Gas filter in operating room

A gas filter and operating room technology, applied in the field of medical equipment, can solve problems such as inability to control temperature and humidity, temperature deviation, missing parts inside the device, etc., to achieve the effect of cleaning the filter plate conveniently and quickly, and preventing overheating or overhumidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

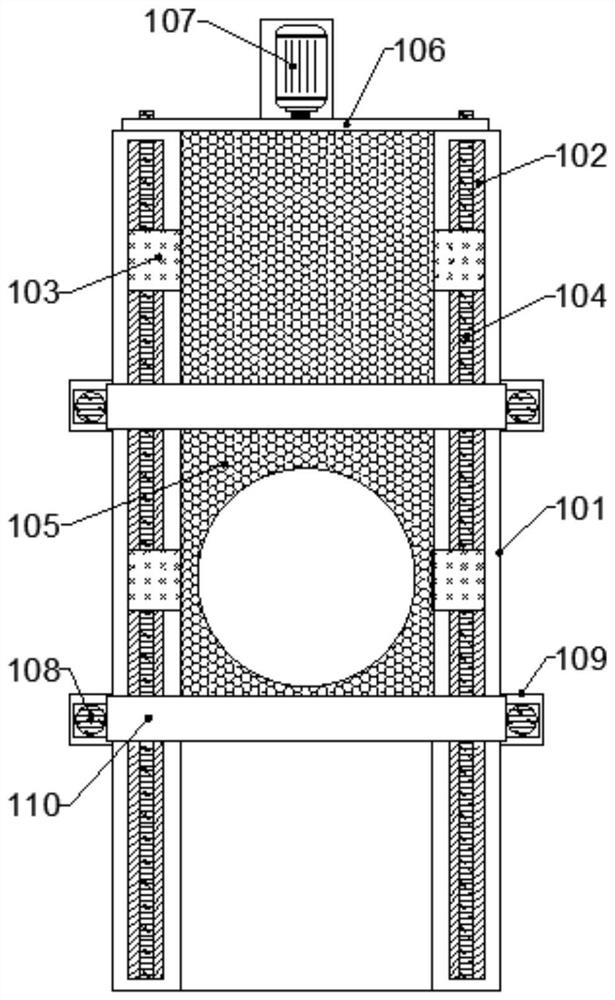

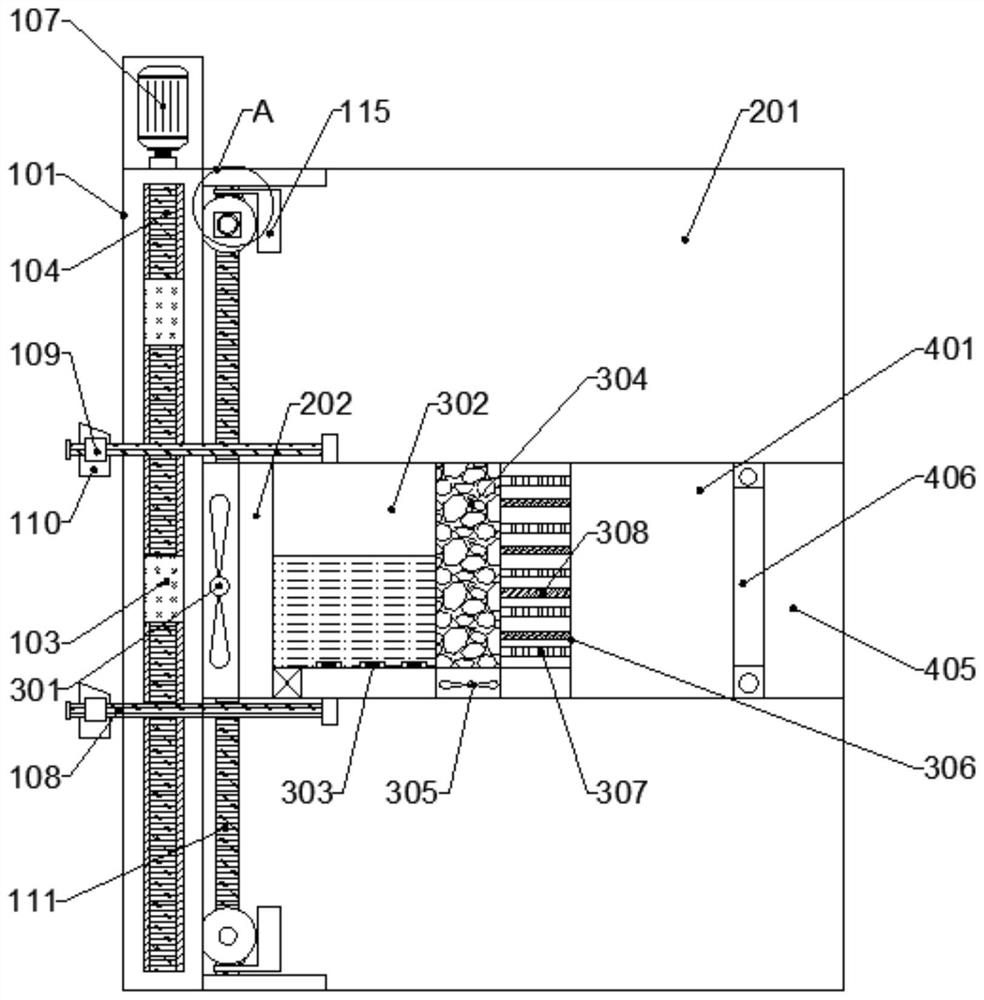

[0019] In this embodiment, a gas filter in an operating room includes a cleaning mechanism 100, a main body 200, a filtering mechanism 300, and an adjustment mechanism 400; the cleaning mechanism 100 is located at one end of the main body 200, and the adjustment mechanism 400 is located inside the main body 200. 300 is also located inside the main body mechanism 200, and the outlet end of the filter mechanism 300 is connected to the inlet end of the adjustment mechanism 400 and is in fluid communication.

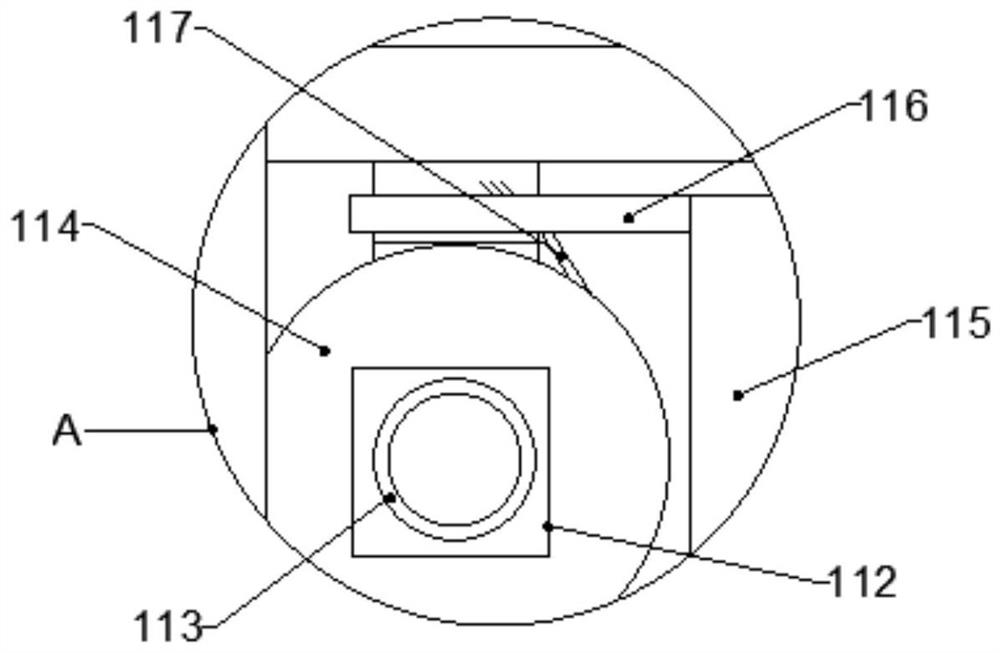

[0020] Such as Figure 1-3As shown, the cleaning mechanism 100 includes a sliding frame 101, a chute 102, a first slide block 103, a first leading screw 104, a filter plate 105, a transmission belt 106, a motor 107, a second leading screw 108, a second slide block 109, a collecting Box 110, the third lead screw 111, the third slide block 112, bearing 113, cleaning roller 114, vacuum cleaner 115, slide plate 116 and scraper 117; the two ends of slide frame 101 are provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com