Method for determining water content of grain in spreading type grain drier

A grain drying machine and grain moisture technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of poor control of grain drying, and achieve simple structure, convenient manufacture and installation, and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

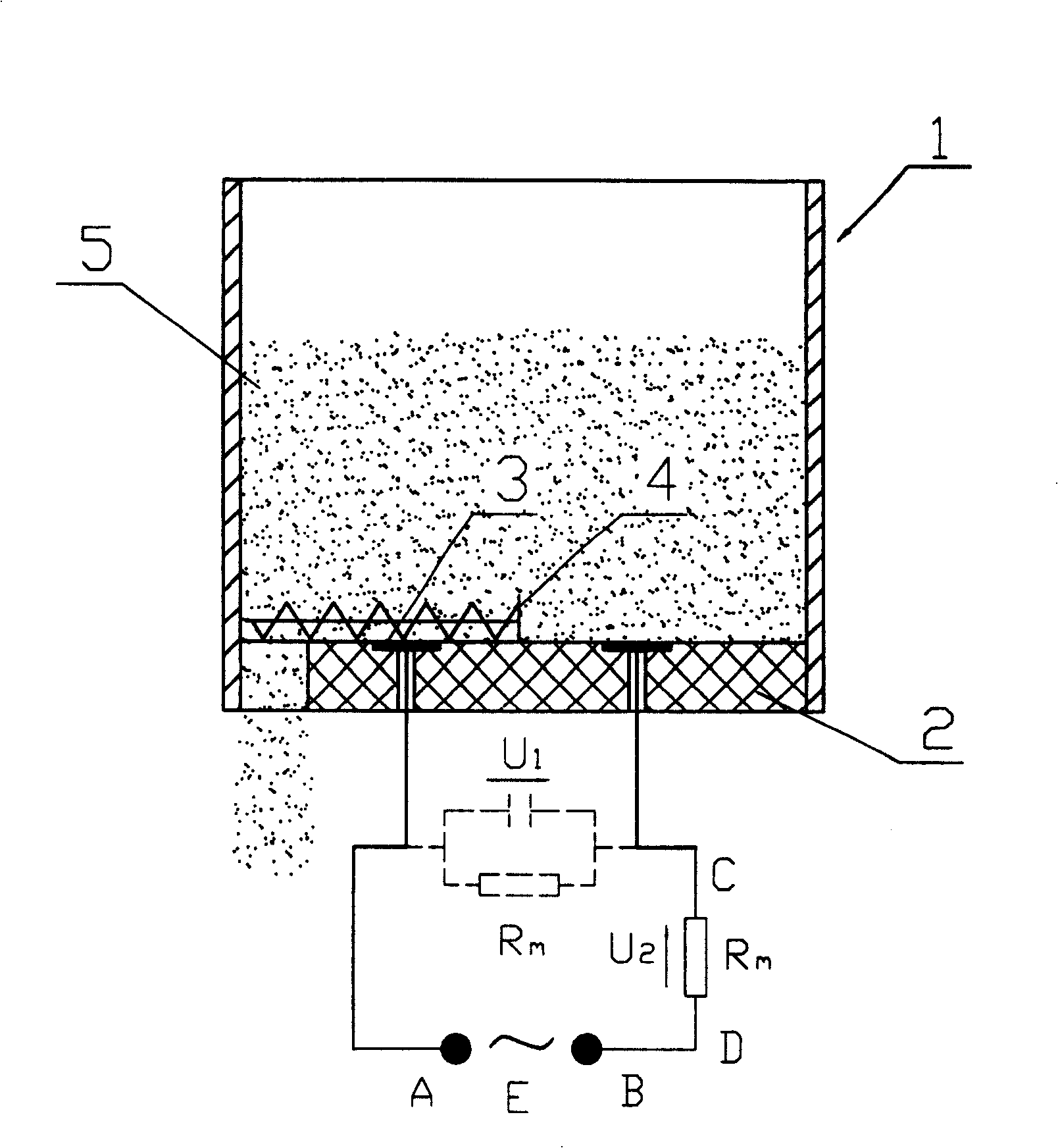

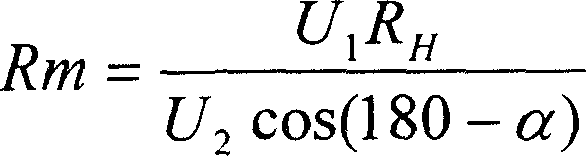

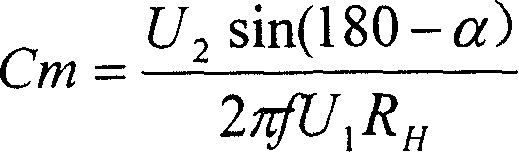

[0042] In this embodiment, Xudao No. 3 is selected and placed in the cylindrical silo of the flat-storage grain dryer 1 with a layer thickness of 50 cm. The plate electrode 3 is placed on the insulating bottom plate 2 on the bottom surface. The frequency f of the high-frequency signal E =9000Hz, measured U 1 = 2.47V, U 2 =0.93V, α=169.34°. According to the function relationship (1), (2), the impedance R of Xudao No. 3 is obtained m =243.230kΩ, capacitive reactance C m = 1.34 -11 F, the water content ω=14.47% is obtained by the fitting function (9) or (10).

Embodiment 2

[0044] In this embodiment, Zhoumai 15 is selected and placed in the cylindrical silo of the flat-storage grain dryer 1, with a layer thickness of 45 cm. The plate electrode 3 is placed on the insulating bottom plate 2 on the bottom. The frequency of the high-frequency signal E is f=5000 Hz, Measured U 1 =2.52V, U 2 =0.88V, α=166.46°. According to the functional relationship (1) and (2), the impedance R of Zhoumai 15 is obtained m =265.095kΩ, capacitive reactance C m = 2.89 -11 F, the water content ω = 10.36% is obtained by the fitting function (7) or (8).

Embodiment 3

[0046] In this embodiment, Zhoumai 15 is selected and placed in the cylindrical silo of the flat-storage grain dryer 1 with a layer thickness of 40 cm. The plate electrode 3 is placed on the insulating bottom plate 2 on the bottom surface. The high-frequency signal E frequency f = 9000 Hz , Measured U 1 =2.43V, U 2 = 0.92V, α = 169.47°. According to the functional relationship (1) and (2), the impedance R of Zhoumai 15 is obtained m =241.789kΩ, capacitive reactance C m = 1.36 -11 F, the water content ω = 10.36% is obtained from the fitting function (11) or (12).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| impedance | aaaaa | aaaaa |

| impedance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com