Composite surface treatment method for aluminum alloy die-casting part

A composite surface treatment and surface treatment technology, applied in the direction of surface reaction electrolytic coating, anodic oxidation, electrolytic coating, etc., can solve the problems of complex composition, uneven oxide film, affecting appearance, etc., achieve uniform color and broad application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The preferred embodiments of the present invention will be further described in detail below.

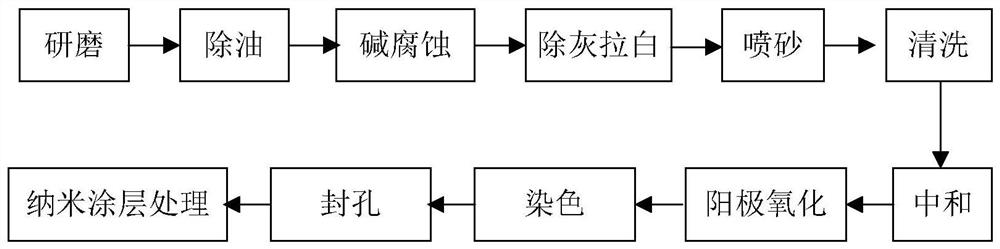

[0050] A composite surface treatment method for aluminum alloy die castings, such as figure 1 As shown, it includes the following steps:

[0051] 1. Grinding

[0052] The main grinding equipment is a vibrating grinder, also known as a vibrating roller mill, which makes the parts and grinding stones grind each other, thereby removing burrs, knife lines, oxide scales, etc. on the surface of the parts. Choosing different grinding stones and grinding aids can improve the smoothness of the surface of the parts and provide a better surface state for subsequent sandblasting. Grinding stones are generally made of high-alumina porcelain, ceramics, and high-frequency porcelain, and an appropriate amount of abrasive is added. The grinding time is about 15 to 30 minutes. After grinding, the parts need to be cleaned with clean water, and then the water is dried before entering the next...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cure temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com