Method for treating surface blackening of automobile wheel hub

A technology for blackening the surface of automobile wheels, applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve problems such as poor wear resistance, loss of protection effect, blackened film scratches, etc. , to achieve significant heat transfer effect, enhance blackening, and promote penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

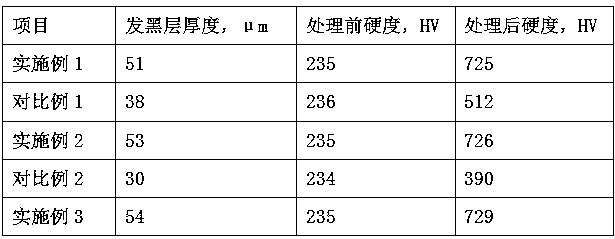

Examples

Embodiment 1

[0017] A method for blackening the surface of an automobile wheel hub, comprising the following steps:

[0018] (1) After cleaning the prepared automobile wheel hub, spray the modifying solution on the surface, then put it into the nitriding furnace, and preheat for 10 minutes, wherein the modifying solution is made of the following components by weight: 6 parts of sulfuric acid, 11 parts of trisodium isocitrate, 18 parts of copper citrate, 360 parts of water;

[0019] (2) Put the automobile wheel treated in step (1) into a salt bath furnace, raise the temperature to 520°C, and treat it in a salt bath for 60 minutes, wherein the base salt of the salt bath is made of the following components by weight: nitrogen 19 parts of carburizing base salt, 1 part of aluminum borate, 1 part of behenic acid amide;

[0020] (3) Put the automobile wheel hub treated in step (2) into the blackening solution, soak for 3 minutes, take it out, and wash it to obtain a finished product, wherein the...

Embodiment 2

[0026] A method for blackening the surface of an automobile wheel hub, comprising the following steps:

[0027] (1) After cleaning the prepared automobile wheel hub, spray the modifying liquid on the surface, then put it into the nitriding furnace, and preheat it for 13 minutes, wherein the modifying liquid is made of the following components by weight: 7 parts of sulfuric acid, 13 parts of trisodium isocitrate, 20 parts of copper citrate, 380 parts of water;

[0028] (2) Put the automobile wheel treated in step (1) into a salt bath furnace, raise the temperature to 530°C, and treat it in a salt bath for 65 minutes, wherein the base salt of the salt bath is made of the following components by weight: nitrogen 20 parts of carburizing base salt, 1 part of aluminum borate, 2 parts of behenic acid amide;

[0029] (3) Put the automobile wheel hub treated in step (2) into the blackening solution, soak for 4 minutes, take it out, and wash it to obtain a finished product, wherein the...

Embodiment 3

[0035] A method for blackening the surface of an automobile wheel hub, comprising the following steps:

[0036] (1) After cleaning the prepared automobile wheel hub, spray the modifying solution on the surface, then put it into the nitriding furnace, and preheat it for 15 minutes, wherein the modifying solution is made of the following components by weight: 8 parts of sulfuric acid, 16 parts of trisodium isocitrate, 22 parts of copper citrate, 400 parts of water;

[0037] (2) Put the automobile wheel treated in step (1) into a salt bath furnace, raise the temperature to 540°C, and treat it in a salt bath for 70 minutes, wherein the base salt of the salt bath is made of the following components by weight: nitrogen 22 parts of carburizing base salt, 2 parts of aluminum borate, 2 parts of behenic acid amide;

[0038] (3) Put the automobile wheel hub treated in step (2) into the blackening solution, soak it for 5 minutes, take it out, and wash it to obtain a finished product, whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com