Patents

Literature

80 results about "Nitrite reductase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

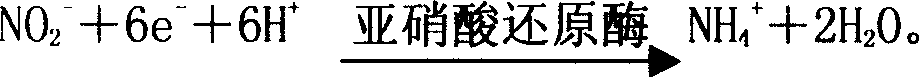

Nitrite reductase refers to any of several classes of enzymes that catalyze the reduction of nitrite. There are two classes of NIR's. A multi haem enzyme reduces NO₂⁻ to a variety of products. Copper containing enzymes carry out a single electron transfer to produce nitric oxide.

Reagent (kit) for diagnosing/determining amino acid and method for determining concentration of amino acid

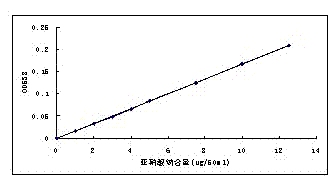

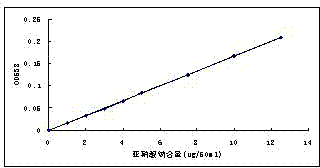

InactiveCN101750327AFast measurementImprove accuracyMicrobiological testing/measurementColor/spectral properties measurementsFerricytochrome cEnzymatic Colorimetry

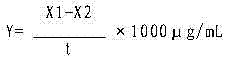

The invention relates to a reagent (kit) for diagnosing / determining amino acid by using an enzyme colorimetric method and an enzyme link method, and also discloses a method for determining the concentration of the amino acid, a composition and components of the reagent, belonging to the technical field of medicine / food / environmental test determination. The reagent (kit) comprises the main components: a buffer solution, a coenzyme, ferricytochrome C, calcium chloride (calcium salt), an amino acid oxidase, a nitrite reductase, a nitrate reductase and a stabilizing agent. A sample and the reagent are mixed according to a certain volume ratio to generate a series of enzymatic reactions, and reactants are placed under an ultraviolet / visible light analyzer for detecting the degree of absorbance rise at the dominant wavelength of 340 nm, thereby measuring and calculating the concentration of the amino acid.

Owner:SUZHOU ANJ BIOTECHNOLOGY CO LTD

Preparation method of nitrite reductase and enzyme product thereof

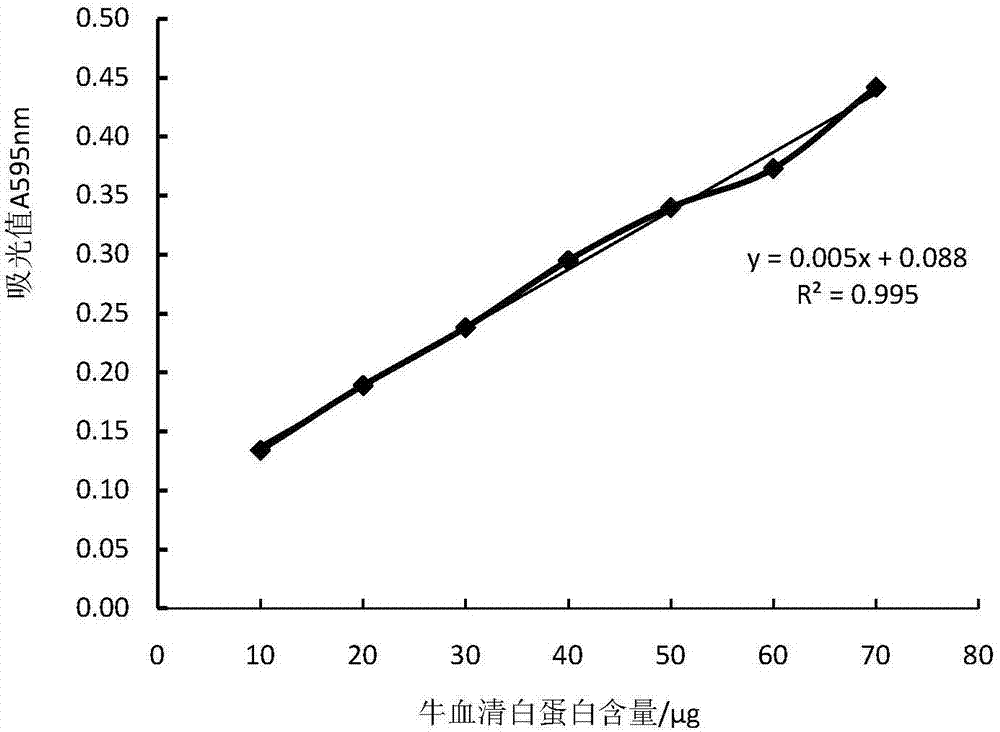

InactiveCN101597598AImprove stabilityImprove safety and qualityMicroorganism based processesAnimal feeding stuffFood poisoningSephadex gels

The invention discloses a preparation method of nitrite reductase, comprising the following steps: inoculating lactobacillus in a MRS culture medium to culture a first generation strain and then to culture a second generation strain; inoculating the second generation strain in a MRS fermentation culture medium to culture for 30-48h; adding sodium nitrite solution in the fermentation solution to culture for 16-32h; collecting precipitate; adding buffer solution in precipitate to fully suspend the fermentation liquor precipitate, adding lysozyme solution and treating the mixture by ultrasonication to obtain broken cell solution, collecting supernatant; filtrating the supernatant and collecting the filtrate; separating the filtrate with a sephadex chromatographic column to obtain precipitate, namely, nitrite reductase and adding 10-50% of starch in the precipitate to obtain the enzyme product. The enzyme preparation prepared by the method can be used to remove the residue of nitrite in food, feed and environment, improves the food safety and quality and prevents the poisoning, cancer and the like caused by nitrite.

Owner:SHANGHAI INST OF TECH

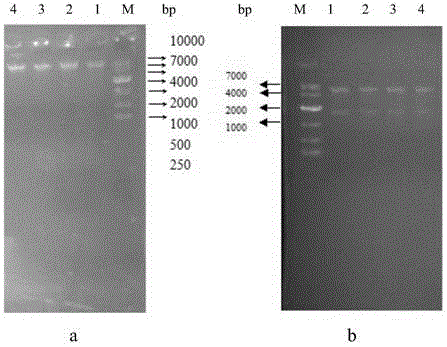

Assimilation nitrate reductase gene and assimilation nitrite reductase gene both extracted from bacillus megaterium as well as applications of assimilation nitrate reductase gene and assimilation nitrite reductase gene

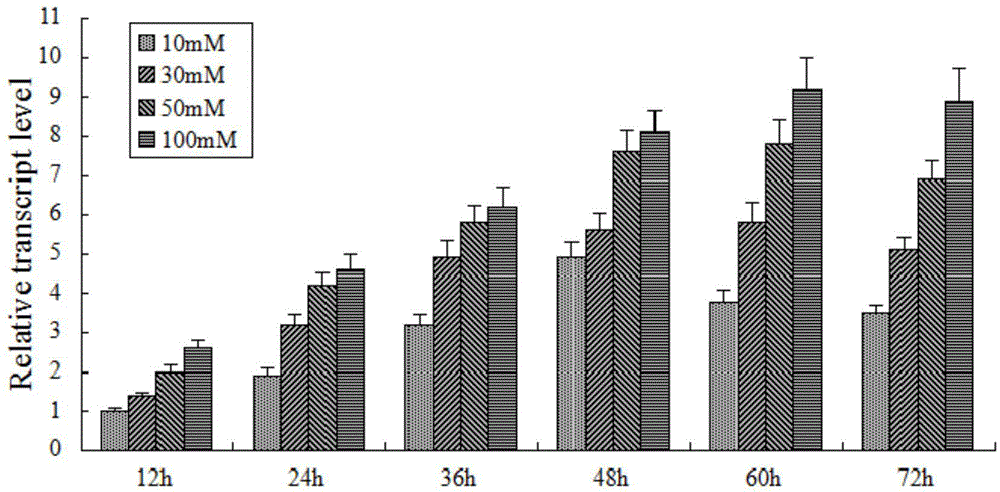

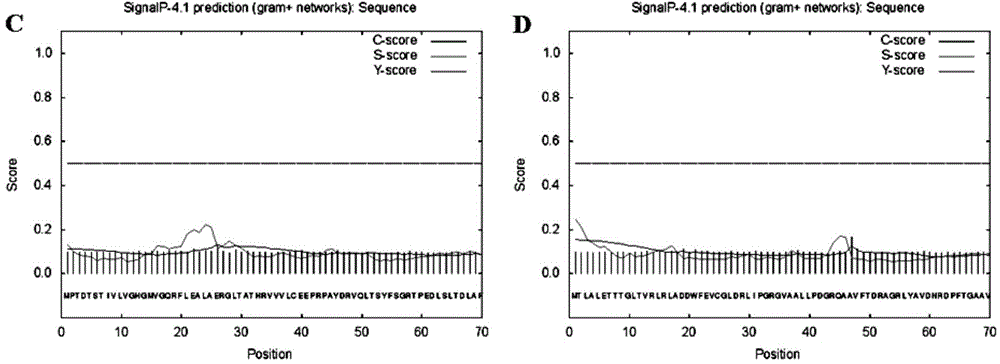

InactiveCN103725654ASolve the removal problemMicrobiological testing/measurementContaminated soil reclamationBacillus megateriumTotal rna

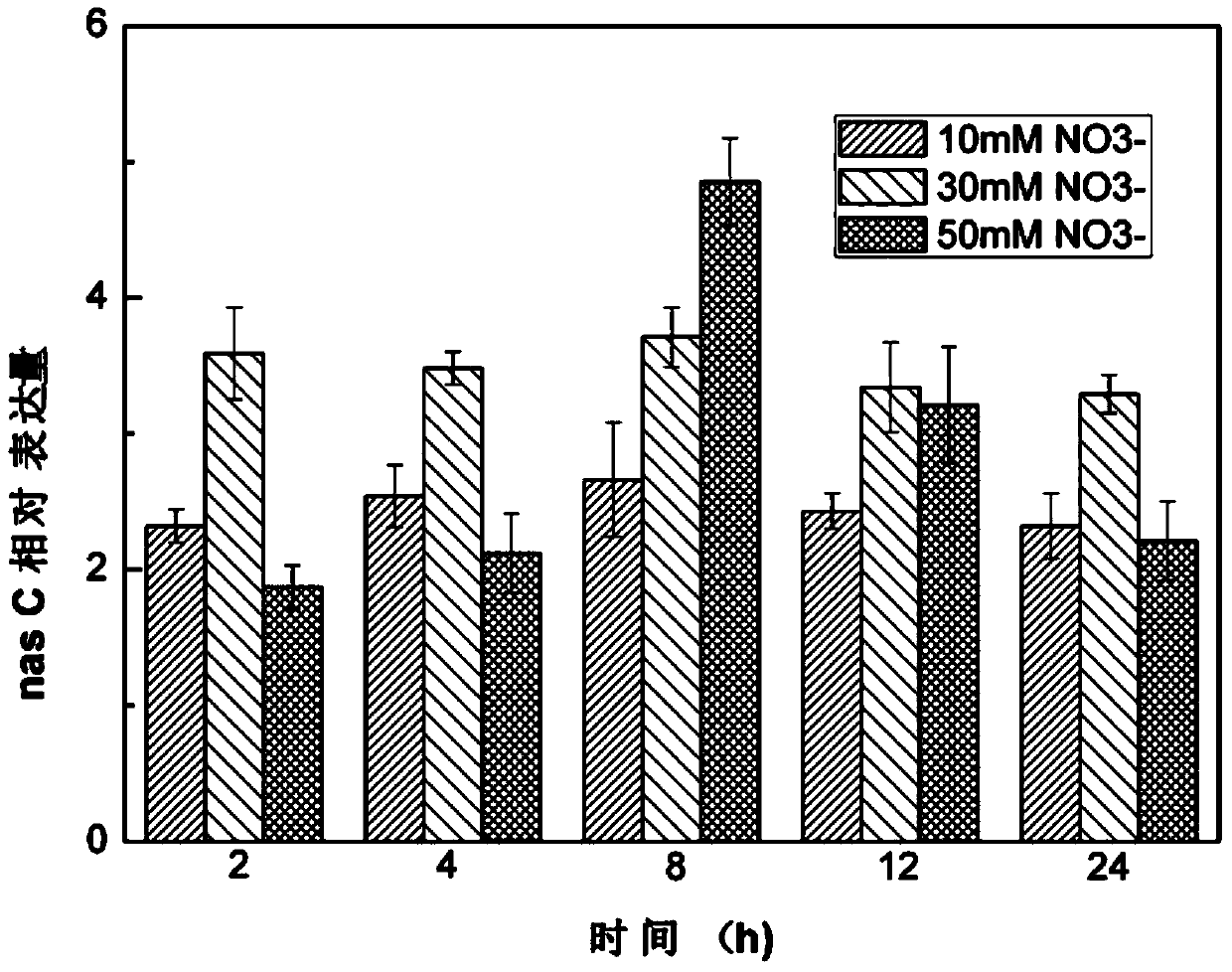

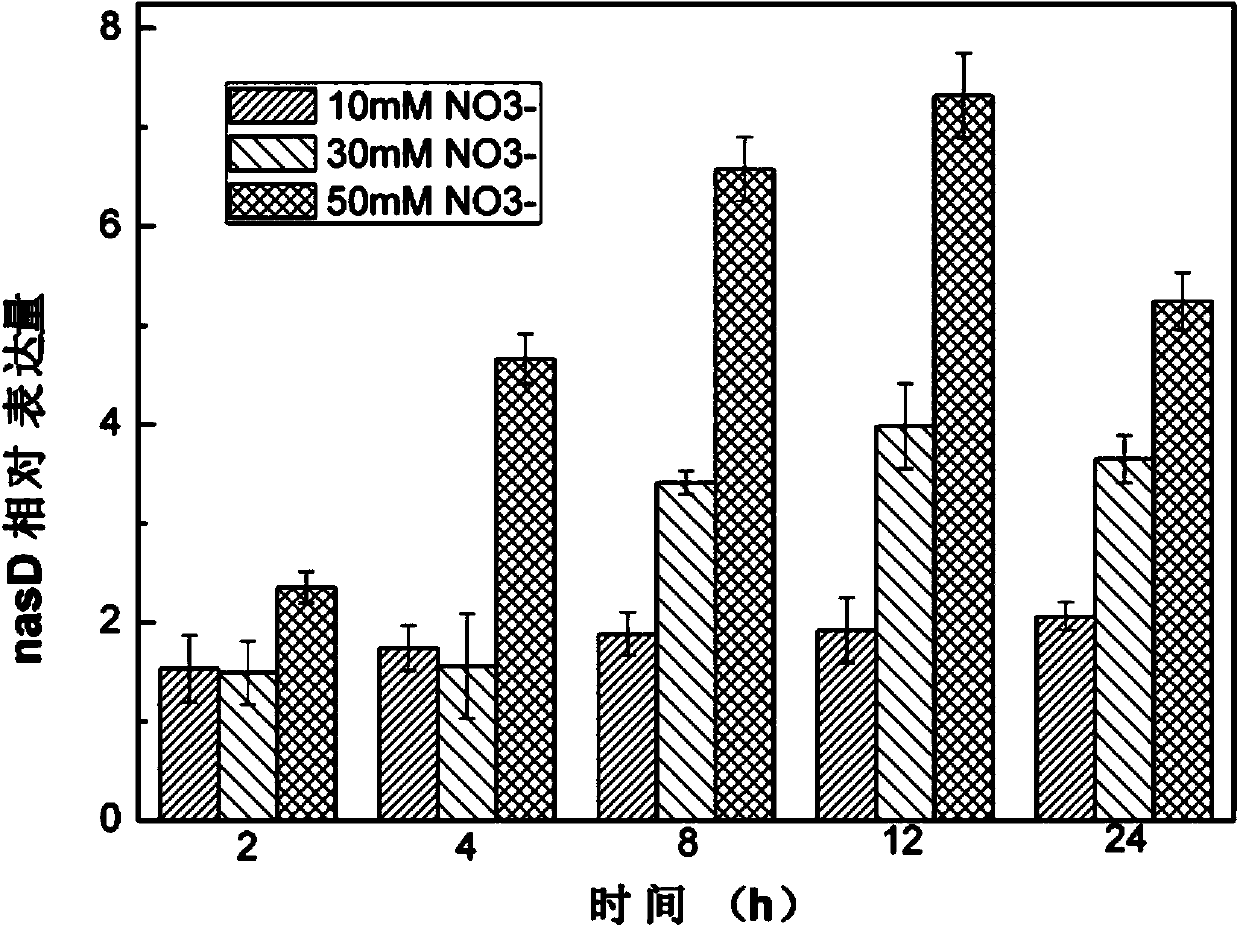

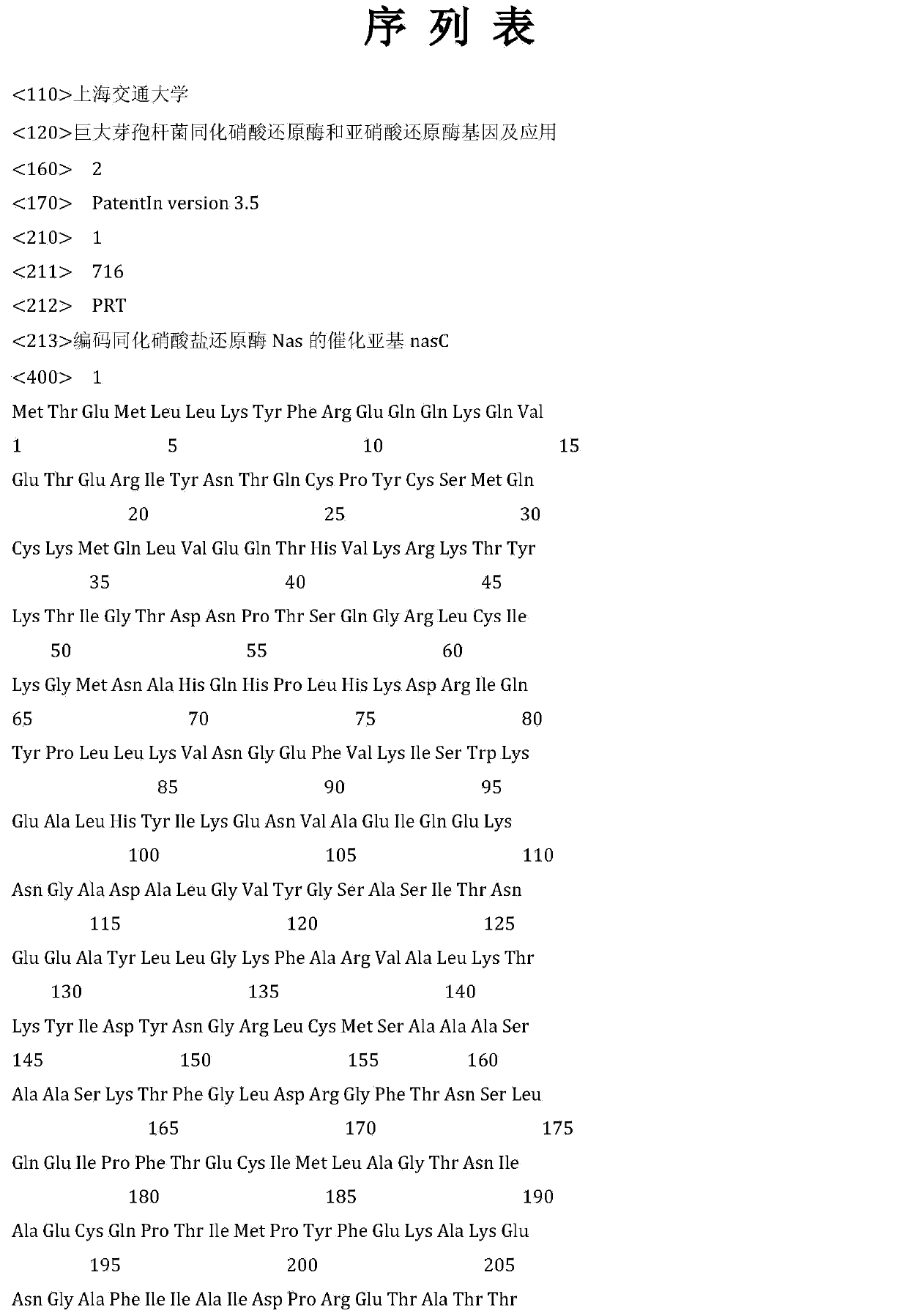

The invention discloses an assimilation nitrate reductase gene and an assimilation nitrite reductase gene both extracted from bacillus megaterium as well as applications of the assimilation nitrate reductase gene and the assimilation nitrite reductase gene, and relates to the field of the biotechnology. The assimilation nitrate reductase gene is catalytic subunit nasC (Seq ID No.1) which codes assimilation nitrate reductase Nas; the assimilation nitrite reductase gene is large subunit nasD (Seq ID No.2) which codes assimilation nitrite reductase NiR. According to the invention, total RNA is extracted from the bacillus megaterium NCT-2, then cDNA synthesis is conducted to obtain a cDNA template, and function representation is realized through fluorogenic quantitative PCR. The assimilation nitrate reductase gene and the nitrite reductase gene can be further applied to research on removal of overmuch nitrate from soil.

Owner:SHANGHAI JIAO TONG UNIV

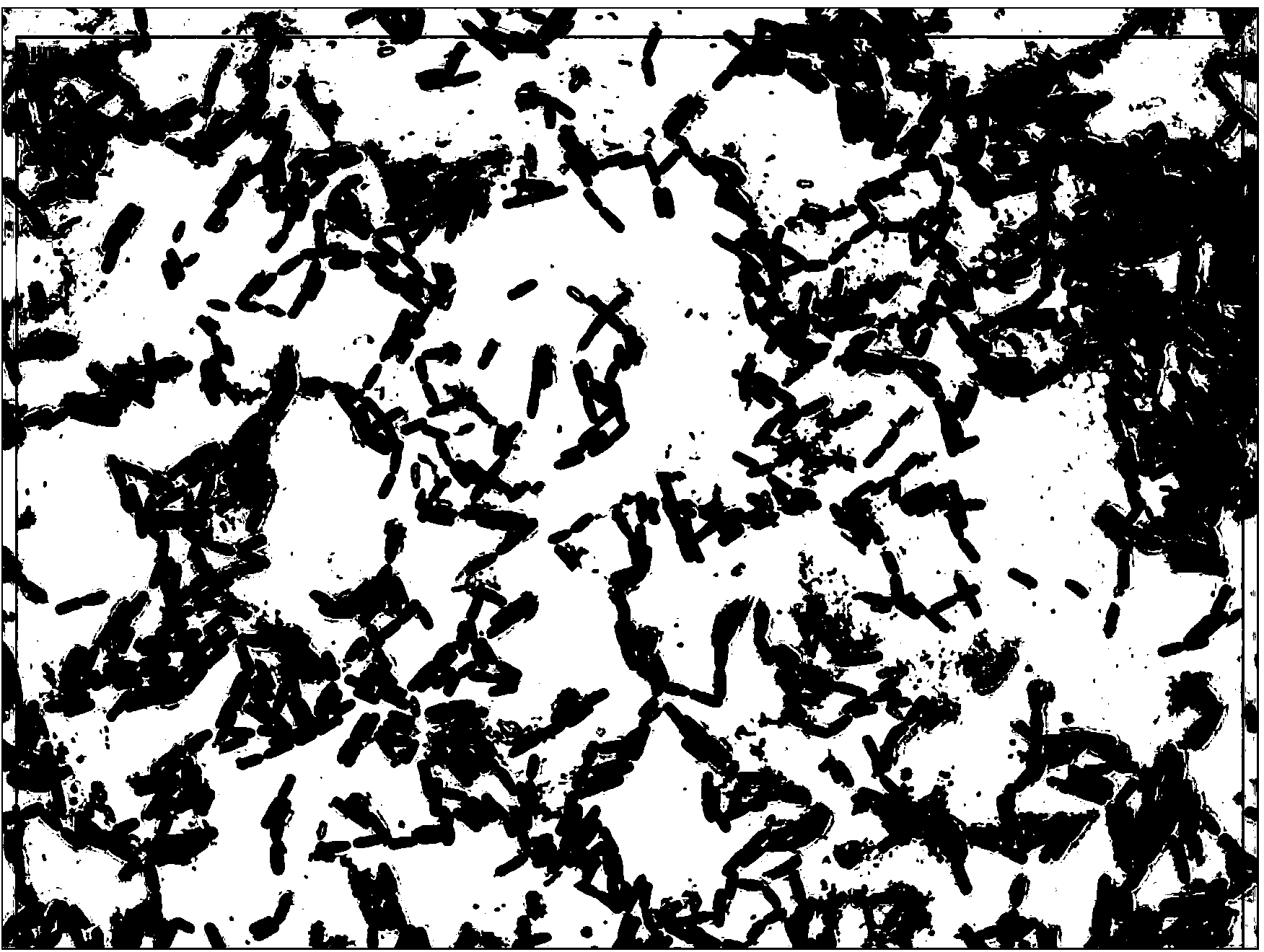

Bacillus cereus and application thereof to preparation of nitrite reductase

ActiveCN104212739AWide variety of sourcesFermented enzyme stableBacteriaMicroorganism based processesBacillus cereusHigh activity

The invention discloses a Bacillus cereus and application thereof to preparation of nitrite reductase. The Bacillus is isolated from thick broad-bean sauce, and is identified as Bacillus cereus LJ01, which has been preserved in China General Microbiological Culture Collection Center in June 19, 2014 and has a preservation number CGMCC No.9360. The strain LJ01 is used for the preparation of nitrite reductase (NiR); NiR extracted from Bacillus cereus LJ01 has high activity; and conditions for NiR to degrade nitrite are simple. The conditions disclosed by the invention can reduce NiR enzyme activity loss to obtain high purity NiR; and NiR provides a novel method for solving the problem of nitrite in three fields of fermented vegetables, meat products and aquaculture.

Owner:SOUTH CHINA UNIV OF TECH

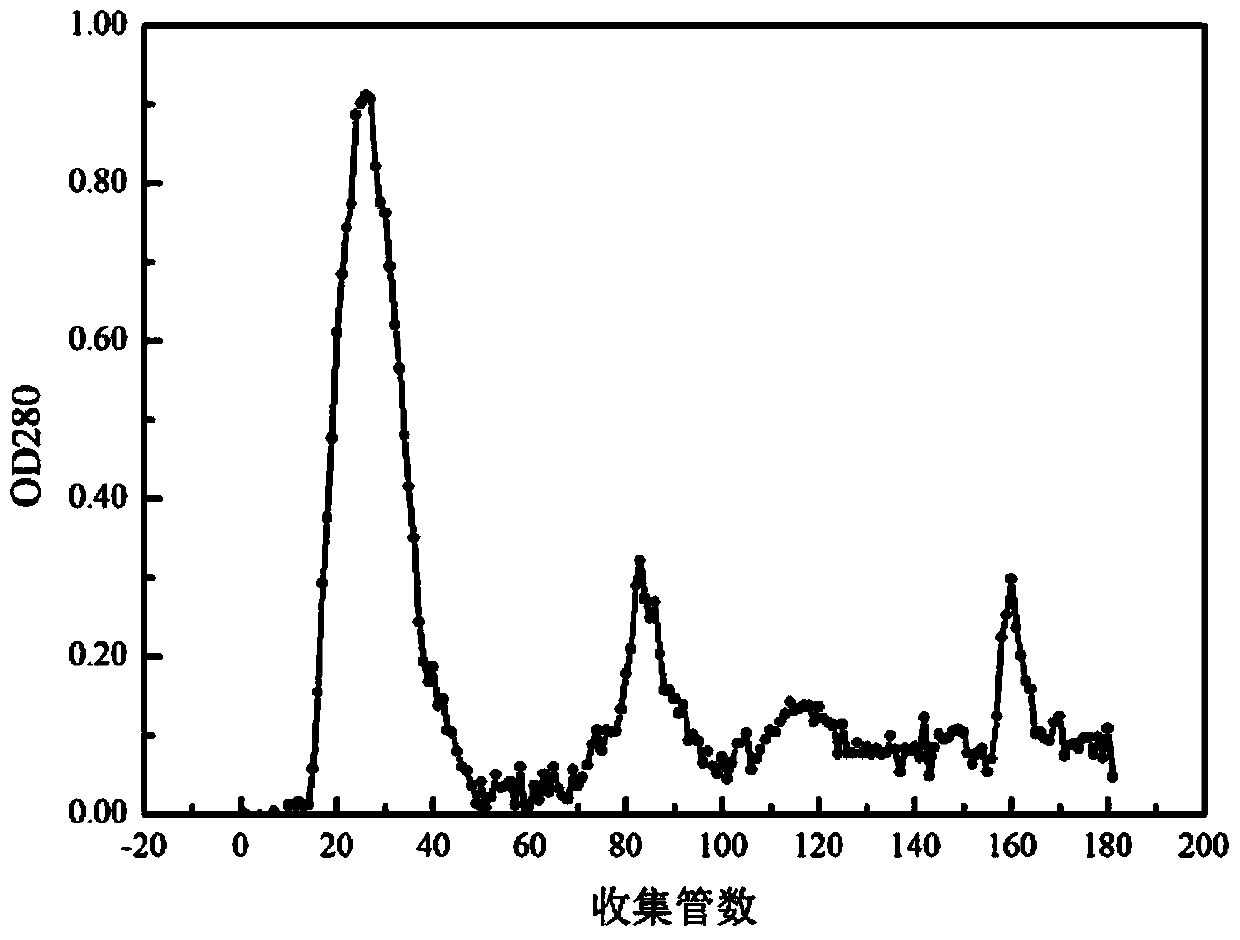

Preparation method of nitrite reductase of lactobacillus casei subsp rhamnosus

InactiveCN104212775AProduces stable NiRWide variety of sourcesMicroorganism based processesOxidoreductasesLactobacillus casei subsp rhamnosusNitrite reductase

The invention discloses a preparation method of nitrite reductase of lactobacillus casei subsp rhamnosus. The method comprises the following steps: firstly, carrying inductive culture of nitrite reductase on lactobacillus casei subsp rhamnosus 6013; adding an enzyme protective agent to extract coarse nitrite reductase when the wall is broken; after carrying out vacuum-freezing and drying, finally preparing pure nitrite reductase sequentially through anion exchange chromatography and / or sephadex chromatography. The activity of NiR extracted from lactobacillus casei subsp rhamnosus is high and the condition for degrading nitrite reductase by NiR is simple. According to the disclosed condition, the enzyme activity loss of NiR is less, and the obtained NiR is high in purity and can be used for solving problem of nitrite in three fields such as vegetable fermentation, meat products and aquatic water.

Owner:SOUTH CHINA UNIV OF TECH

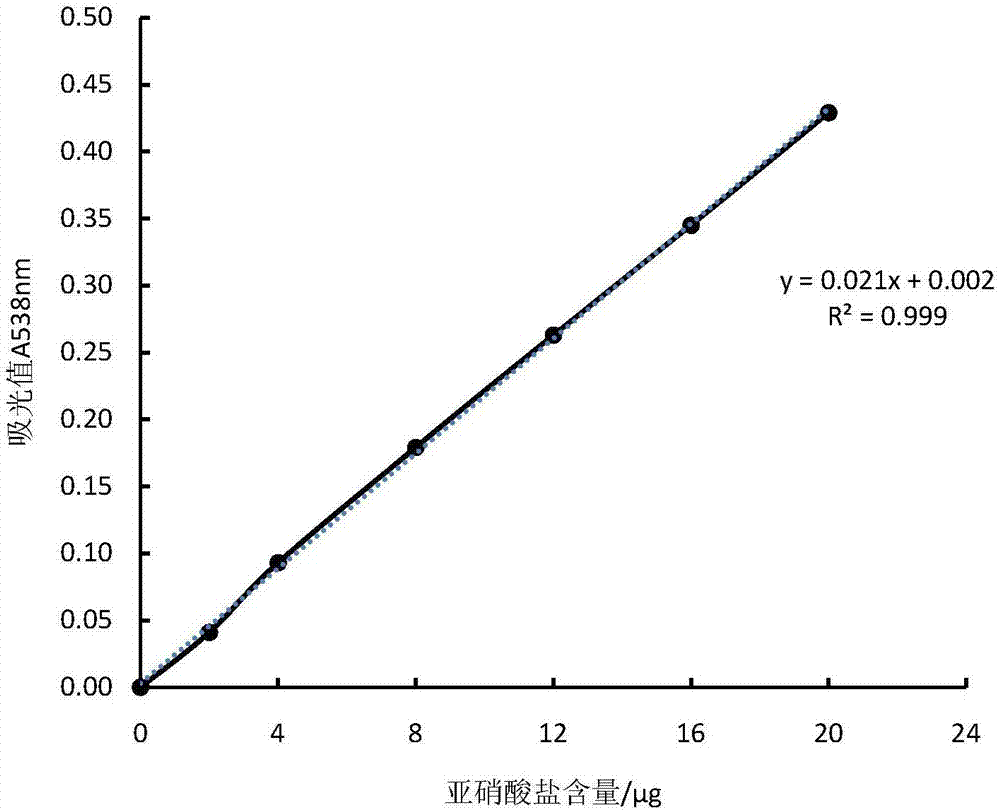

Method for degrading nitrites in foods

The invention discloses a method for degrading nitrites in foods. The method comprises the following steps of adding nitrite reductase in food sauce, performing standing for reaction for 6-12h at the temperature of 27-37 DEG C, then regulating a pH value with an organic acid to 2.0-5.5, and performing standing for reaction for 4-12h at the temperature of 20-37 DEG C, wherein a nitrite reductase gene is from edible bacteria. According to the method provided by the invention, by adopting a method for degrading sodium nitrite by adopting a crude enzyme solution firstly and then adopting the organic acid, and compared with a mode of singly using the organic acid or the nitrite reductase, the method has a good effect; the degradation rate of the sodium nitrite is calculated by determining the concentration of the nitrite in the system with a naphthylethylenediamine hydrochloride method to reach 90 percent or above; and the method can be used for degrading high-nitrite foods with a pH value larger than 5.0, such as pickles.

Owner:SOUTH CHINA UNIV OF TECH

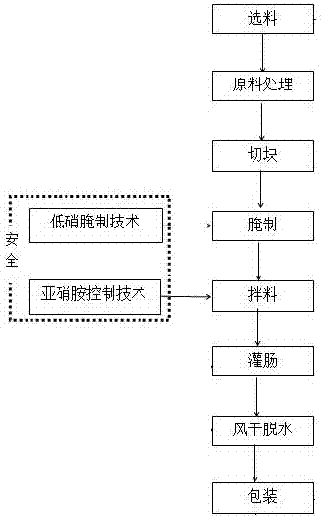

Processing technique for sausage

InactiveCN106858400AImprove quality and safetyAdd lessFood ingredient as taste affecting agentInorganic compound food ingredientsNitrite reductaseDewatering

The invention relates to a processing technique for sausage. The processing technique comprises the processes of selecting materials, treating raw materials, stripping and slicing, pickling, stirring, filling sausage, airing and dewatering and packaging. The pickling process comprises the following steps: adopting a vacuum low-nitrate pickling technique for pickling, placing the treated sausage raw materials into a vacuum pickling machine, and then adding a pickling mixed solution composed of nitrite, lactic acid bacteria and salt into the vacuum pickling machine and soaking the sausage raw materials into the pickling mixed solution. The stirring process comprises the following steps: adopting a vacuum nitrosamine control technique for stirring, namely, adding stirring additive into pickled meat paste, putting into a vacuum stirring machine for stirring, uniformly mixing the meat paste, and then adding 0.3-2wt% of nitrite reductase complex enzyme preparation into the mixed meat paste and uniformly stirring. The invention has the advantages that the processing technique for sausage can reduce the addition of the nitrite and can effectively reduce the nitrite residue in the sausage.

Owner:NANTONG YUTU GROUP

Preparation of nitrite reductase and method for preparing nitrite reductase preparation

InactiveCN101230337AHigh temperature resistantHave physical and mental healthMicroorganism based processesOxidoreductasesCulture fluidFood safety

The invention discloses a preparation method of preparing nitrite reductase and preparing the preparation of the nitrite reductase, which belongs to the preparing technology field of biologic enzyme and enzyme preparation. Bacillus megatherium which can produce nitrite reductase is activated and prepared into seed, the obtained seed culture fluid is inoculate into a liquid ferment substrate by 1-10 percent of inoculation dosage; the initial pH value is 5.0-7.5, at 25-40 DEG C and 100-240r / min of rotation speed, after 20-36 hours of constant temperature cultivation, bacterial suspension is produced. Re-suspending the bacterial suspension by phosphate buffer can produce thalli. After the thalli is smashed by ultrasonic, the supernatant fluid is frozen and centrifugated, and then the rough enzyme solution is obtained. Nitrite reductases of different consistences and purities can be obtained after the rough enzyme solution is separated and purified. Liquid enzyme preparation can be prepared after enzyme protecting solute is added in the nitrite reductase. The enzyme activity of nitrite reductase preparation produced by using the invention is 4000-8000U / mL. The preparing method is simple, the production period is short, and public food safety can be maintained.

Owner:CHINA AGRI UNIV

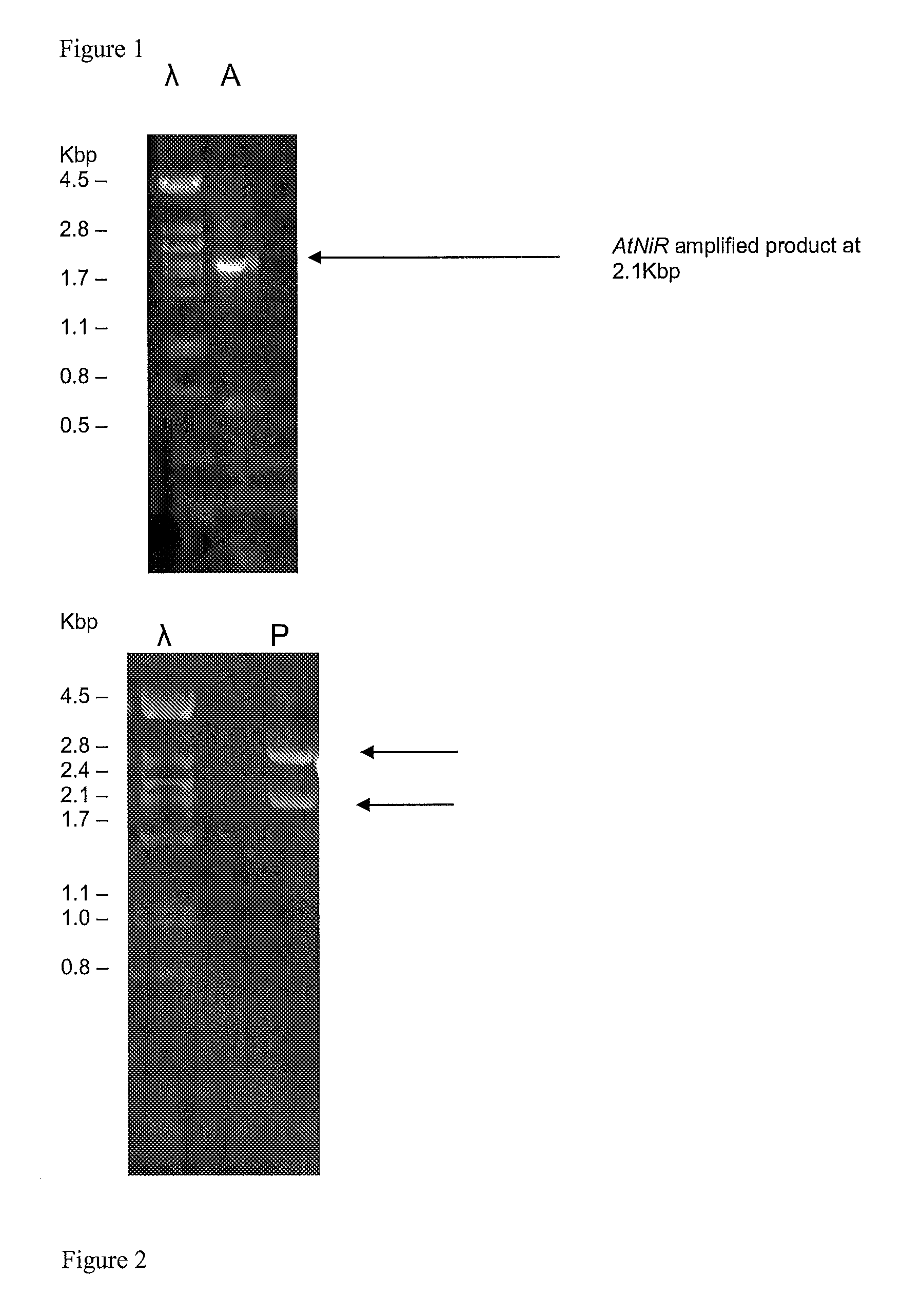

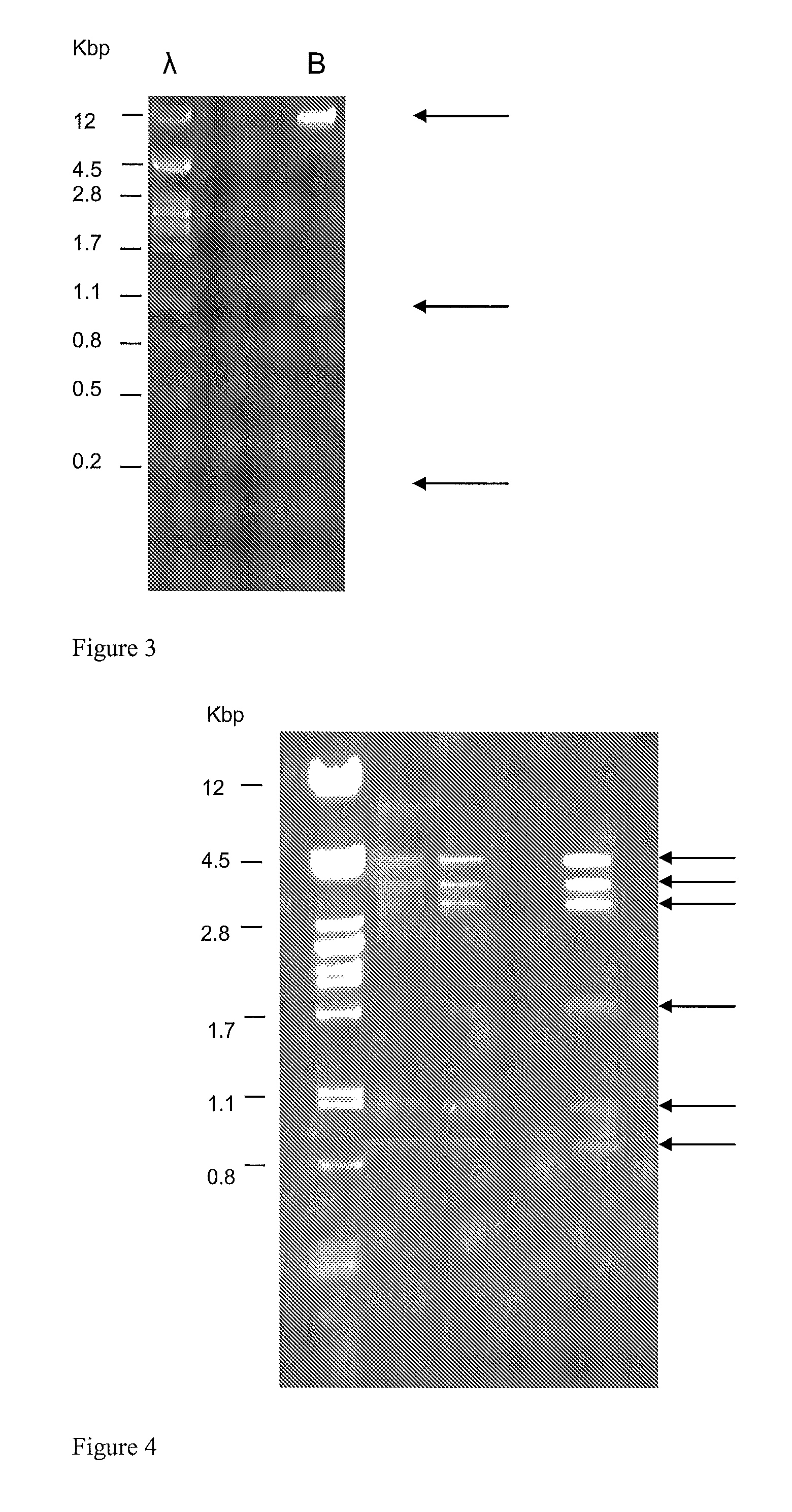

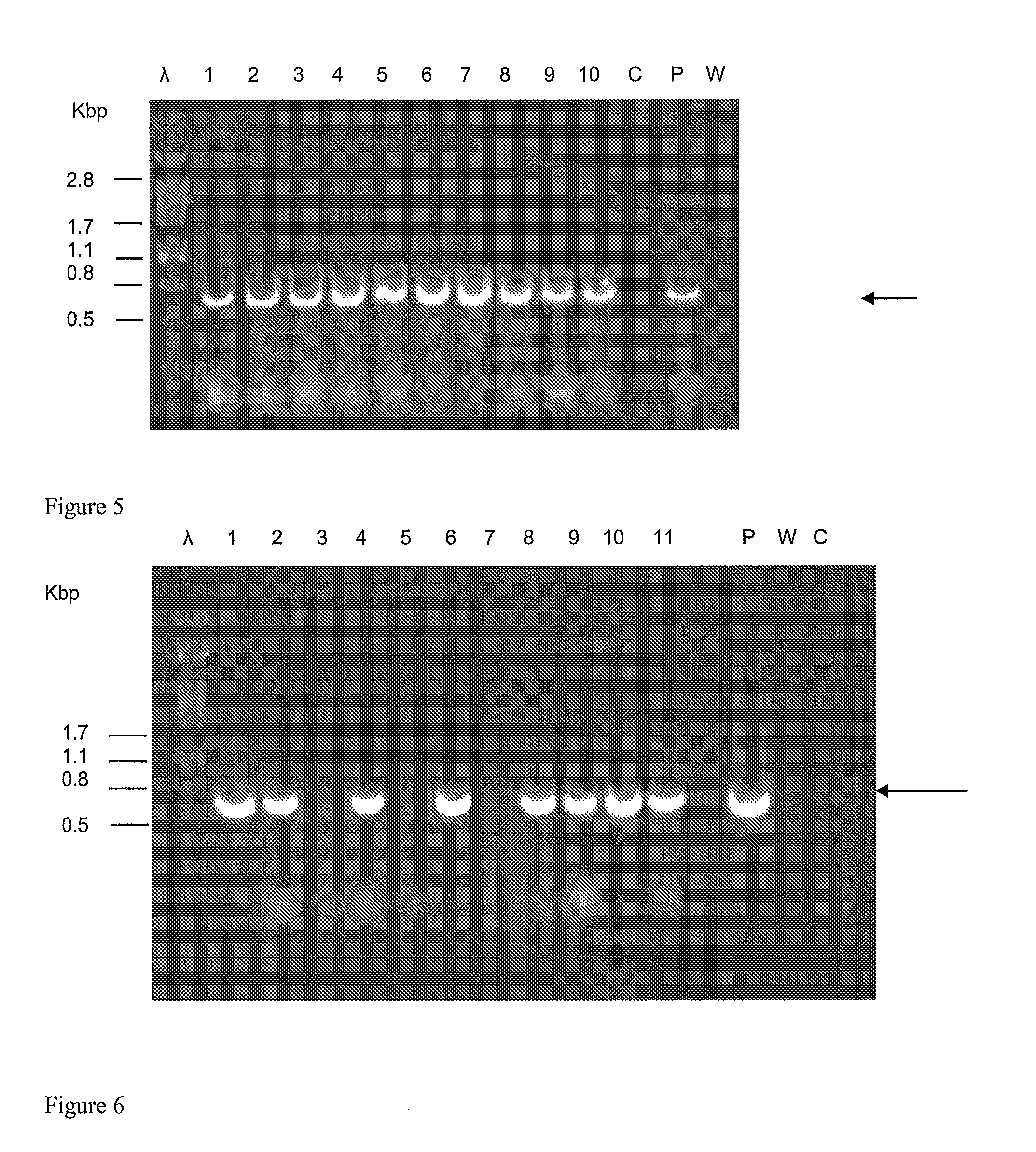

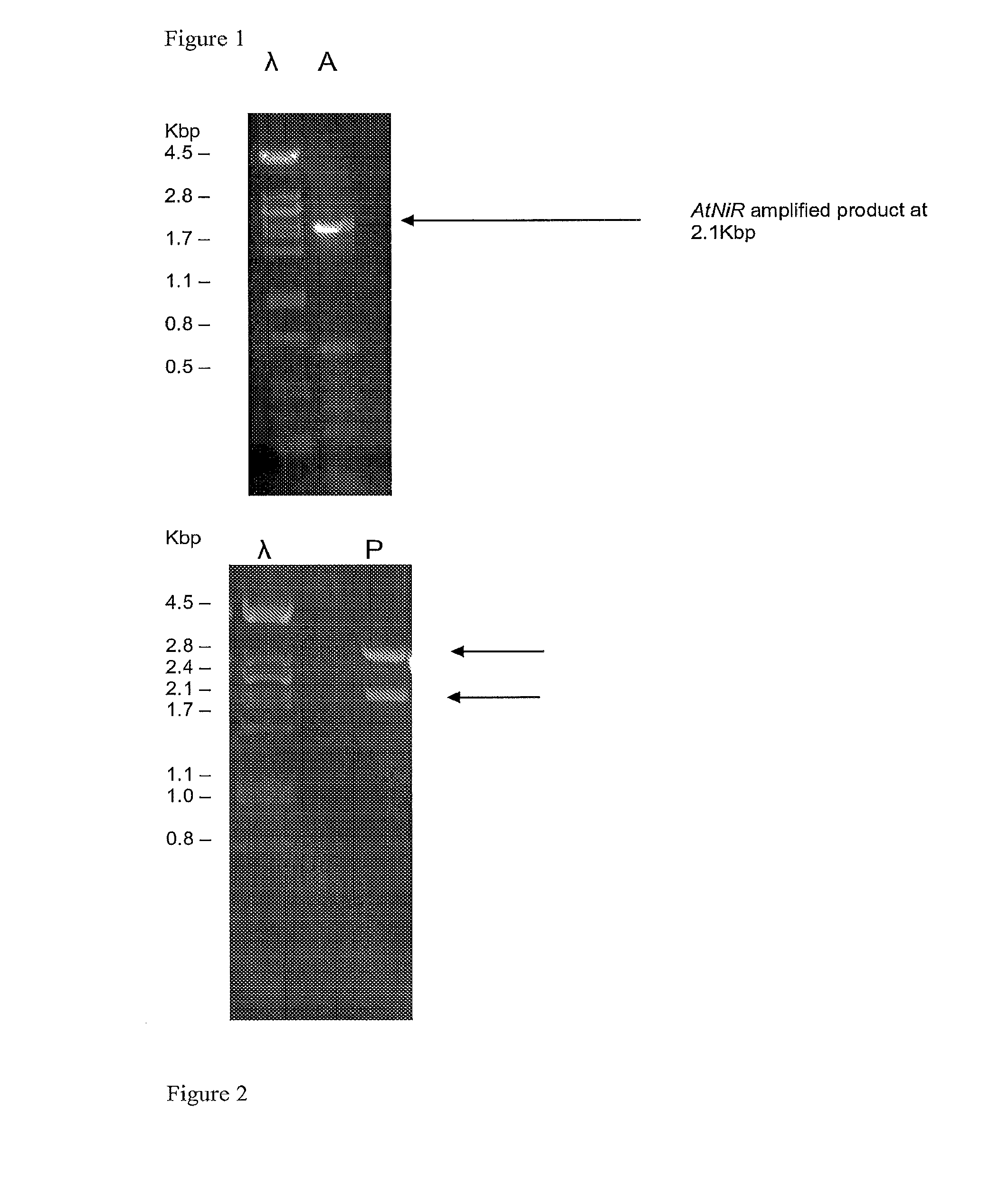

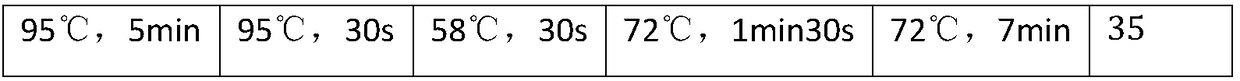

Production of Plants with Decreased Nitrite Content

InactiveUS20110239324A1Reduce contentReduce nitriteSugar derivativesOther foreign material introduction processesPlant cellNitrite reductase

The present invention relates in one aspect to a method for producing a transgenic plant, comprising introducing into an unmodified plant an exogenous gene encoding a nitrite reductase, wherein expression of the nitrite reductase encoded by the exogenous gene reduces nitrite content in the transgenic plant relative to the unmodified plant. Also provided are transgenic plants and plant cells comprising an exogenous gene encoding a nitrite reductase, as well as associated uses, chimaeric genes and plant transformation vectors.

Owner:BRITISH AMERICAN TOBACCO (INVESTMENTS) LTD

Method for degrading nitrite in salted fish through enzymic method

ActiveCN103750409APromote decompositionFacilitate functioningFood dryingFood preparationCold airFresh fish

The invention discloses a method for degrading nitrite in salted fish through an enzymic method. The method comprises the following steps: (1) washing fresh fish or frozen fish, salting the fish with salt, taking out the fish, rinsing with clean water, and draining; (2) adding nitrite reductase into the salted fish, wherein the addition amount of the nitrite reductase is 0.8-1.6g per kg of fish, and the enzymatic activity of the nitrite reductase is 3,500-4,500U / g; (3) airing the fish treated with an enzyme solution on a drying rack for 1-2 hours, putting the fish in a low-temperature heat pump dryer or cold-air drying equipment at the temperature of 28-35 DEG C, and airing the fish until the moisture content of the fish body is 35-45 percent. According to the method, the content of the nitrite generated in the process of processing the salted fish can be effectively reduced, the taste and quality of the salted fish products are kept, and the safety of the salted fish products is guaranteed.

Owner:SOUTH CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Nitrite reductase compound enzyme preparation and method of using the same to degrade nitrite in sausage

The invention belongs to the technology field of application of bio-enzyme preparation and food safety, which relates to the method for nitrite reductase compound enzyme preparation and the function of reducing the nitrite in the sausage, which is about nitrite reductase compound enzyme preparation being applied to reduce the nitrite in food. The nitrite reductase compound enzyme preparation is made by putting FAD of 100 to 400ml, NADPH of 100 to 300ml, cytochrome C of 200 to 400ml and compound phosphate into every liter of nitrite reductase compound enzyme preparation. Putting the nitrite reductase compound enzyme preparation and the flavoring into the cut and mixed meat to continue wring the meat well. The invention can effectively reduce the content of nitrite in the cooked sausage. The invention conducts enzyme reaction without changing the process of sausage cooking, thus effectively reducing the nitrite content in the sausage and realizing low residue or even no residue. The operation is very easy.

Owner:CHINA AGRI UNIV

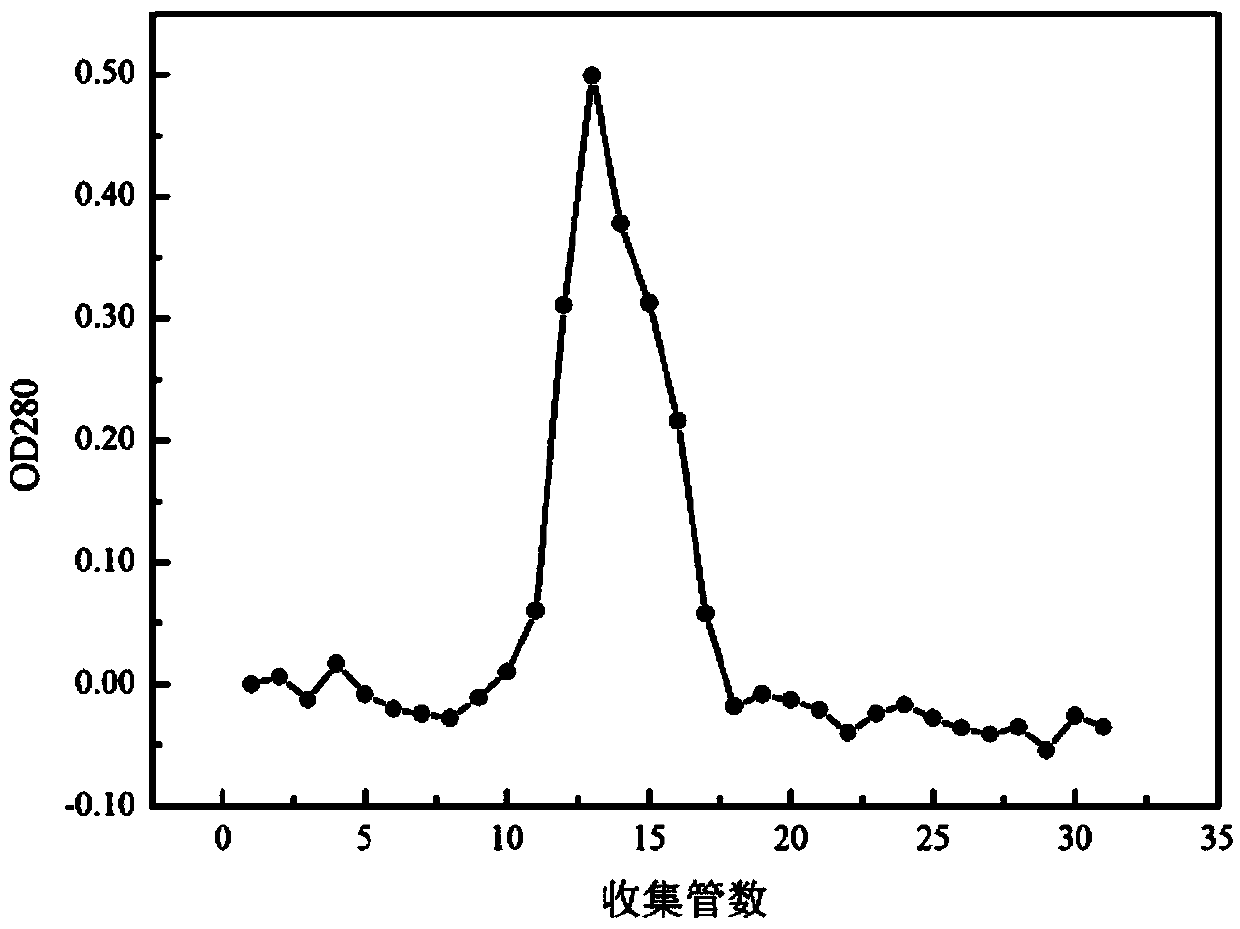

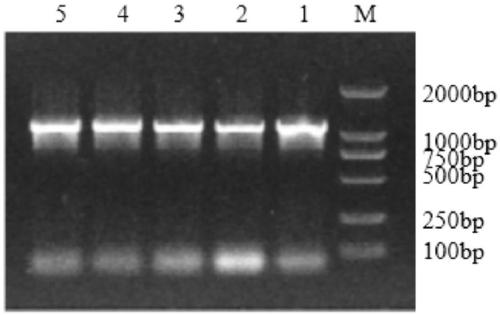

Lactobacillus plantarum nitrite reductase gene, protein coded by gene and applications of protein

PendingCN109609524AEfficient degradationHigh purityBacteriaMicroorganism based processesEscherichia coliNitrite reductase

The invention discloses a lactobacillus plantarum nitrite reductase gene, a protein coded by the gene and applications of the protein, and belongs to the field of bioengineering. In the present invention, the nitrite reductase gene in lactobacillus plantarum is cloned by a PCR technology and induced to express in escherichia coli, and affinity chromatography purification is utilized to obtain a high-purity recombinant protein. The high-purity protein purified by the method of the invention can effectively degrade nitrite in food, and the structure and properties of the protein can be studied.

Owner:DALIAN UNIV

Production of plants with decreased nitrite content

ActiveUS20150203858A1Reduce contentReduce nitriteSugar derivativesMutant preparationNitrite reductasePlant cell

The present invention relates in one aspect to a method for producing a transgenic plant, comprising introducing into an unmodified plant an exogenous gene encoding a nitrite reductase, wherein expression of the nitrite reductase encoded by the exogenous gene reduces nitrite content in the transgenic plant relative to the unmodified plant. Also provided are transgenic plants and plant cells comprising an exogenous gene encoding a nitrite reductase, as well as associated uses, chimaeric genes and plant transformation vectors.

Owner:BRITISH AMERICAN TOBACCO (INVESTMENTS) LTD

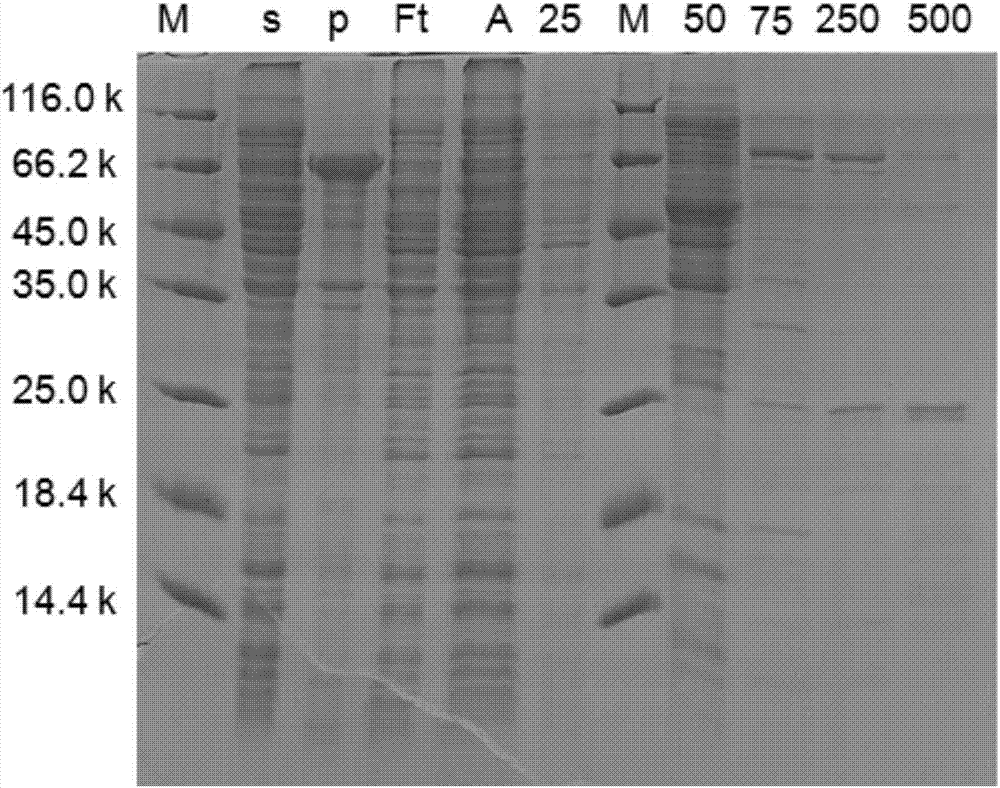

Lactobacillus plantarum nitrite reductase gene, protein encoded by lactobacillus plantarum nitrite reductase gene and preparation method of protein

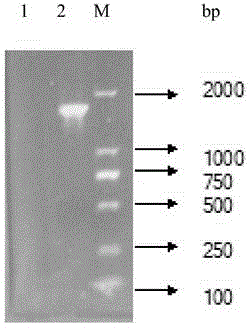

InactiveCN104152469AHigh puritySolve the problem of isolating nitrite reductase with higher purityMicroorganism based processesEnzymesAntigenEscherichia coli

The invention discloses a lactobacillus plantarum nitrite reductase gene, protein encoded by the lactobacillus plantarum nitrite reductase gene and a preparation method of the protein. A nucleotide sequence of the lactobacillus plantarum nitrite reductase gene is as shown in SEQ ID NO.1. A gene sequence shown in the SEQ ID NO.1 is cloned to a prokaryotic expression vector pET-32a(+); inducible expression is carried out in recombinant escherichia coli; high-purity recombinant protein is obtained by affinity chromatography purification. By using the high-purity protein purified by the method disclosed by the invention, nitrite can be effectively degraded, an enzymic preparation can be produced, the nitrite in food can be effectively degraded, and the protein can also be applied to preparation of a lactobacillus plantarum nitrite reductase antibody as an antigen, and can be applied to research of structure and property of the antibody.

Owner:SOUTH CHINA UNIV OF TECH

A kind of production method of lactic acid bacteria nitrite reductase

InactiveCN102286438ASimple production processSimple and fast operationMicroorganism based processesEnzymesBiotechnologyLactic acid bacterium

The invention discloses a production method of lactic acid bacteria nitrite reductase, that is, lactic acid bacteria are activated and cultivated with MRS liquid medium for 2 to 3 generations, and the activated bacteria are obtained by using a seed medium composed of cabbage juice, tomato juice, etc. and fermentation culture The lactic acid bacteria fermented liquid is obtained after medium culture, and the pH value of the lactic acid bacteria fermented liquid is adjusted to 6.3-6.5 with sodium hydroxide, and then 0.4-0.6mg / mL sodium nitrite is added, and the lactic acid bacteria obtained after 32-48 hours of cultivation at 37°C are reduced to nitrite The enzyme fermentation broth is centrifuged to collect the bacteria, and then the bacteria cells are further broken, and the supernatant is collected, and then the nitrite reductase is finally obtained through steps such as precipitation, dialysis, and freeze-drying. The production method of the lactic acid bacteria nitrite reductase of the present invention not only has low production cost, but also has the advantages of simple production process, more convenient operation and the like.

Owner:SHANGHAI INST OF TECH

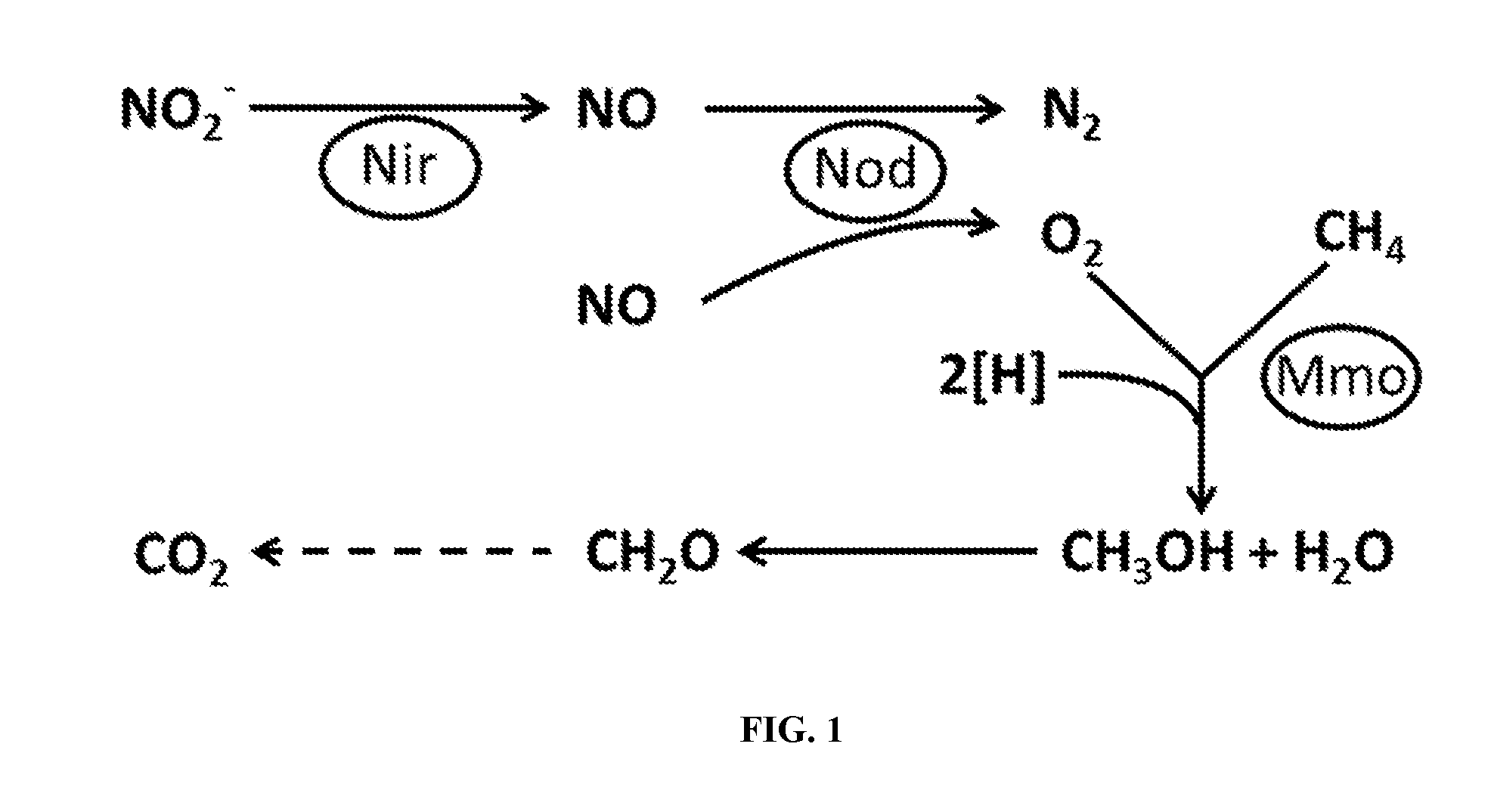

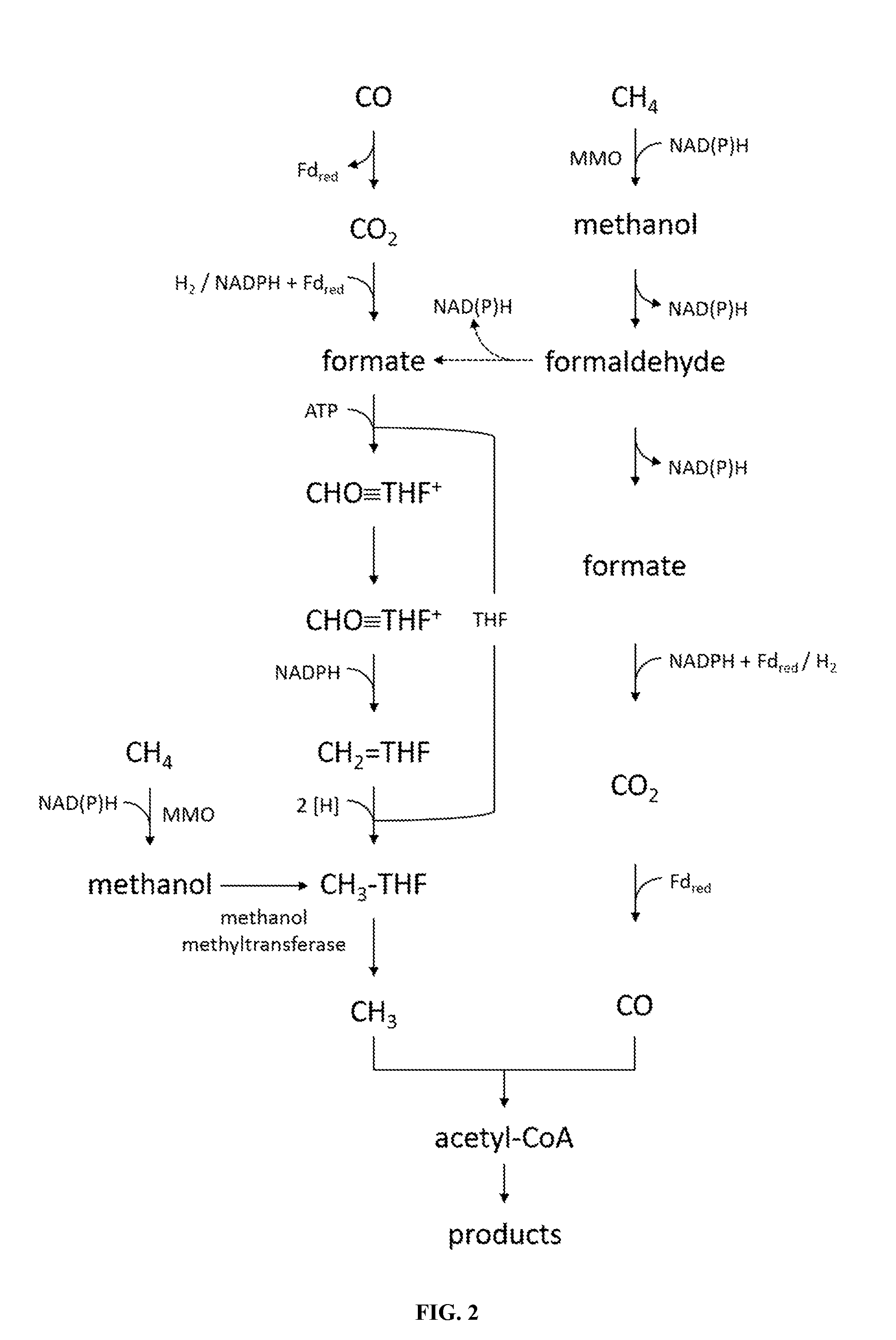

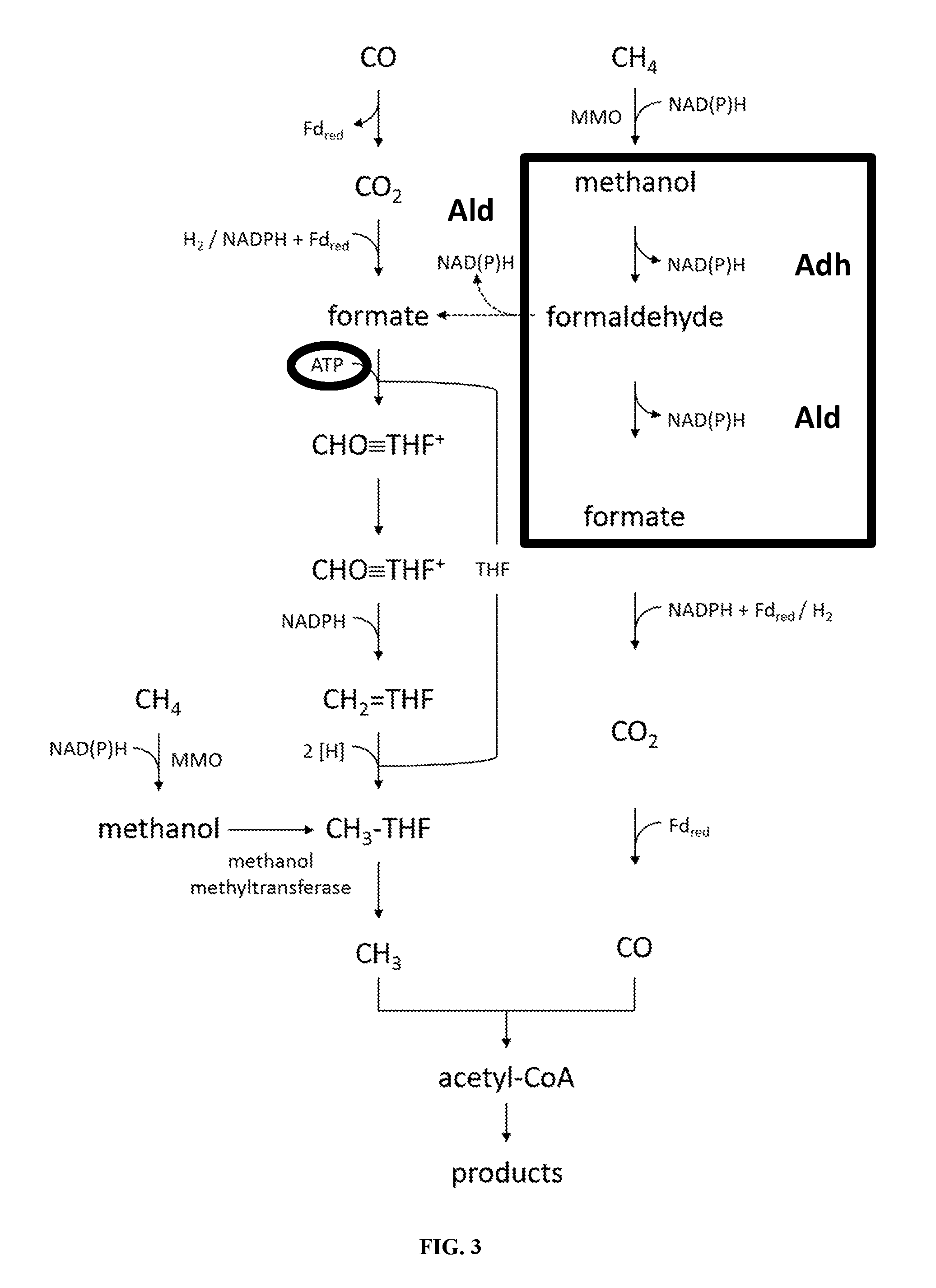

Recombinant acetogenic bacterium for the conversion of methane to products

The invention provides a recombinant, acetogenic bacterium that consumes a substrate comprising CH4 and converts at least a portion of the CH4 to a product. In particular, the bacterium of may comprise one or more of exogenous methane monooxygenase (MMO), exogenous nitrite reductase (NIR), and exogenous nitric oxide dismutase (NOD). The invention further provides a method for producing a product comprising providing a substrate comprising CH4 to a culture comprising a recombinant, acetogenic bacterium, whereby the bacterium converts at least a portion of the CH4 to a product.

Owner:LANZATECH NZ INC

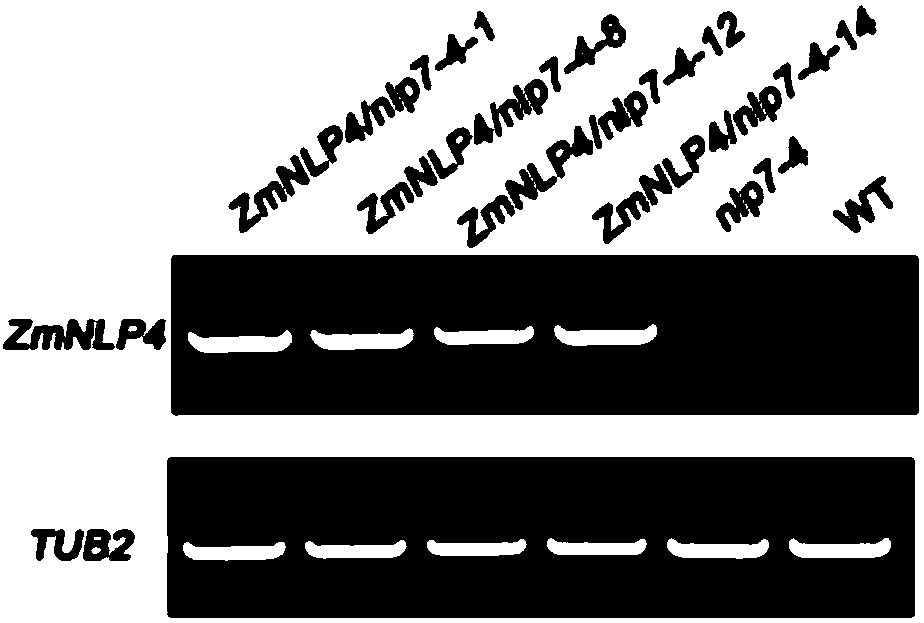

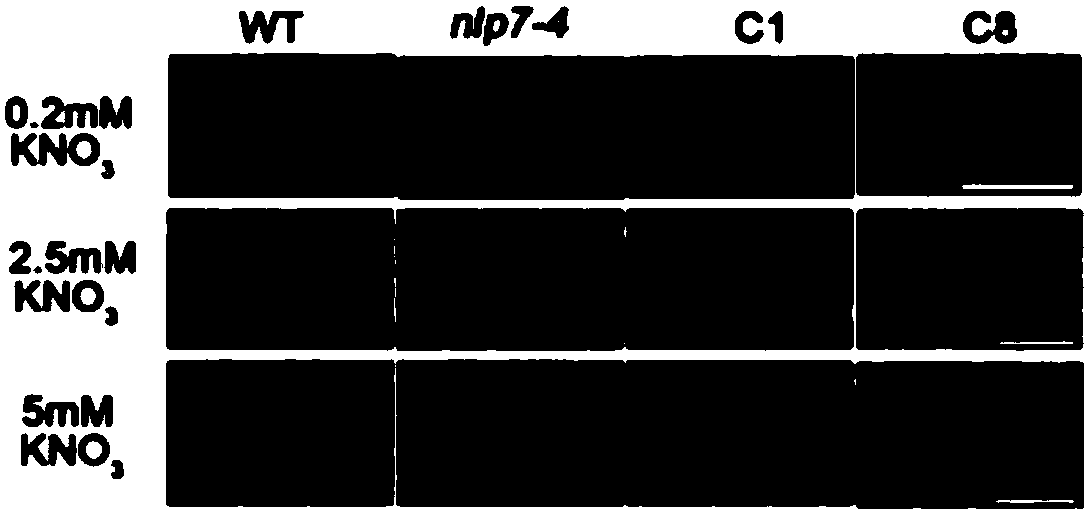

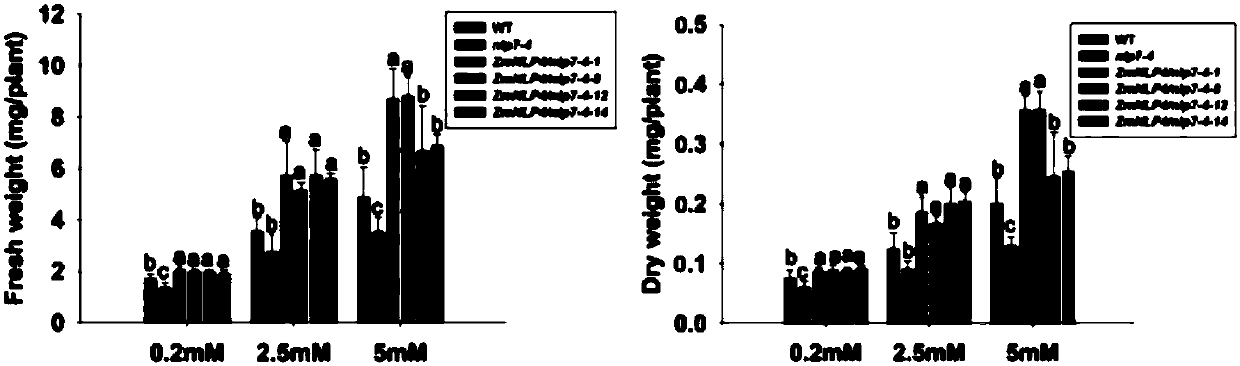

Transcription factor ZmNLP4 derived from corn and application thereof

ActiveCN107602683AIncrease biomassIncrease the content of amino acidsPlant peptidesFermentationNucleotideLateral root

The invention relates to the technical field of plant genetic engineering and provides a transcription factor ZmNLP4 derived from corn and application thereof. A nucleotide sequence of the transcription factor is shown as SEQ ID NO.1, and a coded amino acid sequence of the transcription factor is shown as SEQ ID NO.2. Compared with a receptor Arabidopsis, the Arabidopsis in which the transcriptionfactor is transferred has the advantages that the total biomass is obviously increased, the content of in-vivo amino acids and total nitrogen is increased, the main root length and quantity of lateral roots are obviously increased, the yield per plant is obviously increased, and the expressions of nitrate transporters, nitrate reductase genes and nitrite reductase genes are obviously increased.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

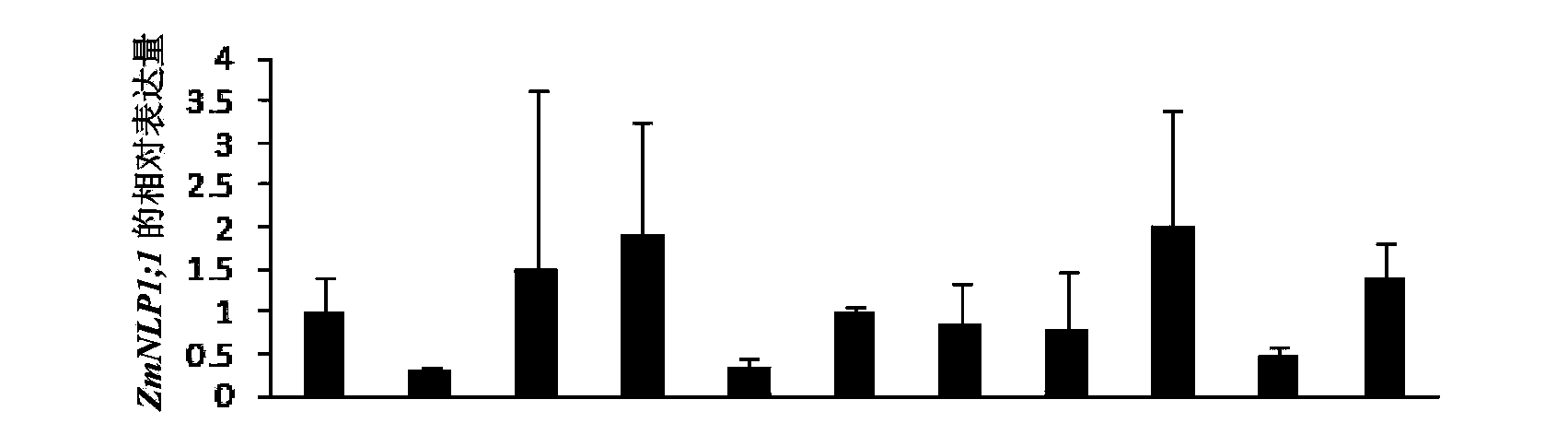

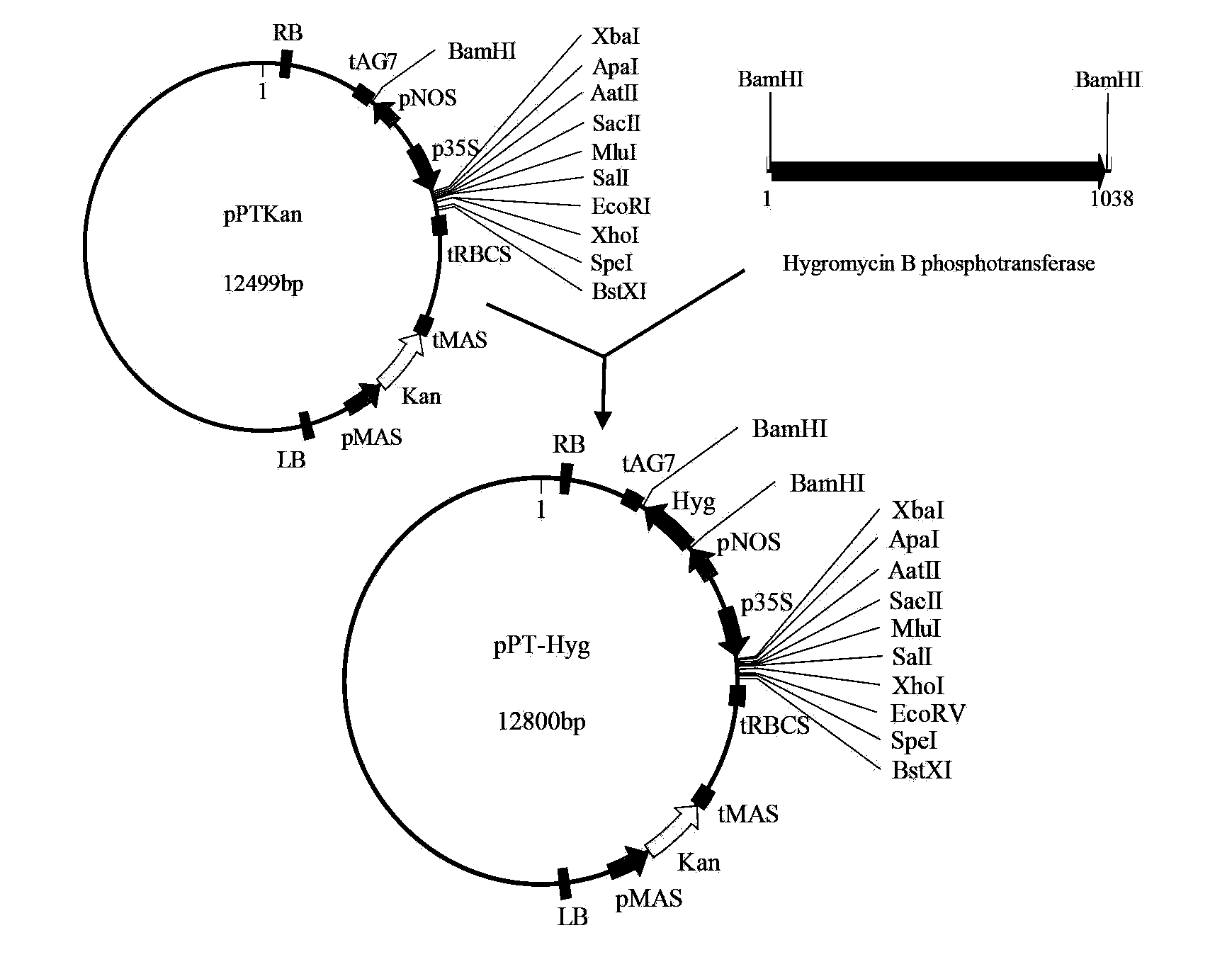

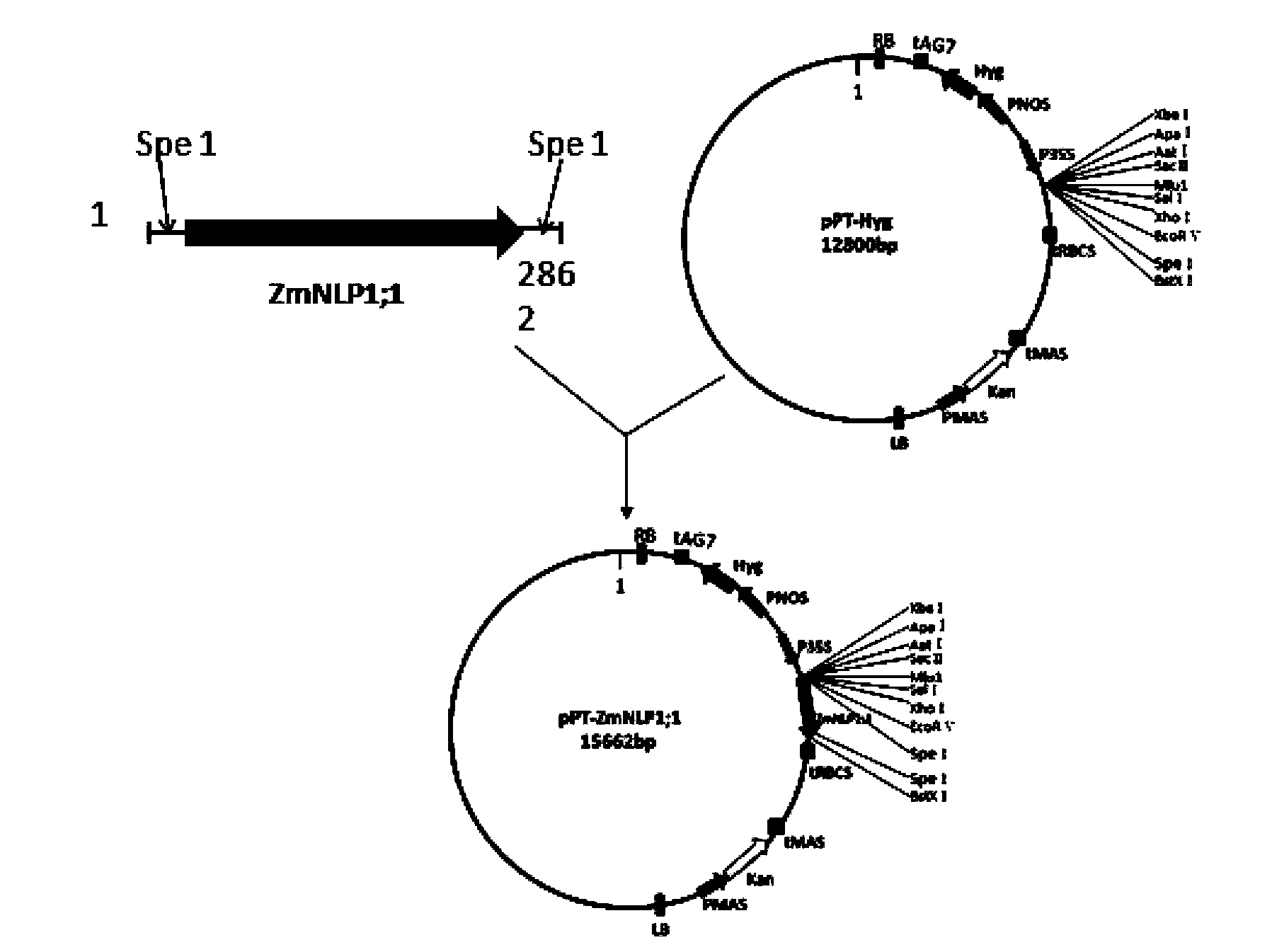

Transcription factor derived from corn and new use of coding gene thereof

The invention discloses a transcription factor derived from corn and new use of a coding gene thereof. The new use provided by the invention is a method using a coding nucleic acid molecule of ZmNLP1;1 to cultivate a transgenic plant. The method is a method for cultivating the transgenic plant with at least one characters of the following 1)-4): 1) aboveground biomass is higher than that of a receptor plant; 2) after induction of a nitrate, the nitrate transport protein gene expression is higher than that of the receptor plant; 3) after induction of the nitrate, nitrate reductase gene expression is higher than that of the receptor plant; and 4) after induction of the nitrate, nitrite reductase gene expression is higher than that of the receptor plant; and the method comprises a step for introducing a ZmNLP1;1 gene into the receptor plant; and the ZmNLP1;1 gene codes a protein shown in SEQ ID No.2. Experiments show that, in the condition of using nitric nitrogen (NO<3->) as a sole nitrogen source, the aboveground biomass and the total biomass of arabidopsis transgenic with the ZmNLP1;1 gene are increased significantly compared with that of receptor arabidopsis.

Owner:CHINA AGRI UNIV

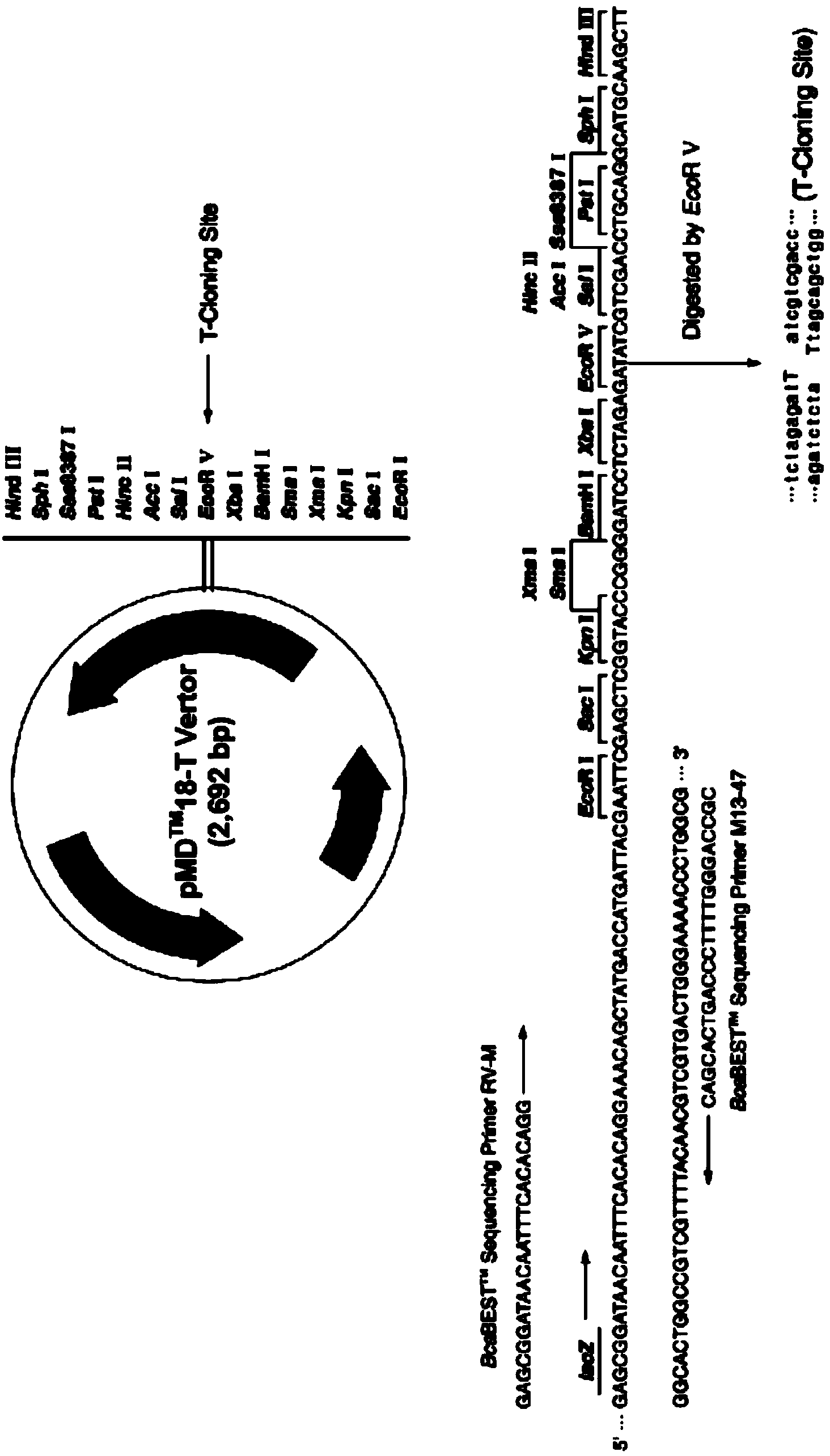

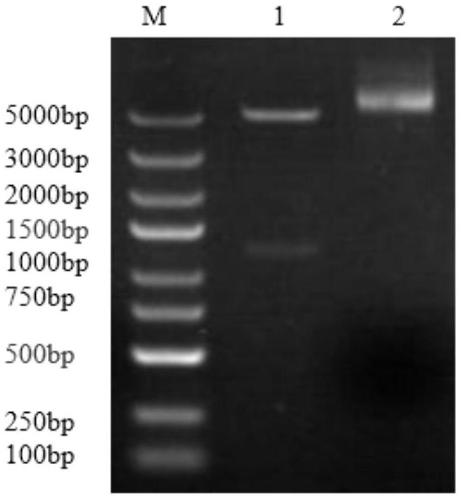

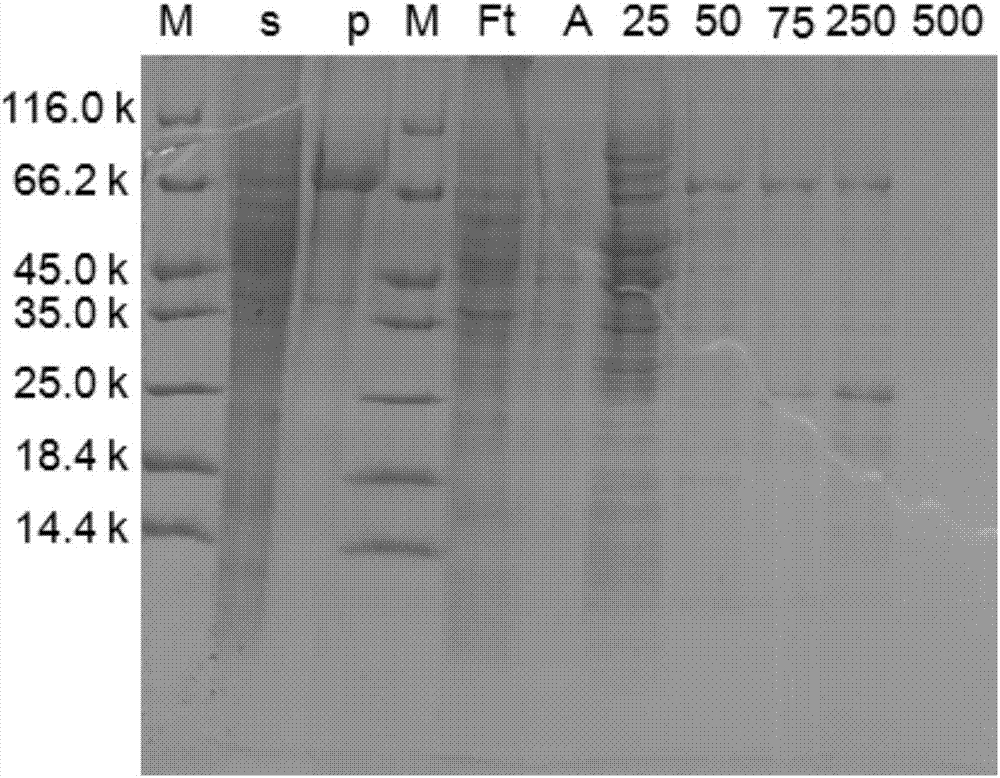

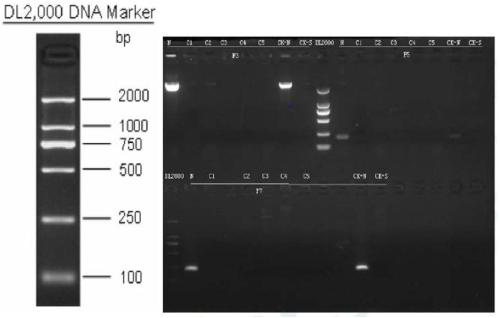

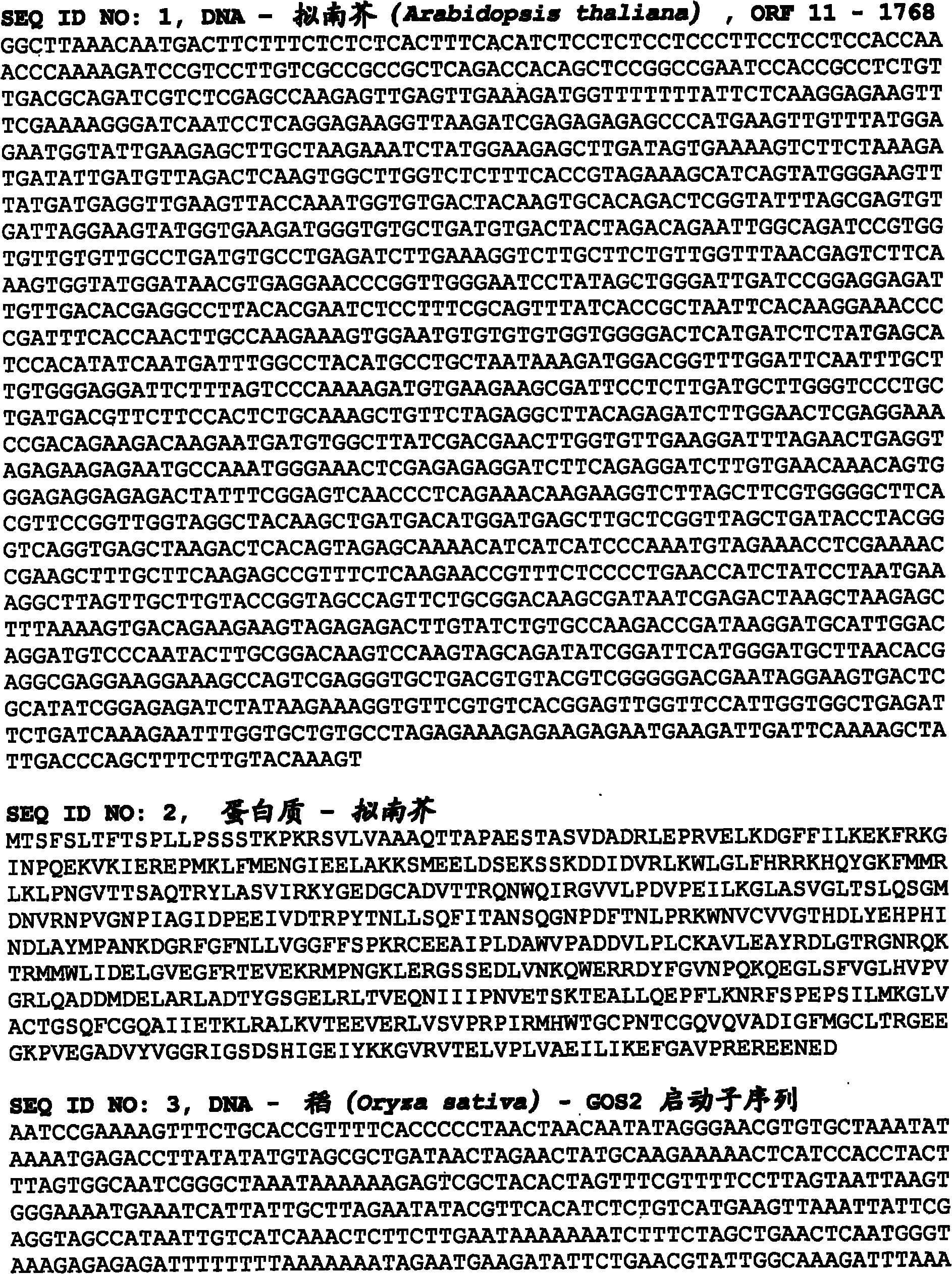

Recombinant nitrite reductase and construction method thereof

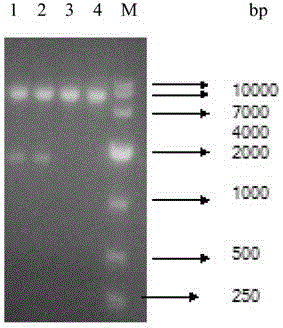

The invention discloses recombinant nitrite reductase and a construction method of the recombinant nitrite reductase. An NiR (nitrite reductase) gene in bacillus cereus LJ01 is amplified by adopting the PCR technology, the amplified gene is cloned to a carrier, an expression host strain is transformed, recombinant bacteria induced by IPTG is added, shaking culture is carried out at 16-37 DEG C, fermentation liquor is centrifugalized, bacterial sludge is taken, resuspending is carried out, high-pressure grinding is carried out, and crude enzyme liquid is extracted, wherein the bacillus cereus LJ01 is assigned with the accession number of CGMCC NO.9360. According to the technical scheme, the NiR gene is cloned, the cloned gene is expressed in a large amount in a host cell, meanwhile, the recombinant protein is provided with a specific label through plasmids, so that the purification process is simplified, and the extraction amount of NiR is improved.

Owner:SOUTH CHINA UNIV OF TECH

Method for producing nitrite reductase by ferment of lactic acid bacteria

InactiveCN1687408AEasy to operateLow costBacteriaOxidoreductasesLactic acid bacteriumNitrite reductase

The invention provide a method for producing nitrite reductase by ferment of lactic acid bacteria, activating lactic acid bacteria, enlarge breeding gradually, preparation liquid seeds, according to ferment liquid 3%-8% put it into the liquid zymogenic culture medium, in the temperature of 26-32 Deg. C breeding 36-72h, adding 40-150mg / L nitrite, continue breeding 12-24h.

Owner:张庆芳 +1

Preparation method of nitrite reduction bottom modification agent

InactiveCN103864223AInhibition of overgrowthImprove eutrophication statusWater contaminantsBiological water/sewage treatmentEutrophicationBacillus cereus

The invention discloses a preparation method of a nitrite reduction bottom modification agent, the nitrite reduction bottom modification agent is prepare from humic acid, zeolite powder, bentonite, a denitrifying bacillus solid, bacillus cereus solid and a nitrifying bacteria solid as raw materials in prescribed amount respectively by the steps of crushing, mixing, granulating, drying and cooling in the air. The method is simple in operation, easily available in raw materials and low in cost, the nitrite reduction bottom modification agent produced by the method can effectively control water body PH in 7.50-8.50, improve water body transparency to 5.3-12.8cm, increase DO (dissolved oxygen) content to 25.67%-32.56%, reduce the content of COD (chemical oxygen demand), PO4-P and nitrite in water body respectively to 28.41%-59.63%, 30.28%-64.58% and 56.32%-86.74%, effectively inhibit the overgrowth of algae in the water body, and improve eutrophication status of aquaculture water bodies.

Owner:QINGDAO ZHONGREN PHARMA

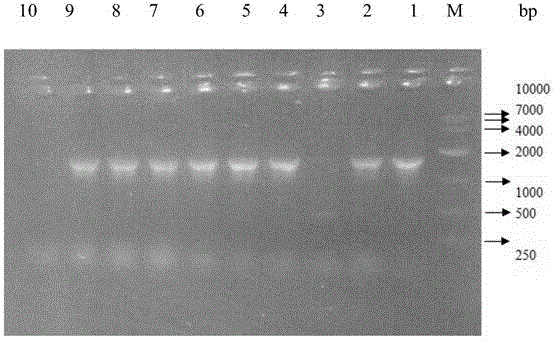

Engineering bacteria based on nitrite reductase and implementation method of engineering bacteria

InactiveCN104152393AGuaranteed purityStable biological activityBacteriaClimate change adaptationNucleotideGenetic engineering

The invention relates to engineering bacteria based on nitrite reductase and an implementation method of the engineering bacteria in the technical field of genetic engineering. The method comprises the following steps: by taking streptomyces griseorubens genome DNA as a template, performing PCR amplification with a primer containing enzyme cutting sites to sequentially obtain nucleotide sequences for encoding nitrite reductase large-subunits and nitrite reductase small subunits; sequentially connecting the gene sequences obtained by amplification to a coexpression vector pETDuet-1, and finally obtaining a recombinant coexpression vector pETDuet-NC-ND; and transforming the nitrite reductase expression vector into an Escherichia coli expression strain. Aiming at the defects that the application range and effect are severely limited because most of the nitrite reductases are intracellular enzymes in a living body and the expression quantity is low in the prior art, the engineering bacteria can realize great in-vitro expression synthesis of the nitrite reductase by using genetic engineering means and has high significance for rapidly repairing secondary salinization soil and realizing precision agriculture.

Owner:SHANGHAI JIAO TONG UNIV

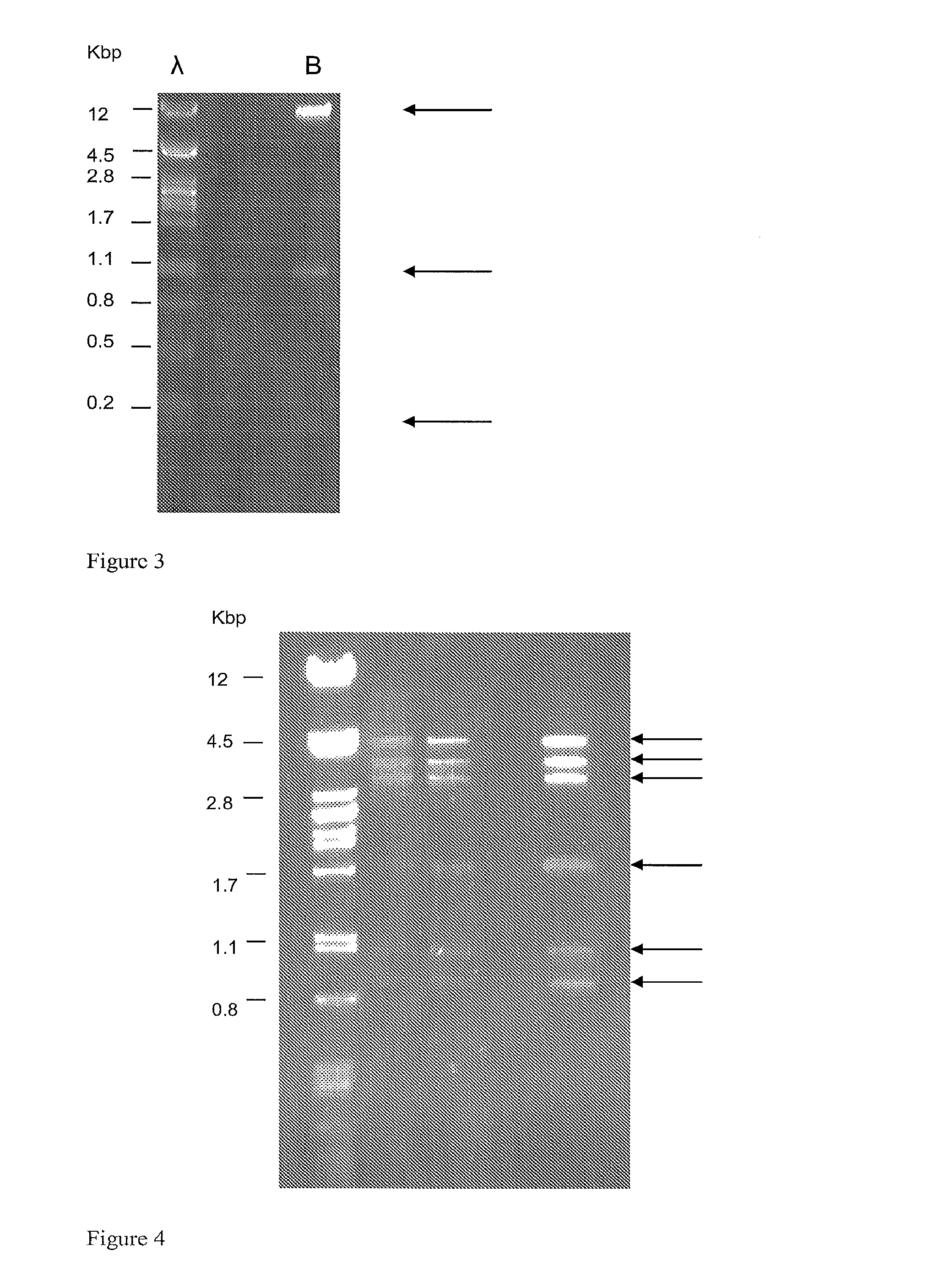

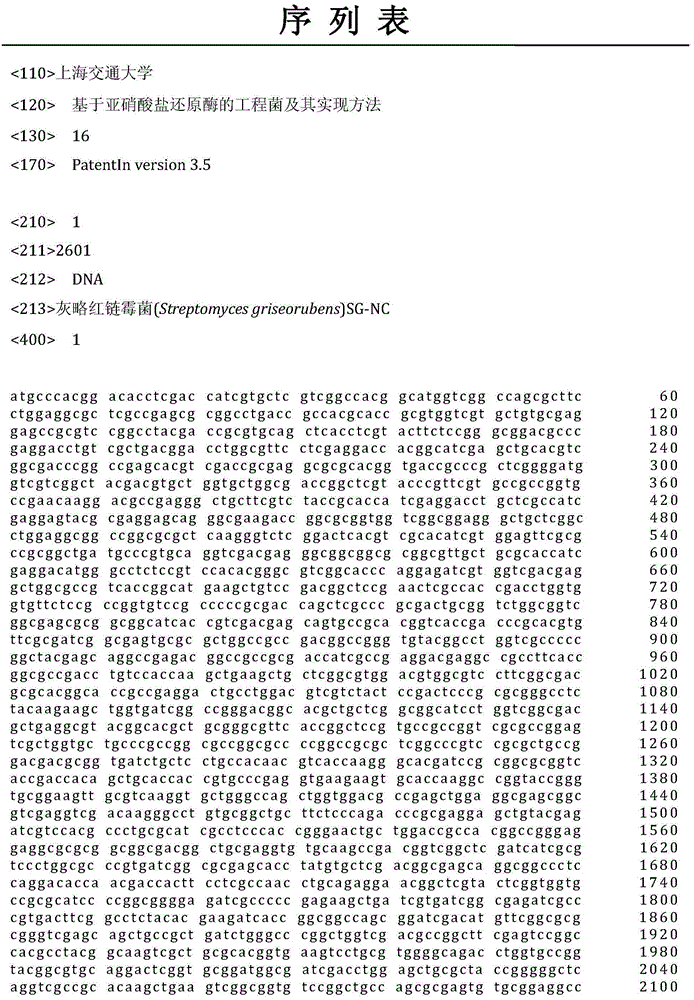

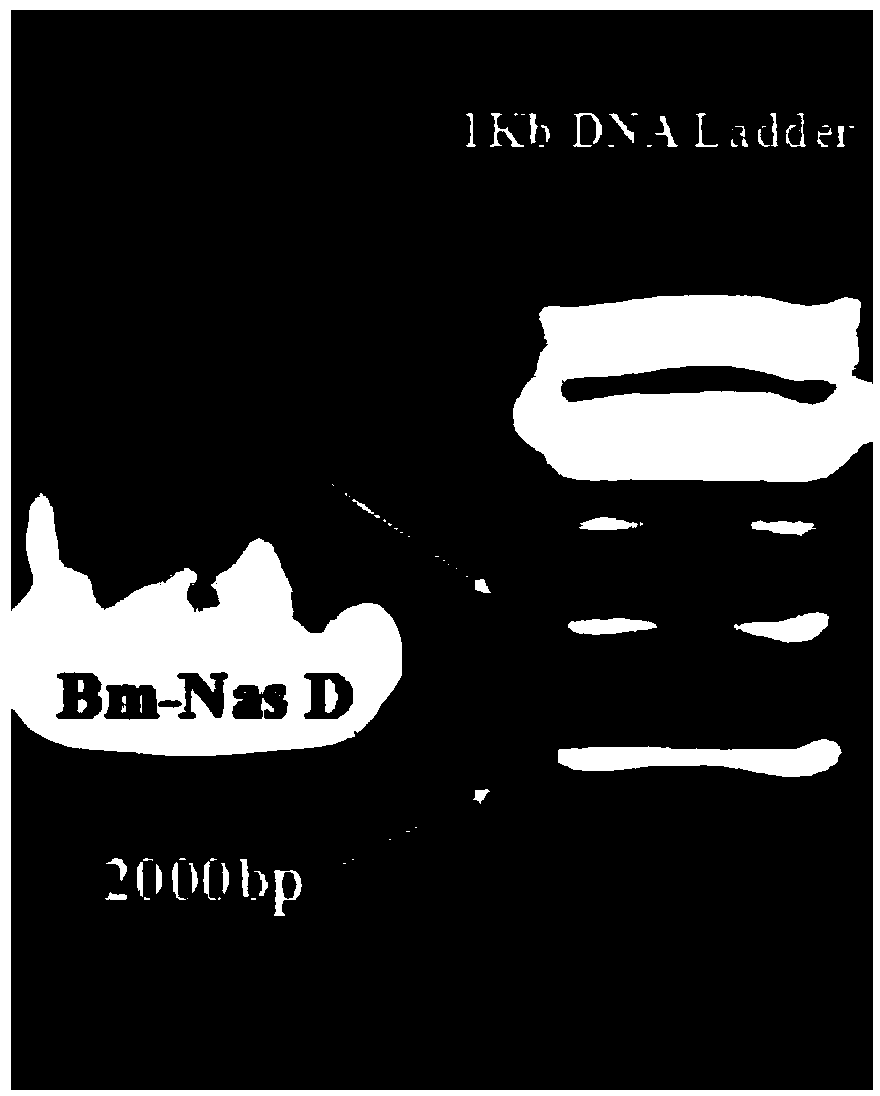

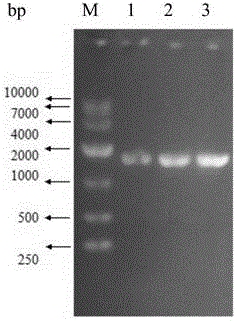

Bacillus megaterium co-expression vector for nitrite reductase and construction method thereof

InactiveCN103614404AExpression guaranteeLimit use effectBacteriaContaminated soil reclamationEscherichia coliBacillus megaterium

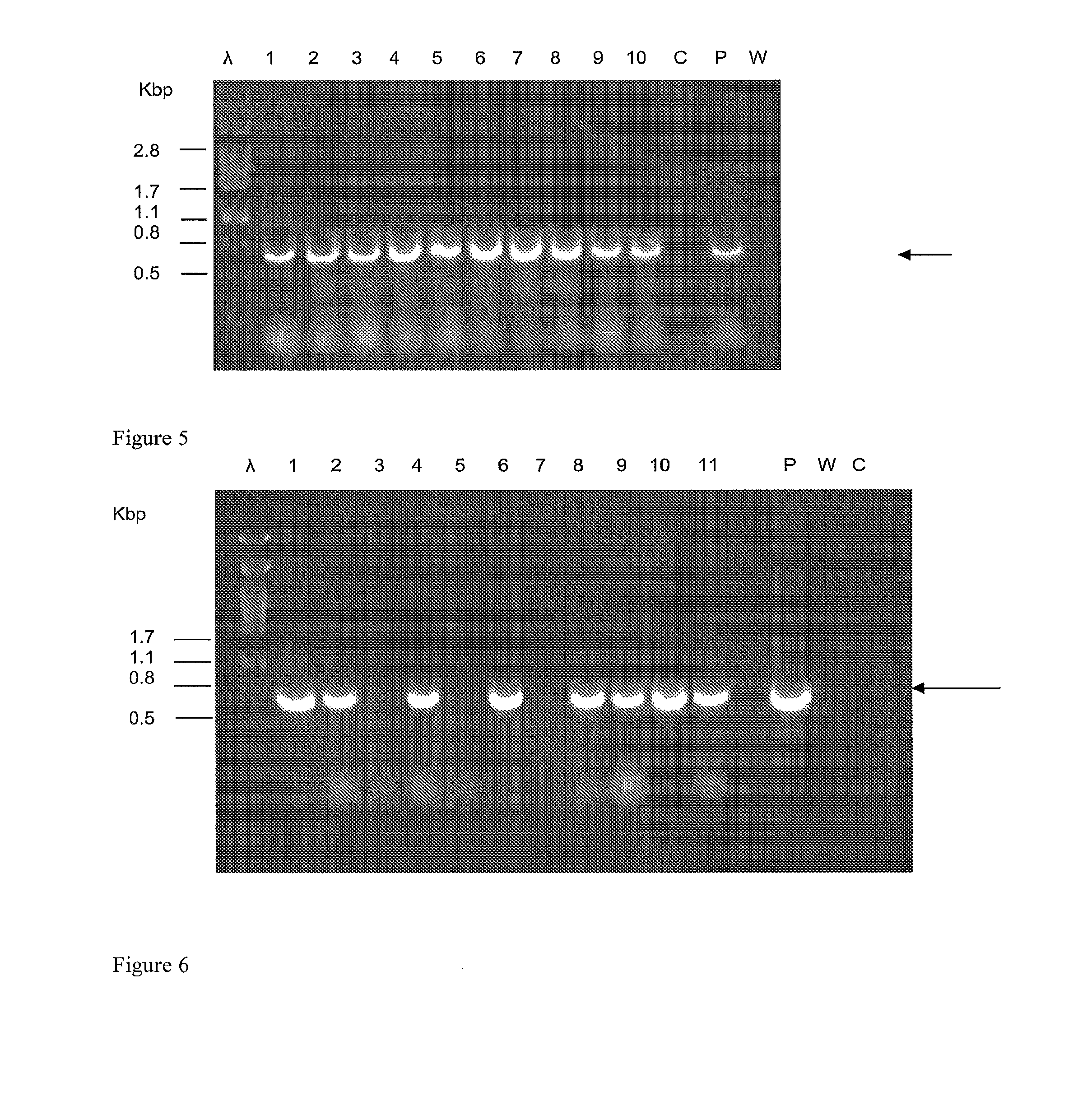

The invention relates to a bacillus megaterium co-expression vector for nitrite reductase and a construction method thereof, belonging to the technical field of genetic engineering. According to the co-expression vector, all genome sequences of bacillus megaterium are determined and serve as a template, gene sequences containing restriction enzyme cutting sites, namely a large subunit (Bm-Nas D) and a small subunit (Bm-Nas E) of nitrite reductase, are amplified according to designed PCR (Polymerase Chain Reaction) primers and are sequentially connected to the co-expression vector pETDuet-1, and positive clones of Escherichia coli DH5alpha containing target gene fragments are selected by a colony PCR technology. The co-expression vector has the advantages that the defect in the prior art that the use effect is seriously restricted due to the fact that the expression level of the gene sequence of the small subunit of nitrite reductase in natural bacillus megaterium is very low is overcome, and the genetic expression level is increased greatly.

Owner:SHANGHAI JIAO TONG UNIV

Method for preparing nitrite reductase from flammulina velutipes

Owner:NANJING UNIV OF FINANCE & ECONOMICS

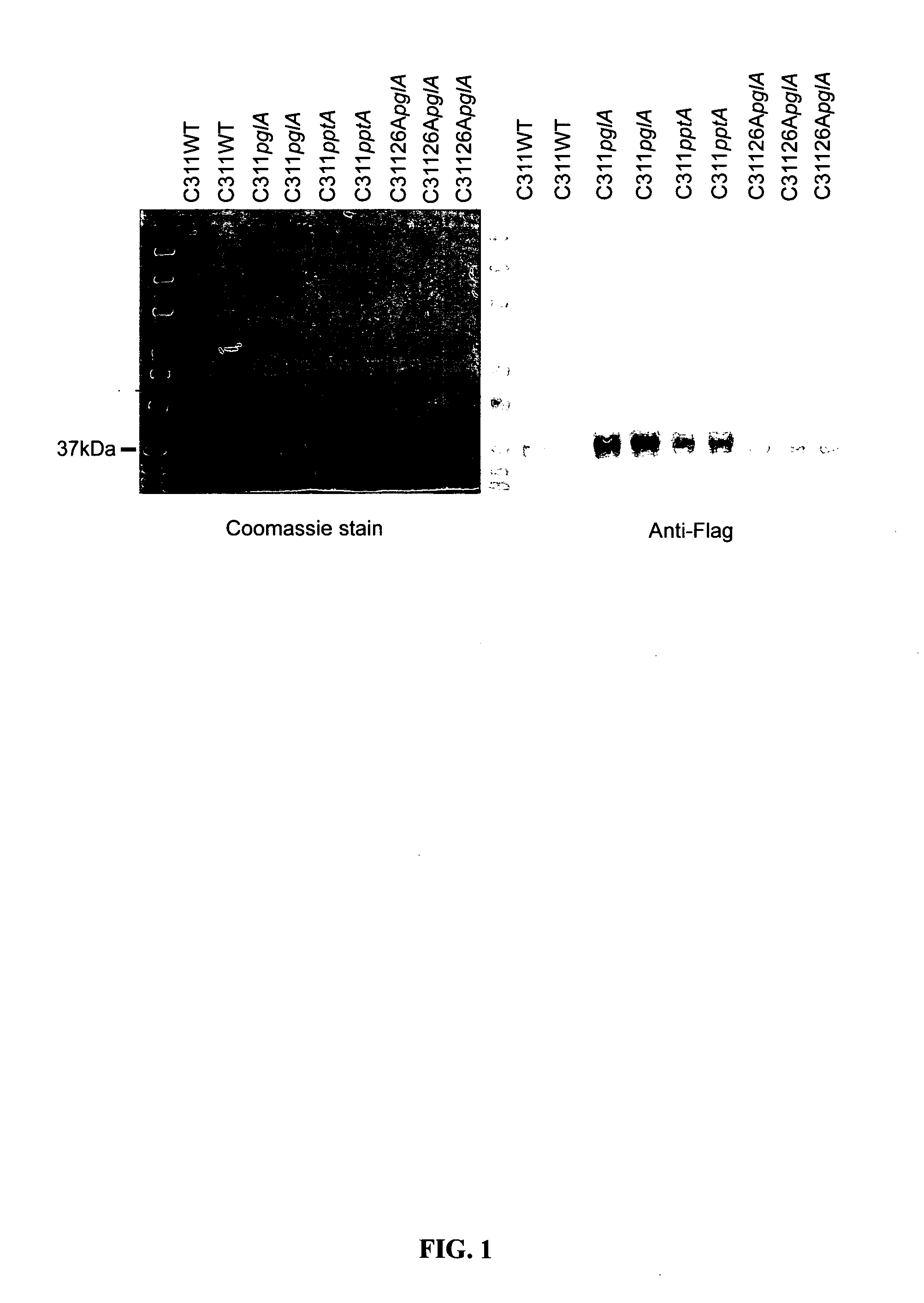

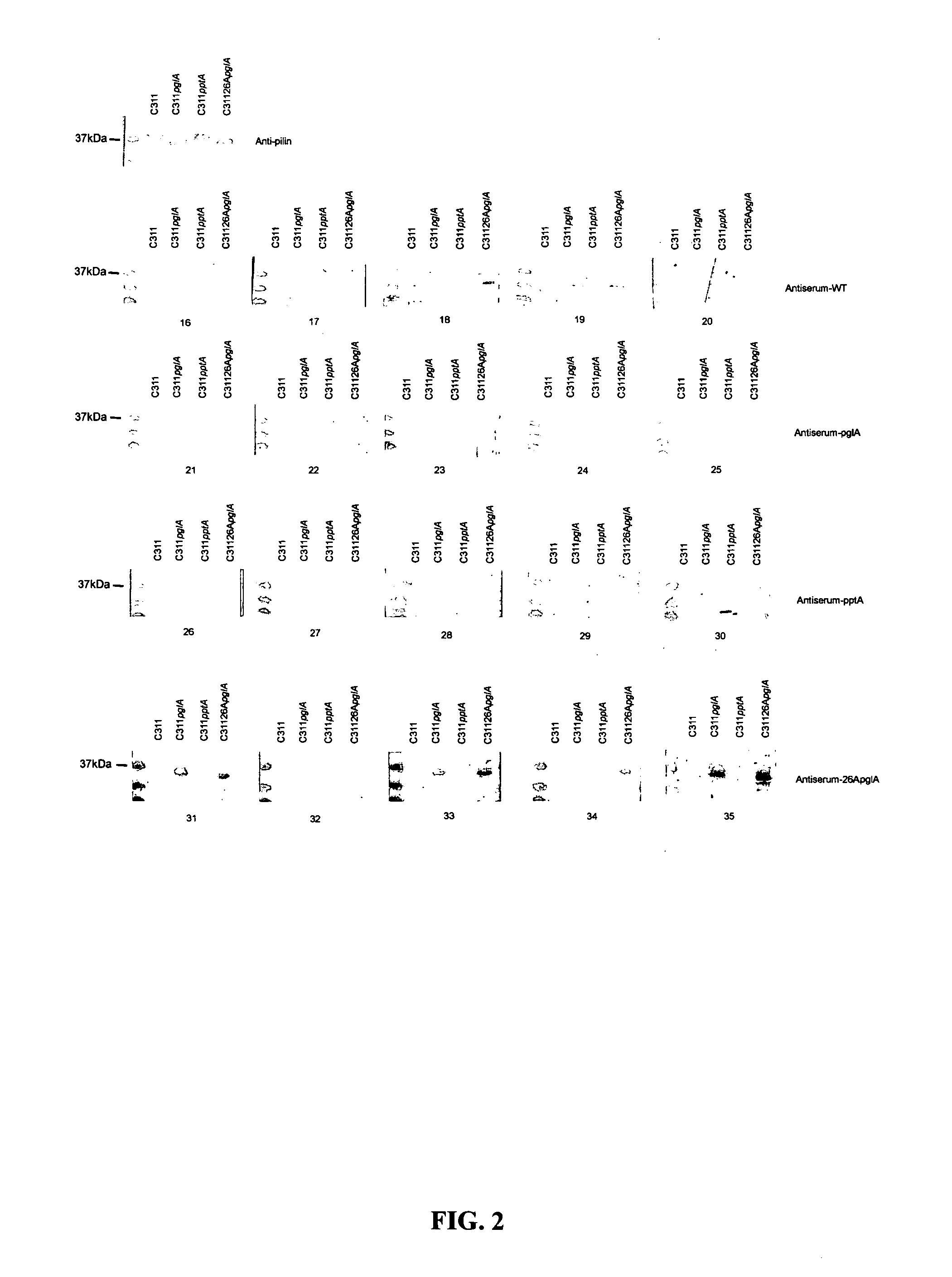

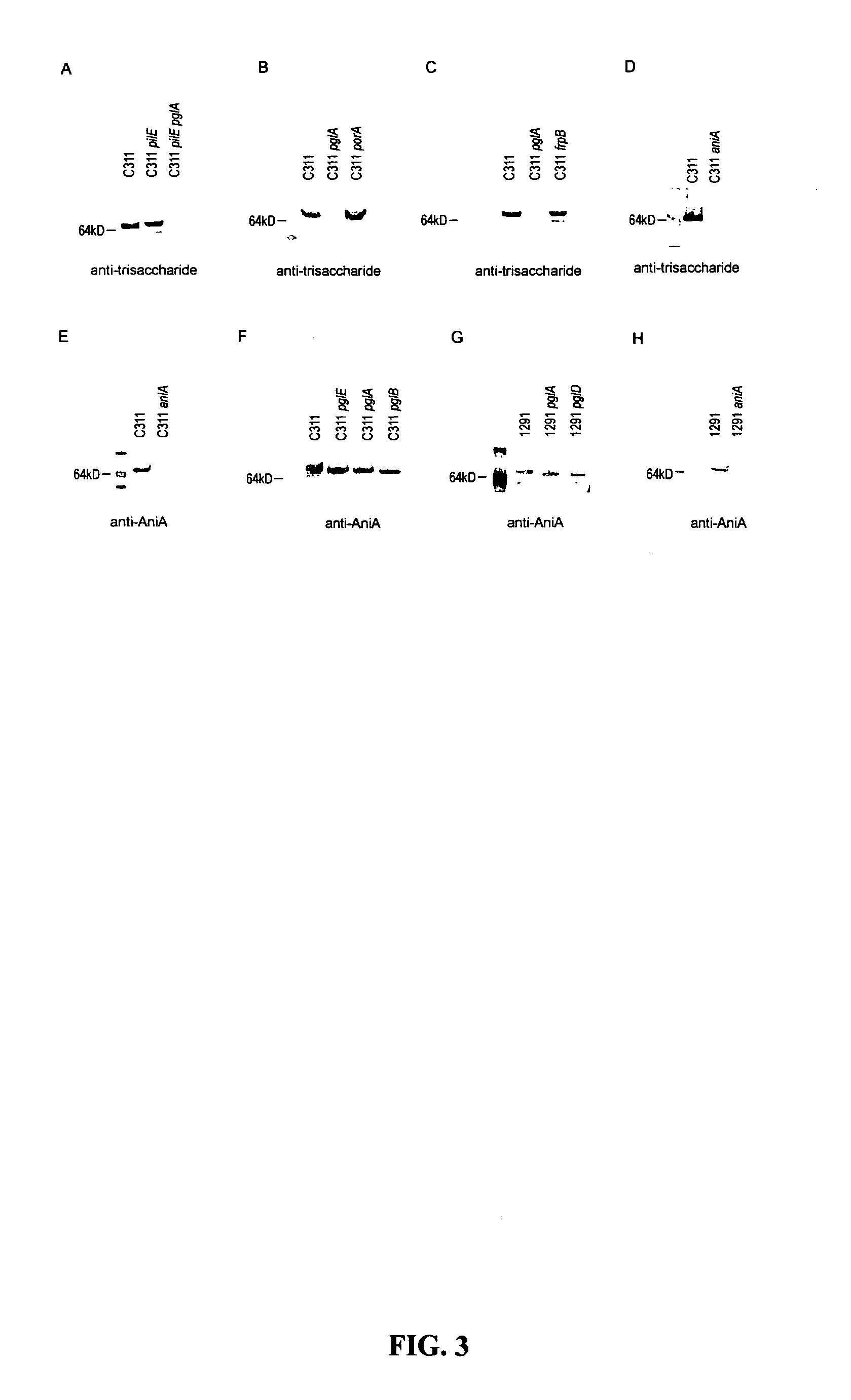

Mutant bacterial glycoproteins and uses thereof

The present invention relates to the use of mutant glycoproteins from pathogenic bacteria lacking one or more phosphorylcholine and / or glycosylation post-translational modifications as immunogens. These post-translational modifications act as masking structures that elicit an immune response which does not confer protection on an infected individual. The removal or modification of these masking structures alters the protein such that it elicits a stronger immune response to the protein and / or the bacterial pathogen. Particular examples are pilin proteins and nitrite reductase glycoproteins of Neisseria bacteria.

Owner:THE UNIV OF QUEENSLAND

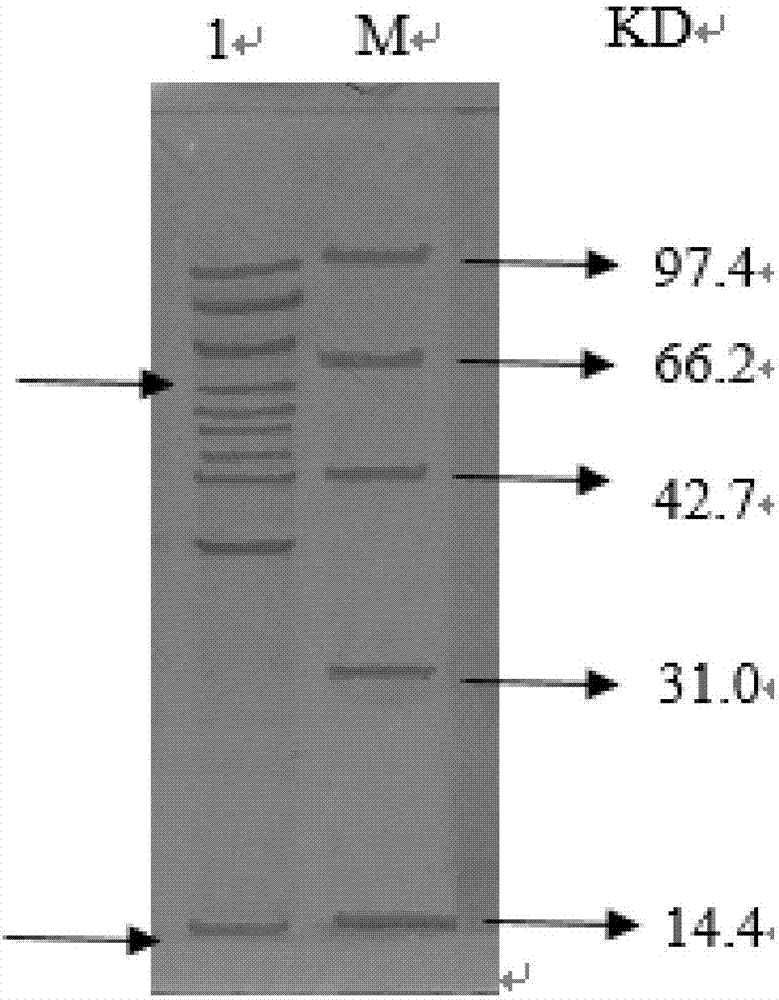

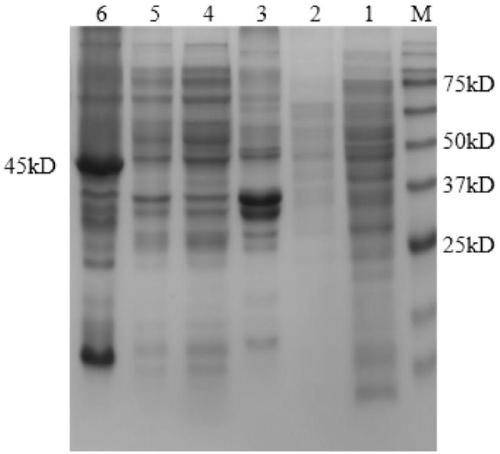

Bacillus cereus NiR (nitrite reductase), gene and application

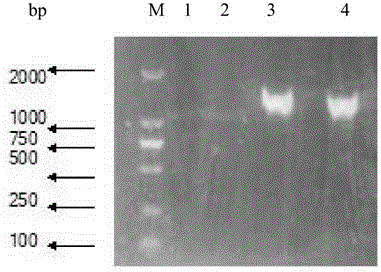

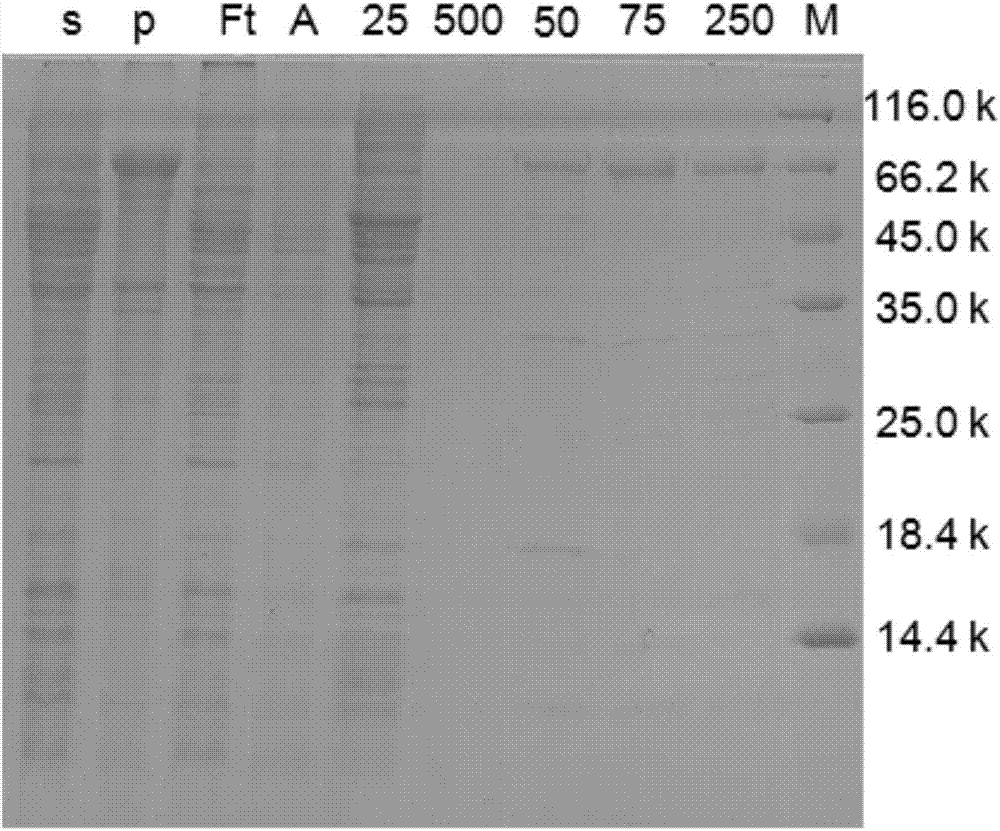

InactiveCN105063066AHigh purityAddressing Purity IssuesWater contaminantsEnzymesEscherichia coliNitrite reductase

The invention discloses a Bacillus cereus NiR (nitrite reductase), a gene and an application. The NiR gene in Bacillus cereus LJ01 is cloned and induced for expression in Escherichia coli with the PCR (polymerase chain reaction) technology, cells of blank-plasmid-containing BL21 subjected to IPTG (isopropyl beta-D-thiogalactopyranoside) induction, recombinant-plasmid-containing BL21 subjected to induction without IPTG and recombinant-plasmid-containing BL21 subjected to IPTG induction are subjected to ultrasonic crushing for extraction of crude enzymes, SDS-PAGE (sodium dodecyl sulfate polyacrylamide gel electrophoresis) is performed on the crude enzymes for detection of recombinant protein expression, high-purity recombinant protein is obtained through affinity chromatography purification, and the problem about separation of NiR with higher purity and content from the Bacillus cereus is solved. A large amount of NiR recombinant protein can be used for degrading nitrite in food, non-acid environments and aquatic water.

Owner:SOUTH CHINA UNIV OF TECH

Aspergillus parasiticus and applications thereof in preparation of nitrite reductase, nitrite reductase gene and genetically engineered bacterium

InactiveCN104312925AReduce energy consumptionPromote degradationFungiMicroorganism based processesNitrite reductaseGenetically engineered

Aspergillus parasiticus and applications thereof in preparation of nitrite reductase, a nitrite reductase gene and a genetically engineered bacterium containing the nitrite reductase are disclosed. The accession number of the aspergillus parasiticus is CCTCC M2013662. The aspergillus parasiticus has characteristics of high efficiency, low energy consumption, good nitrite degradation effects, and rapid and reliable degradation is provided, and can be well applied in preparation of the nitrite reductase, preparation of the nitrite reductase gene and preparation of the genetically engineered bacterium containing the nitrite reductase.

Owner:CHENGDU UNIV

Specific fragment for nitrate-assimilation bacillus megatherium and application thereof

InactiveCN108949755AQuick checkoutEfficient detectionMicrobiological testing/measurementDNA/RNA fragmentationWhole genome sequencingNitrite reductase

The invention discloses a specific fragment for nitrate-assimilation bacillus megatherium and an application thereof. The fragments are specifically shown as Seq ID No. 1-No.3. The bacillus megatherium comprises assimilated nitrate reductase and nitrite reductase genes, is capable of improving secondary salinity soil by utilizing a biological enzyme method, and has the characteristics of being rapid in efficiency and environment-friendly. By performing whole genome sequencing on the nitrate-assimilation bacillus megatherium and performing GenBank database whole-genome sequence parallel comparison, the specific sequence fragments are finally obtained. By virtue of the specific fragments disclosed by the invention, the bacillus megatherium can be rapidly and accurately detected from the environment, and related engineering bacteria are prepared according to the specific fragments.

Owner:SHANGHAI JIAO TONG UNIV

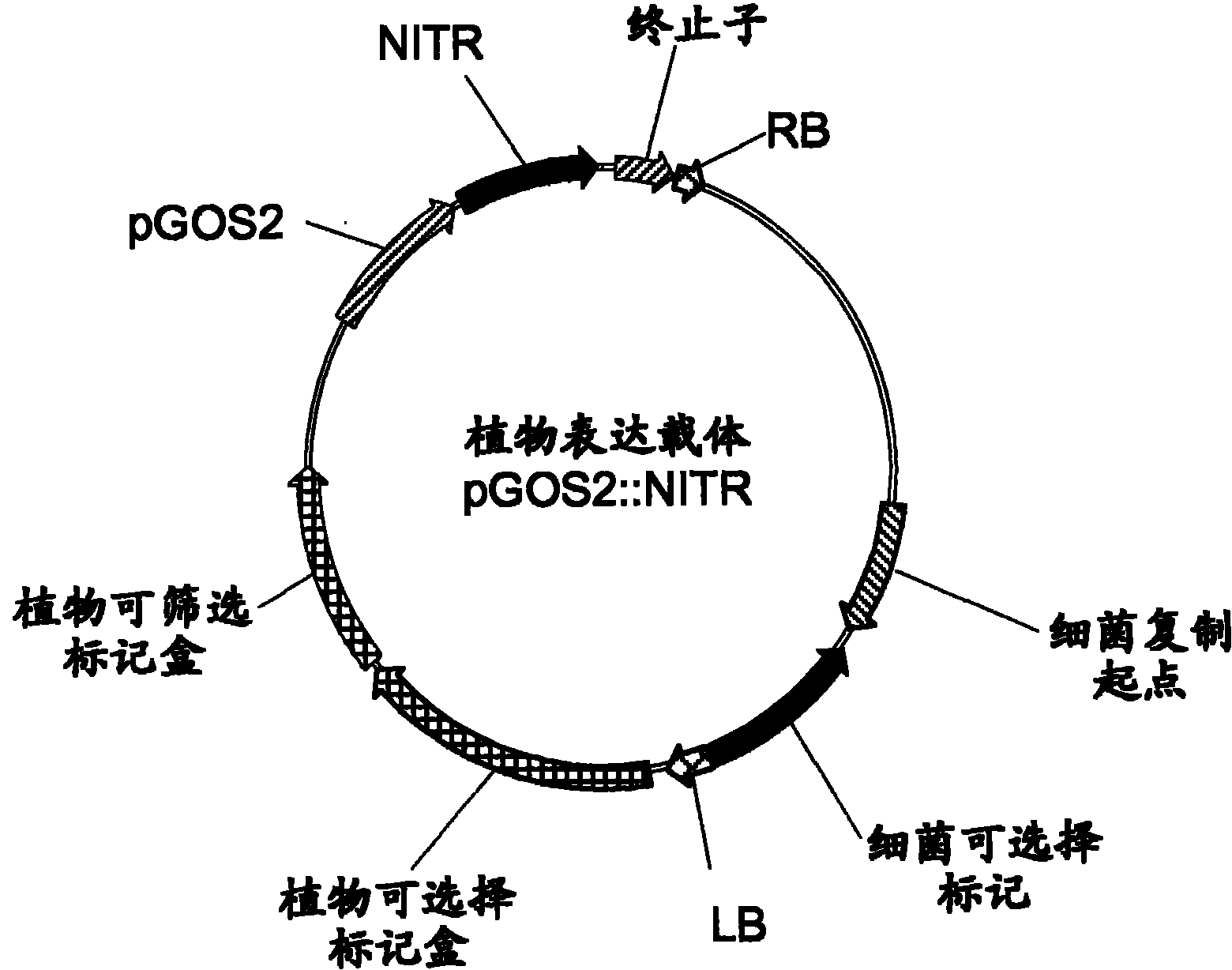

Plants having enhanced yield-related traits and a method for making the same

The present invention relates generally to the field of molecular biology and concerns a method for enhancing various economically important yield-related traits in plants. More specifically, the present invention concerns a method for enhancing yield-related traits in plants by modulating expression in a plant of a nucleic acid encoding a NITR (Nitrite Reductase) polypeptide or an ASNS (Asparagine Synthase) polypeptide. The present invention also concerns plants having modulated expression of a nucleic acid encoding a NITR polypeptide or an ASNS polypeptide, which plants have enhanced yield-related traits relative to control plants. The invention also provides constructs comprising NITR-encoding nucleic acids or ASNS-encoding nucleic acids, useful in performing the methods of the invention.

Owner:BASF PLANT SCI GMBH

Nitrite-reductase (NIRB) as potential Anti-tubercular target and a method to detect the severity of tuberculosis disease

ActiveUS20140242626A1Improve survivalMicrobiological testing/measurementDisease diagnosisDiseaseMedicine

The present invention discloses functional nitrite reductase as a potential drug target for anti-tubercular drug development. The present invention also relates to the development of an easy method for identification of nitrite in clinical samples as well as its correlation with the severity of the disease. Presence of active as well as dormant / latent stages of Mycobacterium tuberculosis (MTB) could be identified from nitrite in clinical samples like sputum of potential TB patients.

Owner:COUNCIL OF SCI & IND RES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com