High-cycle-use feedstock for metal-power injection molding (MIM) and preparation method thereof

A metal powder and injection molding technology, which is used in the field of high-recycling feeding and its preparation for metal powder injection molding, can solve the problems of hardening and brittleness, difficulty in degreasing products, and decreased fluidity, and achieves high degreasing rate and injection molding technology. Stable, high-cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

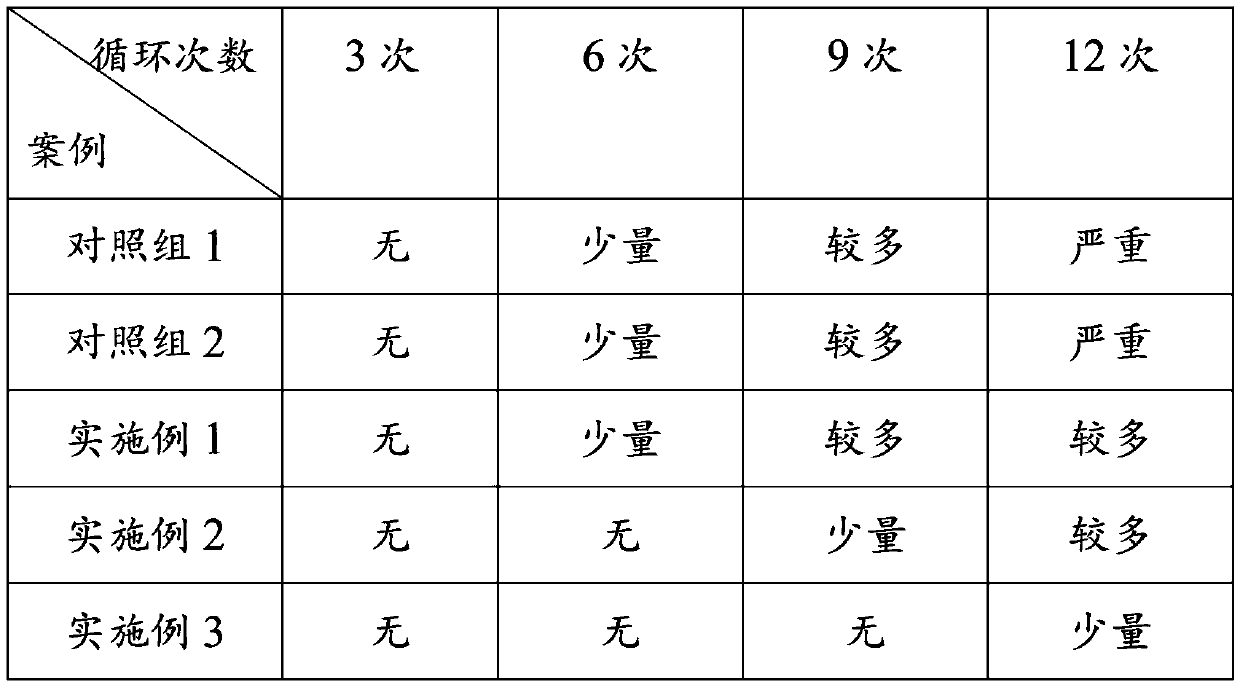

Examples

preparation example Construction

[0031] Therefore, a preparation method based on the above-mentioned control group 1 comprises the following steps:

[0032] (1) Mixing: Add each component into a high-speed mixer and mix according to the above formula. The speed of the high-speed mixer is set at 300-600r / min, and the mixing time is 5-15min.

[0033] (2) Internal mixing and granulation: set the temperature of the internal mixer to 170-185°C, and the screw speed to 60-90r / min. After the system is melted, transfer the feed to the internal mixer for granulation.

[0034] Control group 2

[0035] The total components of the binder of the control group 2 are as follows according to the following formula, and are calculated as the following components in terms of weight percentage: acetal copolymer 85wt.%, TPU+TPE 2wt.%, LDPE 6wt.%, antioxidant 1wt.%, polyethylene Wax 3wt.%, Pentaerythritol stearic acid 3wt.%.

[0036] In this control group, polyoxymethylene copolymer without special end-capping treatment was selecte...

Embodiment 1

[0041] According to the following formula, the total components of the binder are calculated as the following components in terms of weight percentage: 85wt.% of polyoxymethylene, 2wt.% of TPU+TPE, 6wt.% of LDPE, 1wt.% of antioxidant, modified amide wax 3wt.%, pentaerythritol ester stearic acid 3wt.%. A hindered phenolic bisphenol antioxidant is used as an antioxidant. This hydrogen-donating antioxidant is very stable because the single electron in the generated phenoxy radical can be conjugated with the large π system of the aromatic ring.

[0042] The present invention adopts polyoxymethylene after special end-capping treatment, adopts LDPE and TPU+TPE as the material skeleton, and can also make the adhesive base material have certain shape retention and toughness. Auxiliary antioxidants are phosphite antioxidants, whose main function is to prevent or delay the free radicals generated during the oxidation process.

[0043] In this case, the compounding ratio of main and aux...

Embodiment 2

[0048] According to the following formula, the total components of the binder are calculated as the following components by weight percentage: 85wt.% of polyoxymethylene, 2wt.% of TPU+TPE, 6wt.% of LDPE, 1wt.% of antioxidant, and 0.5wt of absorbent %, modified amide wax+EVA3wt.%, pentaerythritol ester stearic acid 2.5wt.%.

[0049] In this case, a parallel twin-screw extruder is selected. Due to the large diameter of the screw in the feeding section of this type of extruder, it plays a very good role in the heat transfer, shearing and plasticization of the material. At the same time, meshing co-rotating twin-screws are used in the design of the twin-screws, which can make the residence time of the materials in the screws narrower and help to improve the thermal stability of the feed. At the same time, the design of the twin-screw adopts the twin-screw of meshing type and rotates in the same direction, and the plasticizing effect of two or more positive meshing blocks is better...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com