Method for producing nitrite reductase by ferment of lactic acid bacteria

A technology of lactic acid bacteria fermentation and nitrous acid, applied in the direction of oxidoreductase, bacteria, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

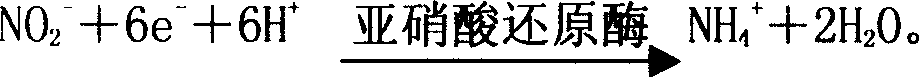

Image

Examples

Embodiment 1

[0015] (1) Culture medium preparation

[0016] ①Strain activation medium: casein peptone 10.0g, beef extract 10.0g, yeast extract 5.0g, glucose 5.0g, sodium acetate 5.0g, diamine citrate 2.0g, Tween 80 1.0g, K 2 HPO 4 1.0g, MgSO 4 ·7H 2 O 0.2g, MnSO 4 ·H 2 O0.05g, CaCO 3 20.0g, 15.0g agar, 1.0L distilled water, pH 6.8, sterilized by high pressure steam at 121℃ for 30min.

[0017] ② Liquid seed medium: 10.0g casein peptone, 10.0g beef extract, 5.0g yeast extract, 5.0g glucose, 5.0g sodium acetate, 2.0g diamine citrate, 1.0g Tween 80, K 2 HPO 4 1.0g, MgSO 4 ·7H 2 O 0.2g, MnSO 4 ·H 2 O0.05g, CaCO 3 20.0g, 1.0L tap water, pH value 7.0, sterilized by high pressure steam at 121℃ for 30min.

[0018] ③Enzyme production medium: 3.0-7.0g casein peptone, 2.0-8.0g beef extract, 3.0-9.0g yeast extract, 3.0-10.0g corn starch sugar, 0.5-2.0g sodium acetate, 0.6-2.0g diamine citrate 2.0g, Tween80 0.3~1.4g, K 2 HPO 4 0.4~1.5g, CaCO 3 20.0g, 1.0L tap water, pH value 7.0, s...

Embodiment 2

[0028] (1) Culture medium preparation

[0029] ①Strain activation medium: casein peptone 10.0g, beef extract 10.0g, yeast extract 5.0g, glucose 5.0g, sodium acetate 5.0g, diamine citrate 2.0g, Tween 80 1.0g, K 2 HPO 4 1.0g, MgSO 4 ·7H 2 O 0.2g, MnSO 4 ·H 2 O0.05g, CaCO 3 20.0g, 15.0g agar, 1.0L distilled water, pH 6.8, sterilized by high pressure steam at 121℃ for 30min.

[0030] ② Liquid seed medium: 10.0g casein peptone, 10.0g beef extract, 5.0g yeast extract, 5.0g glucose, 5.0g sodium acetate, 2.0g diamine citrate, 1.0g Tween 80, K 2 HPO 4 1.0g, MgSO 4 ·7H 2 O 0.2g, MnSO 4 ·H 2 O0.05g, CaCO 3 20.0g, 1.0L tap water, pH value 7.0, sterilized by high pressure steam at 121℃ for 30min.

[0031] ③Enzyme production medium: 3.0-7.0g casein peptone, 2.0-8.0g beef extract, 3.0-9.0g yeast extract, 3.0-10.0g corn starch sugar, 0.5-2.0g sodium acetate, 0.6-2.0g diamine citrate 2.0g, Tween80 0.3~1.4g, K 2HPO 4 0.4~1.5g, CaCO 3 20.0g, 1.0L tap water, pH value 7.0, st...

Embodiment 3

[0041] (1) Culture medium preparation

[0042] ①Strain activation medium: casein peptone 10.0g, beef extract 10.0g, yeast extract 5.0g, glucose 5.0g, sodium acetate 5.0g, diamine citrate 2.0g, Tween 80 1.0g, K 2 HPO 4 1.0g, MgS0 4 ·7H 2 O0.2g, MnSO 4 ·H 2 O0.05g, CaCO 3 20.0g, 15.0g agar, 1.0L distilled water, pH 6.8, sterilized by high pressure steam at 121℃ for 30min.

[0043] ② Liquid seed medium: 10.0g casein peptone, 10.0g beef extract, 5.0g yeast extract, 5.0g glucose, 5.0g sodium acetate, 2.0g diamine citrate, 1.0g Tween 80, K 2 HPO 4 1.0g, MgSO 4 ·7H 2 O 0.2g, MnSO 4 ·H 2 O0.05g, CaCO 3 20.0g, 1.0L tap water, pH value 7.0, sterilized by high pressure steam at 121℃ for 30min.

[0044] ③Enzyme production medium: 3.0-7.0g casein peptone, 2.0-8.0g beef extract, 3.0-9.0g yeast extract, 3.0-10.0g corn starch sugar, 0.5-2.0g sodium acetate, 0.6-2.0g diamine citrate 2.0g, Tween80 0.3~1.4g, K 2 HPO 4 0.4~1.5g, CaCO 3 20.0g, 1.0L tap water, pH value 7.0, st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com