Rustless efficient fabricated building steel cross beam in steel frame structure factory building and bearing column thereof

A kind of structural workshop and prefabricated technology, applied in the direction of building and building structure, can solve the problems of loss of protective film and easy corrosion of steel structure parts, and achieve the effect of avoiding corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

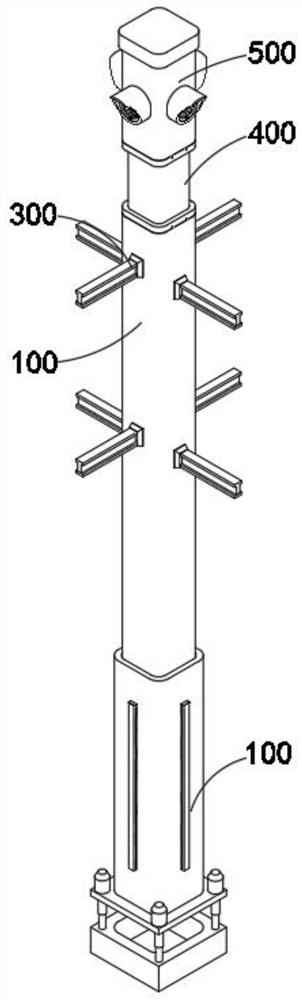

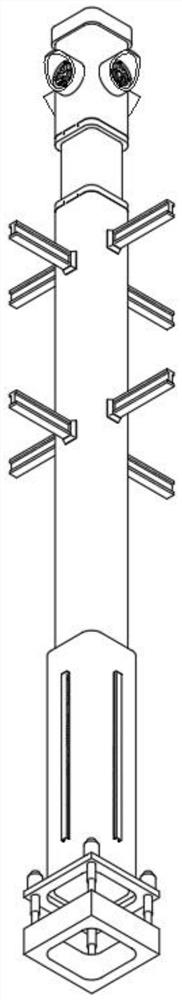

[0054] combine Figure 4 , 7 , 9, 11 and 13, the present invention provides a rust-free high-efficiency assembled building steel beam and its load-bearing column in a steel frame structure factory building, including a load-bearing mechanism 100, a manufacturing mechanism 200, a beam bridging mechanism 300, and a sealing mechanism 400 and the airflow dredging mechanism 500, wherein, the manufacturing mechanism 200 is installed in the load-bearing mechanism 100, and the beam bridging mechanism 300 is installed inside the manufacturing mechanism 200, and the sealing mechanism 400 is plugged on the manufacturing mechanism 200. In addition, the airflow dredging mechanism 500 is plugged onto the sealing mechanism 400 .

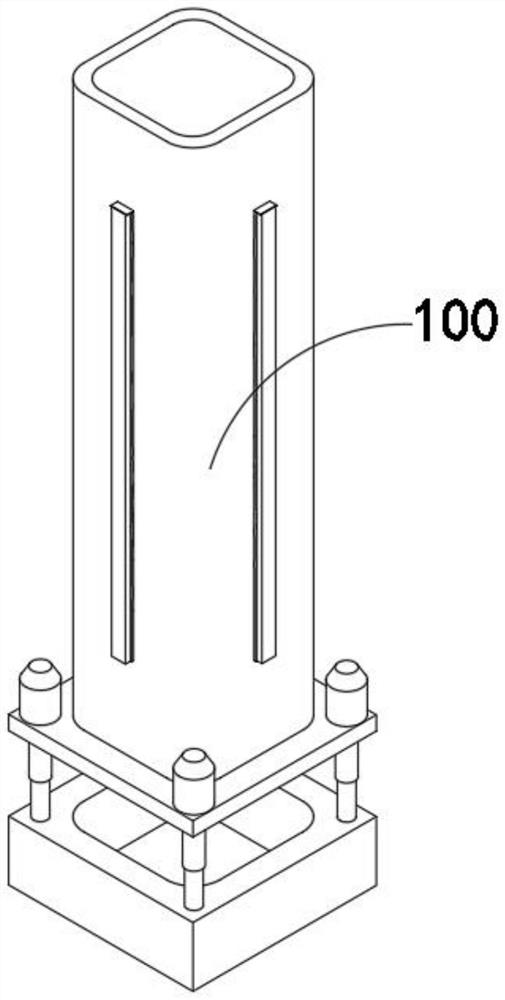

[0055] The load-bearing mechanism 100 includes a steel frame shell 110, a protection assembly 120, a screw 130, a briquetting block 140, a limit assembly 150, a base 160 and a waterproof cover 170, and the manufacturing mechanism 200 includes a steel frame main bo...

Embodiment 2

[0058] combine Figure 4 As shown, in the above-mentioned embodiment, the clockwise rotation and counterclockwise rotation of the screw in the limit assembly 150 are used to push the base 160, so that the overall stability of the load-bearing mechanism 100 on the bottom pile can be achieved, and The screw 130 can be well protected by using the U-shaped clamping shell to be plugged into the vertical slide rail, and at the same time, the rotation of the screw in the limit assembly 150 is used to control the T-shaped fixing rod inside to push the base 160 depth, so that the stability of the base of the steel frame shell 110 can be made, and the auxiliary fixing part includes a protection combination 120 installed outside the steel frame shell 110, a limit combination 150 plugged into the steel frame shell 110, and a limit combination connected to the The base 160 at the bottom of 150 and the waterproof cover 170 sleeved on the top of the limit assembly 150, the protection assembl...

Embodiment 3

[0060] combine Figure 11 and 12 As shown, in the above embodiment, the sealing ring 420 is used to protect the insertion rod 221 against rust, so that the overall rust of the positioning assembly 220 can be avoided. The positioning assembly 220 also includes a latch 223 installed in the sealing mechanism 400, connected to the seal The fixing part 222 in the mechanism 400 and the insertion rod 221 installed in the fixing part 222 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com