Method for processing transparent cover plate and cover plate

A transparent cover, cover technology, applied in chemical instruments and methods, applications, household appliances, etc., can solve problems such as short production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

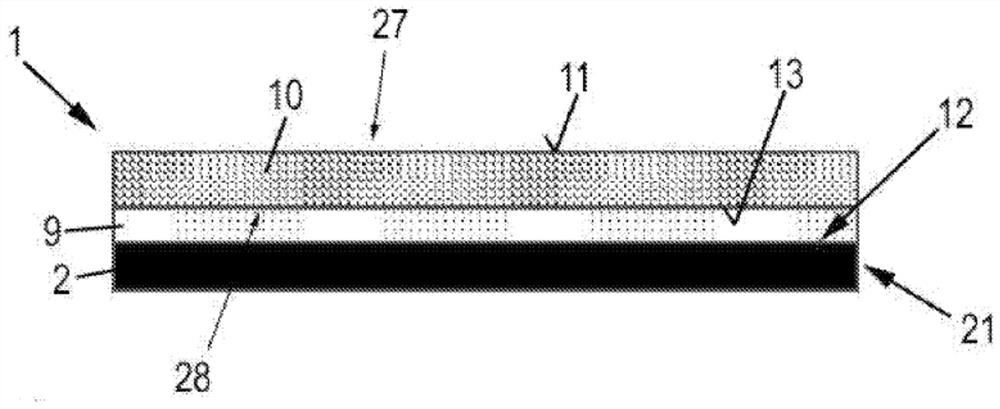

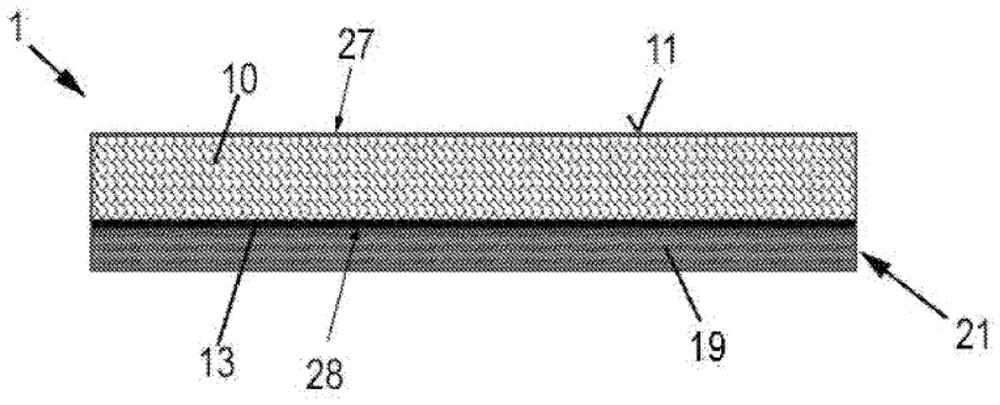

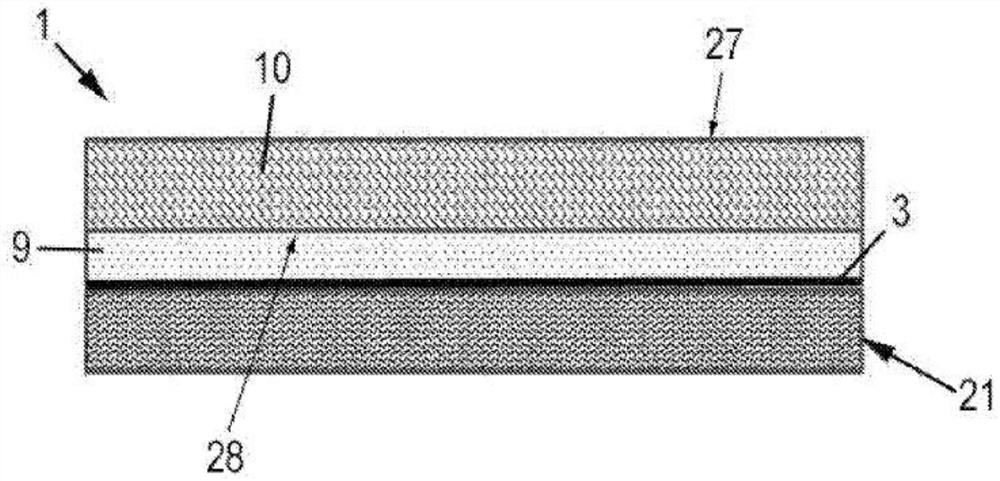

[0094] exist figure 1, a flat body according to the invention is shown schematically in cross-section, which is indicated in its entirety with the reference numeral 1 . In this case, the flat body 1 is, for example, in the form of a solar cell module having a composite panel structure. The cross-sectional view is perpendicular to the component surface. The flat body 1 comprises a cover plate 10 (eg a front glass) and a substrate 2 on the back, which are firmly connected to each other by an adhesive layer 9 (eg a laminate foil). A solar cell 12 (silicon wafer or thin film solar cell) is located on the substrate 2 . The coloured element of the flat body 1 is a coated cover sheet 10 whose outer surface 11 faces the incident light and whose inner surface 13 is connected to the solar cells 12 by an adhesive layer 9 . The outer surface 11 of the cover plate 10 is located on the outer side 27 thereof, and the inner surface 13 is located on the inner side 28 thereof. The substrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inclination | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com