Patents

Literature

111results about How to "Moderately salty" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preserved meat processing method

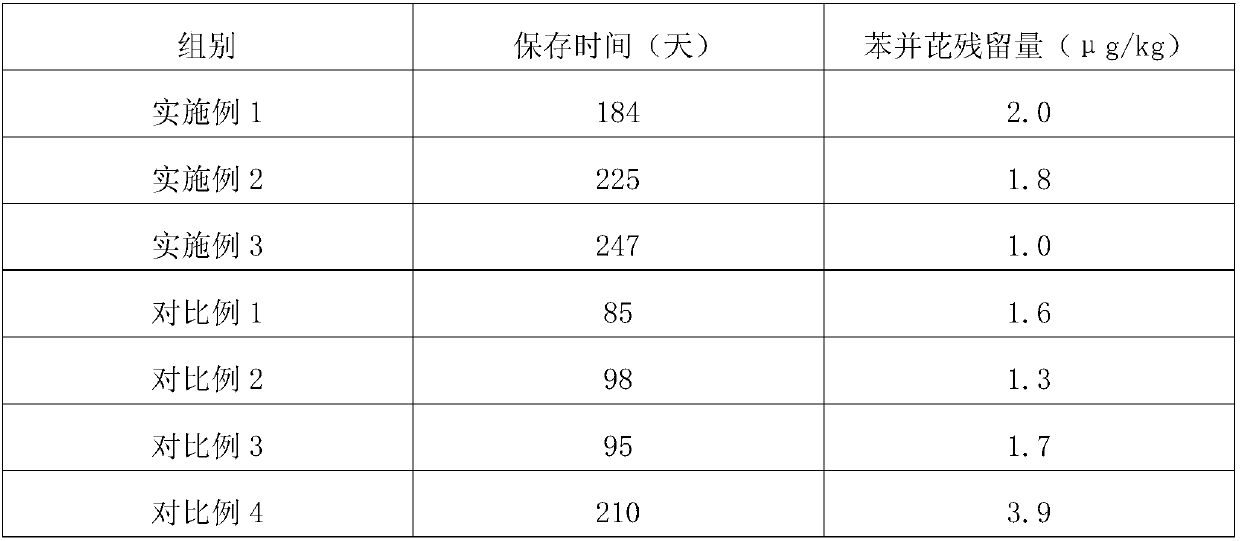

InactiveCN103584135AReduce salt contentReduce the content of benzopyreneFood preservationFood preparationPreservativeProduct processing

The invention relates to the field of meat product processing, and particularly relates to a preserved meat processing method. The preserved meat processing method can lower the content of benzopyrene in a preserved meat product by selecting and controlling the smoking temperature, humidity and smoking materials in the smoking step. The processing method provided by the invention can improve the preserved meat pickling temperature properly by using nisin and biological preservatives to shorten the pickling time from 40 days of the conventional art to 15 days, thereby preventing meat deterioration in the pickling process, improving preservation effect of preserved meat, and improving work efficiency.

Owner:HUNAN AGRICULTURAL UNIV +1

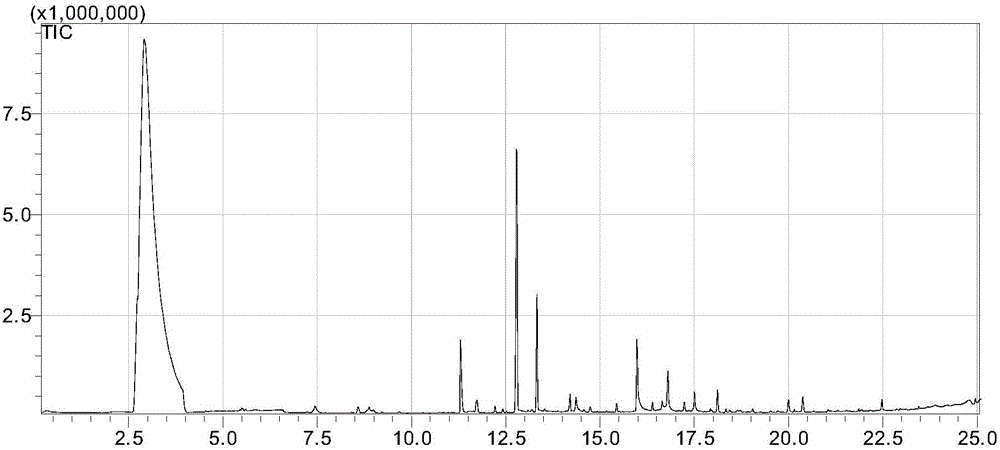

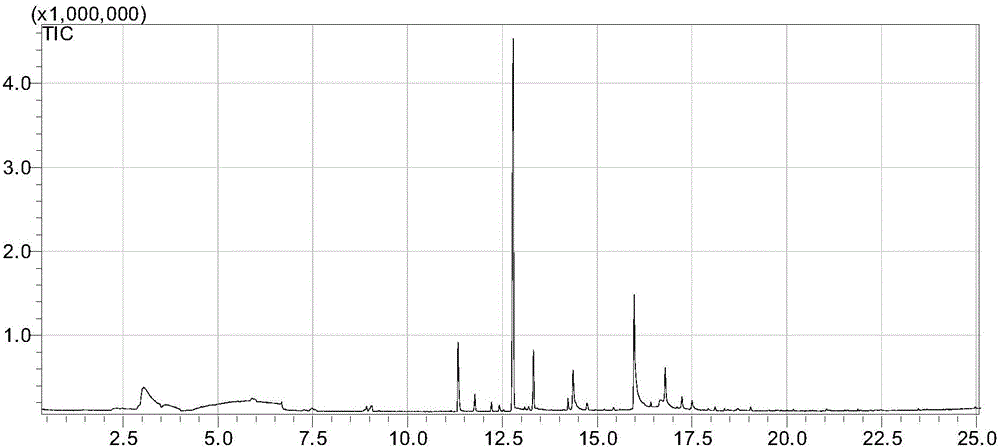

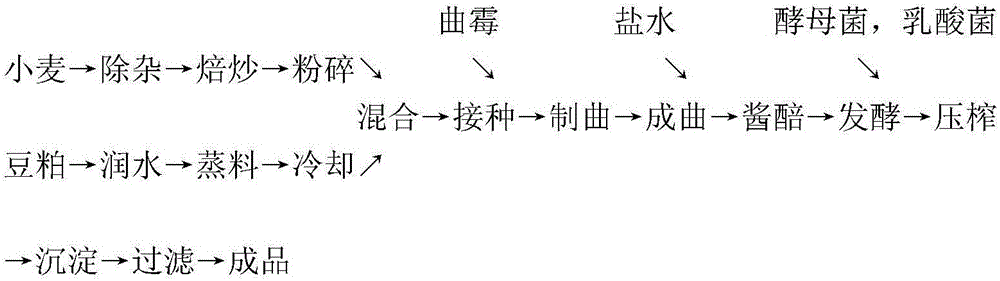

Multi-strain mixed fermentation process for soy sauce

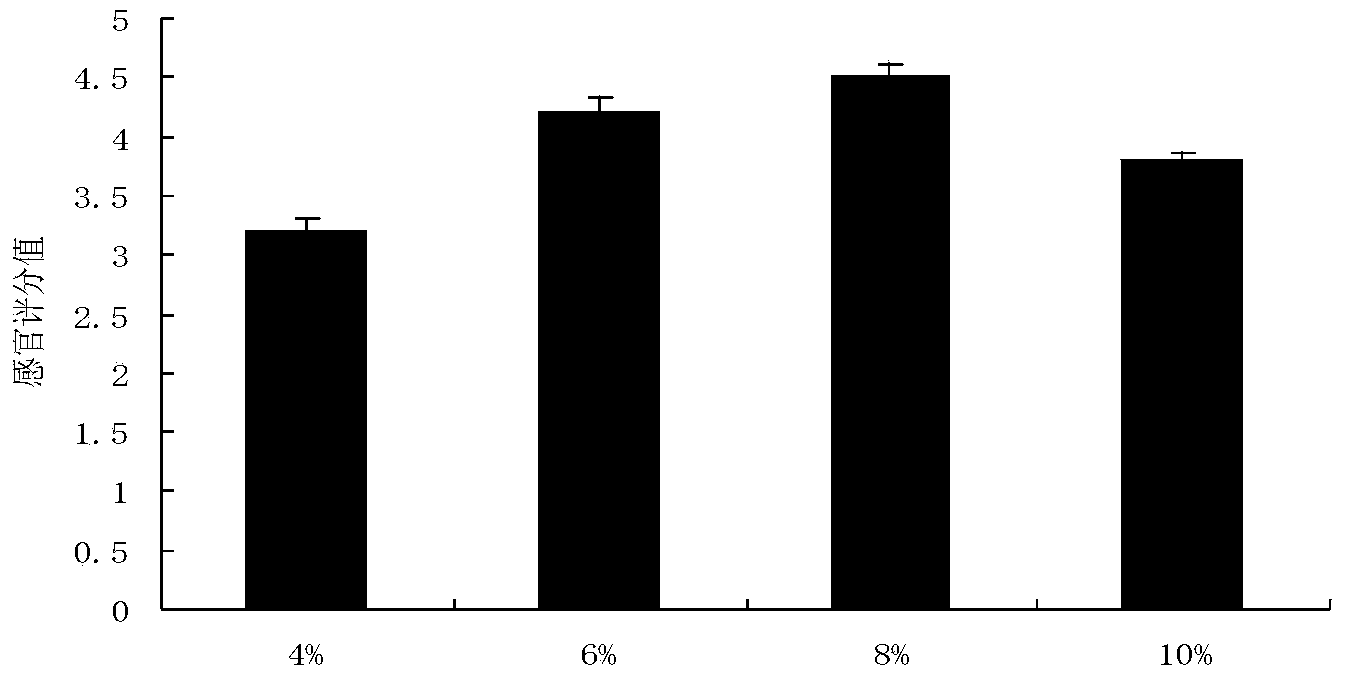

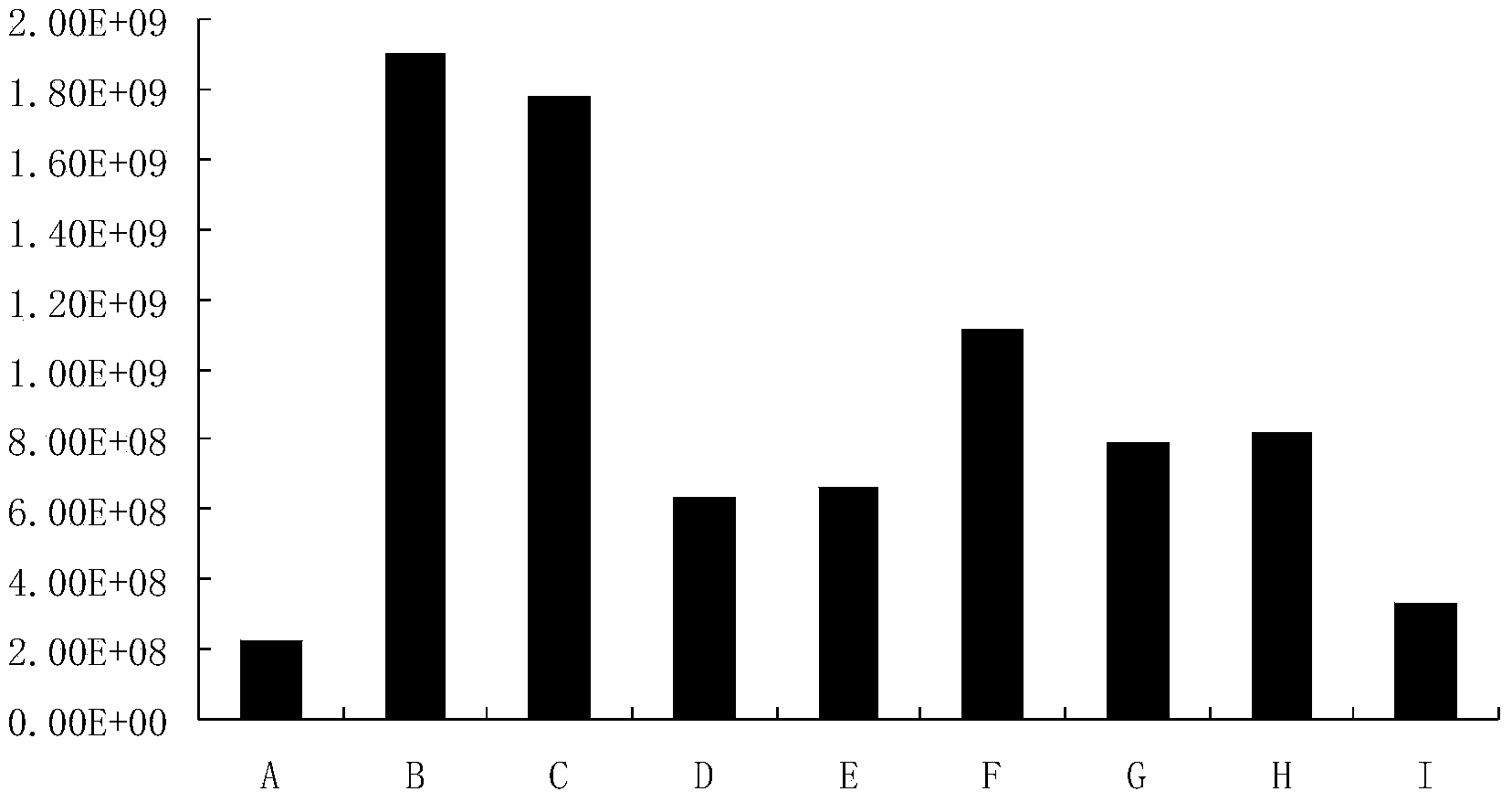

The invention provides a multi-strain mixed fermentation process for soy sauce. The technological process consists of: wheat selection, wheat roasting and crushing, soya bean meal cooking, seed dressing and koji making, finished koji mixing, fermentation, squeezing and the like. The process can enhance the flavor of brewed soy sauce, and the product not only improves the content of amino acid nitrogen and protein utilization rate, but also has significant improvement in the aspects of color, fragrance and taste. The process provided by the invention can improve the product quality, provide practicing technology, facilitate implementation of large-scale production, is conducive to making high-end brewed soy sauce products, and solves the disadvantages of flavor, quality and other aspects in existing soy sauce.

Owner:JIAJIA FOOD GRP

Formula of duck seasoned with soy sauce and preparation method thereof

The invention relates to a formula of livestock seasoned with soy sauce and a preparation method thereof and discloses a formula of a duck seasoned with soy sauce and a preparation method thereof. The duck seasoned with soy sauce is prepared from an eviscerated duck, siberian solomonseal rhizome, Indian buead, yam, barbary wolfberry fruit, dried longan pulp, cannelle, star anise, clove, fennel, white granulated sugar, salt, soy sauce, cooking wine and gourmet powder. The duck seasoned with soy sauce prepared by the formula and the preparation method has the characteristics of excellent mouth feel, proper saline taste, soft, fine and smooth meat, combination of color, smell and taste and concentrated medicinal fragrance, avoids producing a large amount of nitrites in a salting process, has the intrinsic nutritional value of the meat of the duck and gives full play to the functions of nourishing yin and benefiting qi and strengthening spleen and stomach of the added Chinese medicaments, thereby being extremely good for human health.

Owner:HANGZHOU GUANGXINGTANG TRADITIONAL CHINESE MEDICINE CULTURE HEALTH CARE

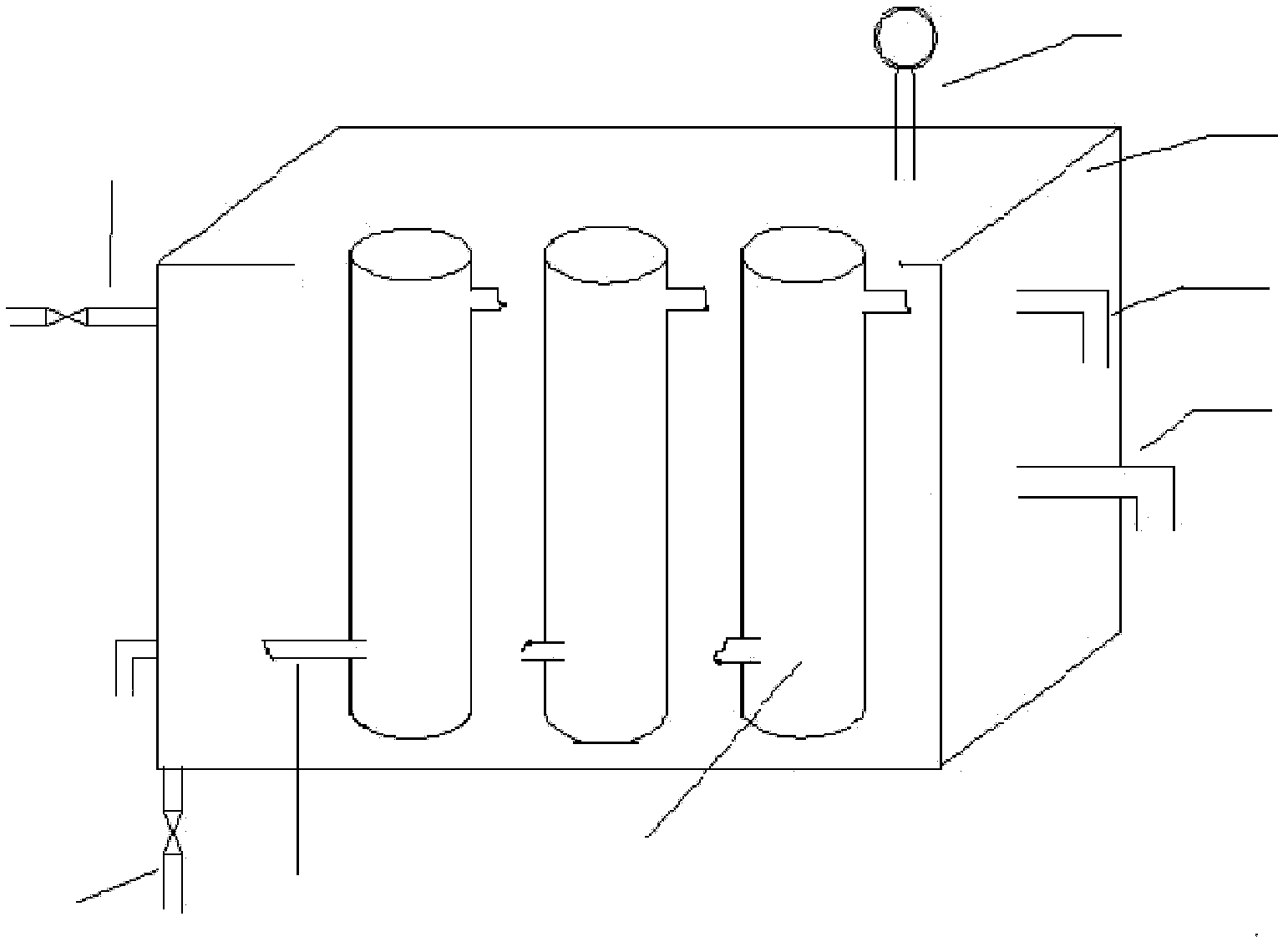

Method and device for fast and cyclically pickling salted eggs

ActiveCN102613603AImprove pickling efficiencyEase of industrial productionFood preparationPickling saltDissolution

The invention discloses a method for cyclically pickling salted eggs. The method comprises the following steps that: A, selecting fresh poultry eggs, cleanly washing the poultry eggs, and placing the eggs into a vacuum pickling tank; B, solution A and solution B for pickling are prepared, 1L of solution A comprises common salt and slaked lime, and 1L of solution B comprises white spirit, acid additives and natural spice; C, the solution A for pickling is filled into a sterilization device with a built-in liquid storage groove and is pumped into the tank containing the poultry eggs after beingsubjected to ultraviolet sterilization, the solution B is filled into an ultrasonic wave dissolution device provided with a built-in liquid storage groove and a stirring paddle, the stirring is carried out, the pump is started, and the solution B passes through a filtering device and the sterilization device and is then pulped into the tank; D, the pump is started, the flow rate is monitored through a flow rate counting meter so that the pickling solution circulates in a pickling device at the specified flow speed; and E, after the cyclic pickling fro a certain time, the eggs are taken out and are cleanly washed, and finished products are obtained. The salinity of the salted eggs is uniform, the flavor is very good, the pickling period is shortened, the shelf life can be prolonged, the utilization rate of the pickling solution is improved, meanwhile, the continuous production can also be realized, the factory building area is reduced, and the environment is protected.

Owner:HUBEI SHUANGGANG AGRI SCI & TECH TRADE CO LTD

Anhydrous rapid preparation method of low-nitrite lactic acid-fermented vegetable

InactiveCN104738484AAvoid pollutionFast fermentationBacteriaMicroorganism based processesBiotechnologySalt content

The invention discloses an anhydrous rapid preparation method of a low-nitrite lactic acid-fermented vegetable. The method comprises the following steps: cleaning and draining off a to-be-fermented vegetable, and segmenting according to the requirements; and adding 1.5%-3.3% of salt and 0.05%-0.35% of functional bacteria powder according to the weight of the vegetable, mixing evenly, and fermenting at a room temperature for 1-4 days, so as to obtain the fermented vegetable product. The low-nitrite lactic acid-fermented vegetable is fast to ferment, low in nitrite and salt content, free of extra addition of water, and simple in production process.

Owner:GUIZHOU UNIV

Preparation method of sausages

The invention provides a preparation method of sausages. The preparation method of sausages comprises the following steps of stirring materials, filling and baking. The preparation method of sausages is characterized in that the baking comprises low, height and low baking stages. The prepared sausages have red and date red lean meat and milk white fat, the surface is glossy, the flavor is pure and strong, the intrinsic flavor of the sausages is unadulterated and rich, the taste is fresh, the salinity is moderate, appearances are complete and uniform, the surface is dry and comfortable, and the sausages have natural winkles after contraction; and the water content is 20-25%, the storage period is long, and the sausages can still keep the unique color, mouthfeel and nutrition within 3-5 years.

Owner:CHONGQING CHENGKOU COUNTY ZHAO XIAOCHUN WILD FOODDEV

Manufacturing method of sauced duck

The invention relates to the technical field of foodstuffs, and specifically relates to a manufacturing method of sauced ducks. The method comprises technological processes of butchering, thawing, washing and finishing, curing, cooking and saucing, quantitative cutting, weighing, packaging, microwave disinfecting, vacuum packaging and sealing, high-temperature sterilizing, cooling, outer-packaging, and examining. After the processes, finished products can be obtained. With the technical scheme provided by the invention, the produced sauced ducks are advantaged in good mouthfeel, appropriate salinity, delicate meat quality, good color, good flavor, and good taste. According to the invention, microwave disinfecting and high-temperature sterilizing are adopted, such that the shelf lives of the products can be effectively prolonged to above one and a half years. According to the invention, a drying process is not adopted, such that the water content in the meat tissues is high, and the meat quality is soft. Also, the method is advantages in high production efficiency, stable color, and suitability for industrialized productions.

Owner:CHANGZHOU ZUNLONG FOOD

Production of ham

InactiveCN1406519AReduce saltinessNot easy to damp, mildew and deteriorationFood preparationNitriteHot peppers

A technology for producing ham includes such steps as examining and pre-treating the pork leg, immersing in the mixture of spirit, sodium chloride, potassium chloride, edible glucose, hot pepper, Caoguo powder and pepper powder, preseriving, drying in air, wrapping by cotton paper, burying in the mixture of dried charcoal and plant ash, fermenting and removing ash. Its advantages are no or a little nitrate, good smell, short fermenting period, and high percentage of qualified products (99%).

Owner:LIJIANG YUYUAN FOOD

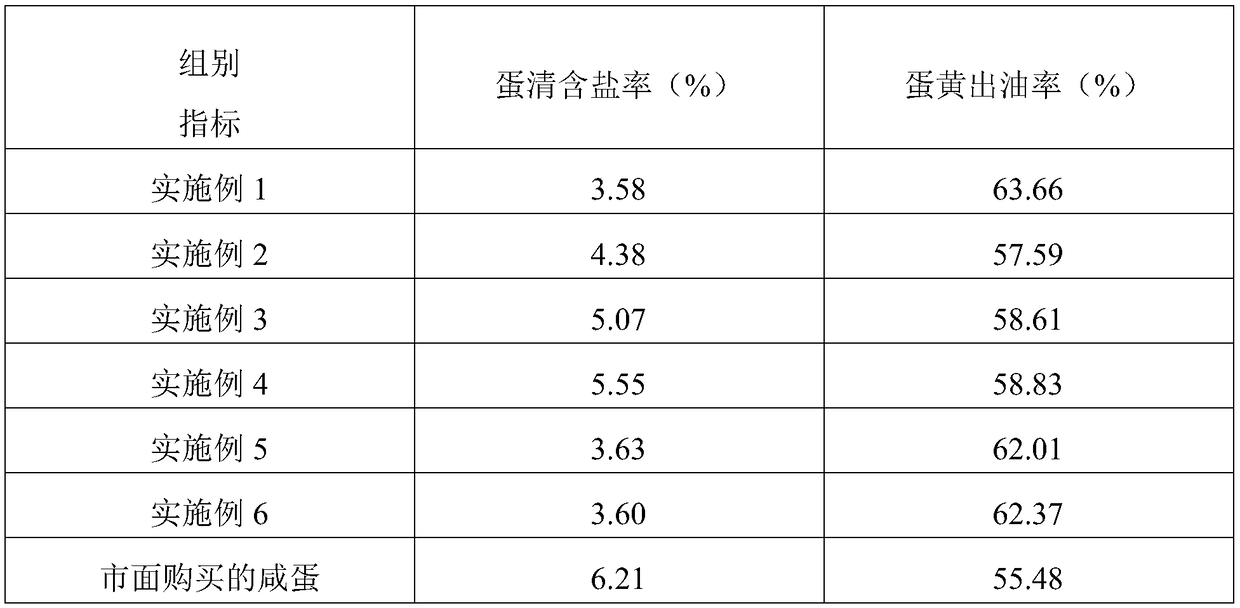

Flavor-improved salted chicken egg yolk

InactiveCN107439997AKeep the flavorReduce oxidation rateFood thermal treatmentFood ingredient as taste affecting agentYolkAcetic acid

The invention discloses flavor-improved salted chicken egg yolk. The flavor-improved salted chicken egg yolk is prepared from raw materials including chicken egg yolk, food-grade ethyl acetate, a food-grade osmotic pressure regulator, food-grade acetic acid, food-grade ethanol, a food-grade antioxidant and table salt. Chicken eggs with the freshness higher than or equal to 72 Ha are subjected to separation of egg white and egg yolk, a flavor substance is added to the egg yolk, ultrasonic pretreatment and heat-cold pretreatment are performed sequentially, the egg yolk is added to an isotonic salting solution to be completely immersed, table salt is added multiple times, so that the salting solution has certain concentration gradients, the egg yolk is salted for a period of time and cooked at 70 DEG C, and the flavor-improved salted chicken egg yolk can be obtained. The flavor-improved salted chicken egg yolk has the characteristics of being refreshing in flavor, fine, moderate in saline taste and high oil yield, the process is simple, a little salt is used, and industrial production is easy to realize.

Owner:马述腾

Method for preparing roast ducks

The invention relates to a method for roasting poultry, and discloses a method for preparing roast ducks. The method comprises: soaking an eviscerated duck in decoction; taking out and cooling the eviscerated duck and hanging the duck in a ventilated place to air-dry the skin of the duck; hanging the duck in an oven; roasting the duck with breast upward for 25 to 30 minutes; repeatedly turning over the duck and roasting the duck till duck skin is golden in color; taking out the duck from the oven and moving the duck into a roast duck cooling chamber; and performing vacuum packaging after cooling. The roast duck prepared through the formulation has the advantages of good taste, moderate salty taste, tender delicious crisp meat, integration of color, aroma and taste, strong herbal aroma, effects of nourishing Yin, replenishing Qi, invigorating spleen and regulating stomach, and great benefit to human health.

Owner:秦玉环

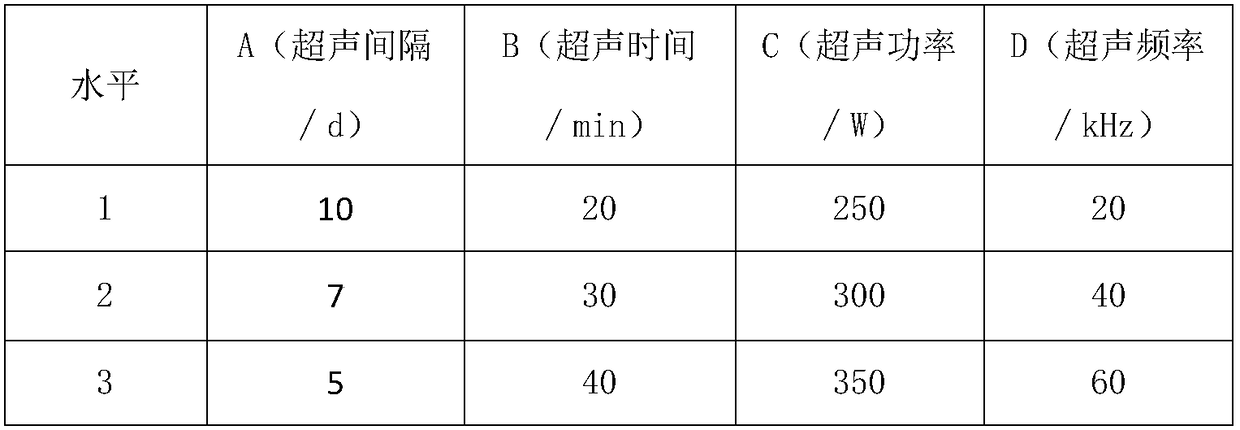

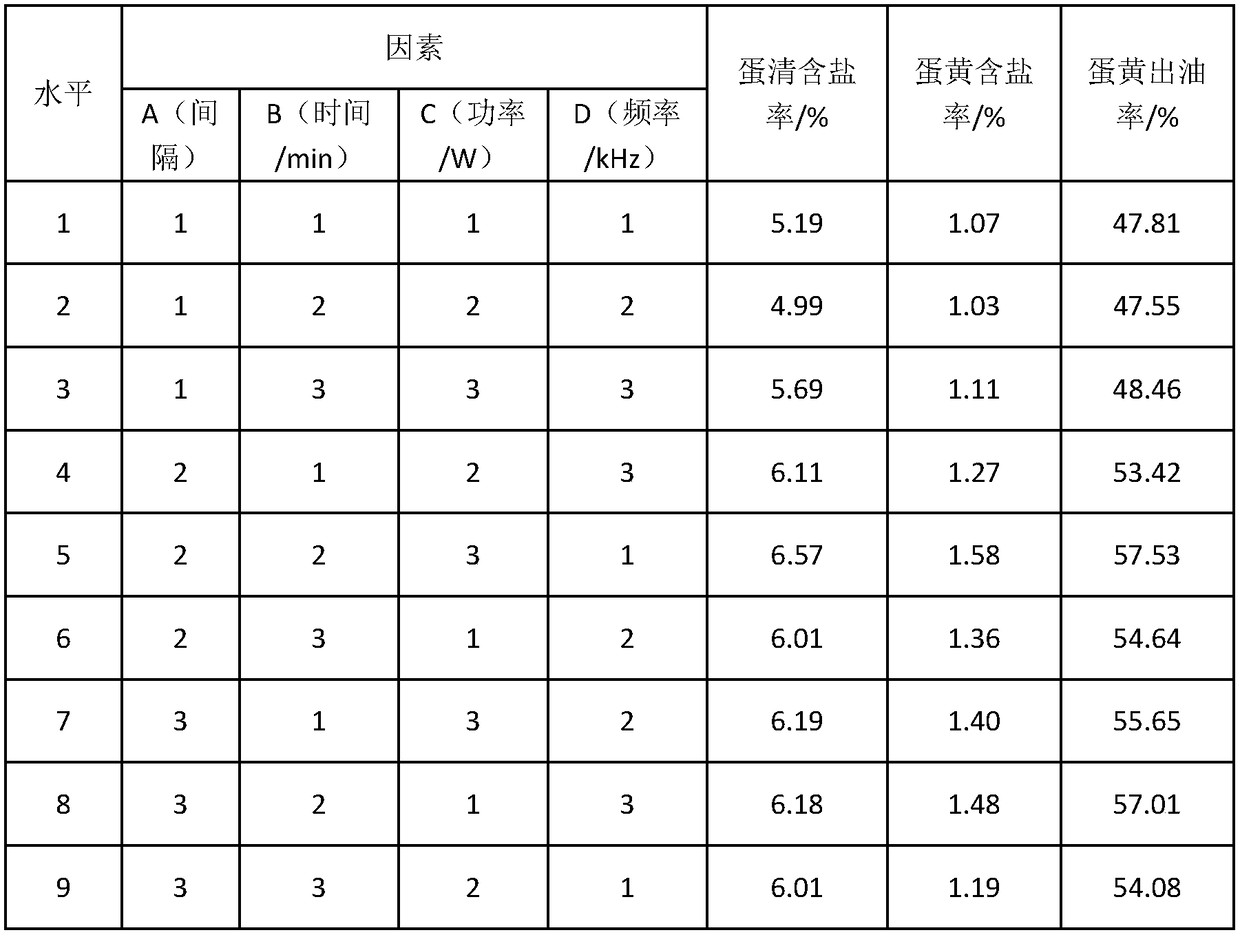

Intermittent ultrasonic assisted low-salt salted egg pickling technology

InactiveCN108634228AIncrease pickling ratePickling rate shortenedFood scienceUltrasonic assistedSalt content

The invention discloses an intermittent ultrasonic assisted low-salt salted egg pickling technology. Low-salt salted eggs can be obtained with the technology through pretreatment of duck eggs, pickling of duck eggs, desalting and cleaning. An ultrasonic technology is creatively used in assisting the salted egg pickling process, the table salt permeation rate is increased, the pickling period is shortened, the salted eggs can be well pickled within 15 days with the technology, and the pickling period is 20 days shorter than that in a traditional method. The well pickled salted eggs are placed in a 1% table salt solution to be desalted, the salt content of salted egg white can be decreased to 3.58% within 6 days, and the salinity is proper. In general, salted eggs with high oil yield and lowsalt can be pickled within 21 days.

Owner:HUAZHONG AGRI UNIV

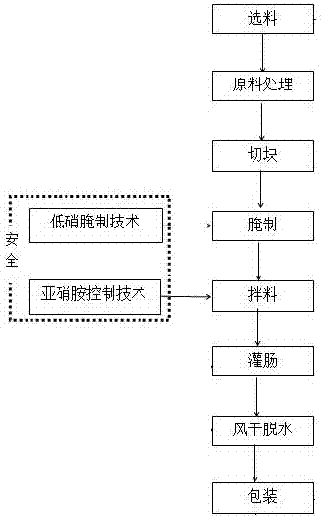

Processing technique for sausage

InactiveCN106858400AImprove quality and safetyAdd lessFood ingredient as taste affecting agentInorganic compound food ingredientsNitrite reductaseDewatering

The invention relates to a processing technique for sausage. The processing technique comprises the processes of selecting materials, treating raw materials, stripping and slicing, pickling, stirring, filling sausage, airing and dewatering and packaging. The pickling process comprises the following steps: adopting a vacuum low-nitrate pickling technique for pickling, placing the treated sausage raw materials into a vacuum pickling machine, and then adding a pickling mixed solution composed of nitrite, lactic acid bacteria and salt into the vacuum pickling machine and soaking the sausage raw materials into the pickling mixed solution. The stirring process comprises the following steps: adopting a vacuum nitrosamine control technique for stirring, namely, adding stirring additive into pickled meat paste, putting into a vacuum stirring machine for stirring, uniformly mixing the meat paste, and then adding 0.3-2wt% of nitrite reductase complex enzyme preparation into the mixed meat paste and uniformly stirring. The invention has the advantages that the processing technique for sausage can reduce the addition of the nitrite and can effectively reduce the nitrite residue in the sausage.

Owner:NANTONG YUTU GROUP

Production method of smoked preserved meat

InactiveCN107927614AExtended shelf lifeQuality assuranceGas treatmentClimate change adaptationGARLIC POWDERFood flavor

The invention discloses a production method of smoked preserved meat and relates to the technical field of food processing. The production method comprises steps of selection and pretreatment of raw materials, pickling, roasting, smoking and the like, wherein pickling material is prepared from raw materials as follows: ginger powder, garlic powder, bay leaf powder, cinnamon powder, fennel powder,a clove extract, a lemongrass extract, dark soy sauce and baijiu; and during smoking, a screen is arranged over a stove of a smoking room, gauze is laid on the screen, and a layer of adsorbent prepared from activated clay and shaddock peel is scattered on the gauze. The expiration date of the preserved meat can be prolonged and the quality of the preserved meat can be guaranteed under the condition that no preservatives are added, the content of cancerogens in the preserved meat can be decreased, and the eating safety can be improved. The preserved meat product has bright color, is yellow withred, tastes mellow and not greasy, has the unique flavor, tastes fine, has moderate saline taste and has special smoking aroma of traditional preserved meat and aroma of preserved meat.

Owner:柳州市象行教育科技有限责任公司

Processing method of salt roasted chicken

ActiveCN103478757AWith tasteBright yellow colorClimate change adaptationFood preparationFlavorRoast chicken

The invention discloses a processing method of salt roasted chicken. The method comprises the following steps: (1) blending marinating liquid, namely adding spices into water, boiling, and adding table salt to prepare the special marinating liquid for processing the salt roasted chicken; (2) preparing broiler chicken, namely adopting a three-pipe killing method to kill live chicken and eviscerating the chicken while keeping the integrity of the broiler chicken; (3) marinating, namely hanging the broiler chicken, heating the marinating liquid in a stainless steel tank, immersing the hung broiler chicken into the marinating liquid for marinating, lifting out the marinated broiler chicken and drying the marinating liquid on the surface of the chicken by blowing; (4) cooling and packaging, namely cooling the salt roasted chicken treated by the step (3) and packaging by a food preservation bag; and (5) storing, namely carrying out low-temperature cold storage on the packaged salt roasted chicken. The salt roasted chicken obtained by a marinating method has bright yellow color and luster, a prominent flavor and moderate salinity, and has the mouth feel, flavor, color and luster of salt roasted chicken produced by a traditional salt roasting method; standardized scale processing can also be realized.

Owner:SERICULTURE & AGRI FOOD RES INST GUANGDONG ACAD OF AGRI SCI

Method for processing half-dried sea bass conditioning food

The invention discloses a method for processing half-dried sea bass conditioning food. The method comprises the following steps: (1) pretreating; (2) slightly pickling; (3) preparing a seasoning liquid; (4) conditioning the taste; and (5) drying and packaging. The half-dried sea bass conditioning food processed by using the method is good in taste, compact in meat structure, free of fishy smell, rich in tea fragrance flavor and can be preserved for more than half a year at a low temperature.

Owner:SOUTH CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

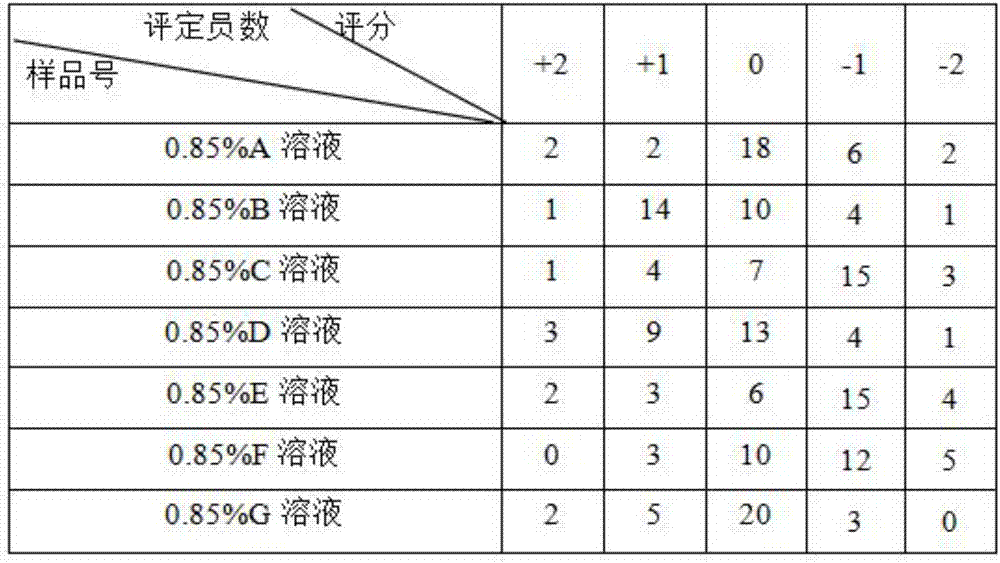

Compound low sodium salt and preparation method thereof

PendingCN107156773ADoes not affect saltinessSavory GuaranteedFood ingredient as taste affecting agentFood shapingRaw materialCalcium

The present invention provides a preparation method of compound low sodium salt. The preparation method comprises the following steps: firstly, potassium chloride, a flavor masking agent and maltodextrin are mixed to obtain flavor masked potassium chloride; then the obtained flavor masked potassium chloride is mixed with calcium source, amino acids, sodium glutamate and sodium chloride to obtain the compound low sodium salt; and wherein the amino acids comprise alanine and uses amounts of each of the raw materials are defined. Firstly, the potassium chloride is mixed with the flavor masking agent and maltodextrin. Under a function of the flavor masking agent carrier of the maltodextrin, the maltodextrin is combined with the flavor masking agent. The flavor masking agent realizes a masking of a bitter mouthfeel of the potassium chloride, is then combined with the calcium source, amino acids, sodium glutamate and sodium chloride, effectively avoids the masking of the own salty taste of the sodium chloride, ensures the salty taste of the added sodium chloride, effectively lowers sodium chloride content and at the same time ensures the salty taste of the sodium chloride.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Method of making spicy and crispy meat slice using venison and deer glue

The invention relates to a method of producing tasty and crispy meat slices with deer meat and deer-horn glue. The invention belongs to the meat processing technology field and solves the technical problems of strong fishy smell, hard meat, hard chewing and flavorless taste which greatly affect the products of deer meat and deer-horn glue. The invention removes the fishy smell of the deer meat and the deer-horn glue by the condiments, sugar, salt and alcohol and makes the deer meat and the deer-horn glue into the tasty and crispy meat slices which are rich in nutrient, tasty and delicious and easy to be stored. The meat slices have the functions of enhancing the immune ability, invigorating qi and strengthening the five organs. The tasty and crispy meat slices of the deer meat and the deer-horn glue of the invention have special favor, are convenient in eating, tasty and delicious and easy to be stored, which can not only enhance the human body immune ability, improve human health but also enhance the added value of byproduct of the deer and promote the application of the deer meat food and the development of the deer breeding industry.

Owner:王有为

Flavor-improved salted goose egg yolk

The invention discloses flavor-improved salted goose egg yolk which comprises the following raw materials: goose egg yolk, food-grade ethyl acetate, a food-grade osmotic pressure regulator, food-grade acetic acid, food-grade ethanol, a food-grade antioxidant and edible salt. The flavor-improved salted goose egg yolk is prepared by the following steps: separating egg white from egg yolk of a goose egg of which the production time is within 2d; adding flavor substances to the egg yolk, carrying out ultrasonic pretreatment, and then carrying out heating-cooling pretreatment; adding and completely soaking the egg yolk into an isotonic pickling liquid; adding the edible salt many times to enable the pickling liquid to have certain gradient concentration; pickling the egg yolk for a certain time; and after curing at 70 DEG C, removing the flavor in vacuum so as to obtain the flavor-improved salted goose egg yolk. The flavor-improved salted goose egg yolk disclosed by the invention has the characteristics of large size, fresh flavor, small smell, fineness, moderate salty taste and more egg yolk oil; and the production process is simple and convenient in technology, low in usage amount of table salt, low in energy consumption, more friendly to the environment, and more likely to realize industrial production.

Owner:马述腾

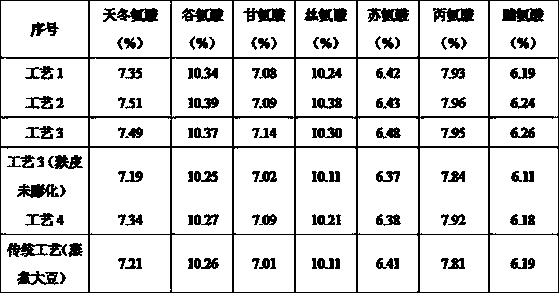

Method for brewing soy sauce through puffing soybeans

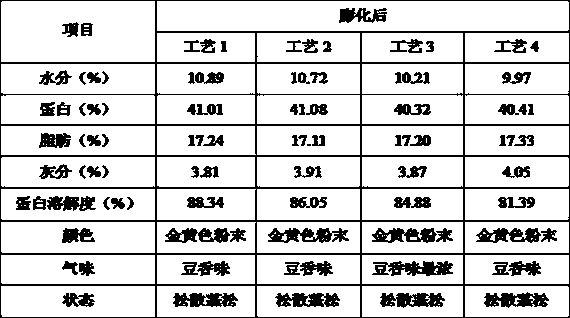

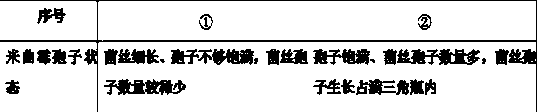

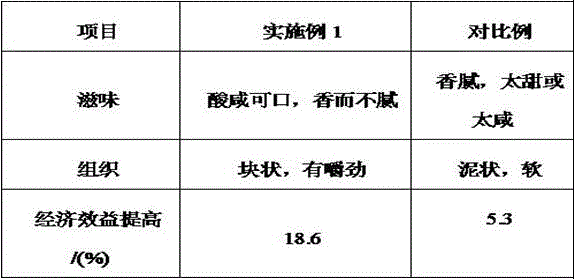

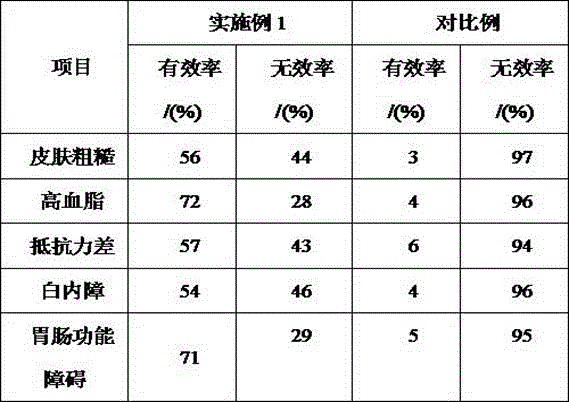

The invention provides a method for brewing a soy sauce through puffing soybeans. The method comprises the steps of pretreating raw materials: performing dust removal and impurity removal on soybeans,cleaning the soybeans after dust removal and impurity removal, crushing the cleaned soybeans to obtain bean granules, performing dust removal and impurity removal on bran, and cleaning the bran afterdust removal and impurity removal; puffing the raw materials: puffing the bean granules and the bran; preparing mother culture: weighing the puffed bran, flour and water, uniformly mixing the weighedbran with the weighed flour and the weighed water in the mass ratio of the weighed bran to the weighed flour to the weighed water being 4 to 1 to 4, performing sterilization, performing inoculation with aspergillus oryzae spores, and performing culturing until the mother culture is mature; preparing finished culture: weighing the puffed bean granules, the flour, the puffed bran and distilled water, uniformly mixing the weighed puffed bean granules with the weighed flour, the weighed puffed bran and the weighed distilled water in the mass ratio of the weighed puffed bean granules to the weighed flour, to the weighed puffed bran to the weighed distilled water being 20 to 16 to 1 to 16, performing sterilization, performing scattering, performing inoculation with mature mother culture havingthe same mass, and performing culturing until materials are covered with peak green spores so that finished culture is obtained; and preparing undecanted wine and performing fermentation: uniformly mixing the finished culture with salt water in the volume ratio of the finished culture to the salt water being 1 to 1.7, performing loading into a jar, and performing fermentation. Compared with a traditional technology, the method for brewing a soy sauce through puffing soybeans provided by the invention has the advantages that the time for brewing the soy sauce is shortened, the utilization rateof protein and the yield rate of the soy sauce can be increased, and the soy sauce is outstanding in palatable taste and unique in flavor and has scorch aroma compared with finished products in the prior art.

Owner:HENAN SHENNONG FEED TECH CO LTD

Fermented chrysanthemum sauce

InactiveCN106387842AFull of nutritionRetain nutritionYeast food ingredientsFood ingredient as taste affecting agentVegetable oilZantedeschia aethiopica

The present invention relates to the field of food processing and discloses a fermented chrysanthemum sauce. The fermented chrysanthemum sauce is prepared from the following raw materials: chrysanthemum, jasmine flowers, lily flowers, zantedeschia aethiopica, chrysanthemum leaves, wheat flour, chrysanthemum roots, chili leaves, dandelions, common sage herbs, xylooligosaccharide, vegetable oil, edible salt, Angel branded aroma enhancing yeasts, lactic acid bacteria, spices and cellulase. The provided fermented chrysanthemum sauce is rich in nutrition, bright in color and luster, harmonious in fragrance, sour, salty and tasty, fragrant but not greasy, and convenient in consumption. The flowers and leaves are subjected to a low-temperature drying, the colors of the flowers can be maintained, the nutrition is maintained, and the flexibility is increased. After twice fermentation, the fermented chrysanthemum sauce is slightly sour and refreshing, and harmonious in fragrance, and can protect the gastrointestinal functions. The flowers and leaves are wrapped using flour, so that the chewiness is increased and the sauce body is richer. The sauce body is rich in unsaturated fat content and moderate in salinity, the high-sugar, high-salt and high-fat characteristics of the traditional sauce body are changed, and the fermented chrysanthemum sauce is nutritional and healthy and protects heart and cerebral vessels. By adding the chrysanthemum, chrysanthemum leaves and chrysanthemum roots, the chrysanthemum plants are fully used and farmers' income is increased by 18.6%.

Owner:安徽国丰农业科技发展有限公司

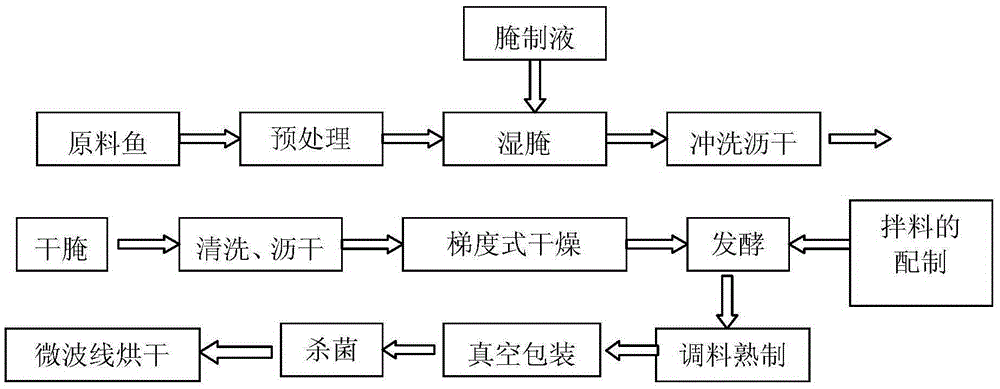

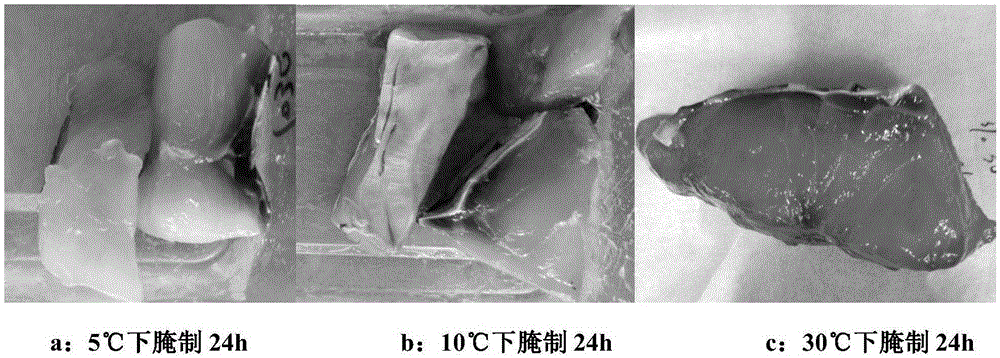

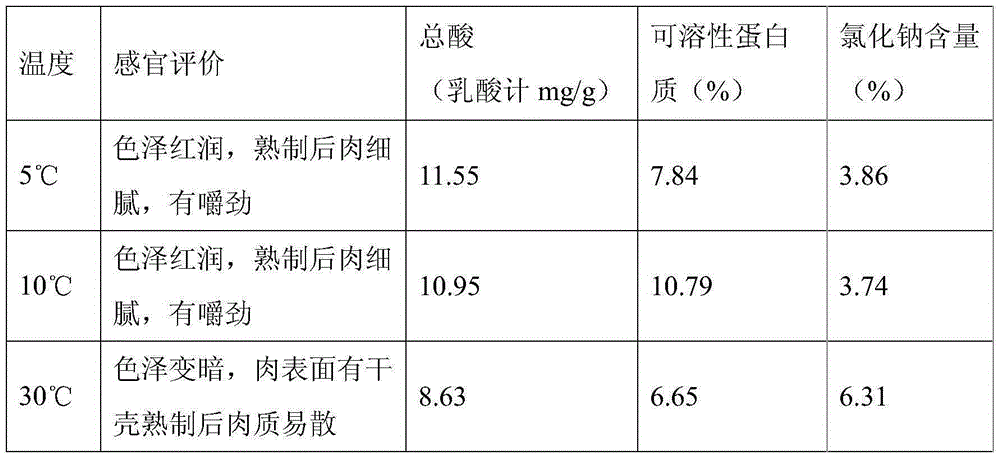

Solid-state fermentation pickled fishes and preparation method thereof

The invention discloses a preparation method of solid-state fermentation pickled fishes. The preparation method comprises the following steps of taking fresh fish blocks, and putting the taken fish blocks into pickling liquid for wet pickling so as to obtain primary pickled fish blocks; taking out the primary pickled fish blocks for dry pickling so as to obtain secondary pickled fish blocks; performing gradient type multistage drying on the secondary pickled fish blocks until the water content of the fish blocks reaches 45-55% so as to obtain dried fish blocks; and mixing the dried fish blocks with seasoning, and then performing sealed fermentation so as to fermentation pickled fishes. The ready-to-eat solid-state fermentation pickled fishes are rich in nutrition, low in salt content, free from fishy taste, rich in fermented flavor, fine and smooth in meat quality, rich in chewiness, and good in mouth feel, and conforms to the eating style of modern people.

Owner:HUNAN AGRI PRODS PROCESSING INST

Processing method of preserved meat

InactiveCN107801929AReduce pollutionQuality assuranceFood ingredient as antioxidantNatural extract food ingredientsSalty tasteLean meat

The invention discloses a processing method of preserved meat, and relates to the technical field of food processing. The processing method comprises the following steps of pretreating raw material meat, preparing a preserving material, performing preserving, performing baking, performing smoking and the like, wherein the preserving material is prepared through the steps of grinding Chinese prickly ash, star aniseeds, Chinese cinnamon and licorice roots into powder, and uniformly mixing the powder with a dandelion extract, a grape seed extract, an aloe extract, ginger juice, table salt, brownsugar juice, Baijiu and sodium nitrate. The dandelion extract, the grape seed extract, the aloe extract and the ginger juice are added to the preserving material, so that the pollution of microorganisms in the preserving process of the preserved meat can be reduced, the quality of the preserved meat is guaranteed, the content of nitrites in the preserved meat can also be reduced, the eating safetyis improved, the residual quantity of nitrites in the prepared preserved meat is 7.6-12.1mg / kg, and the preserved meat is bright yellow in fat meat, red brown in lean meat, mellow in preserving taste, fine and smooth in mouth feel, moderate in salty taste and unique in flavor, and has special smoking fragrance of conventional preserved meat and the fragrance of the preserved meat.

Owner:恭城福茂生油茶文化产业发展有限公司

Method for preparing pickles

The invention discloses a method for preparing pickles. The method comprises the following steps of: (1) preparation of sweet flour paste juice: taking 1 weight part of flour, 1.15 to 1.3 weight parts of water, 0.1 to 0.2 weight part of soybean yeast or edible bean pulp, 0.025 to 0.04 weight part of edible alcohol and 0.015 to 0.025 weight part of salt, liquefying the flour by using alpha-amylase, then saccharifying the flour by using saccharifying enzyme, adding the soybean yeast or the edible bean pulp, the edible alcohol and the salt into the flour at the same time, stirring the mixture uniformly and fermenting the mixture for 10 to 20 days at the temperature of between 38 and 47 DEG C to form fermented paste, filter-pressing the fermented paste, and taking the juice, namely the sweet flour paste juice; and (2) preparation of the pickles: salting vegetables, cutting the vegetables and then desalting and dehydrating the vegetables, saucing the vegetables into the twice-used sweet flour paste juice for 24 hours, extruding the vegetables, then saucing the vegetables into the once-used sweet flour paste juice for 24 hours, extruding the vegetables again, and saucing the vegetables into the unused fresh sweet flour paste juice for 24 to 48 hours. The method has the advantages of short period, small floor area, low production cost, sanitation and reliability.

Owner:HEBEI BAODING HUAIMAO

Method for curing spiced eggs

The invention relates to a method for curing spiced eggs, and belongs to the technical field of curing salted duck eggs. The method comprises the following steps: classifying superior fresh duck eggs which are selected according to cured requirements into four grades of under 60 grams, 61-70 grams, 71-80 grams and more than 80 grams, separately placing the classified fresh duck eggs, cleaning, disinfecting and airing the selected superior fresh duck eggs, putting the aired superior fresh duck eggs into soaking liquid which is compounded by mineral water, Chinese prickly ash, anise, netmeg, alpinia katsumsdai, cloves, refined table salt and straw ash, wherein the weight ratio of the mineral water, the Chinese prickly ash, the anise, the netmeg, the alpinia katsumsdai, the cloves, the refined table salt and the straw ash is 1000:2:1:2:2:1:200:10, and curing the fresh duck eggs for 40-46 days in a curing room at the temperature of 16-21 DEG C. The cured salted duck eggs by the method disclosed by the invention have the advantages that the salty taste is moderate, the fragrance is rich, the appearance is mellow and smooth, the egg whites are milky, the texture is fine and smooth, the yolks are reddish and oily, hard cores are not generated in the middle of the yolks, the cured salted duck eggs have six fresh, fine, tender, spongy,sandy and oily characteristics, and the mouth feel of the cured salted duck eggs are good.

Owner:石礼芹

Method for pickling poultry eggs

The invention discloses a method for pickling poultry eggs, and belongs to the field of food processing. At present, a large amount of salt generally needs to be added in a pickling process to preventduck eggs from going bad and increase the oil yield of egg yolk in a salted duck egg pickling process, thus egg white of pickled duck eggs is excessively salty, and the salt content of one salted duck egg is much more than average daily salt intake of a person. Long-term high salt intake is a cause of diseases such as hypertension and gastric mucosa damage. Through adoption of the method, the defects that the flavor of the duck eggs is influenced and the pickled duck eggs are bad to a human body since the egg white is excessively salty due to adding of excessive table salt in the duck egg pickling process in the prior art are overcome. The invention provides a duck egg pickling method.

Owner:房县味味食品有限公司

Production technology of salted duck eggs

The invention discloses a production technology of salted duck eggs. The technology comprises the following steps of firstly detecting the moisture content and the fresh degree of fresh duck eggs in each batch, and then performing classification, light inspection and tapping selection so as to obtain 5 kinds of duck eggs of different weight classes, namely top-class duck eggs, first-class duck eggs, second-class duck eggs, third-class duck eggs and fourth-class duck eggs; and separately pickling the 5 kinds of duck eggs of different weight classes in different rooms according to different weight classes, wherein the consumption quantity of salt for pickling the duck eggs of the lowest weight class is 1.2-2.0g for each duck egg, the difference between the consumption quantity of the salt for pickling the duck eggs of the lower weight class and the consumption quantity of the salt for pickling the duck eggs of the adjacent weight class is 0.1-0.5g, and the pickling time is 60 days or above. The prepared salted duck eggs are moderate in saline taste and not high in salt content; salted duck egg cores can generate sandy particles, can be bright and generate oil, and are good in mouth feel.

Owner:SICHUAN FUTAI FOOD CO LTD

Pickled Chinese artichoke

The invention relates to a pickled vegetable, in particular to pickled Chinese artichoke. The pickled Chinese artichoke comprises the following components in part by weight: 100 parts of Chinese artichoke, 20 parts of soy and 50 parts of sweet sauce. The pickled Chinese artichoke, produced by the formula and the method, has the benefits of bright color, sweet taste, proper salinity and crisp flavor, and is suitable for people of all ages; the method is simple, and is easy to operate; and the pickled Chinese artichoke is suitable for both family production and industrial production, and improves use channels of the Chinese artichoke.

Owner:山东武定府酿造有限公司

Instant mushroom-flavored drunken-fish can and preparation method thereof

The invention discloses an instant mushroom-flavored drunken-fish can and a preparation method thereof. The instant mushroom-flavored drunken-fish can is prepared from the following raw materials in parts by weight: 35-45 parts of dried mushrooms, 45-60 parts of drunken fishes, 30-50 parts of pickled peppers, 20-30 parts of fresh ginger juice, 3-5 parts of white sugar, 10-20 parts of carrots, 10-20 parts of tender bamboo-shoot tips, 7-12 parts of soybean sauce, 3-8 parts of salt, 5-10 parts of edible oil, 30-50 parts of corns and 27-35 parts of milk. The preparation method comprises the following steps: processing the drunken fish, making pulp, brewing the pulp in a boiler and hot-packaging the brewed pulp. The instant mushroom-flavored drunken-fish can disclosed by the invention has the characteristics of appropriate salty flavor, fresh and tender texture, strong aroma, rich nutrition and chewy taste. The preparation method of the instant mushroom-flavored drunken-fish can is easy to operate, convenient to prepare, low in cost, small in environment pollution and suitable for industrial mass production.

Owner:XIHUA UNIV

Soup blend formula of crisp-fried roasted duck

The invention relates to a formula for roasting fowls, and discloses a soup blend formula of a crisp-fried roasted duck. The main soup blend formula of the crisp-fried roasted duck comprises an eviscerated duck, aucklandia and amomum fruits, star anise, tsaoko amomum fruits, hawthorn, fennel fruits, pricklyash peels, dahurian angelica roots, villous amomum fruits, sarcocarp, cassia barks, licorice, barbary wolfberry fruits, cardamom, clove, ginger, hot pepper, white sugar, honey and black felt hat wine. The roasted duck prepared according to the formula has a good mouthfeel, a moderate salted taste, subtle and crisp meat, perfect combination of color, smell and taste, thick medicinal flavor, has the effects of supplementing qi and nourishing yin, and strengthening the spleen and stomach, and is very beneficial for human body health.

Owner:秦玉环

Sinonovacula constricta flavoured sauce and preparation method thereof

The invention discloses a sinonovacula constricta flavoured sauce and a preparation method of the sinonovacula constricta flavoured sauce. The sinonovacula constricta flavoured sauce is characterized by mainly comprising the following raw materials in parts by weight: 30-40 parts of sinonovacula constricta muddy flesh, 12-16 parts of wheat starch, 1-2 parts of mashed onion, 6-8 parts of table salt, 3-6 parts of soybean sauce, 3-6 parts of white granulated sugar, 3-5 parts of white vinegar and 0.5-2 parts of rattan pepper, wherein the sinonovacula constricta muddy flesh is obtained by subjecting sinonovacula constricta flesh to enzymolysis by flavourzyme for 3-4 hours and the weight ratio of the flavourzyme to the sinonovacula constricta flesh is 0.04-0.06g to 100g. The sinonovacula constricta flavoured sauce has the advantages of unique sinonovacula constricta flavour, delicious taste, uniform texture, simplicity in processing technique and long shelf life. In the preparation method disclosed by the invention, the sinonovacula constricta flesh is subjected to enzymolysis by flavourzyme for 3-5 hours at the temperature of 35-50 DEG C. Thus, the method is beneficial for the decomposition of the protein of sinonovacula constricta flesh and deliciousness is enhanced. In addition, unique sinonovacula constricta flavour is formed.

Owner:NINGBO UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com