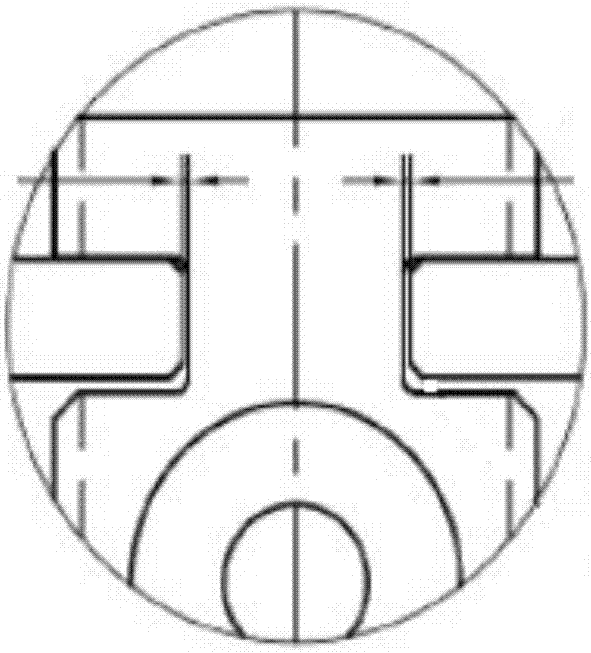

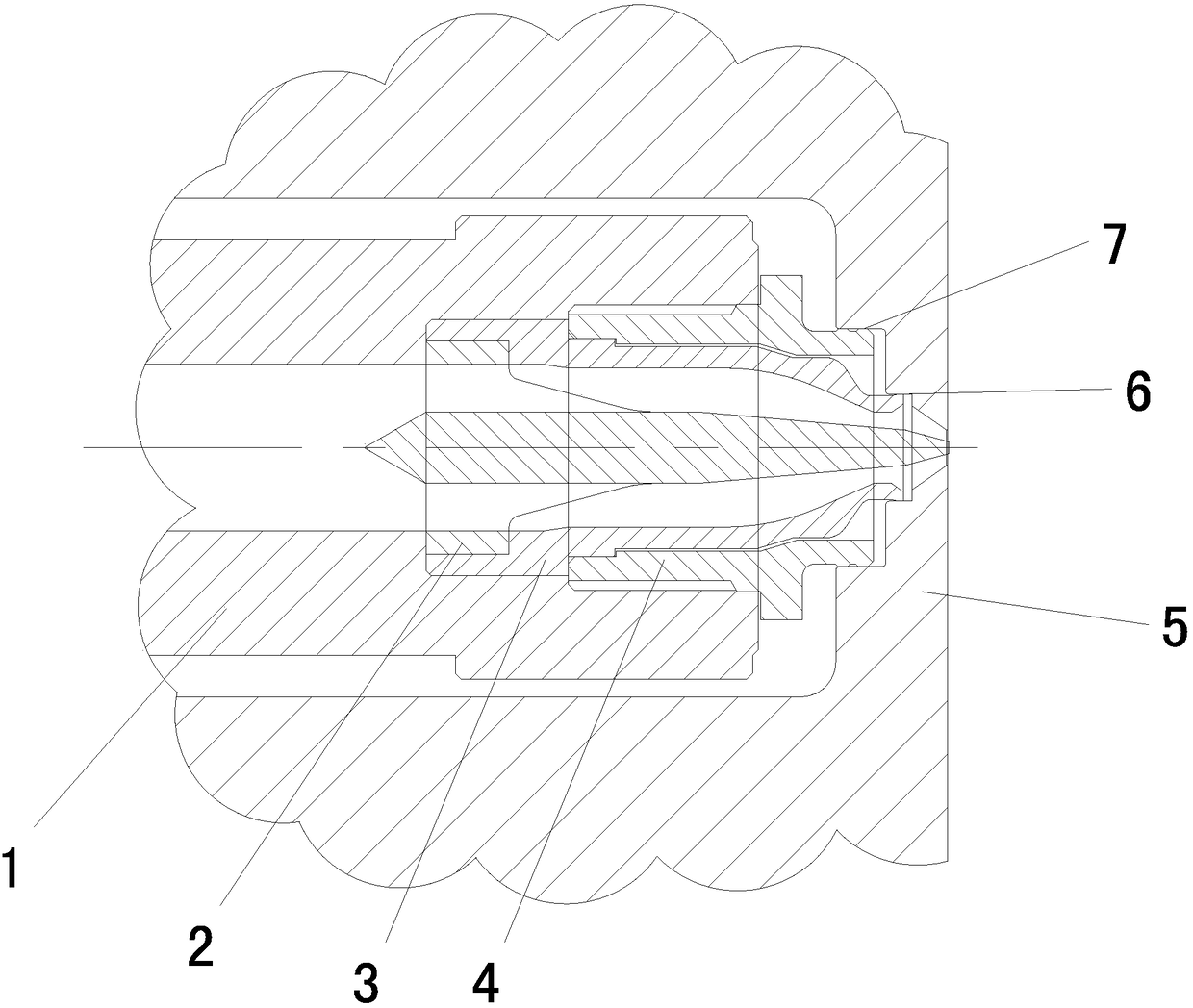

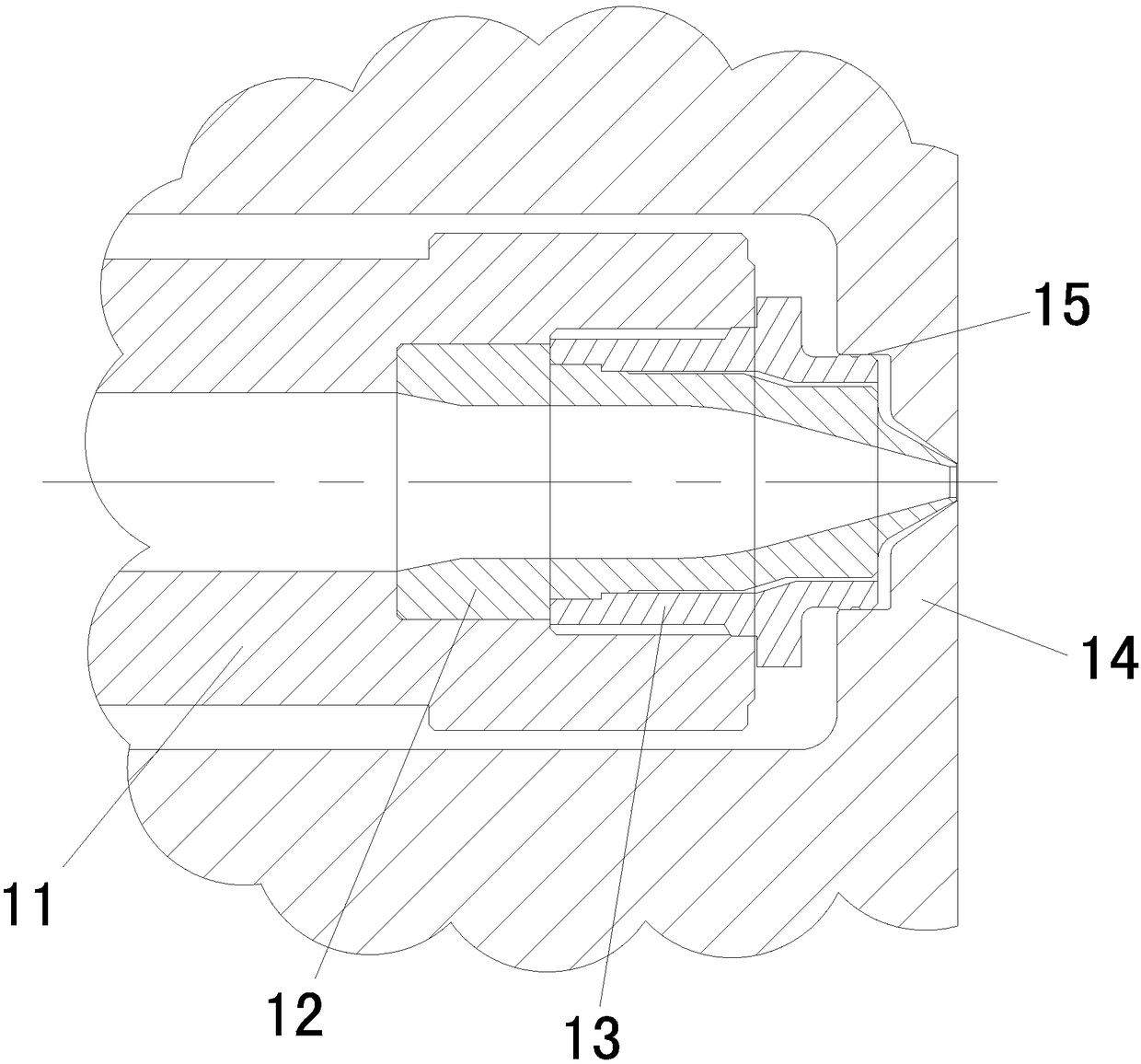

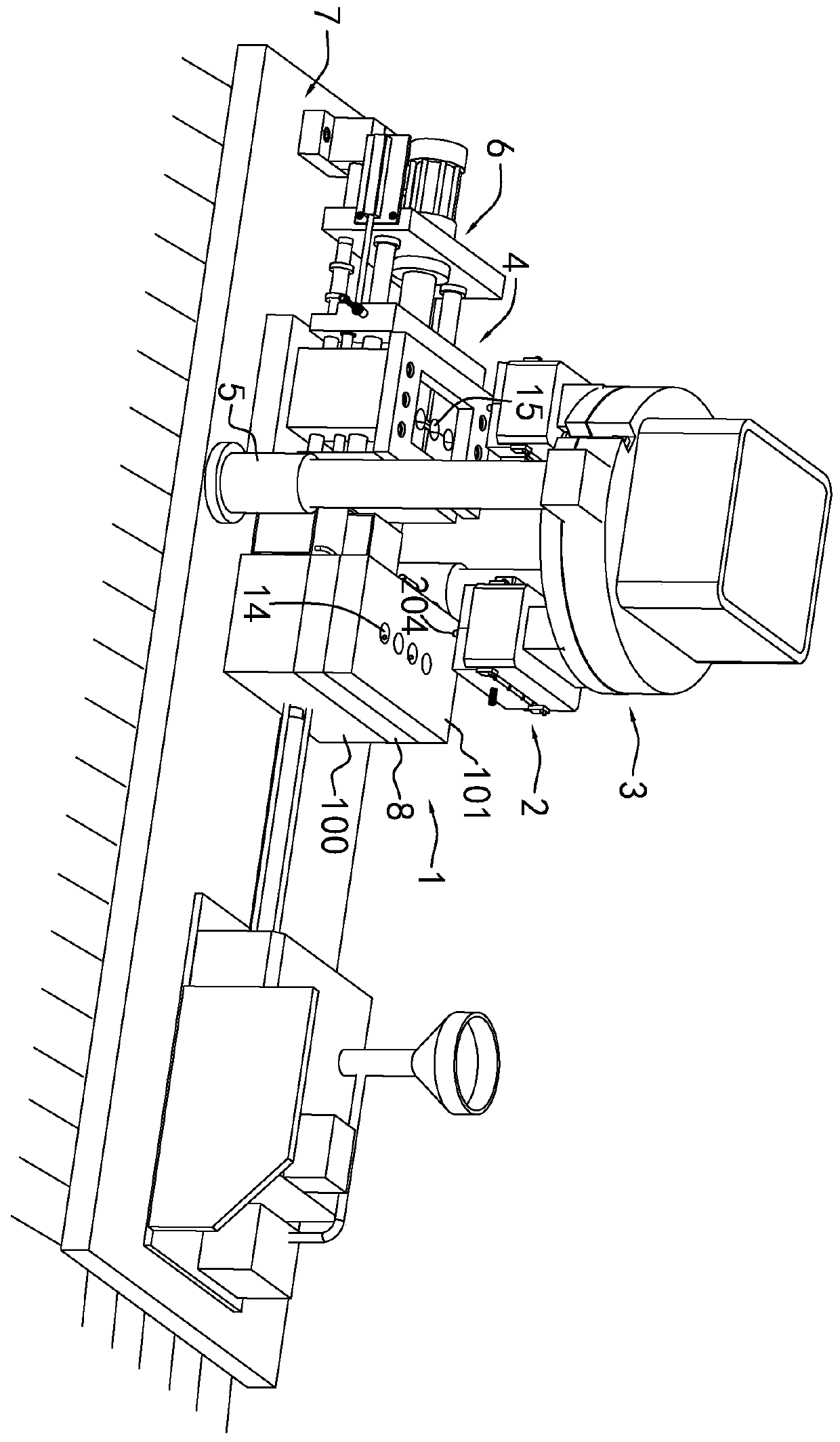

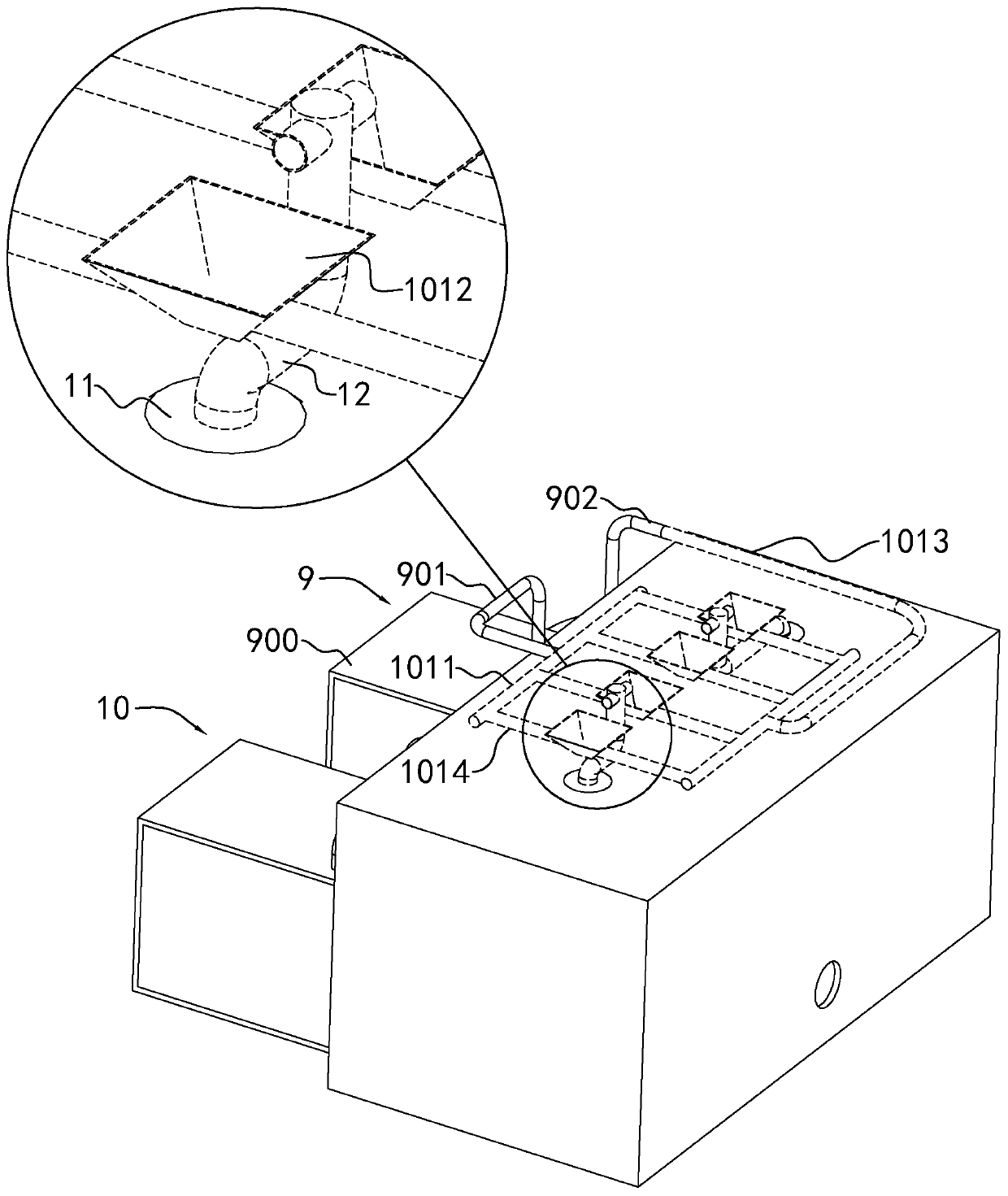

Straight through type hot nozzle assembly for high glass fibers and high carbon fibers

The invention discloses a straight through type hot nozzle assembly for high glass fibers and high carbon fibers. The straight through type hot nozzle assembly comprises a second hot nozzle body, a straight through core and a second mold core plate, wherein a second core cover is arranged on the outer portion of the straight through core in a sleeved manner, the middle portion of the second hot nozzle body is provided with a second through hole, the straight through core is arranged at the end portion of the second through hole, the middle portion of the straight through core is provided witha third through hole, the third through hole is communicated to the second through hole, the second mold core plate is provided with a second gate, the outer portion of the second gate is provided with a third concave groove, the head portion of the straight through core is aligned to the second gate, and the outer wall of the second core cover and the inner wall of the third concave groove are matched to form a sealing glue. According to the present invention, with the straight through type hot nozzle assembly, the high-temperature plastic has low flowing resistance, the filling is rapid, theproduct surface has uniform color, the product does not have fusion, heat loss does not exist, the core temperature is stable, the molding temperature is low compared to the torpedo core, the problems of no glue generation, slow glue generation and plastic carbonization are not easily generated, and the stability of the molded product is good.

Owner:SUZHOU HTS MOLD

Surface treating agent and surface treating process of glass fiber filter cloth

ActiveCN102776777BUniform surface colorHigh folding resistanceFiltration separationGlass fiberPolymer science

The invention relates to a surface treating agent and a surface treating process of a piece of glass fiber filter cloth, belonging to the technical field of the surface treating agent of the glass fiber. The surface treating agent disclosed by the invention comprises 8-15% of PTFE (Polytetrafluoroethylene) dispersing agent, 5-10% of emulsion type high-temperature softening agent, 1-2% of inorganic antistatic agent, 0.5-1% of penetrating agent, 1-2% of silane coupling agent, 0.5-1% of fluorocarbon surfactant and the balance of softened water. The glass fiber filter cloth produced after the treatment of the surface treating agent solves the problems that the corrosion resistance is poor and the air permeability is large in the prior art, and has the advantages that the surface colors are uniform, the flexibility is good, the folding number is large, the air permeability is moderate, and the service life is long.

Owner:SICHUAN FIBERGLASS GRP

Blow-molding processing center for manufacturing LED lampshade without nodes at bottom

The invention relates to a blow-molding processing center for manufacturing an LED lampshade without nodes at the bottom. The blow-molding processing center comprises an injection-molding station, a blow-molding station, a rotating center, a molding component and an oil cylinder, wherein the injection-molding station, the blow-molding station and the rotating center are arranged on an injection-molding machine rack; the molding component is mounted to the rotating center; the oil cylinder is used for driving the rotating center to rise and fall; a mold opening and closing component is arranged on one side of the injection-molding machine rack; a first oil circulating system is arranged in a concave mold; a second oil circulating system is connected with an oil inlet of an oil guiding pipe as well as an oil outlet arranged between the oil guiding pipe and a core mold; an oil plate is arranged between the concave mold and a lower mold; a heat-insulating oil channel is arranged in the oil plate; and a third oil circulating system is connected with the heat-insulating oil channel. No nodes are formed at the bottom of the lampshade processed through the blow-molding processing center; the surface color is uniform; the transparency is consistent; and the work efficiency is improved.

Owner:嘉兴康德照明器材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com