Nickel-phosphorus alloy plating solution for chemical plating of truck tire mold surface and chemical plating method

A technology of nickel-phosphorus alloy and surface chemistry, applied in the direction of liquid chemical plating, metal material coating process, coating, etc., can solve problems such as tire quality degradation, tire mold surface corrosion, coating peeling off, etc., to achieve corrosion resistance and Effects of increased hardness, improved corrosion resistance, and improved friction resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1, described nickel-phosphorus alloy plating solution is to take water as solvent, and constituent is carried out weight ratio by following ratio:

[0039] Nickel sulfate, 23 g / l;

[0040] Sodium hypophosphite, 25 g / l;

[0041] Sodium citrate, 7 g / l;

[0042] Sodium acetate, 12 g / l;

[0043] Thiourea, 1.5 mg / L;

[0044] Wherein, the pH value of the nickel-phosphorus alloy plating solution is between 4.2 and 4.8.

[0045] The proportioning process of the nickel-phosphorus alloy plating solution is: firstly, nickel sulfate powder is added to the water and mixed evenly, and then parked; It needs to be mixed evenly and parked still.

[0046] Apply the above-mentioned nickel-phosphorus alloy plating solution, and the processing method for the electroless plating on the surface of the passenger tire mold is as follows:

[0047] Before and after the plating treatment stage, a pre-treatment stage and a post-treatment stage are respectively performed.

[0048] ...

Embodiment 2

[0058] Embodiment 2, described nickel-phosphorus alloy plating solution, is to take water as solvent, and constituent is carried out weight ratio by following ratio:

[0059] Nickel sulfate, 28 g / l;

[0060] Sodium hypophosphite, 20 g / L;

[0061] Sodium citrate, 3 g / l;

[0062] Sodium acetate, 13 g / l;

[0063] Thiourea, 1.7 mg / L;

[0064] Wherein, the pH value of the nickel-phosphorus alloy plating solution is between 4.2 and 4.8.

[0065] The proportioning process of the nickel-phosphorus alloy plating solution is: firstly, nickel sulfate powder is added to the water and mixed evenly, and then parked; It needs to be mixed evenly and parked still.

[0066]Apply the above-mentioned nickel-phosphorus alloy plating solution, and the processing method for the electroless plating on the surface of the passenger tire mold is as follows:

[0067] Before and after the plating treatment stage, a pre-treatment stage and a post-treatment stage are respectively performed.

[0068] ...

Embodiment 3

[0078] Embodiment 3, described nickel-phosphorus alloy plating solution is to take water as solvent, and constituent is carried out weight ratio by following ratio:

[0079] Nickel sulfate, 35 g / l;

[0080] Sodium hypophosphite, 30 g / L;

[0081] Sodium citrate, 3 g / l;

[0082] Sodium acetate, 18 g / l;

[0083] Thiourea, 1 mg / L;

[0084] Wherein, the pH value of the nickel-phosphorus alloy plating solution is between 4.2 and 4.8.

[0085] The proportioning process of the nickel-phosphorus alloy plating solution is: firstly, nickel sulfate powder is added to the water and mixed evenly, and then parked; It needs to be mixed evenly and parked still.

[0086] Apply the above-mentioned nickel-phosphorus alloy plating solution, and the processing method for the electroless plating on the surface of the passenger tire mold is as follows:

[0087] Before and after the plating treatment stage, a pre-treatment stage and a post-treatment stage are respectively performed.

[0088] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

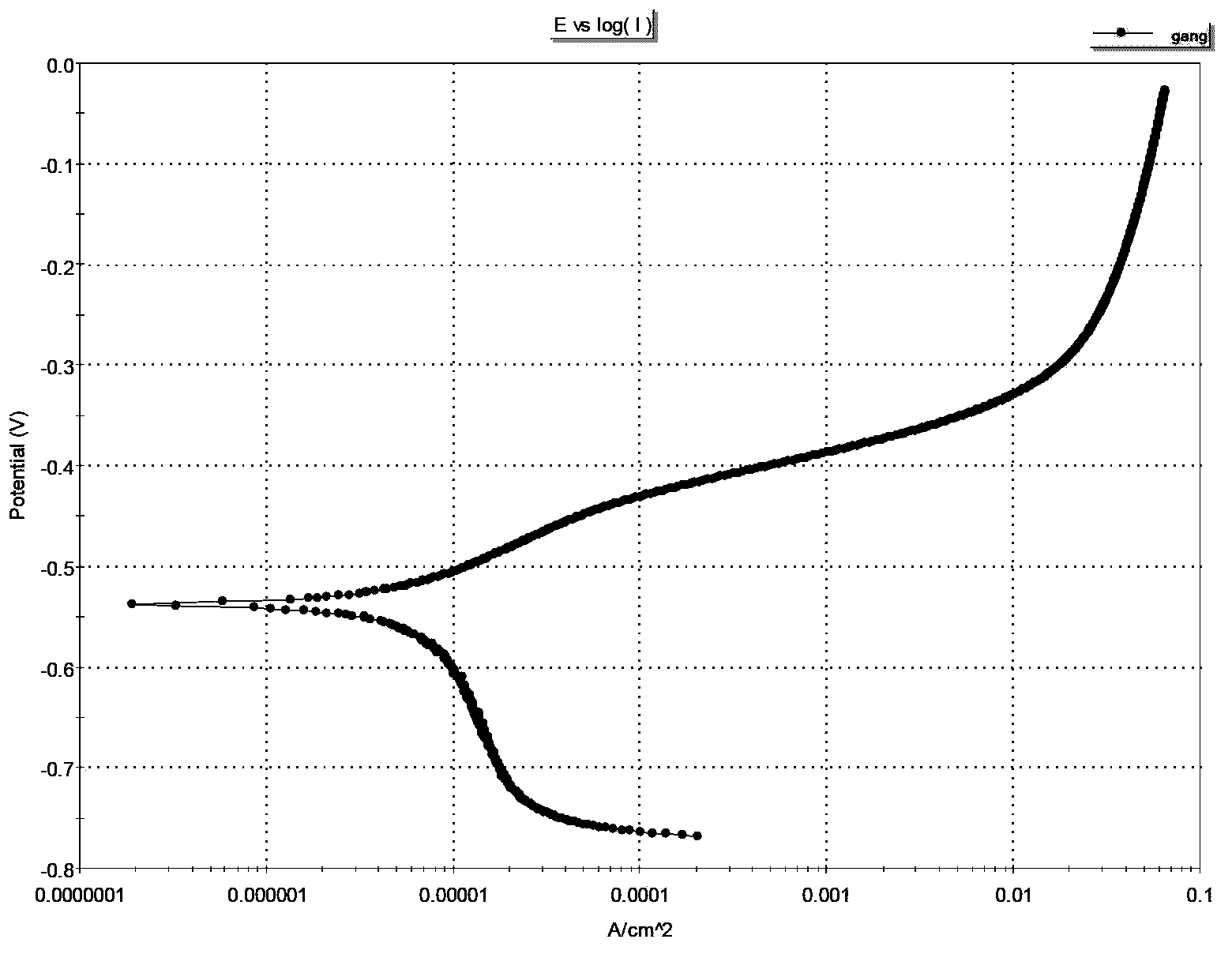

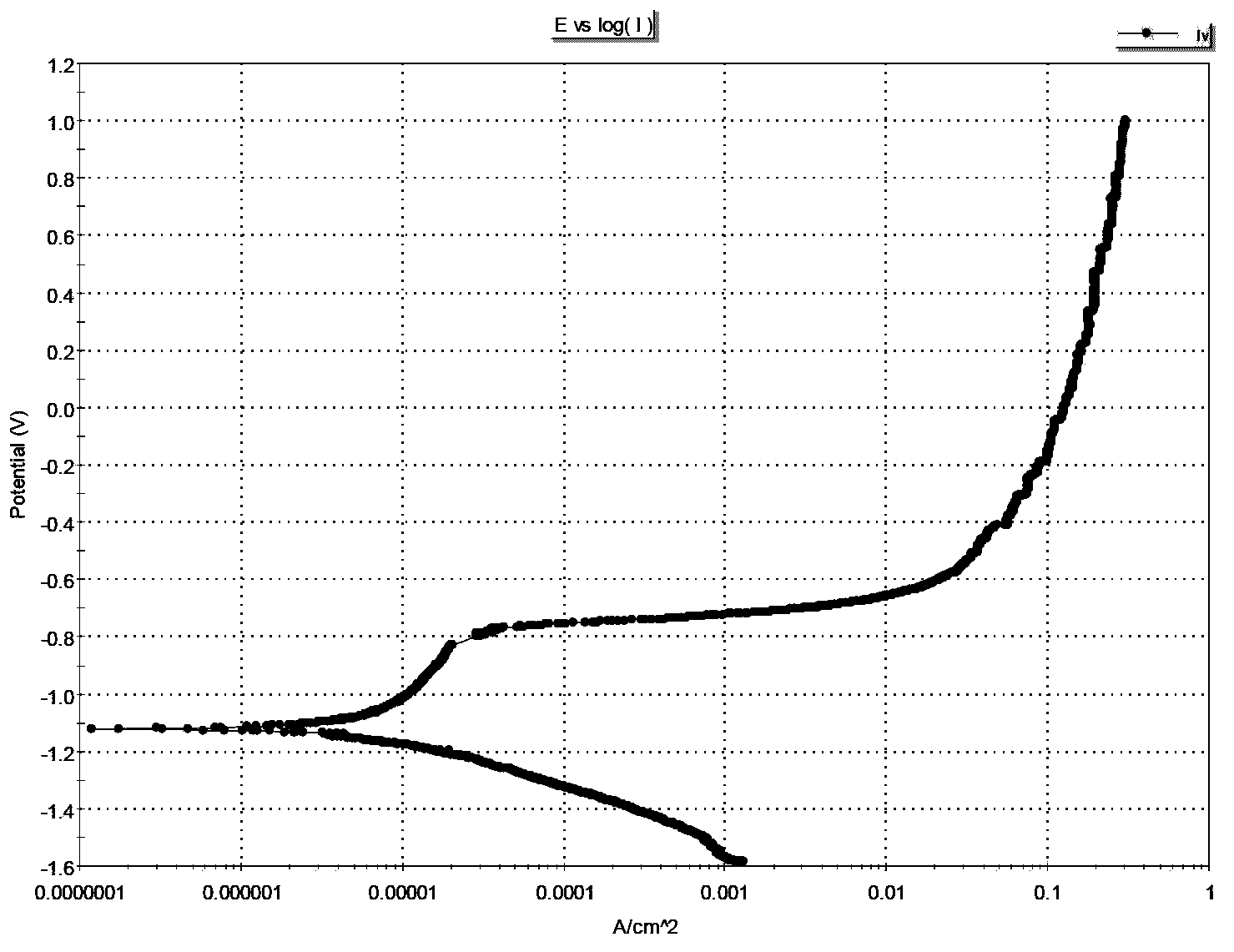

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com