Double-V-shaped floating self-aligning supporting structure and machining method of supporting block in double-V-shaped floating self-aligning supporting structure

A support structure and self-aligning technology, applied in metal processing equipment, manufacturing tools, grinding workpiece supports, etc., can solve problems such as low friction coefficient, and achieve the effect of improving wear and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention can be explained in detail through the following examples, and the purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

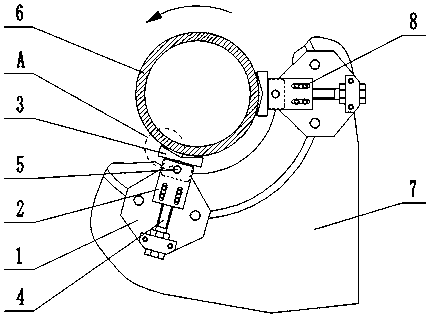

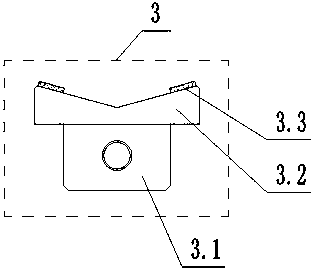

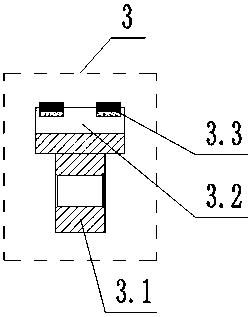

[0026]A double V-shaped floating self-aligning support structure, including two support frame combinations and an arc-shaped positioning seat 7, the two support frame combinations are fixed on the arc-shaped positioning seat 7 of the grinding machine by bolts; the support frame combination It includes a support frame 1, a support seat 2, and a support head 3; the support frame 1 is rotated with an adjusting screw 4, and the support seat 2 is movably connected with the support frame 1 through the adjustment screw 4; the support head 3 is connected to the support by a pin 5 The seat 2 is rotationally connected; when the support frame combination is actually used, the position of the support seat 2 is adjusted by rotating the adjusting screw 4, and the suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com