Solid-state fermentation pickled fishes and preparation method thereof

A solid-state fermentation and sealed fermentation technology, which is applied in the field of food processing, can solve the problems of high product texture, no scientific technical theoretical basis, and high production costs, so as to prevent product quality from deteriorating, solve quality and safety problems, and shorten the production cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

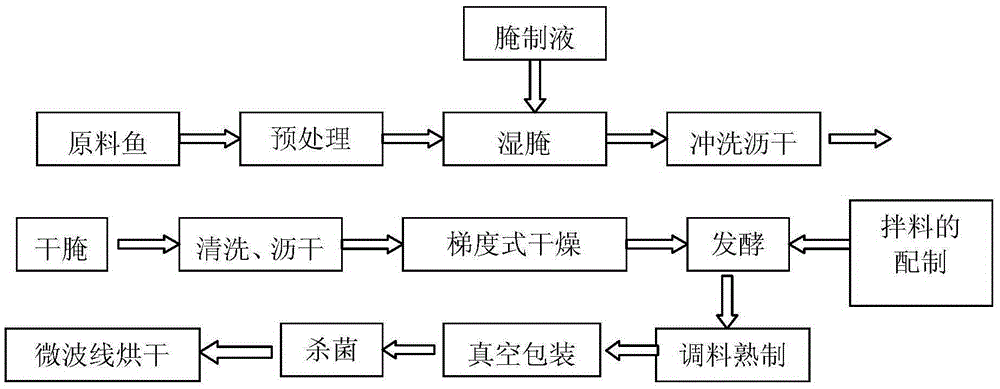

[0036] refer to figure 1 : a kind of solid-state fermented bream of the present invention, adopts following preparation method to prepare:

[0037] (1) Pretreatment: Take 4kg of fresh grass carp, remove phosphorus, cut it open along the back or abdomen, remove the head, tail and viscera, and cut it into strips with a width of 3cm.

[0038] (2) Preparation of pickling solution: first measure 1000ml of water and put it into the pot, then put 1w / v% salt, then put the spices wrapped in gauze (the spices include 0.6g cinnamon, 3.0g cloves, 1.6g star anise, 2.6g fennel and 20g dried ginger slices); according to the addition amount of 2w / v%, put it into the pot and boil it on high heat, then boil it on low heat (control the temperature of low fire so that the water keeps boiling, generally 90°C ~ 100°C) Boil for 30 minutes, cool to normal temperature to obtain pickle liquid.

[0039] (3) One-time pickling: put the fish pieces processed in step (1) into the pickling solution prepare...

Embodiment 2

[0050] (1) Pretreatment: Take 3 kg of fresh silver carp, remove phosphorus, cut it open along the back or abdomen, remove the head, tail and viscera, and cut it into strips with a width of 2 cm.

[0051] (2) Preparation of pickling solution: first measure 1000ml of water and put it into the pot, then put 1% (w / v) salt, then put the spices wrapped in gauze (the spices include 0.6g cinnamon, 3.0g cloves, 1.6 g star anise, 2.6g fennel and 20g dried ginger slices) according to the addition of 2% (w / v) is put into the pot and boiled on high heat, after boiling, simmer for 30min on low heat, and cool to normal temperature to obtain pickled liquid.

[0052] (3) One-time pickling: put the fish pieces processed in step (1) into the pickling solution prepared in step (2) to soak, so that the fish meat can be completely soaked in the pickling solution, and pickle at 5°C 50min, and stir once every 10min to get a marinated fish piece.

[0053] (4) Secondary pickling: remove the first-cure...

Embodiment 3

[0062] (1) Pretreatment: take 2kg of fresh grass carp, dephosphorize, cut open along the back or abdomen, remove the head, tail and viscera, and cut into strips with a width of 3 cm;

[0063] (2) Preparation of pickling solution: first measure 1000ml of water and put it into the pot, then put 1% (w / v) salt, then put the spices wrapped in gauze (the spices include 0.6g cinnamon, 3.0g cloves, 1.6 g star anise, 2.6g fennel and 20g dried ginger slices); according to the addition amount of 3% (w / v), put it into a pot and boil on high heat, after boiling, simmer for 30min on low heat, and cool to normal temperature to obtain a pickling solution.

[0064] (3) One-time pickling: put the fish pieces processed in step (1) into the pickling solution prepared in step (2) to soak, so that the fish meat can be completely soaked in the pickling solution, and pickle at 5°C 60min, and stir once every 10min to get a marinated fish piece.

[0065] (4) Secondary pickling: remove the first-cured ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com