Velveteen-like composite leather and it production technique

A composite leather and cotton lint-like technology, applied in the textile field, can solve the problems of color deviation on the surface of the fabric and the influence of the surface quality, so as to keep the color unchanged, improve the service life and slow down the color migration effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

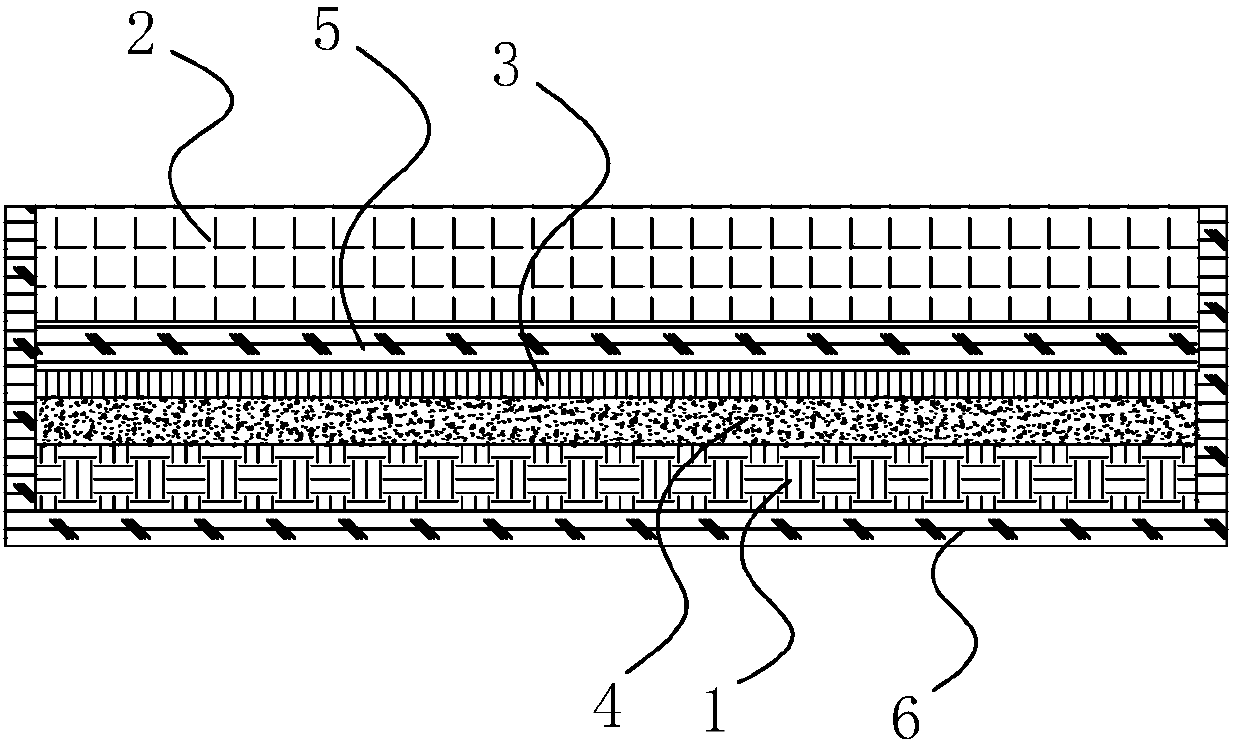

[0035] A kind of cotton-velveteen composite leather, with reference to figure 1 As shown, including the leather layer 2 and the leather base cloth arranged up and down, because after a period of use, color migration between the leather base cloth and the leather layer 2 is easy to occur, so the leather base cloth is made of polyester woven from colored fibers. Yarn warp-knitted leather base cloth body 1.

[0036] The leather base cloth body 1 is warp-knitted from polyester yarns. During the warp-knitting process, the polyester yarns include polyester filaments and polyester low-elasticity yarns, and the ratio of polyester filaments and polyester low-elasticity yarns is 3: 7.

[0037] Both polyester filament and polyester low elastic yarn are woven from colored fibers. The colored fiber is also divided into polyester filament colored fiber and polyester low elastic yarn colored fiber. Polyester filament colored fiber is made of appropriate amount of masterbatch and polyester f...

Embodiment 2

[0041] A production process of imitation cotton velvet composite leather, comprising the steps of:

[0042] Step A: Raw material selection, select an appropriate amount of purified terephthalic acid (PTA), dimethyl phthalate (DMT) and ethylene glycol (MEG) as raw materials for polyester filaments, and select an appropriate amount of polyester chips (PET) as Raw material of polyester low elastic yarn;

[0043] Step B: Add color masterbatch, add the desired color and appropriate amount of color masterbatch to the raw materials of polyester filament and polyester low elastic yarn, and mix the raw material and color masterbatch evenly by stirring, and dry the mixture at the same time ;

[0044] Step C: melt extrusion, feeding the mixed raw materials into a screw extruder to heat, melt and extrude;

[0045] Step D: Filtration, adding the melt-extruded intermediate to a melt filter for filtration, and distributing through a metering pump;

[0046] Step E: Spinning, filtering the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com