Safe flame-retardant garbage can

A trash can and safety technology, applied in the field of trash cans, can solve the problems of long burning duration, spontaneous combustion of trash cans, passing pedestrians, hazards of surrounding facilities, etc., and achieve the effect of shortening burning time and reducing oxygen content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

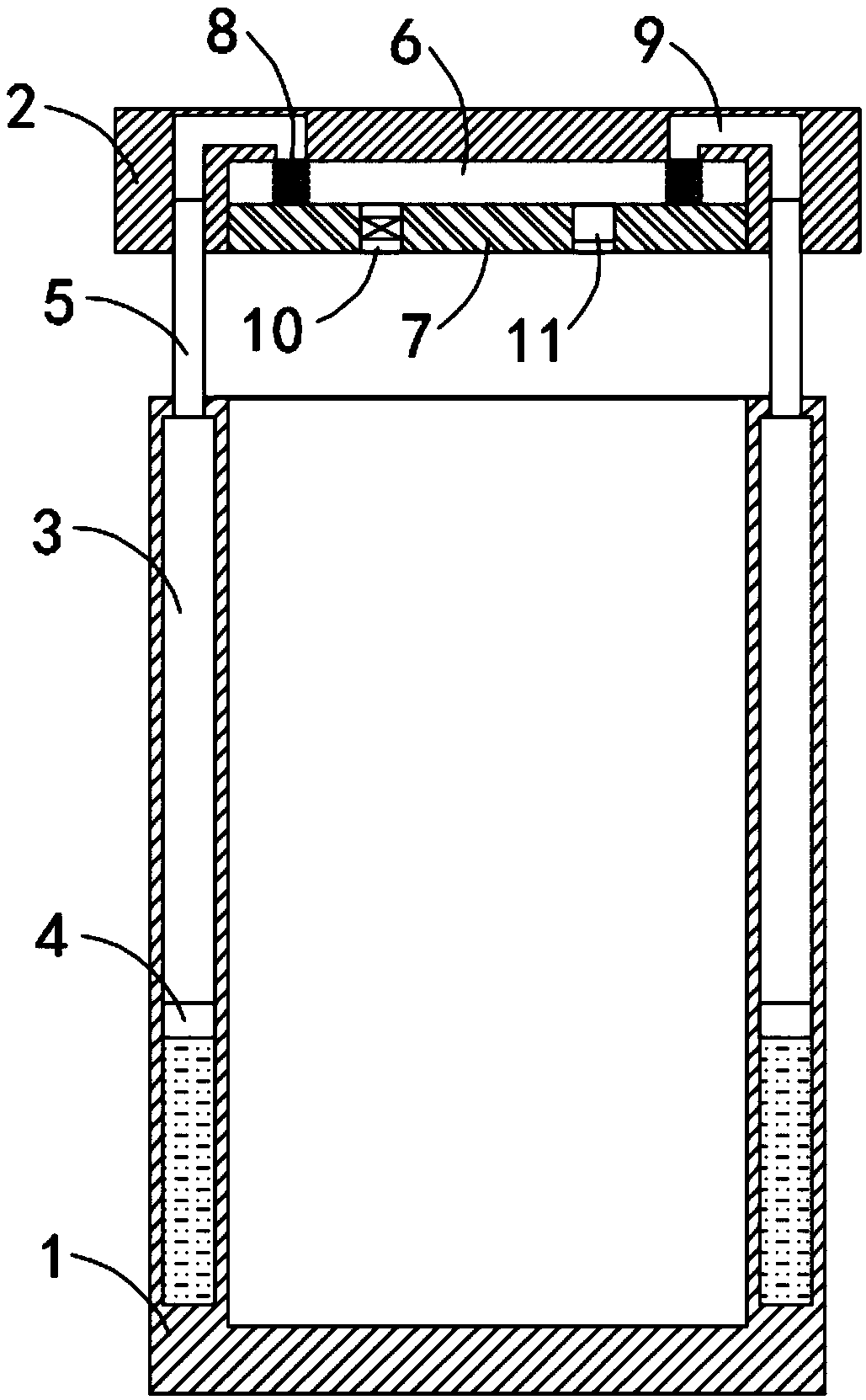

[0018] Such as Figure 1-3 As shown, a safe flame-retardant garbage can includes a barrel body 1 and a cover body 2. An annular cavity 3 is provided in the side wall of the barrel body 1, and a piston ring 4 is connected to the annular cavity 3 in a sliding seal. The piston ring 4 is connected to the The sealed space formed at the lower part of the annular chamber 3 is filled with evaporating liquid. It should be noted that the evaporating liquid is chloroform (boiling point is 61-62° C.), which can meet the conditions for storing garbage cans outdoors and can be stored in a heated environment. In the case of vaporization, the four corners of the lower end of the cover body 2 are fixedly connected with connecting pipes 5, the lower end of the connecting pipe 5 is fixedly connected with the upper end of the barrel body 1, the lower end of the connecting pipe 5 communicates with the annular cavity 3, and the The lower surface is provided with a receiving groove 6, and a sealing ...

Embodiment 2

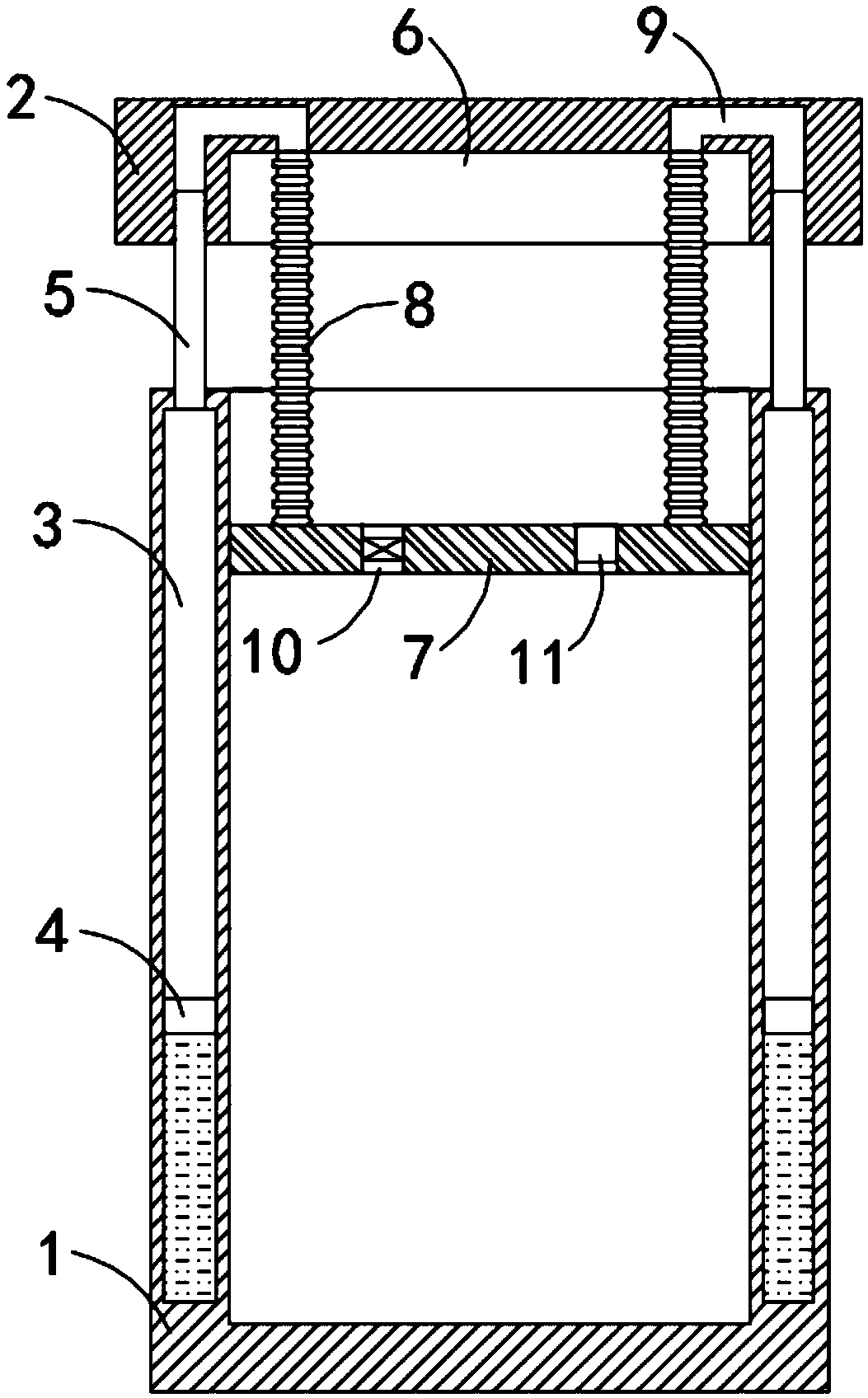

[0022] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that: a heat conduction plate 12 is fixedly connected to the inner side wall of the barrel body 1, and an annular opening is provided on the side wall of the annular chamber 3 close to the inside of the barrel body 1, and the inner side wall of the annular opening An annular heat conducting plate 13 is fixedly connected, and the annular heat conducting plate 13 is in contact with the heat conducting plate 12 .

[0023] In this embodiment, when combustion occurs in the barrel body 1, the heat will be conducted to the ring-shaped heat-conducting plate 13 through the heat-conducting plate 12, and the evaporating liquid will be heated through the ring-shaped heat-conducting plate 13 to improve the heat conduction efficiency. At the same time, after the fire ends, The residual heat in the barrel body 1 can be conducted to the outside through the heat conduction plate 12, so that the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com