Steak processing device

A technology of processing device and steak, which is applied in roaster/barbecue grid, roasting, kitchen utensils, etc., can solve the problems of burnt, steak easily adhered to iron plate, beef moisture loss, etc., and achieve the effect of uniform surface color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

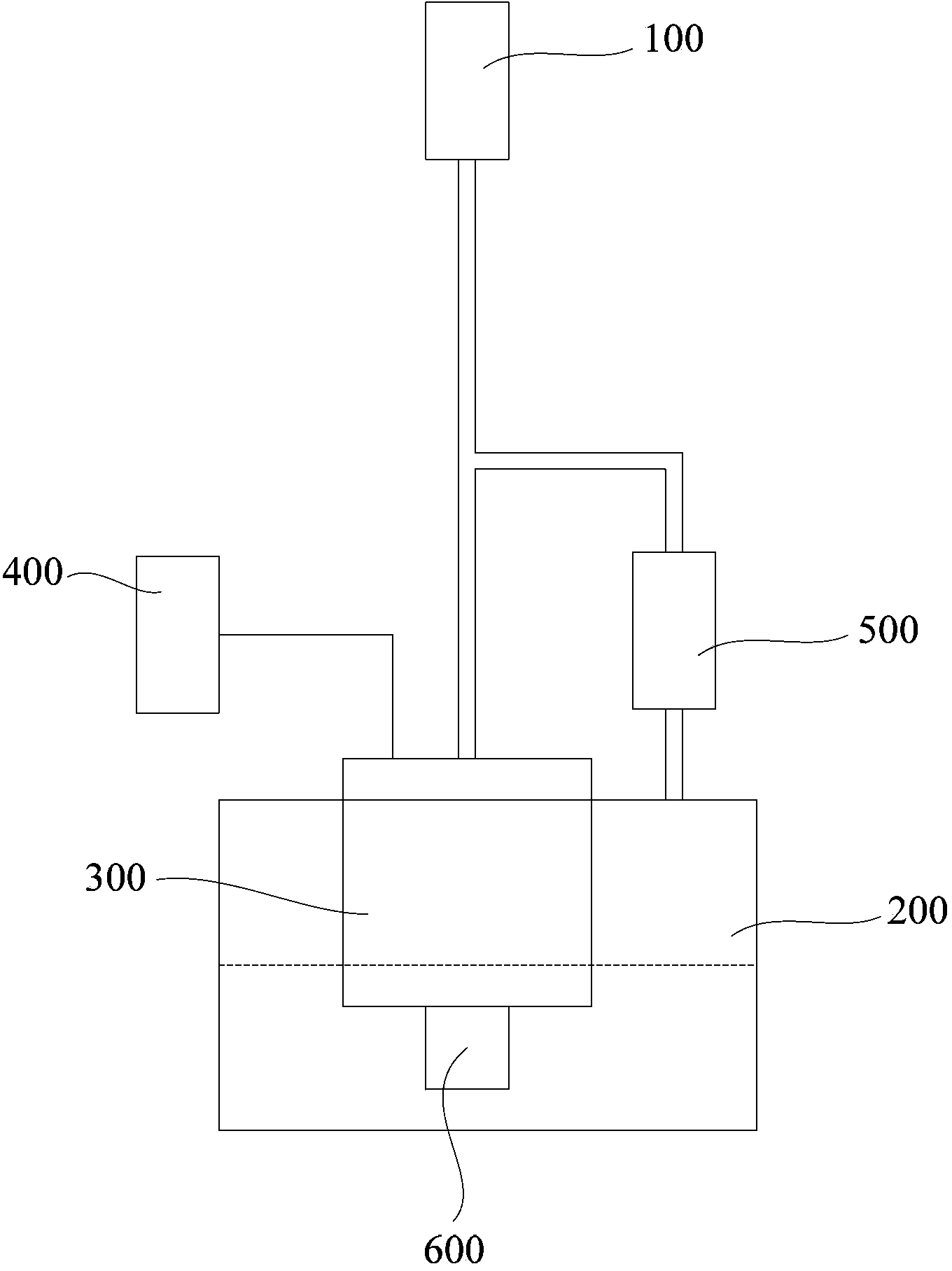

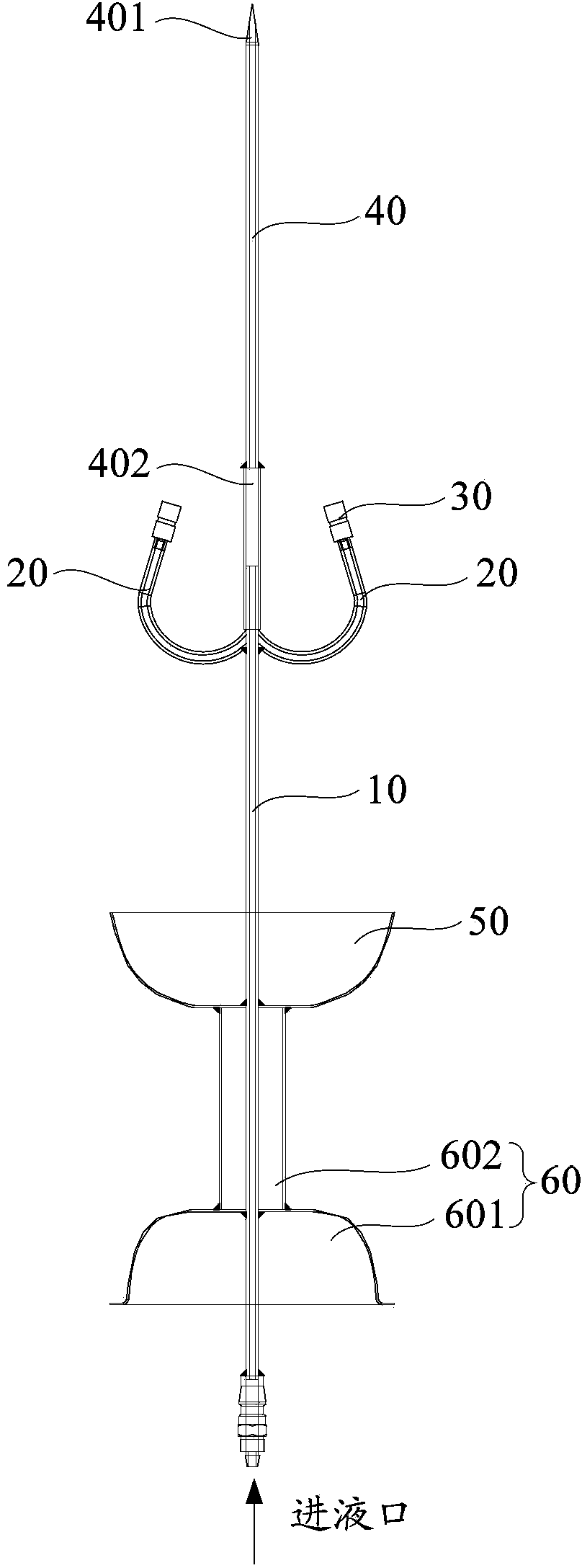

[0022] refer to figure 1 and figure 2 , figure 1 It is a structural schematic diagram of a preferred embodiment of the steak processing device of the present invention; figure 2 It is a structural schematic diagram of the flame spraying assembly in the preferred embodiment of the steak processing device of the present invention.

[0023] The cutlet processing device proposed in this embodiment is mainly to reprocess the cutlet that has been baked to the desired maturity, so as to lock the moisture inside the cutlet and improve the taste of the cutlet. The steak processing device can process various steaks, such as steaks, pork chops, chicken chops and the like. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com