Baking-resistant simulated fruit and preparation method and application thereof

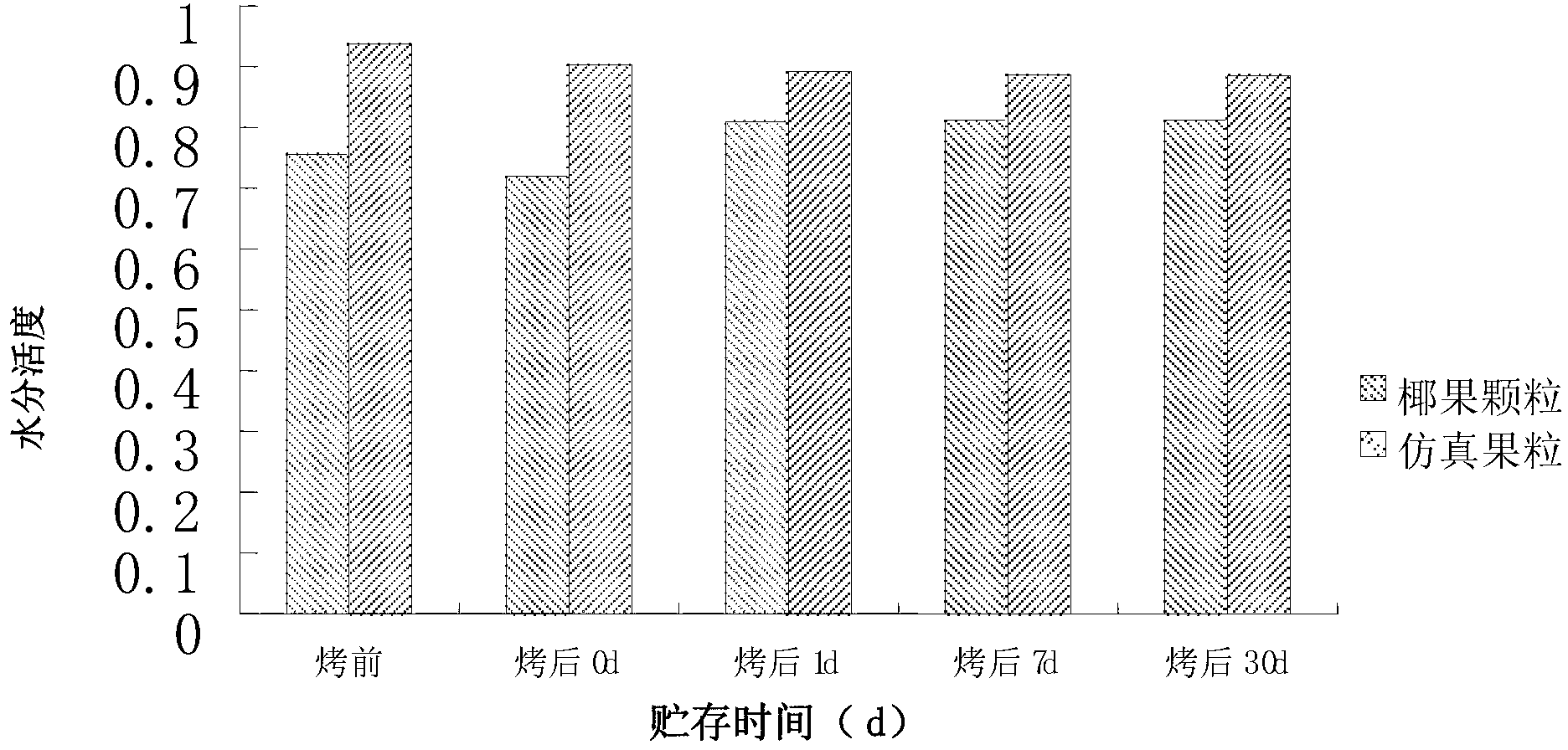

A technology that is resistant to baking and fruit grains. It is applied in the fields of application, food preparation, and food science. It can solve the problems of packaging difficulties, shorten the shelf life, and accelerate the aging of baked products, and achieve good high-temperature baking performance, good water holding capacity, and The effect of extending the shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The composition and content (mass percentage) of baking-resistant artificial fruit grains are as follows: fresh pineapple pulp 20%, modified starch (acetylated distarch phosphate, CJ5025, Roquette (China) Fine Chemical Co., Ltd.) 6%, sucrose 13.6%, soybean oil 3.0%, sorbitol liquid (68% soluble solid content) 5%, glycerin (71% soluble solid content) 1.0%, edible emulsifier 0.2% (molecular distillation monoglyceride 0.15%, 0.05% sucrose ester), 2.0% edible colloid (including 1.4% carrageenan, 0.3% sodium carboxymethyl cellulose, 0.3% sodium alginate), 0.5% sour taste regulator (which contains 0.05% calcium lactate, 0.1% lemon NaCl, 0.15% malic acid, 0.2% citric acid), 0.03% potassium chloride, 0.1% salt (NaCl), 0.01% potassium sorbate, 0.002% edible lemon yellow pigment, 0.1% food flavor, and the balance is water.

[0059] (1) Weigh the above materials according to the quantity, then dry mix the modified starch, sucrose, edible colloid, edible emulsifier, preservative, s...

Embodiment 2

[0066] The composition and content of baking-resistant artificial fruit grains are as follows: 25% fresh orange juice, 10% modified starch (hydroxypropyl distarch phosphate, H278, Foshan Huahao Huafeng Starch Co., Ltd.), 10% sucrose, fructose syrup ( Soluble solids 70%) 30%, soybean oil 2%, sorbitol liquid (soluble solids 68%) 8%, glycerin (soluble solids 71%) 5%, edible emulsifier 0.1% (of which stearyl Calcium lactate 0.05%, sodium stearoyl lactylate 0.05%), edible colloid 1.55% (of which carrageenan 1.0%, sodium alginate 0.25%, konjac gum 0.3%), sour taste regulator 0.4% (of which sodium citrate 0.10%, lemon acid 0.30%), salt 0.12%, potassium chloride 0.03%, potassium sorbate 0.05%, food flavor 0.2%, food coloring 0.005%, and the balance is water.

[0067] (1) Weigh the above materials according to the quantity, then dry mix the modified starch, sucrose, edible colloid, edible emulsifier, preservative, salt, potassium chloride and sodium citrate in sour taste regulator into...

Embodiment 3

[0074] The composition and content of baking-resistant artificial fruit grains are as follows: 23% banana pulp, modified starch (hydroxypropyl distarch phosphate, H8, Foshan Huahao Huafeng Starch Co., Ltd.) 8%, sucrose 20%, fructose syrup ( Soluble solid content is 70%) 15%, soybean oil 1%, sorbitol liquid (soluble solid content is 68%) 6%, glycerin (soluble solid content is 71%) 3%, edible emulsifier 0.15% (of which Distilled monoglyceride 0.075%, sodium stearoyl lactylate 0.075%), edible colloid 1.0% (of which carrageenan 0.7%, sodium alginate 0.2%, konjac gum 0.1%), sour taste regulator 0.6% (of which potassium citrate 0.10%) , calcium lactate 0.05%, citric acid 0.30%, malic acid 0.15%), salt 0.14%, potassium chloride 0.01%, potassium sorbate 0.05%, food flavor 0.2%, food coloring 0.005%, and the balance is water.

[0075] (1) Weigh the above materials according to the quantity, then dry mix the modified starch, sucrose, edible colloid, edible emulsifier, preservative, salt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com