Hanging and rotating preventing thrust sliding bearing device

A thrust sliding bearing and anti-hanging technology, applied in sliding contact bearings, bearings in rotating motion, bearings, etc., can solve the problems of equipment operation without safety guarantee, inability to install, inconvenient installation, etc., to achieve no environmental pollution, easy installation, The effect of high installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

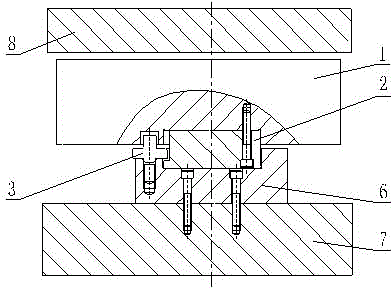

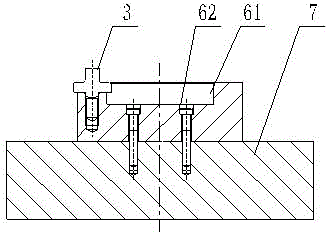

[0025] Referring to the accompanying drawings, the present invention is realized in this way: the pivot 2 is fixedly connected in the notch of the thrust shoe 1 through the screw light hole 21 through the screw, the lower end of the pivot 2 is fitted with the notch 61 of the bearing plate 6, and the anti-hanging block 3. The threaded end of the lower shaft 31 is fastened and installed in the screw hole 64 of the recess 63 of the bearing plate 6; the bearing plate 6 is installed on the frame 7 through the screw hole 62 through the screw; the thrust plate 8 is installed above the thrust shoe 1.

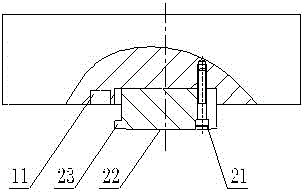

[0026] Such as figure 2 and Figure 8 As shown, the pivot 2 is in the shape of a cylinder, the upper end of the cylinder is a plane, and four evenly distributed screw holes 21 are drilled on the plane; the lower end of the cylinder is a spherical surface 22, so that it can be tilted inward at the seam 61 of the bearing plate 6 Pendulum; one side of the pivot 2 cylinder is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com