Egg-duck whole-course flat dry feeding process

A whole-process, planar technology, which is applied in the field of whole-process planar dry raising of laying ducks, can solve the problems of excessive pathogenic microorganism content, damage to the natural environment, high cost, etc., and achieve the goal of promoting growth and health, improving egg yield and low damage rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

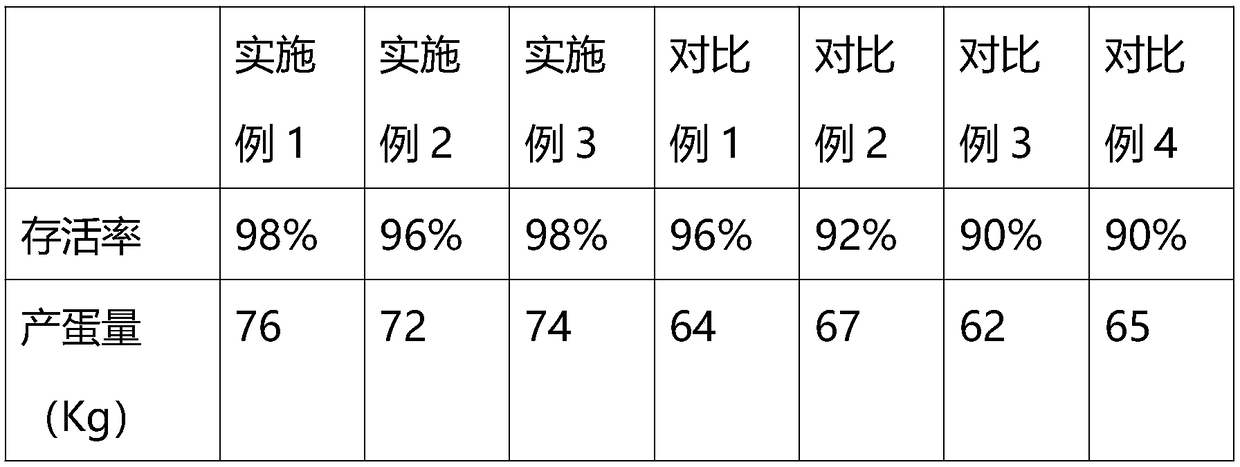

Examples

Embodiment 1

[0023] A whole-process planar dry raising process for laying ducks, characterized in that the feeding area includes an activity area and an egg-laying area; the activity area adopts a mesh bed structure with a mesh size of 3 cm; a manure scraping device under the mesh bed, and the scraped manure part is exposed to the sun. After drying, it is mixed with dry soil at a ratio of 1:7.5 to obtain a dry manure mixture. The remaining part is fermented first and then used as fertilizer on the surrounding farmland; the egg production area is consistent with the activity area and connected without obstacles. The egg production area uses rice straw and rice bran , hay, and dry manure mixture as litter, the weight ratio of the rice straw, rice bran, hay, and dry manure mixture is 7.5:7.5:2.5:2.5, and the litter height is 15cm; the laying time is 2-5 o'clock in the morning, Keep the light dim; build a barn above the breeding area, and install isolation around the barn; install temperature c...

Embodiment 2

[0025] A whole-process planar dry raising process for laying ducks, characterized in that the feeding area includes an activity area and an egg-laying area; the activity area adopts a mesh bed structure with a mesh size of 2 cm; a manure scraping device under the mesh bed, and the scraped manure part is exposed to the sun. After drying, it is mixed with dry soil at a ratio of 1:10 to obtain a dry manure mixture, and the remaining part is fermented first and then used as fertilizer on the surrounding farmland; the egg production area is consistent with the activity area and is connected without obstacles. The egg production area uses rice straw and rice bran , hay, and dry manure mixture is litter, and the weight ratio of the rice straw, rice bran, hay, and dry manure mixture is 5:10:2:5, and the litter height is 10cm; Keep the light dim; build a barn above the breeding area, and install isolation around the barn; install temperature control equipment in the barn, cool down to b...

Embodiment 3

[0027] A whole-process planar dry raising process for laying ducks, characterized in that the feeding area includes an activity area and an egg-laying area; the activity area adopts a net bed structure with a mesh size of 4 cm; a manure scraping device under the net bed, and the scraped manure part is exposed to the sun. After drying, it is mixed with dry soil at a ratio of 1:5 to obtain a dry manure mixture. The remaining part is fermented first and then used as fertilizer on the surrounding farmland; the egg production area is consistent with the activity area and connected without obstacles. The egg production area uses rice straw and rice bran , hay, dry manure mixture is litter, the weight ratio of the rice straw, rice bran, hay, dry manure mixture is 10:5:5:2, the litter height is 20cm; egg laying time is 2-5 in the morning, Keep the light dim; build a barn above the breeding area, and install isolation around the barn; install temperature control equipment in the barn, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com