Braid, braid manufacturing method and outdoor chair with braid

A webbing and outdoor technology, which is applied in the field of outdoor chairs, can solve the problems of easy aging of elastic webbing and reduce the service life of the seat, so as to achieve the effect of improving the appearance, prolonging the service life and easing the visual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

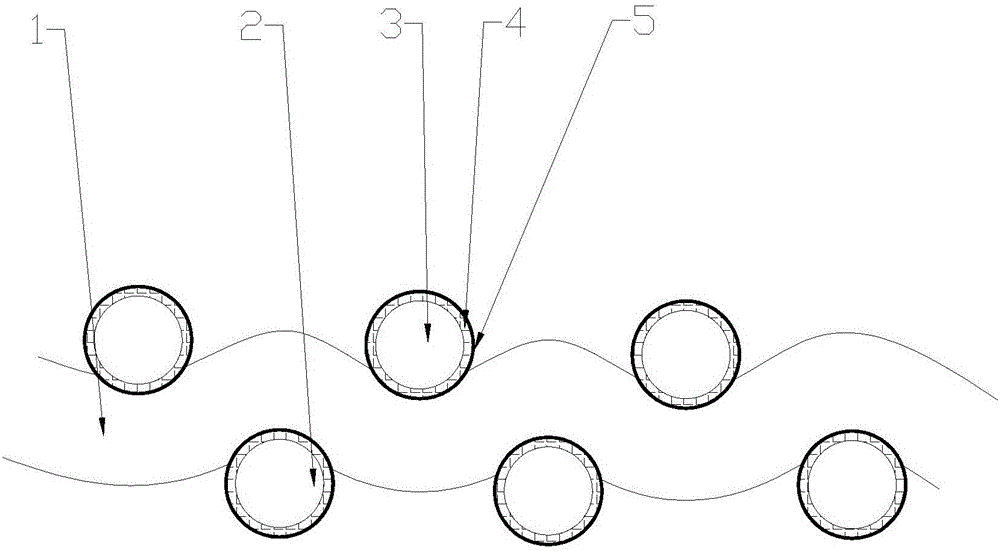

[0042] a webbing, cf. figure 1 As shown, it includes the webbing body interwoven with warp 2 and weft 1. Both warp 2 and weft 1 are polyester filaments 4. According to the thickness and elasticity requirements of the webbing in actual situations, the denier of polyester filaments 4 is selected. This implementation The preferred example is 900D, so that both warp 2 and weft 1 have better strength and elasticity. The polyester filament 4 is formed by doubling loose fibers, the loose fibers are preferably polyester staple fibers, and its length is preferably 64mm. The raw material structure of polyester staple fibers is short and hairy, so that the braided webbing is compact and has high strength. The short fiber is processed by colored process when raw materials, and different colored masterbatches are added in the process, so that the short fiber can obtain one of the colors that constitute the final color of the webbing. According to the actual situation, the short fiber is pr...

Embodiment 2

[0045] A method for manufacturing a webbing, comprising the following steps: selecting materials, adding auxiliary agents, dyeing, doubling, slicing and weaving webbing, selecting short fibers with a length of 64 mm as raw materials, and adding anti-ultraviolet rays to the raw and auxiliary materials Additives, anti-ultraviolet additives are compounded from salicylates, benzophenones, benzotriazoles, acrylonitriles, triazines and hindered amines, and then carry out the process of producing colored fibers. The process includes pre-crystallization and drying, pre-crystallization of slices, and then drying; adding and mixing color masterbatches, drying the color masterbatches with hot air, and then press 3-10% ratio, feed the masterbatch into the screw extruder, and mix it evenly with the dried flakes; extrude, heat and melt the mixture of the dried flakes and the masterbatch in the screw extruder, After the heated and molten polymer melt is extruded by the screw, it enters the o...

Embodiment 3

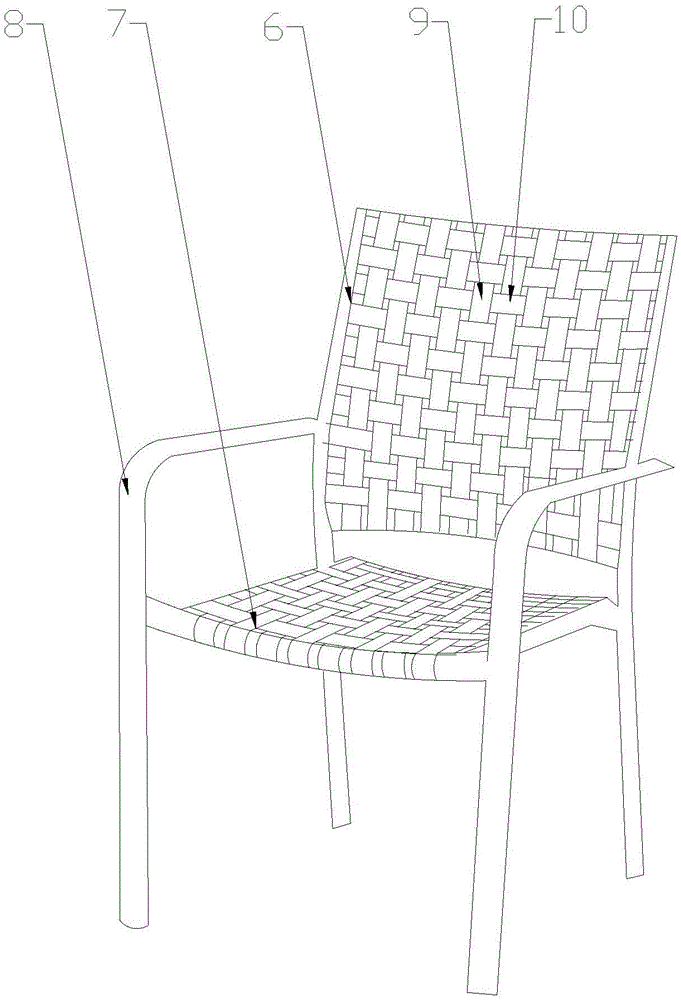

[0048] A kind of outdoor chair, refer to figure 2 As shown, including chair back 6, seat seat 7 and armrest 8, chair back 6 and seat seat 7 all include the bracket that is connected to armrest 8 at both ends, and bracket includes four interconnected connecting rods, and the middle of them is hollow state, A warp webbing 9 and a weft webbing 10 are braided between the four connecting rods, which are longitudinally and transversely symmetrical, respectively. Both the warp webbing 9 and the weft webbing 10 are made of the webbing in Embodiment 1. , there is a certain gap between the adjacent warp ribbons 9 and weft ribbons 10, when the adjacent warp ribbons 9 and weft ribbons 10 are woven, one of them touches the upper surface of the weft ribbons 10, and the other adjacent Contradicting the lower surface of the weft webbing 10, the outdoor chair has good performance. When sitting, relying on the polyester yarn 4, the chair back 6 and the seat 7 have high-strength characteristics...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com