A method for dyeing wood chips as ground cover for urban landscapes

A technology for ground coverings and urban landscapes, applied in the field of dyeing of environmentally friendly organic coverings, can solve the problems of affecting the beautification effect, high consumption of organic dyes or paints, and difficulty in obtaining dyeing effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

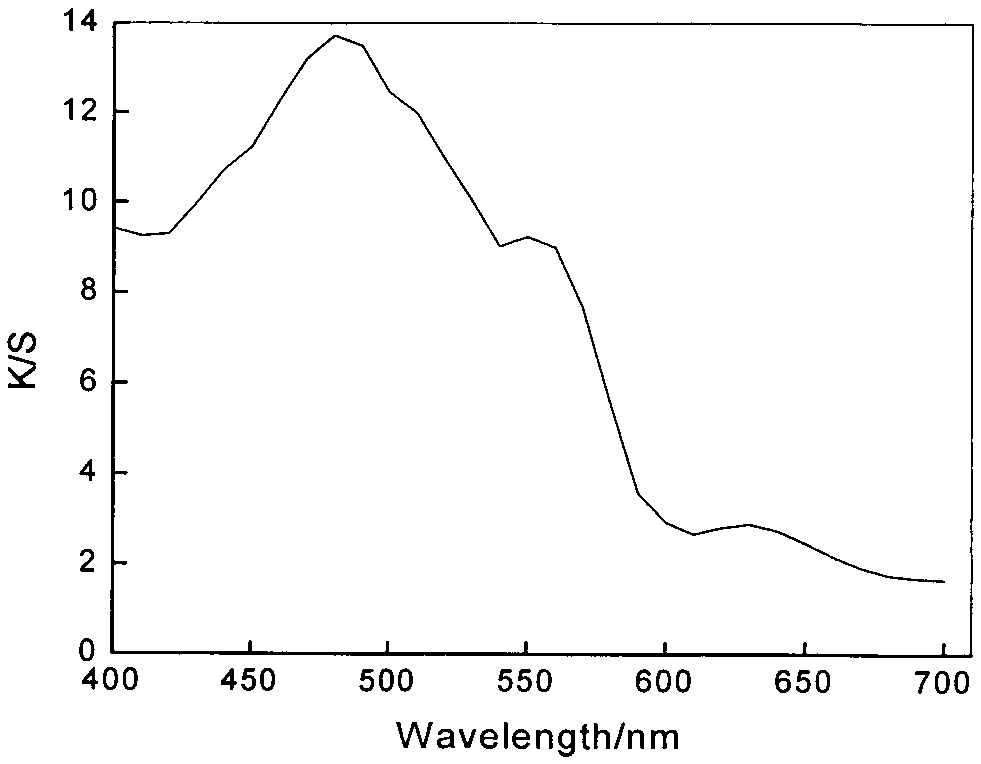

Image

Examples

Embodiment 1

[0021] 1. Pretreatment of sawdust: under stirring conditions, first use an aqueous solution containing sodium hydroxide with a concentration of 10.0g / L and sodium dodecylbenzenesulfonate with a concentration of 5.0g / L to boil the sawdust for 40 minutes. Take it out, wash it with water for 5 times and dry it at 100°C;

[0022] 2. Preparation of acid dye solution (I): Dissolve Acid Red A, Acid Black 10B and Acid Orange 156 of different qualities in water at room temperature, stir fully and let it stand for 30 minutes to obtain dye solution (I) , so that the concentration of Acid Red A is 5.0g / L, the concentration of Acid Black 10B is 0.5g / L, and the concentration of Acid Orange 156 is 0.25g / L;

[0023] 3. Primer dyeing process: above-mentioned dye liquor I and sawdust are placed in the normal temperature dyeing machine, keep bath ratio (ratio of sawdust weight (kg) and organic dye liquor volume (liter)) to be 1: 30. Then heat up to 95°C at a speed of 5°C / min, and dye at this te...

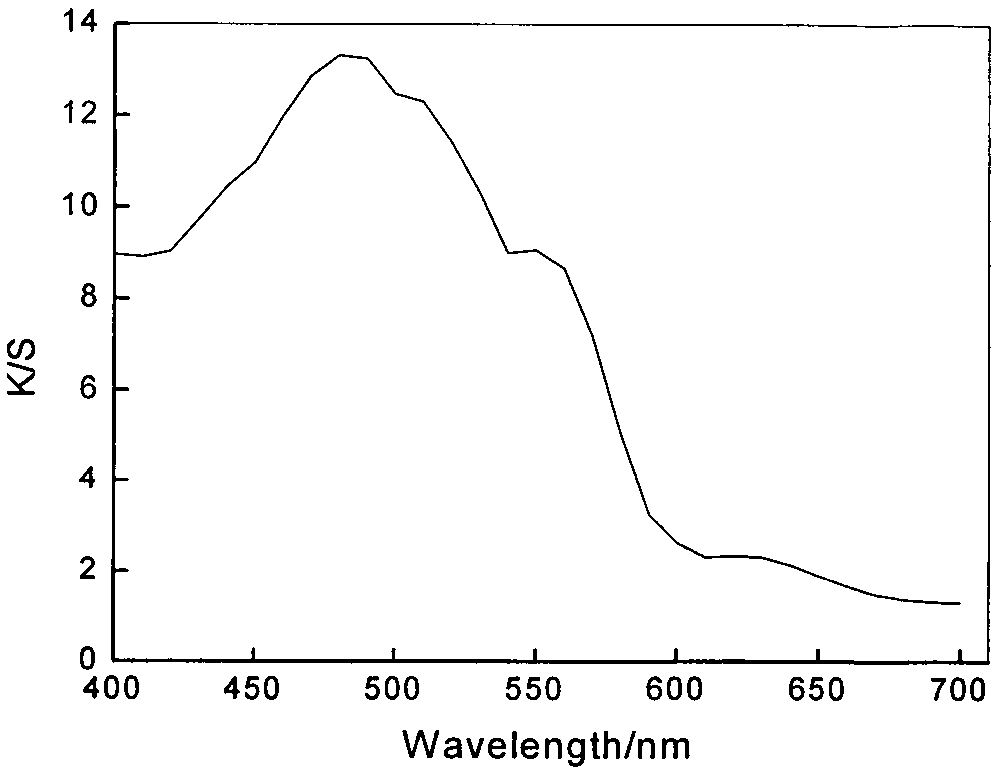

Embodiment 2

[0027] 1. The process is the same as Step 1 in Example 1.

[0028]2. The concentration of the acid red A is set to 3.0g / L, the concentration of acid black 10B is set to 1.0g / L, and the concentration of acid orange 156 is set to 0.5g / L, and all the other are the same as in Example 1 Step 2 in .

[0029] 3. The process is the same as step 4 in Example 1.

[0030] 4. the concentration of described iron red is set as (125g / L), the concentration of acrylic adhesive is (150g / L), and all the other processes are respectively identical with step 4 in embodiment 1.

[0031] 5. The process is the same as step 5 in Example 1, and the dyed sample obtained is abbreviated as Example dyed sample 2#.

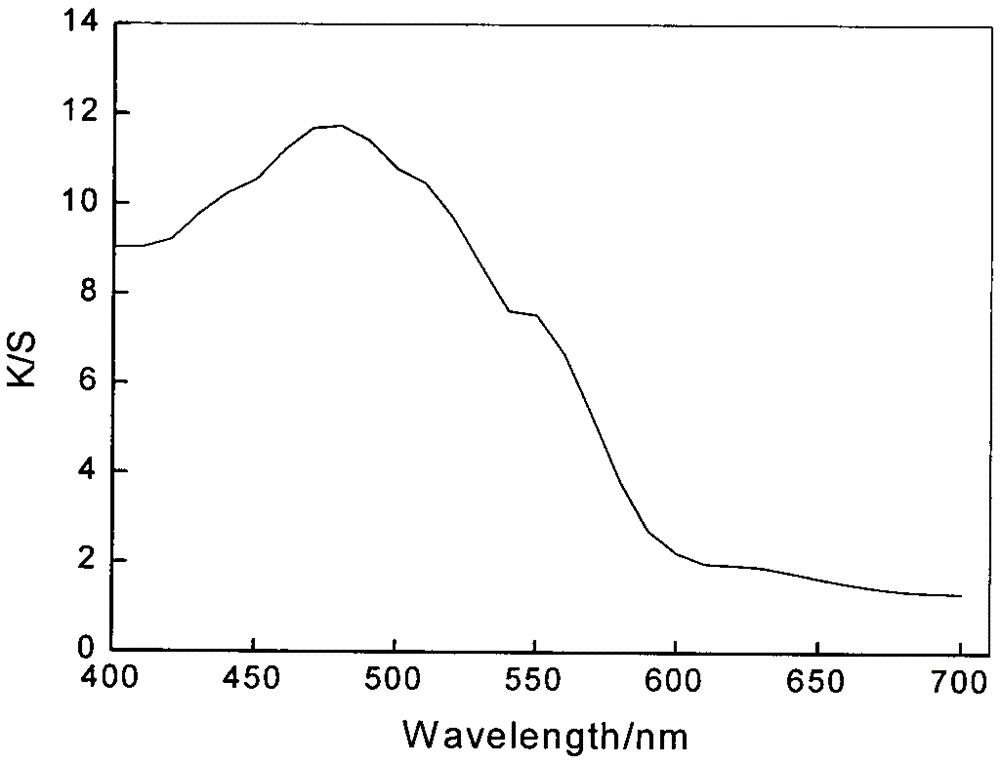

Embodiment 3

[0033] 1. The process is the same as Step 1 in Example 1 respectively.

[0034] 2. the concentration of described Acid Red A is set at 1.0g / L, the concentration of Acid Black 10B is set at 1.0g / L, and the concentration of Acid Orange 156 is set at 3.0g / L, and all the other are the same as in Example 1 Step 2 in .

[0035] 3. The process is the same as step 4 in Example 1 respectively.

[0036] 4. the concentration of described iron red is set as (135g / L), and the concentration of acrylic adhesive is (170g / L), and all the other processes are respectively identical with step 4 in embodiment 1.

[0037] 5. The process is respectively the same as step 5 in Example 1, and the dyed sample obtained is abbreviated as Example dyed sample 3#.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com