Sodium fire pressure relieving device and method

A sodium fire pressure relief and pressure technology, which is used in emergency protection devices, reactors, and greenhouse gas reduction. It can solve problems such as damage, and achieve the effect of avoiding excessive loss, ensuring safety, and good compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

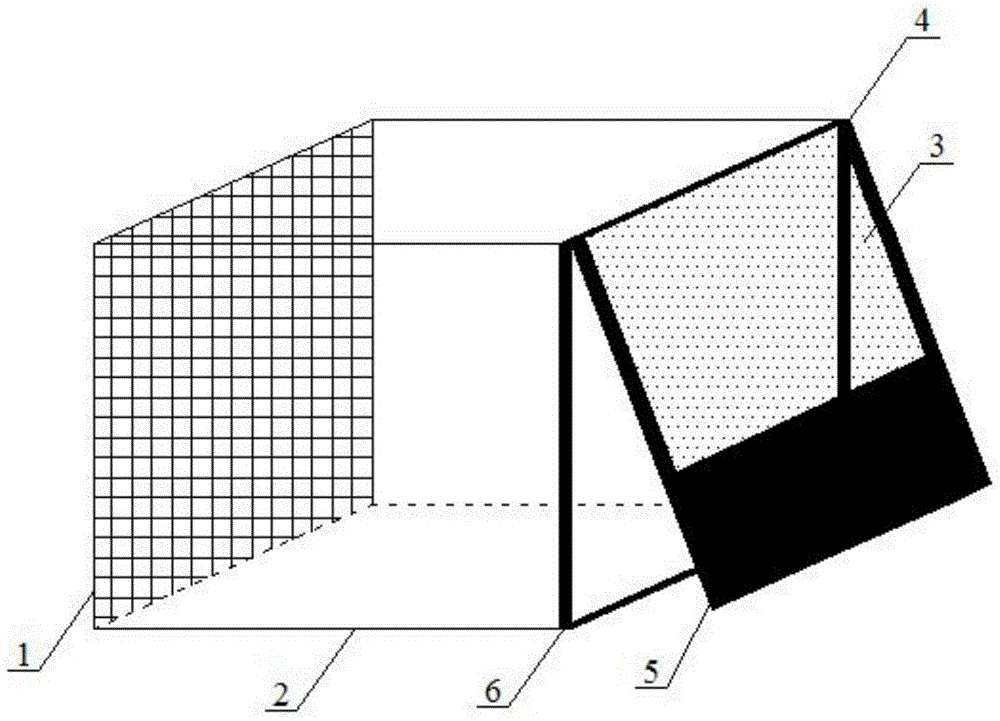

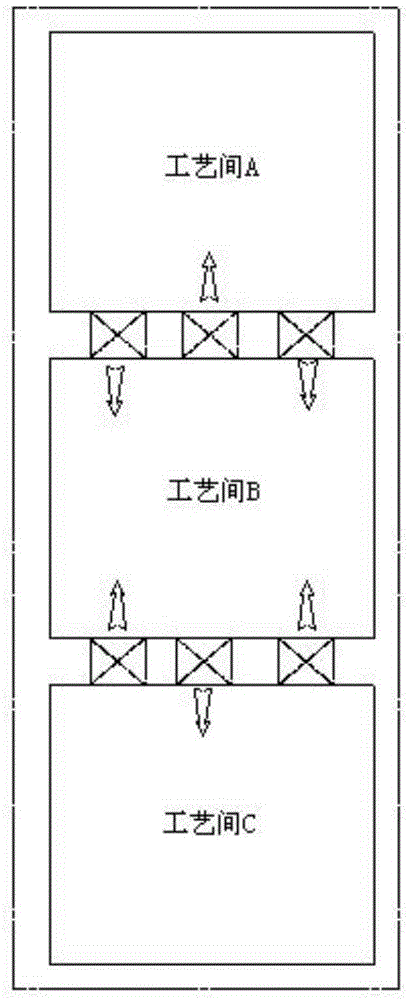

[0019] as attached image 3 As shown, the fast reactor sodium process room A and B, B and C are respectively arranged as attached figure 1 Sodium fire pressure relief device shown.

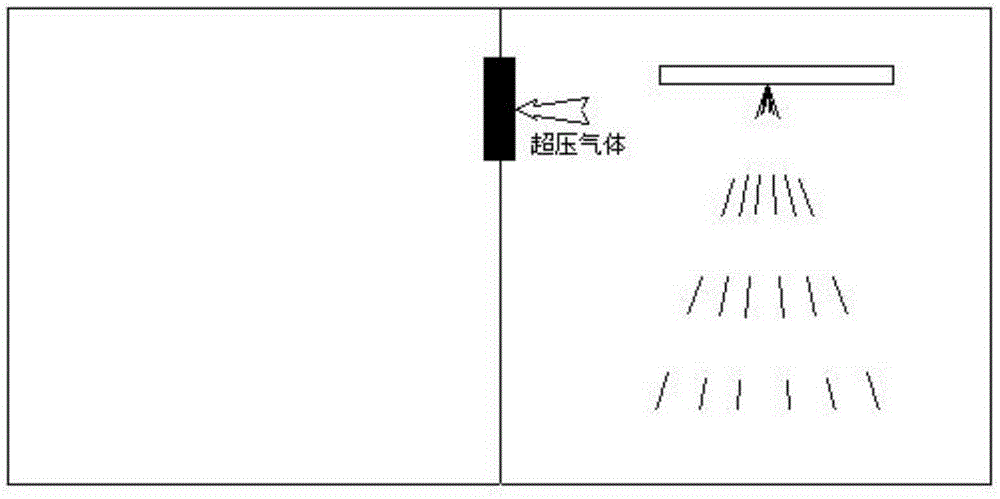

[0020] When a foggy sodium fire accident occurs in process room B, the pressure in process room B rises rapidly. When the pressure rises higher than the opening pressure limit of the sodium fire pressure relief device, the decorative panel and the sealing cover are pushed away, and the process room B releases pressure to the adjacent process rooms A and C. The principle is as attached figure 2 shown. Subsequently, when the pressure in process room B drops below the limit value, the sodium fire pressure relief device is automatically closed.

[0021] If the pressure in process room B rises again and exceeds the opening pressure limit of the sodium fire pressure relief device, the sodium fire pressure relief device will automatically open again to release pressure, and so on until the pressure i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com