Polymer powder volatile component removing apparatus and polymer powder volatile component removing method

A devolatilization device and polymer powder technology, which is applied in the field of polyolefin production devices, can solve the problems of inability to guarantee the drying of polymer powder and complicated operation process, and achieve the effect of short process, simple process and efficient removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

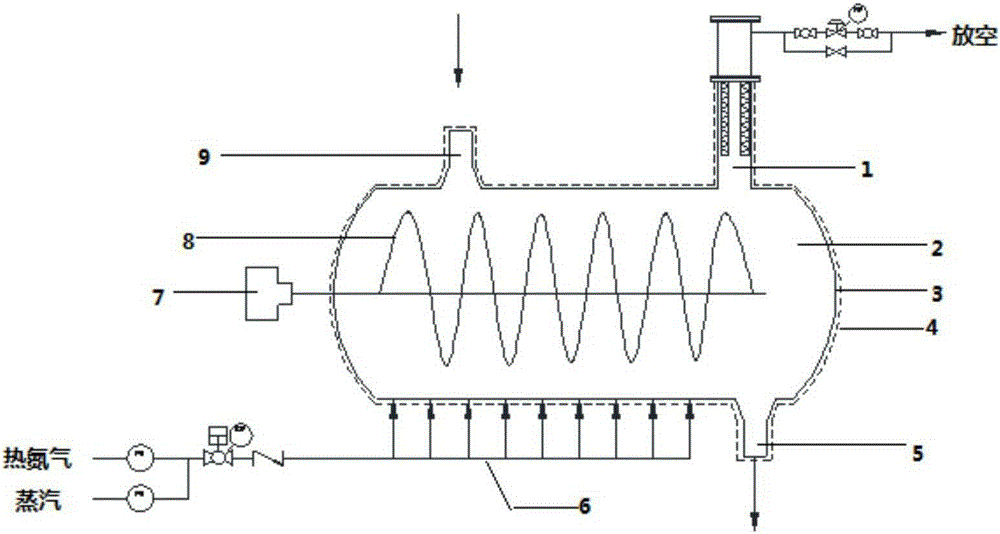

[0049] Such as figure 1 As shown, the polymer powder devolatilization device is a 0.5m horizontal stirring 3 Constant pressure vessel, the control pressure is 0.2MPa, the agitator is a ribbon type, and the set speed is 5r / h; the proportion of steam in the mixed gas is 100%, and the steam is evenly dispersed from the bottom of the devolatilization device near the side of the stirring actuator Enter, fully contact with the polymer powder entering from the top of the devolatilization device close to the side of the stirring actuator to form a fully mixed flow state; the polymer powder is transported to the other side of the horizontal container through the continuously running stirring paddle, and polymerized The residence time of the polymer powder in the devolatilization device is 60min; the gas is filtered through the filter on the top side away from the stirring actuator and then emptied, and the devolatilized polymer powder is discharged from the devolatilization device from...

Embodiment 2

[0051] Such as figure 1 As shown, the polymer powder devolatilization device is a 0.5m horizontal stirring 3 Constant pressure vessel, the control pressure is 0.3MPa, the agitator is ribbon type, the set speed is 60r / h; the proportion of steam in the mixed gas is 5%, the temperature of hot nitrogen is 80°C, the mixed gas of hot nitrogen and steam Evenly disperse and enter from the side of the bottom of the devolatilization device close to the stirring actuator, and fully contact with the polymer powder entering from the top of the devolatilization device near the side of the stirring actuator to form a fully mixed flow state; The polymer powder is transported to the other side of the horizontal container, and the residence time of the polymer powder in the devolatilization device is 30 minutes; the gas is filtered through the filter on the side away from the stirring actuator at the top and then emptied, and the polymer powder after devolatilization The material is discharged...

Embodiment 3

[0053] Such as figure 1 As shown, the polymer powder devolatilization device is a 0.5m horizontal stirring 3 Constant pressure vessel, the control pressure is 0.7MPa, the agitator is a ribbon type, the set speed is 300r / h; the proportion of steam in the mixed gas is 0%, the temperature of the hot nitrogen is 100°C, and the hot nitrogen is from the bottom of the devolatilization device The side close to the stirring actuator is uniformly dispersed and enters, and fully contacts with the polymer powder entering from the top of the devolatilization device close to the stirring actuator to form a fully mixed flow state; the polymer powder is transported to the On the other side of the horizontal container, the residence time of the polymer powder in the devolatilization device is 5 minutes; the gas is filtered through the filter on the side away from the stirring actuator at the top and then emptied, and the devolatilized polymer powder is away from the stirring from the bottom T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com