Manufacturing method and apparatus of black silicon cell

A manufacturing method and a manufacturing device technology, which are applied in the field of PECVD coating of black silicon batteries, can solve problems such as light color, yellowing around, and easy-to-protrude surface grains, so as to achieve uniform surface color and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] As mentioned in the background technology section, the existing PECVD equipment will cause the surrounding color of the silicon wafer to be lighter (film thickness), and the color of the black silicon battery to be darker. Can cause chromatic aberration at the edges of black-backed components.

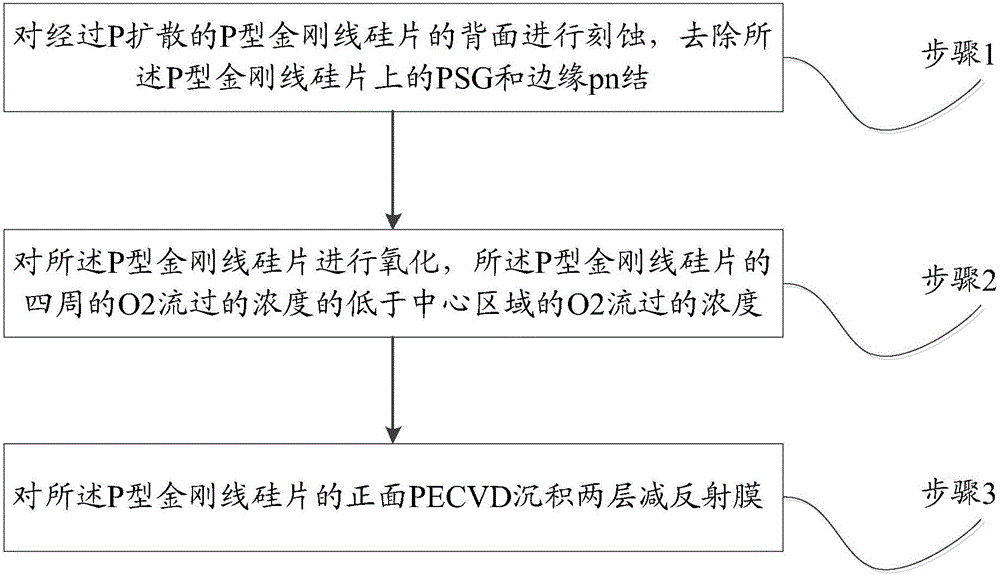

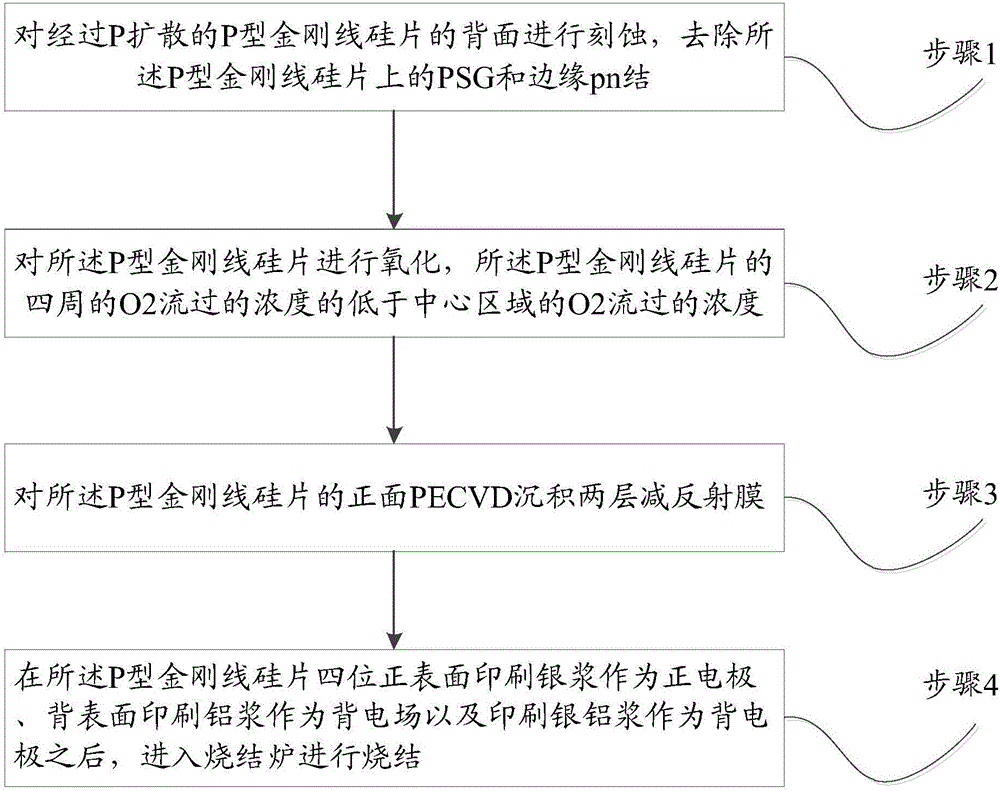

[0037] Based on this, an embodiment of the present invention provides a method for manufacturing a black silicon battery, including:

[0038] Step 1, etching the back side of the P-type diamond wire silicon wafer after P diffusion, and removing the PSG and edge pn junction on the P-type diamond wire silicon wafer;

[0039] Step 2, oxidizing the P-type diamond wire silicon wafer, the concentration of O2 flowing around the P-type diamond wire silicon wafer is lower than the concentration of O2 flowing through the central region;

[0040] Step 3, depositing two layers of anti-reflection films by PECVD on the front side of the P-type diamond wire silicon wafer.

[0041] In additio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com