Processing technique for sausage

A processing technology, sausage technology, applied in the direction of bacteria used in food preparation, food ingredients as antimicrobial preservation, food ingredients as odor modifiers, etc., can solve problems such as human injury, improve quality and safety, reduce sterilization, etc. Effect of temperature and shortening of sterilization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

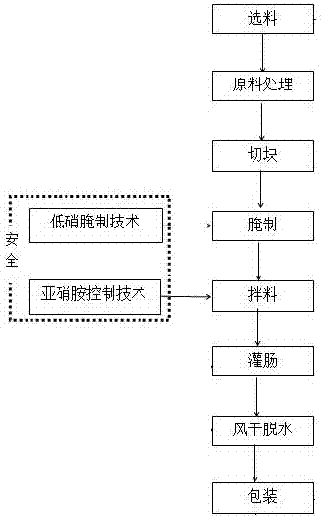

Image

Examples

Embodiment 1

[0031] The processing technology of present embodiment sausage, this processing technology comprises the steps:

[0032] (1) Material selection, raw material processing and cutting: select the fresh lean meat of pork front shoulder and hind legs, wash and cut into shredded meat with a width of 0.5-1 cm and a length of 5-10 cm; Fat fat, washed and cut into shredded meat with a width of 0.5-1 cm and a length of 5-10 cm;

[0033] (2) Pickling: Use vacuum low-nitration pickling technology for pickling, that is, put the processed sausage raw materials in a vacuum pickling machine, according to the weight of fresh lean meat and fresh fat fat 4:3, and then pickle in vacuum Add 0.02wt% nitrite, 0.02wt% lactic acid bacteria and 3.2wt% salt to the machine to soak the sausage raw materials in the pickling mixture. The time is 6h;

[0034](3) Mixing: Vacuum nitrosamine control technology is used for mixing, that is, the marinated minced meat is added with stirring auxiliary agent, put i...

Embodiment 2

[0039] The processing technology of present embodiment sausage, this processing technology comprises the steps:

[0040] (1) Material selection, raw material processing and cutting: select the fresh lean meat of pork front shoulder and hind legs, wash and cut into shredded meat with a width of 0.5-1 cm and a length of 5-10 cm; Fat fat, washed and cut into shredded meat with a width of 0.5-1 cm and a length of 5-10 cm;

[0041] (2) Pickling: Use vacuum low-nitration pickling technology for pickling, that is, put the processed sausage raw materials in a vacuum pickling machine, according to the weight of fresh lean meat and fresh fat fat 4:3, and then pickle in vacuum Add 0.02wt% of nitrite, 0.02wt% of lactic acid bacteria and 3.2wt% of salt to the machine to soak the sausage raw materials in the pickling mixture. The time is 4h;

[0042] (3) Mixing: Vacuum nitrosamine control technology is used for mixing, that is, the marinated minced meat is added with stirring auxiliary ag...

Embodiment 3

[0047] The processing technology of present embodiment sausage, this processing technology comprises the steps:

[0048] (1) Material selection, raw material processing and cutting: select the fresh lean meat of pork front shoulder and hind legs, wash and cut into shredded meat with a width of 0.5-1 cm and a length of 5-10 cm; Fat fat, washed and cut into shredded meat with a width of 0.5-1 cm and a length of 5-10 cm;

[0049] (2) Pickling: Use vacuum low-nitration pickling technology for pickling, that is, put the processed sausage raw materials in a vacuum pickling machine, according to the weight of fresh lean meat and fresh fat fat 4:3, and then pickle in vacuum Add 0.02wt% of nitrite, 0.02wt% of lactic acid bacteria and 3.2wt% of salt to the machine to soak the sausage raw materials in the pickling mixture. The time is 5h;

[0050] (3) Mixing: Vacuum nitrosamine control technology is used for mixing, that is, the marinated minced meat is added to the stirring auxiliary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com