Bacillus cereus and application thereof to preparation of nitrite reductase

A technology of bacillus cereus and nitrite, which is applied in the application field of preparing nitrite reductase, and achieves the effects of low fermentation production cost, good commercial prospects, and simple conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

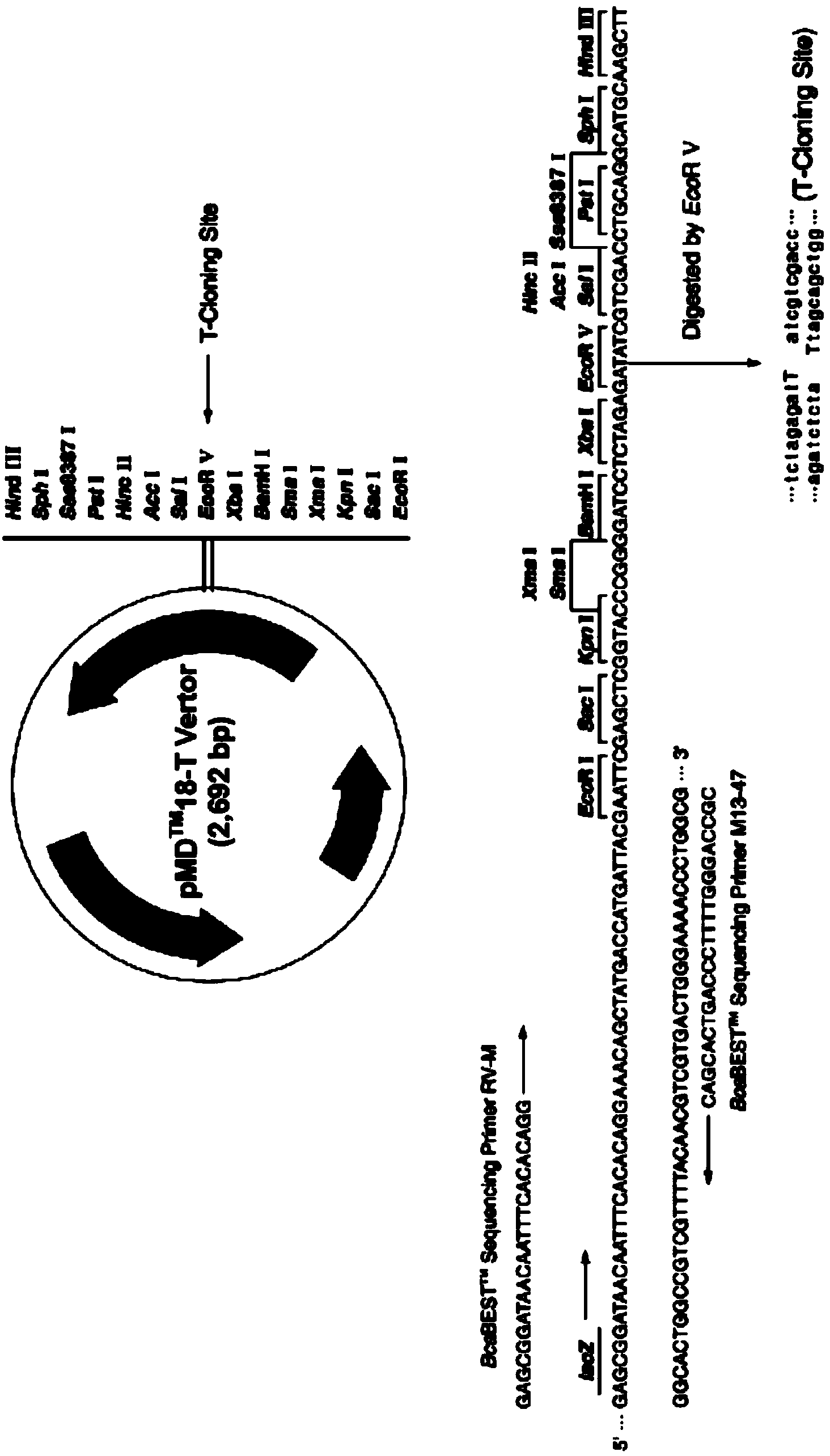

Method used

Image

Examples

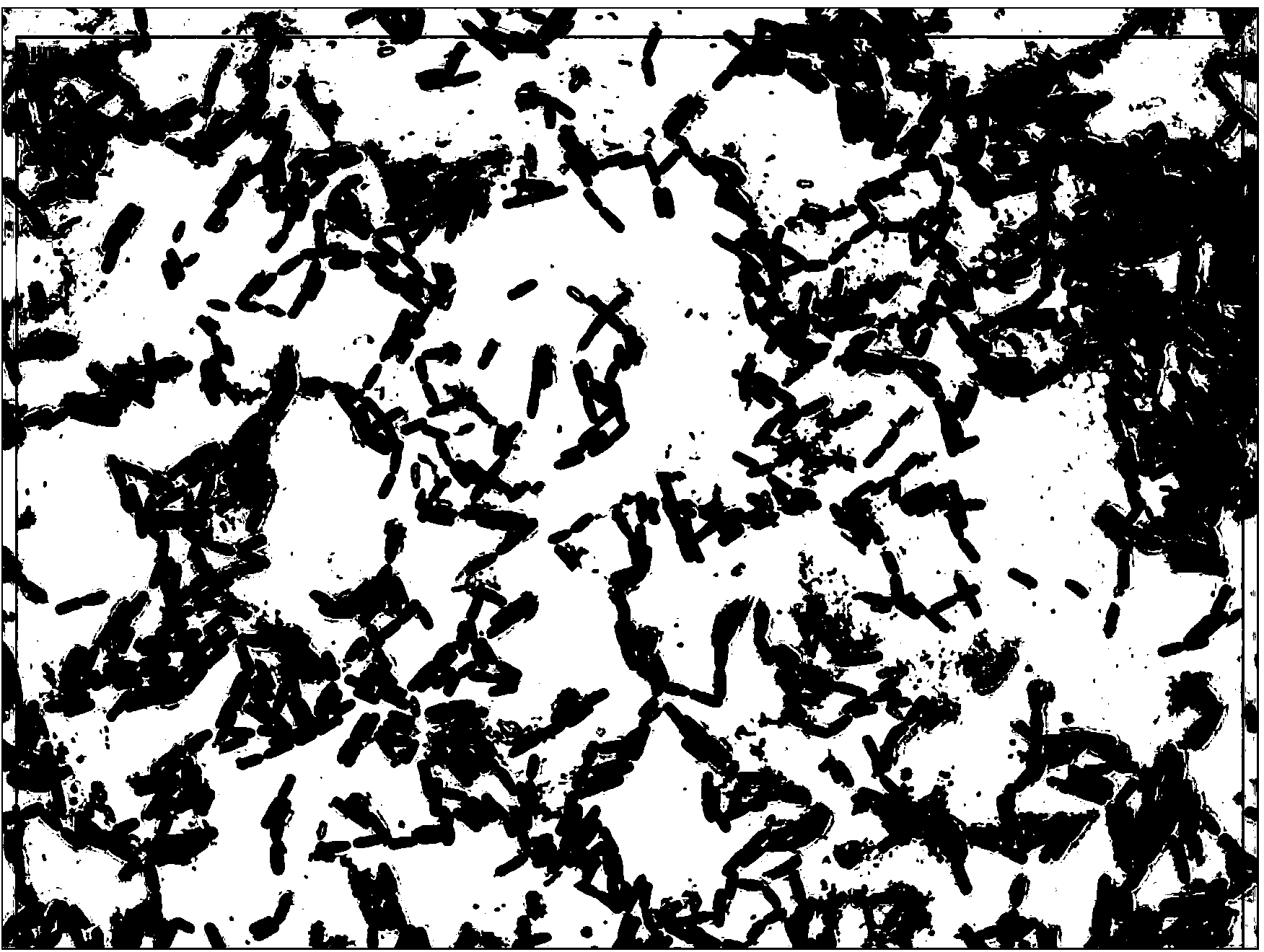

Embodiment 1

[0035] Pick a loop of bacteria from the slant of the LJ01 test tube into a 250mL Erlenmeyer flask containing 100mL of seed medium, and cultivate it on a constant temperature shaker at 30°C and 180r / min for 24h to obtain the LJ01 seed solution. The composition of the seed medium is: 10g of peptone, 3g of beef extract powder, 5g of NaCl, 1L of distilled water, and the final pH is 7.4±0.2.

[0036] Prepare a fermentation induction medium containing 50mg / mL ~ 100mg / mL sodium nitrite, adjust its pH to 7.4, sterilize and cool at 121°C, and insert the LJ01 seed solution according to the inoculation amount of 1% ~ 5% (volume percentage) After culturing at 30°C to 40°C and 150r / min to 250r / min for 18h to 30h, the fermented liquid obtained was centrifuged at 4°C and 9000r / min for 10min, the supernatant was removed, the sludge was washed with sterile water and placed in Centrifuge at 4°C and 9000r / min for 10min, repeat the washing and centrifuging operations twice, get bacteria and weigh...

Embodiment 2

[0043] The method for producing and preparing NiR by bacillus cereus

[0044] The fermentation induction medium (broth medium) containing 100mg / mL sodium nitrite and pH 7.4 was sterilized and cooled at 121°C, and then inserted into the LJ01 seed solution according to the inoculum size of 2% (volume percentage), at 30 After culturing for 24 hours at ℃ and 250r / min, the fermented liquid was centrifuged at 4℃ and 9000r / min for 10min, removed the supernatant, washed with sterile water, centrifuged at 4℃ and 9000r / min for 10min, washed and centrifuged The operation was repeated twice, the cells were obtained and weighed, and the enzyme extraction buffer (containing 3 μg / mL trypsin inhibitor and 0.5 μmol / mL DTT) was added to make the concentration of LJ01 cells 200 mg / mL, and lysozyme was added , so that the concentration of lysozyme was 20mg / mL, after mixing, the LJ01 cell wall was broken at 30°C and 180r / min for 3h, and then centrifuged at 8000r / min for 20min at 4°C, the supernata...

Embodiment 3

[0052]Prepare a fermentation induction medium containing 75 mg / mL sodium nitrite and adjust the pH to 7.4. After sterilizing and cooling at 121°C, insert the seed liquid at a 3% (volume percentage) inoculum size, and place it at 35°C and 180r / min. After culturing for 20 hours, the fermented liquid was centrifuged at 4°C and 9000r / min for 10min, the supernatant was removed, the bacteria sludge was washed with sterile water and then centrifuged at 4°C and 9000r / min for 10min, and the cleaning and centrifugation operations were repeated twice. The thalline was obtained and weighed, adding enzyme extracting buffer (containing 1 μg / mL trypsin inhibitor and 2 μmol / mL DTT) to make the concentration of LJ01 thallus 300 mg / mL, adding lysozyme to make the concentration of lysozyme 5 mg / mL, after mixing, break the LJ01 cell wall at 30°C and 180r / min for 4h, then centrifuge at 8000r / min for 20min at 4°C, the supernatant after centrifugation is NiR crude enzyme solution, and its NiR enzyme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com