Two-stage rotary oxygen-enriched external heating oxidation process and device for dry and semi-dry desulfurization ash

A semi-dry desulfurization and oxidation process technology, applied in the field of CaCO3 oxidation treatment process and equipment, can solve the problems of difficult industrialization, large-scale production, high energy consumption and cost, long oxidation time, etc., and achieve a balanced oxidation temperature and oxygen content Insurable and environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

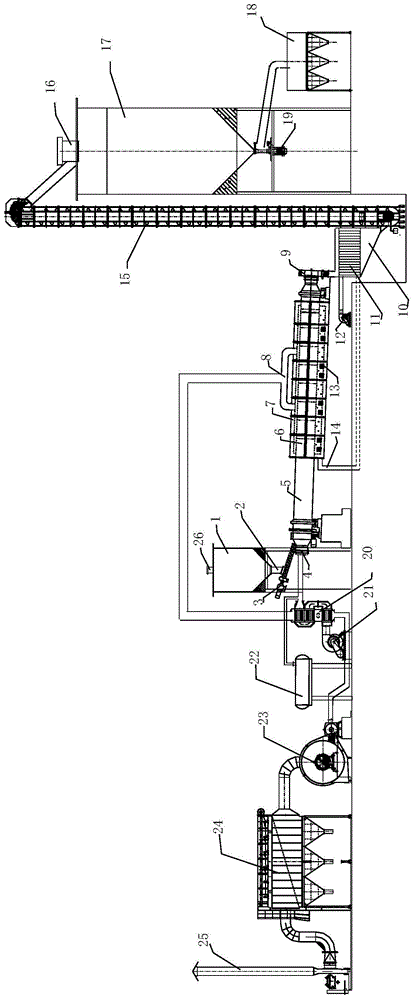

[0031] See figure 1 , is the process flow chart of the present invention, and the dry process and semi-dry process desulfurization ash of the present invention two-stage rotary oxygen-enriched external heating oxidation process comprises the following steps:

[0032] 1) The desulfurized ash in the desulfurized ash storage bin 1 is sent into the two-stage rotary oxidation kiln by the screw feeder 3 at the bottom through the storage bin discharge port 2, and is preheated by hot air in the preheating section 5, and is heated in the kiln body. Move to the heating section 6 under the action of rotation;

[0033] 2) The oxygen in the oxygen storage tank 22 is transported to the front end of the kiln head blower 21 through the oxygen delivery pipe, and enters the oxidation kiln simultaneously with the hot air, and the oxygen content in the oxidation kiln ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com