Safe and high-efficiency preparation method of master culture medium material of edible fungi

A technology of main culture medium and production method, applied in microorganism-based methods, biochemical equipment and methods, bacteria, etc., can solve the problems of waste of degradable resources, risk of pesticide residues and low biotransformation rate, and achieve improved biotransformation. efficiency, reducing pesticide residues, and shortening the growth cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

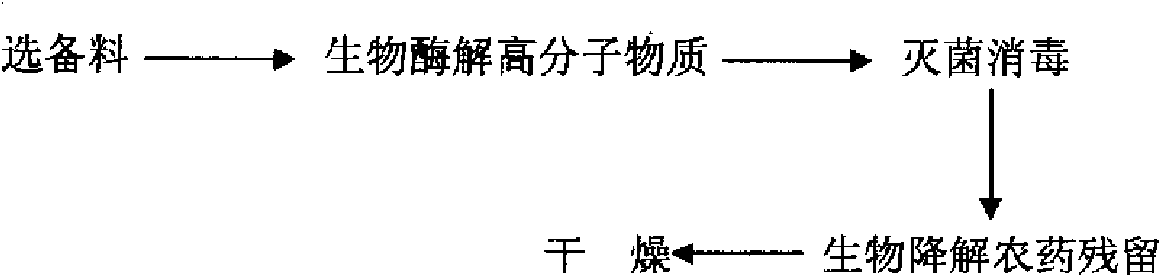

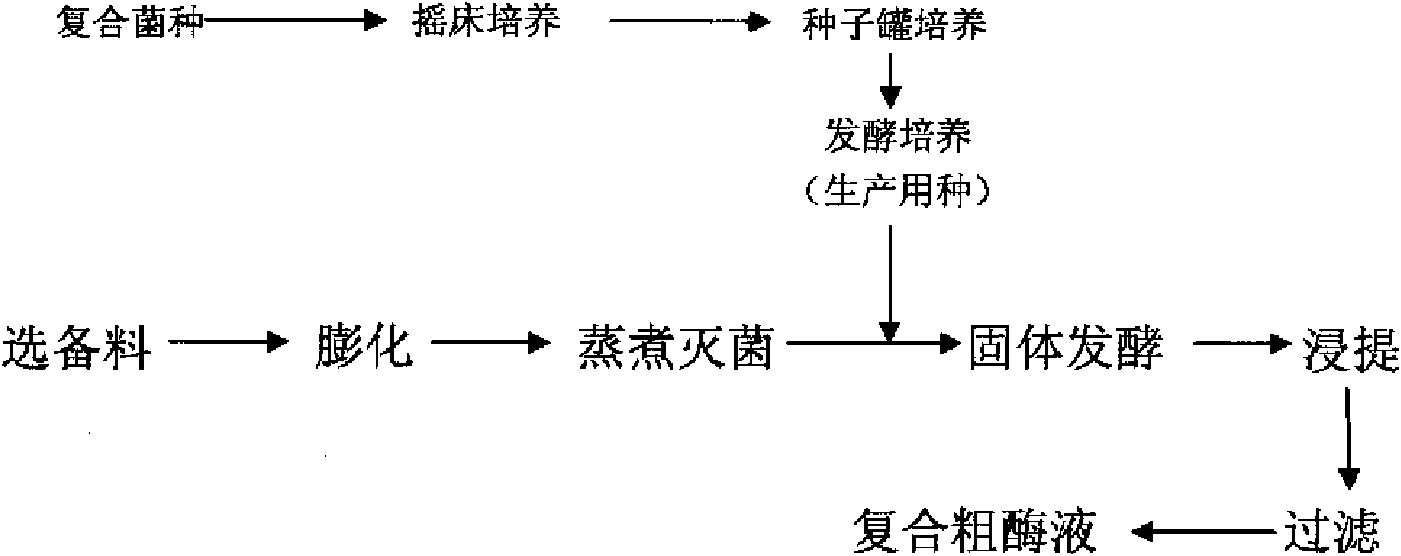

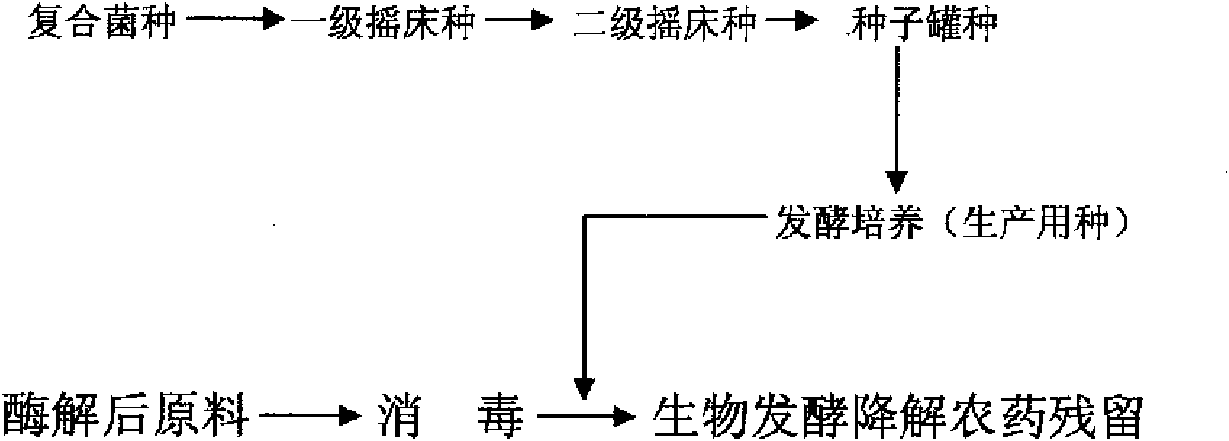

Method used

Image

Examples

Embodiment

[0068] Embodiment: the cotton stalk harvested in Liangxinbao Town, Junshan District, Yueyang in 2008 and the rice straw from Sanfengsi Town, Huarong County were made into edible fungus main culture materials according to the production method of this invention respectively.

[0069] (1) Choose and prepare materials

[0070] Select clean and dry raw material cotton stalks and straws, crush the cotton stalks and straws to about 2cm (such as skins, shells, chips, leaves, etc., to 20 meshes), put the crushed raw materials into the fermentation device, and then add 50% tap water by weight of raw materials, and stir evenly.

[0071] (2) Biological enzymatic hydrolysis of polymer substances

[0072] Add the prepared compound crude enzyme liquid into the fermentation device equipped with raw material cotton stalks and rice straw according to the amount of 10% of the above raw material weight, and stir evenly, keep warm at 45°C for 10hrs, and detect the crude fiber and lignin content ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com