Hot-rolled pickling steel plate for deep drawing quality electro-galvanizing and production method thereof

A hot-rolled pickling and production method technology is applied to the hot-rolled and pickled steel sheet for deep-drawing electrogalvanizing and its production field, and can solve the problems of high production cost, obvious surface color difference, complicated production process, etc., and achieve stable performance, The effect of uniform surface color and uniform texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

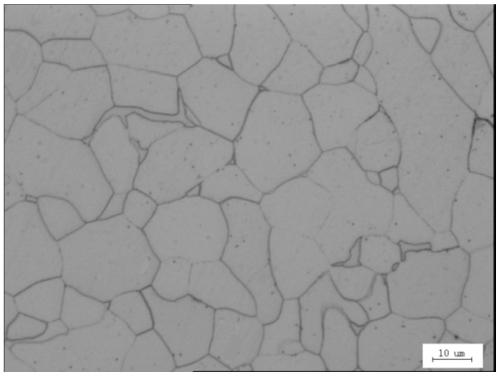

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with examples.

[0035] Table 1 shows the chemical composition and weight percentages of the hot-rolled pickled steel sheets for deep-drawing electrogalvanizing in each embodiment and comparative example. The production method of the hot-rolled pickled steel plate for deep-drawing electrogalvanizing includes the following steps: molten iron pretreatment, converter smelting, alloy fine-tuning, RH furnace refining, continuous casting, slab heating, hot rolling, laminar cooling, coiling , pickling, smoothing; among them:

[0036] In the molten iron pretreatment step, it is required to remove slag before and after removing slag, reduce the sulfur content, and improve the purity of molten steel.

[0037] In the converter smelting process, pig iron and slag steel are not added; self-circulating scrap steel is used to tap steel to strengthen converter dephosphorization and slag retaining operations; lime i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com