A kind of fruit button surface dyeing method and fruit button

A dyeing method and button technology, applied in the direction of dyeing method, buttons, fasteners, etc., can solve the problem of unsatisfactory quality, texture, color symmetry and effect of fruit buttons, different dyeing degrees, difficult to produce products with soft color and luster. Color effect uniformity and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

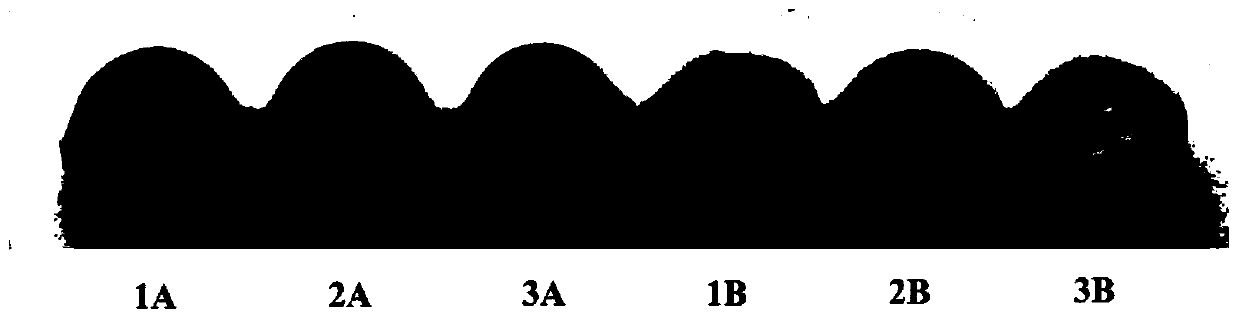

Image

Examples

Embodiment 1

[0043] Add 300mL of 400g / L polyethyleneimine condensate, 60g sodium alginate, and 10g glycerin cocoate to 600g of water at 30°C, and stir to obtain the treatment solution; then place the buttons in the treatment solution prepared above for treatment , the treatment is carried out in a constant temperature water bath at 30° C.; after 3 hours of treatment, the button is taken out, washed with clean water, and dyed to obtain the fruit button 1 .

[0044] With GB / T3921.1 as the testing standard, the color fastness of the dyed fruit button 1 was measured. The experimental results showed that the color fastness of the fruit button 1 to washing was ≥ 4.0; the color fastness to dry cleaning was ≥ 4.0; the color fastness to machine washing Degree ≥ 4.0; color fastness to steam ironing ≥ 4.0.

Embodiment 2

[0046] Add 250mL of 600g / L glycine betaine condensate, 80g of sodium caseinate, and 20g of palmityl dimethyl tertiary amine into 700g of water at 40°C, and stir to obtain a treatment solution; then place the buttons in the treatment solution prepared above The treatment is carried out in a constant temperature water bath at 40° C.; after 4 hours of treatment, the button is taken out, washed with clean water, and dyed to obtain the fruit button 2 .

[0047] With GB / T3921.1 as the testing standard, the color fastness of the dyed fruit button 2 was measured. The experimental results showed that: the color fastness of the fruit button 2 to washing ≥ 4.0; the color fastness to dry cleaning ≥ 4.0; the color fastness to machine washing Degree ≥ 4.0; color fastness to steam ironing ≥ 4.0.

Embodiment 3

[0049] Add 200mL of 800g / L dicyandiamide formaldehyde resin condensate, 120g sodium acetate, and 40g alkylphenol polyoxyethylene ether to 800g of water at 50°C, and stir to obtain a treatment solution; then place the buttons in the treatment solution prepared above The treatment is carried out in a constant temperature water bath at 50° C.; after 5 hours of treatment, the button is taken out, washed with water, and dyed to obtain the fruit button 3 .

[0050] Taking GB / T3921.1 as the testing standard, the color fastness of the dyed fruit button 3 was measured. The experimental results showed that: the color fastness of the fruit button 3 to washing ≥ 4.0; the color fastness to dry cleaning ≥ 4.0; the color fastness to machine washing Degree ≥ 4.0; color fastness to steam ironing ≥ 4.0.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com